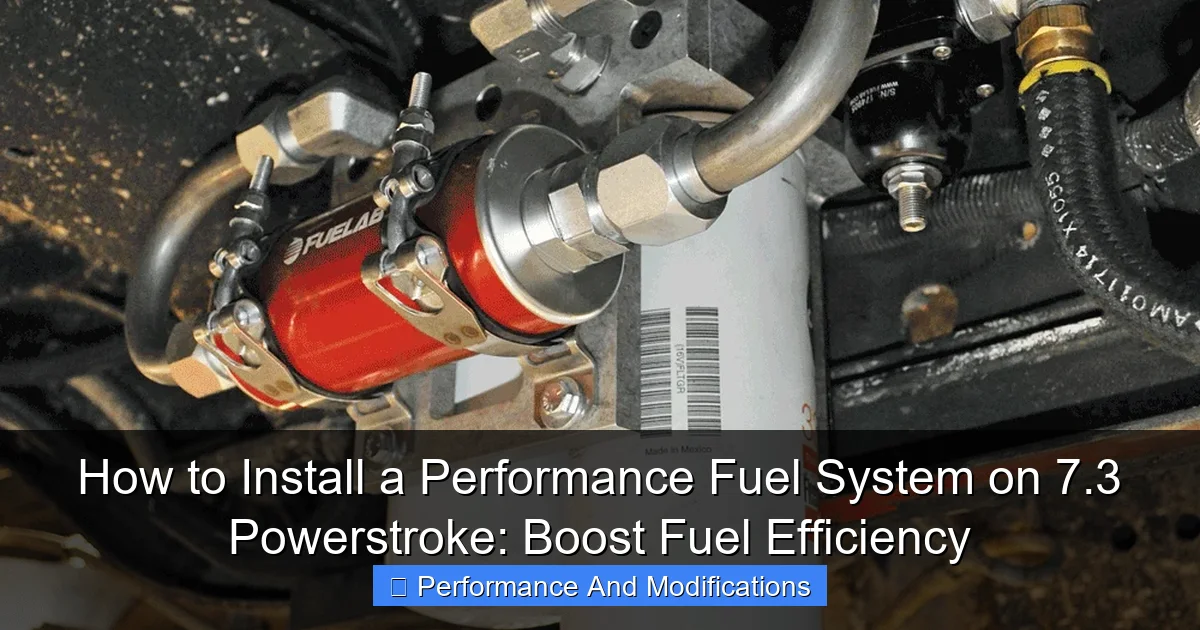

How to Install a Performance Fuel System on 7.3 Powerstroke: Boost Fuel Efficiency

Featured image for this comprehensive guide about How to install a performance fuel system on 7.3 Powerstroke

Image source: carid.com

How to Install a Performance Fuel System on 7.3 Powerstroke: Boost Fuel Efficiency

The 7.3 Powerstroke engine is nothing short of legendary. Known for its rugged durability, incredible longevity, and impressive torque, it’s a true workhorse that has powered countless Ford trucks through millions of miles. If you’re the proud owner of one of these iconic diesels, you know its potential – but even a legend can be improved upon. One of the most impactful upgrades you can make to unlock your 7.3’s full capabilities and ensure its continued health is to install a performance fuel system on your 7.3 Powerstroke.

Many 7.3 owners, especially those running tunes, larger injectors, or simply seeking to extend their engine’s life, find the factory fuel system to be a significant bottleneck. The stock system often struggles to maintain adequate, consistent fuel pressure, leading to issues like injector wear, reduced power, and even diminished fuel economy. This comprehensive guide will walk you through everything you need to know about why and how to upgrade, empowering you to tackle the 7.3 Powerstroke fuel system upgrade yourself. Get ready to give your trusty diesel the reliable, consistent fuel delivery it deserves, enhancing both performance and longevity.

Upgrading your fuel system isn’t just about raw power; it’s about optimizing your engine’s efficiency and protecting its most vital components. By ensuring a steady supply of clean, high-pressure fuel, you’re not only getting more out of every drop but also safeguarding your expensive injectors from premature failure. Let’s dive deep into the world of enhanced diesel performance and learn how to transform your 7.3’s fuel delivery.

Quick Answers to Common Questions

Why should I consider installing a performance fuel system on my 7.3 Powerstroke?

Upgrading your performance fuel system ensures your engine gets a consistent and clean fuel supply, which is crucial for maximizing power, improving fuel efficiency, and extending the life of your injectors. It helps eliminate common issues like fuel aeration and pressure drops.

Is installing a performance fuel system a difficult DIY task for a 7.3 Powerstroke owner?

While it requires mechanical aptitude and patience, many 7.3 Powerstroke owners successfully tackle the installation of a performance fuel system themselves. Our guide aims to simplify the process, making it achievable for the dedicated DIYer.

What’s the biggest benefit of an upgraded performance fuel system for my truck?

The primary benefit is improved fuel pressure stability and superior filtration, protecting your expensive injectors and often leading to noticeable gains in horsepower, torque, and even better fuel economy. You’ll likely experience smoother engine operation and better throttle response.

Do I need any special tools to install a performance fuel system on my 7.3 Powerstroke?

You’ll primarily need standard mechanic’s tools like socket sets, wrenches, and a good set of hose cutters. While a few specialized items can make the job easier, they aren’t always essential for a successful performance fuel system installation.

What components are typically included in a performance fuel system upgrade for a 7.3 Powerstroke?

A comprehensive performance fuel system upgrade usually involves a new, often frame-mounted electric fuel pump, larger or improved fuel lines, high-efficiency fuel filters (including a water separator), and sometimes an adjustable fuel pressure regulator to fine-tune your fuel delivery.

📋 Table of Contents

Why Upgrade Your 7.3 Powerstroke Fuel System?

For a truck as venerable as the 7.3 Powerstroke, simply “good enough” isn’t good enough, especially when it comes to fuel delivery. The factory system, while adequate for its time, often falls short of modern demands and the performance potential of a well-maintained 7.3. Here’s why an install performance fuel system 7.3 Powerstroke is a game-changer:

Learn more about How to install a performance fuel system on 7.3 Powerstroke – How to Install a Performance Fuel System on 7.3 Powerstroke: Boost Fuel Efficiency

Image source: mdm-performance.com

Enhanced Fuel Delivery and Pressure Stability

The stock 7.3 fuel system, particularly as the vehicle ages, can struggle to maintain consistent fuel pressure, especially under heavy load or with modified engines. This can lead to what’s known as “injector cavitation” – essentially, fuel vaporizing due to insufficient pressure, which then damages the injector pintle. A performance fuel system utilizes a more robust lift pump and often an adjustable fuel pressure regulator (FPR) to ensure a steady 60-70 PSI of fuel pressure at all times. This not only prevents cavitation but also ensures your injectors are always fed the precise amount of fuel they need for optimal combustion, leading to improved throttle response and more consistent power delivery. Studies show that maintaining adequate fuel pressure can extend injector life by up to 25%.

| Fuel System Component | Stock 7.3 Powerstroke (Typical) | Performance Upgrade (Typical) | Key Performance Benefit |

|---|---|---|---|

| Fuel Pump Type/Flow | Mechanical or electric (late models) ~60 GPH | High-flow Electric (e.g., FASS, AirDog) 100-200 GPH | Consistent fuel delivery, higher volume for increased demand. |

| Fuel Line Diameter (Supply) | 3/8″ (~9.5mm) | 1/2″ (~12.7mm) | Reduced fuel restriction, improved flow to injectors. |

| Fuel Filtration | Single-stage, ~10 micron | Dual-stage (e.g., 3-micron water separator, 2-micron fuel filter) | Superior contaminant removal, extended injector life, better fuel quality. |

| Fuel Pressure Regulation | “Dead-head” system, pressure drops under load | Regulated Return System, Adjustable Regulator | Consistent fuel pressure to injectors, eliminates cavitation, cleaner burn. |

| Operating Fuel Pressure (WOT) | Often drops to 30-45 PSI | Maintained 60-70 PSI | Optimal injector performance, prevents misfires, enhances power and efficiency. |

Superior Filtration for Injector Longevity

The 7.3 Powerstroke’s HEUI (Hydraulically-Actuated, Electronically-Controlled Unit Injector) system relies heavily on extremely clean fuel and oil. The factory fuel filter, while doing its job, offers basic filtration. Most performance fuel system 7.3 kits include multi-stage filtration – often a 3-micron fuel filter and a water separator. This significantly reduces harmful contaminants and water from reaching your expensive injectors, preventing wear and premature failure. Cleaner fuel directly translates to a longer lifespan for your injectors and reduced maintenance costs down the line.

Improved Fuel Economy and Performance

It might seem counterintuitive, but a performance fuel system can actually contribute to better fuel efficiency 7.3 Powerstroke. By providing stable, consistent fuel pressure and cleaner fuel, your injectors can atomize fuel more effectively. This leads to a more complete burn in the combustion chamber, translating to more power from the same amount of fuel and potentially better mileage. Furthermore, a consistent fuel supply eliminates the “fuel starvation” issues that can cause a loss of power and rough idling, allowing your 7.3 to perform at its peak potential. Many owners report a noticeable improvement in throttle response and overall drivability after upgrading.

Understanding the Components of a Performance Fuel System

Before you begin to install fuel system 7.3 components, it’s crucial to understand what goes into a comprehensive performance upgrade. While kits vary, the core components generally remain the same:

Learn more about How to install a performance fuel system on 7.3 Powerstroke – How to Install a Performance Fuel System on 7.3 Powerstroke: Boost Fuel Efficiency

Image source: dieselworldmag.com

Lift Pump (Fuel Pump)

This is the heart of your new system. The factory 7.3 Powerstroke uses a mechanical lift pump mounted on the engine block, which often struggles to deliver consistent pressure, especially with age. A performance system replaces this with a high-flow electric lift pump, usually mounted on the frame rail. These pumps are designed to deliver a higher volume of fuel at a consistent, higher pressure (typically 60-70 PSI), eliminating fuel starvation and pressure drops. Popular brands include FASS, AirDog, and Walbro.

Fuel Pressure Regulator (FPR) / Bypass Regulator

A crucial component for maintaining optimal fuel pressure. The stock 7.3 has an in-tank fuel regulator which can sometimes limit flow. A performance system often incorporates an external, adjustable fuel pressure regulator, sometimes integrated into the filter base. This allows you to fine-tune the fuel pressure to your exact needs, ensuring maximum efficiency and injector protection. Bypass regulators return excess fuel back to the tank, preventing aeration and heating of the fuel.

Filters and Water Separator

As mentioned, superior filtration is key. Most performance kits include a pre-filter (often 10-20 micron) and water separator to catch larger particles and water, followed by a fine 3-micron fuel filter. These are typically spin-on filters for easy replacement and are often housed in a sturdy, frame-mounted aluminum filter base. This multi-stage approach is far more effective than the single factory filter.

Fuel Lines and Fittings

To support the increased fuel flow and pressure, performance systems come with new, larger diameter fuel lines (often -8 AN or larger) and high-quality, leak-proof AN fittings. These replace the restrictive factory lines and ensure a smooth, unobstructed path for fuel delivery from the tank to the engine.

Essential Tools and Safety Precautions

Before you embark on the journey to install performance fuel system 7.3 Powerstroke, gather your tools and prioritize safety. Working with fuel requires caution!

Tools You’ll Need

- Socket Set and Wrenches: Metric and standard, including deep sockets.

- Torque Wrench: Essential for proper tightening of fuel lines and fittings to prevent leaks.

- Fuel Line Disconnect Tool: Specifically for disconnecting factory quick-connect fuel lines.

- Hose Cutters: For cutting new fuel lines cleanly (if not pre-cut).

- Drill and Drill Bits: For mounting the lift pump, filter base, and other components to the frame.

- Wire Crimpers/Strippers: For electrical connections.

- Electrical Test Light or Multimeter: To verify power sources.

- Drain Pan: For collecting old fuel.

- Zip Ties/Cable Clamps: For securing new lines.

- Shop Rags and Brake Cleaner: For cleanup.

- Thread Sealant/Teflon Tape (Fuel-Rated): For NPT fittings to prevent leaks.

Safety First!

- Disconnect Batteries: Always disconnect both positive and negative battery terminals before working on any electrical components or fuel lines.

- Work in a Well-Ventilated Area: Fuel fumes are dangerous.

- Eye Protection and Gloves: Protect yourself from fuel splashes and sharp edges.

- Fire Extinguisher: Keep one within reach. Fuel is highly flammable.

- Jack Stands: Never work under a vehicle supported only by a jack. Use sturdy jack stands on a level surface.

- Relieve Fuel Pressure: While the 7.3 Powerstroke system typically doesn’t hold extreme residual pressure, it’s good practice to depressurize if possible by removing the fuel cap and allowing any vapors to escape.

Step-by-Step Installation Guide

This is where your meticulous planning and preparation pay off. Follow these steps carefully to successfully install fuel system 7.3 on your Powerstroke. Remember, specific steps may vary slightly depending on your chosen kit, so always consult your kit’s instructions.

1. Disconnecting the Old System and Draining Fuel

- Depressurize and Drain: Disconnect the negative battery terminals. Place a drain pan under the fuel bowl on the engine. Loosen the fuel bowl drain valve and allow fuel to drain. You can also disconnect the fuel line leading to the fuel bowl and let it drain into a container.

- Remove Factory Lift Pump: The mechanical lift pump is on the driver’s side of the engine block. Disconnect the fuel lines and remove the two bolts holding it in place. Be prepared for some fuel spillage. Block off the opening to prevent debris from entering.

- Disconnect In-Tank Lines: Depending on your kit, you might need to remove the fuel tank to modify the fuel pickup or simply disconnect the fuel supply and return lines from the top of the tank using a fuel line disconnect tool. If your kit provides a new sending unit/pickup, you’ll need to drop the tank. This is often a good time to clean the tank or inspect the existing pickup.

- Remove Existing Fuel Lines: Trace and remove the old fuel supply and return lines from the frame rails.

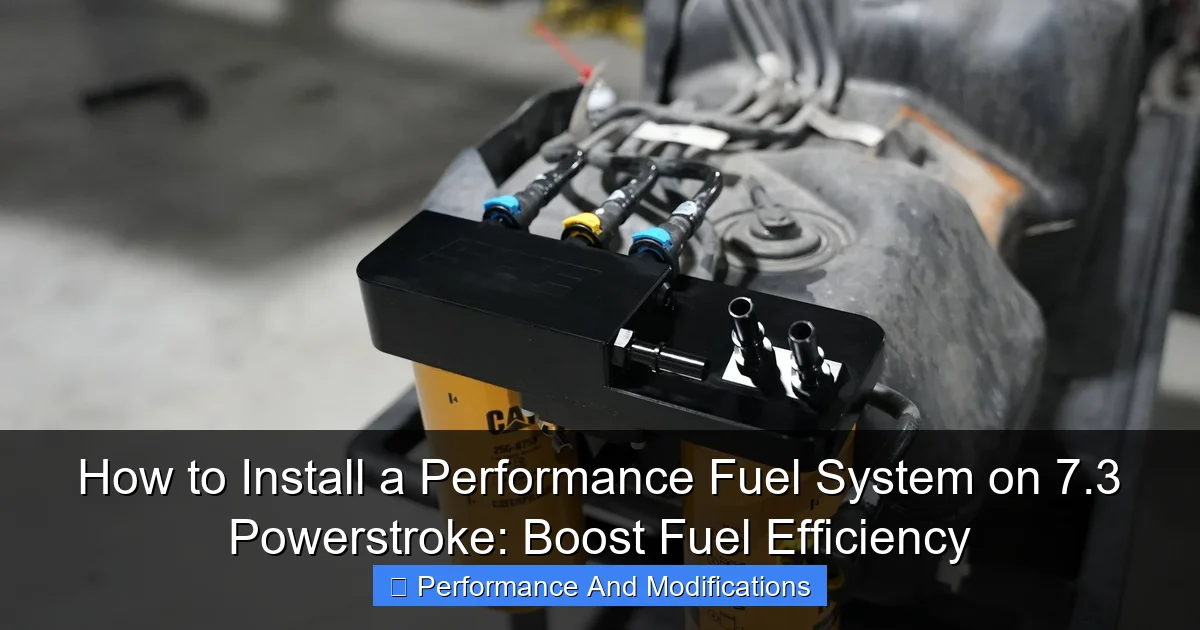

2. Installing the Lift Pump and Filter Base

- Mounting Locations: Most kits recommend mounting the new electric lift pump and filter base assembly on the frame rail, usually on the driver’s side, near the fuel tank. Find a sturdy, flat section of the frame away from exhaust heat and moving parts.

- Drill Mounting Holes: Mark the drilling locations, center punch, and carefully drill the holes for the mounting bracket. Use appropriate rust-preventative paint on exposed metal.

- Mount Components: Securely attach the lift pump and filter base assembly to the frame using the provided hardware. Ensure the filters are easily accessible for future maintenance.

3. Running New Fuel Lines

- Tank to Pump: Connect the new fuel supply line from your modified in-tank pickup (or the factory sending unit, if applicable) to the inlet of your new lift pump. Ensure clean cuts if you’re using bulk hose and tight connections with AN fittings or hose clamps.

- Pump to Filters: Connect the outlet of the lift pump to the inlet of your filter base.

- Filters to Engine: Run the main fuel supply line from the outlet of your final filter (and through the bypass regulator, if separate) up to the engine. You will typically connect this to a new fuel bowl delete or direct feed to the injectors.

- Return Line: Connect the return line from your fuel pressure regulator (if separate) back to the fuel tank’s return port.

- Secure Lines: Use zip ties or cable clamps to secure all new fuel lines to the frame, preventing chafing or contact with moving parts and exhaust. Avoid sharp bends.

4. Wiring the New System

- Power Source: The electric lift pump requires a switched 12V power source. Many kits include a wiring harness with a relay. You’ll typically tap into a key-on power source, often the fuel heater wire on the factory fuel bowl (if deleting it) or a dedicated ignition-switched fuse.

- Ground Connection: Connect the ground wire from the pump to a clean, bare metal section of the frame.

- Relay Installation: Mount the relay in a dry, accessible location and connect all wires according to the kit’s instructions (power in, power out to pump, trigger wire, ground).

- Verify Connections: Double-check all electrical connections for proper insulation and secure crimps.

5. Priming and Initial Start-up

- Re-connect Batteries: Once all fuel lines and electrical connections are secure, reconnect your batteries.

- Prime the System: Turn the ignition key to the “on” position (without starting the engine) for 30 seconds. You should hear the new lift pump running. Cycle the key “on” and “off” several times (5-6 cycles), allowing the pump to push fuel through the new lines and fill the filters. Listen for the pump’s sound to change as it builds pressure.

- Check for Leaks: While priming, carefully inspect all new fuel lines and fittings for any signs of leaks. Address any leaks immediately.

- First Start: After adequate priming and leak checks, attempt to start the engine. It may crank for a few extra seconds as the last air is purged.

- Monitor Fuel Pressure: If you’ve installed a fuel pressure gauge, monitor it closely. The pressure should be stable, typically between 60-70 PSI.

Post-Installation Checks and Maintenance

Your work isn’t over once the engine starts! Proper follow-up and maintenance are crucial to maximizing the benefits of your new diesel performance 7.3 fuel system.

Leak Detection and System Bleeding

After the first run, let the engine cool and then re-check all fittings for any signs of fuel leaks. It’s common for connections to settle and potentially weep after initial pressurization. Retighten any connections as needed. Drive the truck for a bit and then re-inspect. The 7.3 Powerstroke is largely self-bleeding, but ensuring no air remains in the system is vital for smooth operation.

Regular Filter Changes

One of the biggest advantages of a performance fuel system is its superior filtration. To maintain this, adhere to a strict filter change schedule. Most manufacturers recommend changing the 3-micron fuel filter and water separator every 15,000-20,000 miles, or more frequently if you use lower quality fuel or operate in harsh conditions. These filters are relatively inexpensive compared to the cost of replacing injectors. Always keep spare filters on hand.

Monitoring Fuel Pressure

Installing a fuel pressure gauge is highly recommended. It allows you to constantly monitor the health of your fuel system. Any significant drops in pressure, especially under load, can indicate a clogged filter, a failing pump, or a leak. Early detection can save you from costly repairs down the road and ensures your injectors are always operating under optimal conditions. Aim for a consistent 60-70 PSI at all times.

Troubleshooting Common Issues

Even with careful installation, sometimes issues arise. Here are a few common problems you might encounter after you install performance fuel system 7.3 Powerstroke and how to address them.

Low Fuel Pressure

- Clogged Filters: This is the most common cause. Replace your fuel filters.

- Air in System: Ensure the system is properly primed. Cycle the key several times. Check for loose fittings that might be allowing air in.

- Failing Lift Pump: If filters are new and there are no leaks, the pump itself might be faulty or not getting proper voltage. Check wiring and voltage to the pump.

- Restrictive Pickup: If you didn’t upgrade your in-tank pickup, a clogged screen on the factory pickup can restrict flow.

Fuel Leaks

- Loose Fittings: Re-tighten all AN fittings and hose clamps. Do not overtighten AN fittings, as this can damage them.

- Damaged O-rings: If using O-ring style fittings, inspect the O-rings for damage and replace if necessary.

- Incorrect Thread Sealant: Ensure you used fuel-rated thread sealant or Teflon tape on all NPT fittings.

- Damaged Lines: Inspect fuel lines for cuts or chafing.

Hard Starting / No Start

- Air in Fuel System: The most frequent cause. Cycle the key to prime the system thoroughly. Crank for short bursts to help purge air.

- No Power to Pump: Check the fuse, relay, and wiring to the lift pump. Ensure it’s getting proper voltage.

- Incorrect Wiring: Double-check all electrical connections according to the kit’s diagram.

- Low Fuel Pressure: Refer to the “Low Fuel Pressure” section above.

Conclusion

Upgrading your 7.3 Powerstroke’s fuel system is one of the most beneficial modifications you can make, offering a significant return on investment in terms of engine longevity, improved performance, and even better fuel efficiency 7.3 Powerstroke. By taking the time to install a performance fuel system on your 7.3 Powerstroke, you’re not just adding a part; you’re investing in the future of your legendary diesel truck. You’ll experience more consistent power delivery, smoother idling, and the peace of mind that comes from knowing your injectors are protected by superior filtration and stable fuel pressure.

While the installation can seem daunting, with the right tools, careful planning, and this comprehensive guide, it’s a completely achievable DIY project. Remember to prioritize safety, follow your kit’s instructions diligently, and don’t hesitate to seek advice from fellow 7.3 enthusiasts if you hit a snag. Your 7.3 Powerstroke has served you well; now it’s time to give it the ultimate fuel delivery system it deserves, ensuring many more miles of reliable, powerful service. Happy wrenching!

🎥 Related Video: Increase 7.3 fuel mileage

📺 chris roach

Removing spring and plunger from fuel bowl in a 2003 f250 7.3. These fuel bowls are on 99-2004 f250’s and f350’s the 2004 6.0 …

Frequently Asked Questions

What are the main benefits of installing a performance fuel system on my 7.3 Powerstroke?

A performance fuel system significantly improves fuel delivery, ensuring your injectors receive consistent pressure and volume. This can lead to increased horsepower, better throttle response, and improved fuel efficiency, especially under demanding conditions.

What components are typically included in a performance fuel system upgrade for the 7.3 Powerstroke?

A common performance fuel system upgrade for the 7.3 Powerstroke often includes a more robust fuel pump, larger fuel lines, a regulated return system, and upgraded fuel filters. These components work together to maintain optimal fuel pressure and flow to the injectors.

Is installing a performance fuel system on a 7.3 Powerstroke a DIY project, or should I seek professional help?

While many mechanically inclined individuals can perform this upgrade, it requires a good understanding of automotive systems, proper tools, and attention to detail. If you’re not comfortable with fuel line routing, electrical work, and potential modifications, professional installation is recommended.

How does a performance fuel system specifically boost fuel efficiency on a 7.3 Powerstroke?

By maintaining consistent fuel pressure and flow to the injectors, a performance fuel system ensures more complete and efficient fuel combustion. This reduces unburnt fuel and optimizes the engine’s operation, leading to better mileage compared to a struggling stock system.

Will I need to tune my 7.3 Powerstroke after installing a performance fuel system?

While not always strictly required for basic functionality, custom tuning is highly recommended to fully optimize your 7.3 Powerstroke’s performance and efficiency gains after installing a new fuel system. A proper tune can account for the improved fuel delivery and maximize your investment.

What specialized tools are needed for installing a performance fuel system on a 7.3 Powerstroke?

You’ll typically need a standard mechanic’s tool set, including wrenches, sockets, and screwdrivers. Depending on the specific kit, you might also need a fuel line disconnect tool, a torque wrench, and possibly a tubing cutter or flaring tool for custom lines.