Revive Your Car’s Communication System: A Comprehensive Guide on How to Fix SAE J1850 VPW

If you’re facing issues with the SAE J1850 VPW protocol, you’re not alone. Many automotive technicians struggle with decoding this data exchange standard. Fixing SAE J1850 VPW requires a solid understanding of the protocol and the right tools.

In this quick guide, we’ll cover the fundamentals of SAE J1850 VPW protocol, common issues, and troubleshooting tips to help you get your vehicle running smoothly in no time. So, buckle up and get ready to learn!

Understand the Protocol

If you’re trying to fix SAE J1850 VPW protocol, the first step is to understand what the protocol is and how it works. SAE J1850 VPW stands for “Society of Automotive Engineers J1850 Variable Pulse Width.” It’s a communication protocol that allows electronic systems in a vehicle to communicate with each other.

Specifically, it allows the Engine Control Module (ECM), Transmission Control Module (TCM), and other modules to communicate with each other over a single wire. The protocol uses a specific pulse width to transmit data, with a longer pulse representing a bit value of “1” and a shorter pulse representing a bit value of “0.” By understanding how this protocol works, you can better diagnose and fix issues with communication between modules in your vehicle.

So, if you’re having issues with the SAE J1850 VPW protocol in your vehicle, start by understanding the basics of how it works.

What is SAE J1850 VPW

SAE J1850 VPW is a communication protocol used in automobiles to transmit data between different electronic control units (ECUs). It was developed by the Society of Automotive Engineers (SAE) to establish a standard for transmitting information between different systems in a vehicle. The protocol uses variable pulse width modulation (VPW) to communicate over a single wire at a data rate of

4 kbit/s. The VPW signal is a series of pulses, where the duration of the pulse indicates a “1” and the absence of a pulse indicates a “0”. This protocol is used in many modern vehicles for communication between various modules, such as the powertrain control module (PCM), body control module (BCM), and climate control module (CCM).

Understanding the SAE J1850 VPW protocol is critical for diagnosing and repairing issues in modern vehicles.

How does it work?

The protocol that underlies a blockchain determines how transactions are processed and validated within the network. In simple terms, a blockchain is a decentralized ledger that records transactions between participants in a secure and transparent way. When a transaction is initiated, it is broadcasted to the network, and validators (or miners) compete to validate the transaction.

This is done by solving a complex mathematical puzzle that requires significant computational power. Once the transaction is validated, it is added to the blockchain, and a new block is created. Every block contains a reference to the previous one, forming a chain of blocks (a blockchain).

The security of a blockchain arises from its decentralized nature, which means that every participant in the network has a copy of the ledger and can validate transactions independently. This makes it virtually impossible to manipulate the network since any attempt to do so would require a majority of the participants to collude and agree on the fraudulent action. In summary, the blockchain protocol ensures that transactions are processed in a secure, transparent, and decentralized way, with no need for intermediaries.

Tips for Troubleshooting

If you’re having trouble with the SAE J1850 VPW protocol system, there are a few tips that can help you troubleshoot it. First, check all of the connections to make sure that they’re secure and free from any corrosion or damage. If you find any issues, repairing or replacing these components may be necessary.

Additionally, you might want to check the wiring and connectors to make sure that they’re properly grounded and not experiencing any interference. Another potential issue could be a faulty sensor, which may need to be replaced. Finally, make sure that you have the correct software and programming for the system, as this can also affect performance.

By following these tips and systematically diagnosing the problem, you should be able to fix the SAE J1850 VPW protocol system and get your vehicle back to working properly.

Check the Connections

When troubleshooting any kind of electronics, one of the first things you should check is the connections. Loose or faulty connections can cause all kinds of problems, from intermittent sound to complete device failure. Start by checking all cables and connections, making sure they’re securely plugged in and not damaged in any way.

If you’re still having issues, try unplugging and reconnecting the cables to ensure a snug fit. In some cases, you may need to replace a faulty cable or adapter. Remember, even the tiniest connection issue can cause major problems, so it’s best to start with the basics before moving on to more complex troubleshooting techniques.

Use a Scanner Tool

If you’re experiencing issues with your vehicle, using a scanner tool can help troubleshoot the problem. These tools connect to your car’s computer system and provide information about the issue at hand. One of the most significant benefits of using a scanner tool is that it can save you time and money by quickly identifying the problem, allowing repairs to be made before the damage worsens.

However, it’s essential to ensure that the scanner tool you’re using is compatible with your vehicle’s make and model. Some scanner tools are more advanced than others, offering real-time data and the ability to reset specific codes. So, before purchasing a scanner tool, research the options available and choose one that best suits your needs.

They may seem daunting, but with some basic knowledge and research, scanner tools can be an effective way to troubleshoot issues with your vehicle.

Inspect the Wiring Harness

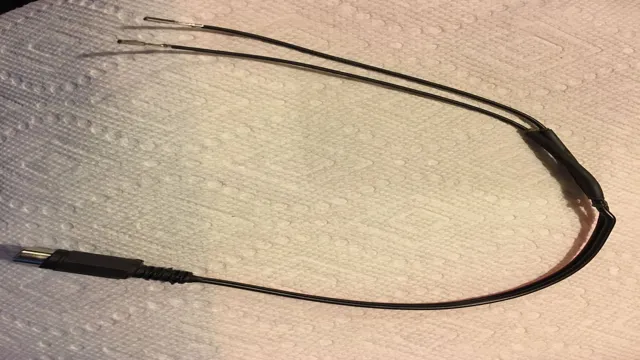

When it comes to troubleshooting your vehicle’s electrical issues, inspecting the wiring harness should be on your checklist. This is because a faulty wiring harness can be the cause of various problems, such as electrical shorts or open circuits, which can lead to malfunctioning equipment or even fires in severe cases. To inspect the wiring harness, start by checking if there are any visible signs of wear and tear on the wires, such as cracks or frayed ends.

Keep an eye out for any loose connections or corroded terminals, as these can cause issues with electricity flow. It’s also advisable to use a multimeter to test the wiring’s continuity and resistance levels, which can help identify any problems that may not be visible to the naked eye. Taking the time to inspect the wiring harness thoroughly can save you from headaches down the road.

Replacing Faulty Components

If you’re dealing with a faulty SAE J1850 VPW, the first thing you’ll want to do is diagnose the issue. Once you’ve identified the problem, whether it’s a faulty component or a loose connection, you can start working on a solution. In some cases, you may be able to simply replace the faulty component, such as a damaged wire or malfunctioning sensor.

However, if the issue is more complex, you may need to enlist the help of a professional mechanic or technician to properly diagnose and repair the problem. Don’t try to tackle this type of repair on your own if you’re not comfortable with the process, as you could cause further damage or create more issues down the line. Always make sure to follow proper safety protocols when working with automotive electrical systems.

With the right tools, knowledge, and expertise, it is possible to fix a faulty SAE J1850 VPW without too much hassle.

Identify the Problem Component

When a component in your electronic device malfunctions or goes bad, the first step is to identify the problem component. This can be done by running diagnostic tests or visually inspecting the device. Once you have identified the faulty component, you can begin the process of replacing it.

This requires ordering a replacement part and carefully removing the old component without damaging the surrounding parts. Installing the new component requires precision and attention to detail to ensure that everything is connected properly and working seamlessly. It is important to remember that not all components are easily replaceable or worth the cost of replacement.

Before diving into replacing a component, it is important to weigh the cost and benefits and consider professional assistance if needed. With some basic knowledge and careful attention, replacing faulty components can be a simple and effective solution to prolonging the life of your electronic device.

Choose the Right Replacement

When it comes to replacing faulty components, it’s essential to choose the right replacement to avoid further damage or malfunction. It’s crucial to identify the cause of the fault before purchasing a new component to ensure that you’re addressing the root of the problem and not just the symptoms. Whether you’re replacing a faulty circuit board, a hard drive, or a power supply, it’s essential to consider compatibility and quality.

Ensure that the replacement component is compatible with your device to avoid any compatibility issues and incorrect wiring. Additionally, choosing a high-quality replacement component will ensure that your device operates smoothly and lasts longer. In some cases, it might be tempting to opt for a cheaper replacement component to save money.

However, it’s important to remember that not all components are made equal. Substituting a low-quality replacement component for a high-quality one can have adverse effects and lead to further problems down the line. In summary, choosing the right replacement component is essential to ensure that your device operates smoothly and lasts longer.

Always consider compatibility and quality when selecting a replacement component and avoid opting for cheaper alternatives that could cause more problems in the long run.

Preventing Future Problems

If you’re looking to fix SAE J1850 VPW, there are a few things you can try to prevent future problems. First, make sure your vehicle’s diagnostic equipment is up to date and compatible with the J1850 protocol. This can help prevent errors caused by outdated equipment.

Additionally, it’s important to regularly inspect your vehicle’s wiring and connectors for any signs of damage or corrosion. A damaged wire or connector can cause communication errors and other issues. Finally, if you do experience problems with your J1850 VPW system, it’s important to address them promptly to prevent further damage.

Take your vehicle to a qualified mechanic who can diagnose and fix any issues with your system. By taking these steps to prevent and address problems, you can ensure that your J1850 VPW system runs smoothly and reliably for years to come.

Regular Maintenance

Regular maintenance is the key to preventing future problems with your equipment or machinery. Neglecting routine maintenance can lead to unexpected downtime and costly repairs. By conducting regular maintenance checks, you can ensure that your equipment is in proper working condition and resolve any potential issues before they become major problems.

A thorough maintenance schedule includes tasks such as cleaning, lubrication, inspection of parts and components, and replacement of worn-out parts. Not only does regular maintenance prevent future problems, but it also helps to extend the life of your equipment. Similar to how taking your car in for regular oil changes and tune-ups can extend its lifespan and prevent breakdowns on the side of the road, taking care of your machinery can help to avoid costly repairs and replacements.

It’s always better to be proactive rather than reactive when it comes to equipment maintenance. So, set a regular maintenance schedule and stick to it to keep your equipment running smoothly.

Don’t Ignore Warning Signs

When it comes to preventing future problems, one of the best things you can do is to pay attention to warning signs. Ignoring these signals will only lead to bigger issues down the road. Whether it’s your car making strange noises or your body exhibiting unexpected symptoms, it’s important to take action and address the problem before it worsens.

By doing so, you can save yourself time, money, and hassle in the long run. For example, if you hear your brakes squeaking, don’t wait until they fail before bringing your car in for service. Similarly, if you notice a lump or persistent pain, get it checked out by a doctor sooner rather than later.

Taking action now can mean avoiding more serious consequences later on. So, don’t ignore the warning signs – they’re there for a reason!

Upgrade to a Newer Protocol

Upgrading to a newer protocol is an essential method for preventing future problems in your system. A protocol is a set of rules that govern communication between devices, and advances are made to protocols over time to address security breaches and improve performance. By upgrading to the latest protocol available, you can minimize the risk of data breaches and slow connections.

This upgrade can also offer new features and functionalities that were not previously available. Think of it like a software update for your phone or computer. You want the latest version to ensure that your device runs smoothly and efficiently.

The same idea applies to protocols. So, when it comes to maintaining your system’s security and performance, don’t hesitate to upgrade to the latest protocol available.

Conclusion

In conclusion, fixing the SAE J1850 VPW requires a bit of technical know-how and a dash of ingenuity. Start by identifying the root cause of the issue, whether it be a malfunctioning sensor or a faulty wiring connection. Then, utilize resources such as wiring diagrams and diagnostic tools to pinpoint the problem area and make any necessary repairs.

But perhaps the most important component to fixing the SAE J1850 VPW is a willingness to think outside the box. Sometimes the solution isn’t obvious or straightforward, and it takes a bit of creativity and innovation to get the job done. So don’t be afraid to experiment and try new approaches – after all, a clever fix is often the most effective one.

“

FAQs

What is SAE J1850 VPW?

SAE J1850 VPW is a communication protocol used by some vehicles to transmit data between different onboard systems, such as the engine and transmission.

How do I know if my vehicle uses SAE J1850 VPW?

You can check your vehicle’s specifications or consult the owner’s manual to see if it uses SAE J1850 VPW. Alternatively, you can use an OBD-II scanner to scan for supported protocols.

What are common issues with SAE J1850 VPW?

Some common issues with SAE J1850 VPW include communication errors, data dropouts, and signal interference. These issues can cause various diagnostic trouble codes (DTCs) to appear.

How do I fix SAE J1850 VPW communication issues?

To fix SAE J1850 VPW communication issues, you can try the following steps:

– Check the wiring and connectors for damage or corrosion

– Ensure the voltage levels are within the specified range

– Verify that all systems and modules are properly powered and grounded

– Use a quality OBD-II scanner to diagnose and clear any DTCs

– Consider using a signal booster or filter to reduce signal interference.