Unlock the Secret to Fixing SAE J1850 PWM with These Easy Tips and Tricks

Have you ever encountered issues with your vehicle’s communication system? SAE J1850 PWM is a standard protocol used by many car manufacturers to communicate between different components of the car, such as the engine control module and the instrument cluster. While this protocol is widely used, it can sometimes pose challenges when trying to diagnose and fix issues. But fear not, for there are ways to tackle these problems and get your car running smoothly again.

In this blog, we’ll explore some common issues that arise with SAE J1850 PWM and provide practical solutions to fix them. Whether you’re a seasoned mechanic or a DIY enthusiast, these tips will come in handy when troubleshooting communication problems in your vehicle. We’ll cover topics such as identifying communication errors, understanding the different components of the protocol, and using diagnostic tools to pinpoint the source of the problem.

With our step-by-step approach, you’ll be able to diagnose and fix even the toughest communication issues in no time. So if you’re ready to learn how to take on SAE J1850 PWM challenges head-on, keep reading and discover some useful tips that will help you keep your car running smoothly.

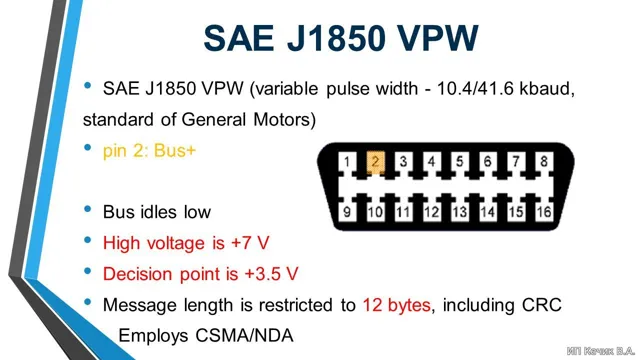

What is SAE J1850 PWM?

SAE J1850 PWM is a communication protocol used in the automotive industry for transmitting data between various components of the vehicle. It is an acronym for Society of Automotive Engineers (SAE) and Pulse Width Modulation (PWM). This protocol uses a pulse signal to transmit data over a single wire, with the frequency and duration of the pulses changing depending on the information being transmitted.

If you are experiencing issues with the SAE J1850 PWM communication line, it can cause problems with engine performance, emissions, and other vital systems in your vehicle. A common fix for this issue is to check for any loose or damaged wires and connections in the communication system, and if necessary, replace them with new ones. It’s also important to ensure that the components using this protocol are functioning correctly and have the latest firmware updates installed.

By taking these steps to resolve any issues with SAE J1850 PWM, you can ensure that your vehicle runs smoothly and efficiently.

Explaining the standard and its purpose

SAE J1850 PWM is a standard communication protocol used in many vehicles. PWM stands for Pulse Width Modulation, which means that the digital signal is sent by varying the width of the signal pulse. This protocol allows communication between different electronic control units in the vehicle, such as the engine control module and the transmission control module.

The purpose of this standard is to ensure that these different modules can work together seamlessly to provide the best possible driving experience for the user. With SAE J1850 PWM, different modules can communicate with each other in a timely and accurate manner. This means that the vehicle’s systems can work together to optimize performance while also detecting and correcting any issues that arise.

Whether you are a vehicle manufacturer or a driver, understanding SAE J1850 PWM is vital to ensure that your vehicle operates efficiently and safely.

Common Problems with SAE J1850 PWM

SAE J1850 PWM is a widely-used communication protocol that provides serial data communication over a single wire. However, there are common problems that can occur with this protocol, which can make it challenging to work with. One of the main issues is that it can be difficult to diagnose communication errors, which can lead to frustration and wasted time trying to fix problems that may not be related to the protocol itself.

Another issue is that it can be prone to interference, which can cause data corruption and other issues. To fix these problems, it’s important to use quality wiring and connectors, as well as to ensure that the system is properly grounded. Additionally, it may be necessary to use filtering and buffering techniques to help protect the signal and ensure that it is received properly.

With a little effort and attention to detail, it’s possible to overcome these common problems and achieve reliable, consistent communication with SAE J1850 PWM.

Listing common issues with the standard

One of the most common issues found with the SAE J1850 PWM standard is its vulnerability to electromagnetic interference (EMI), which can adversely affect the quality of signal transmission. Another problem is the limited bandwidth of the standard, which restricts its usage in applications that require high-speed data transfer. The standard also faces issues with compatibility between different makes and models of vehicles, which can be problematic for automotive technicians.

Another challenge with the standard is its inability to support advanced diagnostic features, which leads to limited fault detection capabilities. Additionally, the standard relies heavily on the vehicle’s battery voltage level to function correctly, leading to issues if the battery is low or has any faults. In summary, while the SAE J1850 PWM standard has been widely adopted, it faces significant challenges in terms of signal quality, bandwidth, compatibility, and advanced diagnostic features.

Symptoms of a failing system

If you’re experiencing issues with your vehicle’s communication system, it could be due to a failing SAE J1850 PWM protocol. This common communication standard is used in many vehicles to transmit data between different parts of the car. Symptoms of a failing system can include intermittent connection problems, difficulty starting the engine, or even complete system failure.

If you notice any of these issues, it’s essential to take your vehicle to a mechanic or dealership for a diagnostic test. Attempting to fix the problem yourself could cause more harm than good and may even lead to further issues down the line. Overall, keeping an eye out for signs of a failing SAE J1850 PWM system is crucial to ensure your vehicle stays running smoothly and efficiently for years to come.

Steps to Fix SAE J1850 PWM

Fixing SAE J1850 PWM issues can be a daunting task, but it doesn’t have to be. Here are some simple steps to get you started. First, make sure that your vehicle’s diagnostic system is properly connected and functioning correctly.

This may involve checking the wiring or replacing a faulty cable. Next, check the diagnostic tool you are using to ensure it is compatible with the SAE J1850 PWM protocol. If it’s not, you may need to switch to a different diagnostic tool.

Finally, if all else fails, you may need to replace the PCM (powertrain control module) in your vehicle. This is a more complicated and expensive fix, but it may be necessary if all other options have been exhausted. By following these steps, you can successfully fix any SAE J1850 PWM issues and keep your vehicle running smoothly.

Identifying the cause of the problem

SAE J1850 PWM When troubleshooting the SAE J1850 PWM system, it is essential to identify the cause of the problem before proceeding with any repairs. The first step is to use a diagnostic tool that can read and interpret error codes from the system. Once the diagnostic tool has identified the error code, the next step is to evaluate the wiring harness, connectors, and other components for any apparent damage or wear.

It is crucial to inspect the wiring for any signs of corrosion or exposed wires as these can cause intermittent connectivity issues. If the wiring is in good condition, the next step is to verify all the power and ground connections to the system modules are secure. Any loose connections can cause issues that affect the network’s performance.

Lastly, to identify the cause of the problem, a comprehensive system check must be performed. This will help to identify any potential system faults, sensor malfunctions, or other issues that could be causing the problem. By following these steps, technicians can effectively diagnose and fix SAE J1850 PWM issues, restoring full system functionality and performance.

Replacing faulty components

If you’re having trouble with your SAE J1850 PWM protocol, replacing faulty components may be the solution. There are a few steps you can follow to fix the issue. First, you’ll need to identify the faulty component.

This may involve using a diagnostic tool to pinpoint the problem. Once you’ve identified the component, you’ll need to remove it and replace it with a new one. This can be a tricky process, as the component may be in a hard-to-reach location or require specialized tools.

It’s important to follow the manufacturer’s instructions carefully, and to make sure the replacement component is of the correct type and rating. Once you’ve completed the replacement, you can test the protocol to make sure the issue has been resolved. With a bit of patience and persistence, you can fix your SAE J1850 PWM protocol and get back to smooth and reliable communication.

Testing the system after repairs

If you’ve identified an issue with your vehicle’s communication system, specifically the SAE J1850 PWM, there are steps you can take to fix it. The first step in the process is to ensure that all of the necessary tools are on hand. You will need an OBD-II scanner, a multimeter, and a wiring diagram to help you identify which wires need to be tested.

Once you have your tools ready, you can begin testing the system to find the source of the issue. If you have identified a broken wire, the next step is to repair it. Cut out the faulty section of the wire and replace it with a new one.

Make sure to use the proper wire gauge and follow the wiring diagram to ensure that the new wire is connected correctly. After you have made the needed repairs, it’s important to test the system once more to make sure that everything is in working order. Use your multimeter to check the continuity of each wire and make sure that it is properly grounded.

Then, use your OBD-II scanner to check for any error codes and to ensure that the communication system is functioning properly. By following these steps and making the necessary repairs, you can fix issues with your vehicle’s communication system and get back on the road. Remember, always follow safety precautions and use the appropriate tools when working on your vehicle.

Preventing Future Issues with SAE J1850 PWM

Are you tired of experiencing issues with your SAE J1850 PWM protocol? While there may not be a single solution to this problem, there are certainly some steps you can take to prevent future issues from arising. One of the best things you can do is to regularly perform diagnostic checks on your vehicle’s systems. This can help you catch small issues before they turn into bigger problems.

Additionally, make sure you are using high-quality equipment that is designed to work with the SAE J1850 PWM protocol. Cheaper, knock-off brands may not work as well and can lead to compatibility issues or even cause damage to your vehicle. Finally, educate yourself on best practices for working with this protocol.

The more you know, the better equipped you will be to handle any issues that may arise. By taking these steps, you can help prevent future problems with your SAE J1850 PWM protocol.

Tips on maintaining a healthy system

If you’re looking to maintain a healthy system and avoid future issues with SAE J1850 PWM, there are a few tips that you can follow. First, make sure to keep your system clean and free from any dirt or debris that may accumulate over time. This can be done by regularly wiping down the components of your system and cleaning out any vents or fan filters.

Additionally, it’s important to keep up with any software updates or upgrades that may be available. These updates can help keep your system running smoothly and can often include important security patches. Another important aspect of maintaining a healthy system is to be mindful of the power supply.

Make sure that your system is adequately cooled and that you’re using a power supply that can handle the demands of your system. By following these tips and staying vigilant with regular maintenance, you can help prevent future issues and keep your system running effectively and efficiently.

Conclusion

Fixing SAE J1850 PWM can be a daunting task for even the most experienced automotive enthusiasts. However, the solution may be simpler than you think. First, ensure that all wires are properly connected and in good working order.

Next, check and replace any faulty sensors or modules that may be causing communication issues. And finally, don’t forget to give your vehicle some love with regular maintenance and TLC – because a healthy car is a happy car! With these steps in mind, you’ll have your SAE J1850 PWM purring like a kitten in no time. Remember, it’s not rocket science – but it does take a little bit of patience, ingenuity, and a whole lot of love for your ride.

“

FAQs

What is SAE J1850 PWM?

SAE J1850 PWM stands for Society of Automotive Engineers J1850 Pulse Width Modulation. It is a standard communication protocol used for communication between electronic control modules (ECMs) in vehicles.

How to diagnose a problem with SAE J1850 PWM?

Use a scan tool to read error codes and monitor live data from the ECM to diagnose problems with SAE J1850 PWM communication.

How to fix SAE J1850 PWM communication problems?

Check the wiring and connectors for any damage or corrosion. Repair or replace any damaged components. Also, update the ECM’s firmware to the latest version.

Can a faulty ECM cause SAE J1850 PWM communication problems?

Yes, a faulty ECM can cause SAE J1850 PWM communication problems. In such cases, the ECM needs to be replaced or repaired.