How to Fix 6.0 Powerstroke Hard Acceleration Issues: Troubleshoot and Repair

Featured image for this comprehensive guide about How to fix 6.0 Powerstroke hard acceleration issues

Image source: powerstroke.org

Ah, the legendary 6.0 Powerstroke. A truck revered for its pulling power and robust frame, yet often whispered about for its complex engine quirks. If you’re reading this, chances are you’re intimately familiar with one of the most frustrating performance issues: 6.0 Powerstroke hard acceleration issues. That moment when you press the pedal, expecting a surge of power, and instead, you get hesitation, surging, a noticeable lack of oomph, or a feeling that your truck is struggling to breathe.

This isn’t just an annoyance; it can be a significant safety concern, especially when merging onto highways or towing heavy loads. The good news? While the 6.0 Powerstroke can be a puzzle, many of its common acceleration problems have well-documented causes and, more importantly, effective solutions. Often, these issues stem from a handful of notorious components that, once understood, can be diagnosed and repaired, bringing your beast back to its full, powerful glory.

In this comprehensive guide, we’ll dive deep into the world of 6.0 Powerstroke hard acceleration issues. We’ll explore the common culprits, equip you with the knowledge to diagnose the problems, and provide actionable repair strategies. From understanding your fuel system to tackling turbo woes and electrical gremlins, consider this your ultimate resource to troubleshoot and fix your 6.0 Powerstroke’s hesitation and return to smooth, reliable power.

Quick Answers to Common Questions

Why is my 6.0 Powerstroke suddenly accelerating hard or hesitating?

Hard acceleration or hesitation in your 6.0 Powerstroke often points to fuel delivery problems, sensor malfunctions, or even a sticking turbocharger. Identifying the exact cause is the first step to fixing these 6.0 Powerstroke hard acceleration issues.

Is hard acceleration in a 6.0 Powerstroke dangerous to ignore?

Absolutely! Ignoring 6.0 Powerstroke hard acceleration issues can lead to more severe engine damage and compromise your vehicle’s safety and reliability. It’s best to address it promptly to prevent further complications.

What’s the very first thing I should check for 6.0 Powerstroke hard acceleration issues?

Start by checking for any diagnostic trouble codes (DTCs) with an OBD-II scanner, as these often point directly to the underlying problem. Also, visually inspect your fuel filter and air filter, as simple clogs can cause 6.0 Powerstroke hard acceleration issues.

Can I fix 6.0 Powerstroke hard acceleration issues myself, or do I need a mechanic?

Many common causes, like clogged filters or minor sensor replacements, can be DIY-friendly if you’re comfortable with basic tools. However, more complex diagnostics for 6.0 Powerstroke hard acceleration issues might require professional help.

What are the most common parts that fail, causing 6.0 Powerstroke hard acceleration issues?

Often, issues like a failing Injector Control Pressure (ICP) sensor, Exhaust Gas Recirculation (EGR) valve, or a Variable Geometry Turbocharger (VGT) solenoid are culprits. Problems with the fuel injection control module (FICM) can also contribute to 6.0 Powerstroke hard acceleration issues.

📋 Table of Contents

- Understanding 6.0 Powerstroke Hard Acceleration Issues: Symptoms and Causes

- Fuel System Integrity: The Foundation of Smooth Power

- Turbocharger Performance: The Heart of 6.0 Power

- Sensor & Electrical System Diagnostics: Reading the Engine’s Mind

- Exhaust System & Catalytic Converter Restrictions

- Advanced Diagnostics & Professional Assistance

- Conclusion: Reclaiming Your 6.0 Powerstroke’s Performance

Understanding 6.0 Powerstroke Hard Acceleration Issues: Symptoms and Causes

Before we can fix anything, we need to understand what we’re dealing with. Hard acceleration issues in a 6.0 Powerstroke can manifest in various ways, but they all point to the engine not receiving, processing, or delivering power efficiently. Identifying the precise symptoms is your first crucial step towards diagnosis.

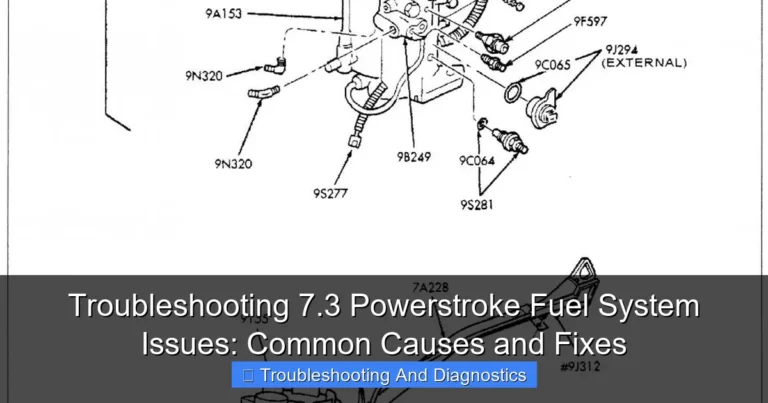

Learn more about How to fix 6.0 Powerstroke hard acceleration issues – How to Fix 6.0 Powerstroke Hard Acceleration Issues: Troubleshoot and Repair

Image source: i222.photobucket.com

Common Symptoms of Hard Acceleration Problems

- Hesitation or Lag: When you press the accelerator, there’s a noticeable delay before the engine responds. This can feel like a “dead pedal.”

- Surging or Bucking: The truck accelerates unevenly, sometimes jumping forward and then momentarily losing power, creating a bucking sensation.

- Lack of Power/Sluggishness: The engine feels weak, struggles to climb hills, or can’t maintain speed, especially under load. This is a classic sign of 6.0 Powerstroke loss of power.

- Black or White Smoke from Exhaust: Excessive smoke during acceleration can indicate combustion issues, fuel problems, or turbo trouble.

- Rough Idle: While not directly an acceleration issue, a rough idle can often be a precursor or accompanying symptom of underlying fuel or injector problems that affect acceleration.

- Check Engine Light (CEL): Always pay attention to this. A CEL often accompanies these issues and can provide valuable diagnostic trouble codes (DTCs).

Why the 6.0 Powerstroke is Prone to These Issues

The 6.0 Powerstroke, produced from 2003-2007, uses an advanced high-pressure oil system (HEUI – Hydraulically actuated Electronic Unit Injector) to operate its fuel injectors, a variable geometry turbocharger (VGT), and an exhaust gas recirculation (EGR) system. While innovative, these systems have specific weak points:

| Symptom/Observation | Common Cause(s) | Diagnostic Approach | Typical Solution(s) |

|---|---|---|---|

| Engine Hesitation/Stuttering during acceleration | Low Fuel Pressure, Injector Stiction, Sticking VGT Turbo | Monitor fuel pressure (idle & WOT), check ICP/IPR values, VGT duty cycle, scan for codes (e.g., P026x, P0069). | Replace fuel filters, use stiction eliminator additive, clean/replace turbo unison ring, replace fuel pressure regulator. |

| Sluggish/Weak Acceleration, Lack of Power | Boost Leaks (CAC boots), Low IPR/ICP Pressure, Failing FICM, Clogged Air Filter | Perform boost leak test, monitor MAP/BARO, ICP/IPR values, check FICM voltage (must be ≥48V), inspect air filter. | Replace damaged CAC boots, replace IPR valve/ICP sensor, repair/replace FICM, replace air filter, inspect HPOP system. |

| Jerky/Erratic Acceleration, Rough Idle | Sticking/Failing EGR Valve, Faulty Injectors, Wiring Issues | Inspect EGR valve for carbon, perform cylinder contribution test, check injector harness/connectors, scan for misfire codes. | Clean or replace EGR valve, replace faulty injectors, repair/replace damaged wiring or connectors. |

| Excessive Black Smoke during acceleration | Turbocharger Issues (VGT vanes, failing turbo), Faulty Injectors, Boost Leaks | Inspect turbo for play/sticking, monitor boost pressure, perform cylinder contribution test, check for exhaust restrictions. | Clean or replace turbocharger, replace faulty injectors, address any identified boost leaks. |

- Complex Fuel & Oil System: The HEUI system relies on incredibly precise oil pressure. Issues with this system are a leading cause of 6.0 Powerstroke hard acceleration issues.

- EGR System: Prone to clogging with soot, leading to restricted airflow and performance problems.

- VGT Turbocharger: The mechanism that adjusts turbo vanes can stick due to soot buildup, preventing proper boost.

- Electrical Sensitivity: Various sensors and modules (like the FICM) are critical for smooth operation and can fail, leading to widespread issues.

Fuel System Integrity: The Foundation of Smooth Power

A healthy 6.0 Powerstroke relies on a meticulously calibrated fuel system. Any disruption here, from inadequate pressure to compromised injectors, can directly lead to 6.0 Powerstroke sluggish acceleration and other performance woes.

Learn more about How to fix 6.0 Powerstroke hard acceleration issues – How to Fix 6.0 Powerstroke Hard Acceleration Issues: Troubleshoot and Repair

Image source: powerstroke.org

Fuel Pressure Regulator (FPR) and Fuel Filters

Maintaining proper fuel pressure is paramount for the 6.0. The factory fuel pressure regulator can be a weak point, leading to insufficient fuel delivery to the injectors. Simultaneously, clogged fuel filters restrict flow, starving the engine of fuel.

- Symptoms: Hard starting, lack of power, rough running, particularly under load. These often feel like classic 6.0 Powerstroke hard acceleration issues.

- Diagnosis:

- Fuel Pressure Test: Connect a fuel pressure gauge to the test port on the fuel filter housing. You should see around 50-65 PSI at idle. Pressure dropping significantly during acceleration indicates a problem. Ford’s recommended minimum is 45 PSI at wide open throttle (WOT).

- Filter Inspection: Check both the primary and secondary fuel filters. They should be replaced regularly (every 10,000-15,000 miles, or more frequently if fuel quality is suspect).

- Repair:

- Replace Filters: Start here. It’s inexpensive and often overlooked.

- Upgrade FPR: Many owners opt for an aftermarket regulated return system or a higher-quality fuel pressure spring to ensure consistent pressure.

- Inspect Fuel Pump: If pressure remains low after filter and FPR checks, the fuel pump may be failing.

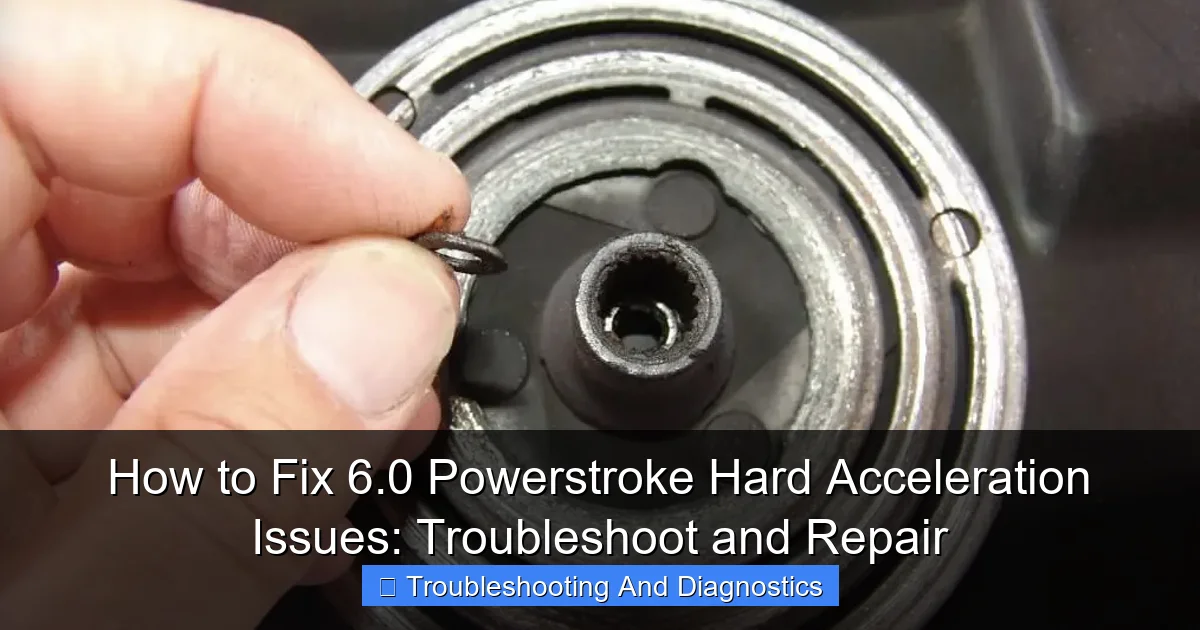

Injector Issues: Stiction and O-Ring Failure

The 6.0 Powerstroke’s HEUI injectors are complex and often a source of trouble. Two common issues are “stiction” and failed O-rings.

- Stiction (Sticking Injectors): This occurs when engine oil breaks down and leaves residue, causing the spool valve inside the injector to stick. This prevents the injector from firing properly or consistently.

- Symptoms: Rough idle (especially when cold), misfires, hesitation, and a general feeling of 6.0 Powerstroke hard acceleration issues. It often improves as the engine warms up.

- Diagnosis: Often identified by specific DTCs (P0261-P0284 – injector circuit low/high or contribution/balance faults) and by observing cylinder contribution tests with a diagnostic scanner.

- Repair: Start with an oil additive specifically designed for injector stiction (e.g., Archoil AR9100). If that doesn’t work, individual injectors may need to be replaced.

- O-Ring Failure: The O-rings seal the injector against the cylinder head, preventing high-pressure oil and fuel from leaking.

- Symptoms: Oil in the fuel, fuel in the oil, hard starting, white smoke, and significant loss of power, contributing to 6.0 Powerstroke hard acceleration issues.

- Diagnosis: Visible leaks, oil analysis, and sometimes specific cylinder contribution tests.

- Repair: Replacement of the faulty O-rings or the entire injector. This is a more involved repair.

Turbocharger Performance: The Heart of 6.0 Power

The 6.0 Powerstroke’s variable geometry turbocharger (VGT) is designed to provide quick boost across a wide RPM range. When it malfunctions, you’ll immediately feel a significant drop in power and responsiveness, leading to serious 6.0 Powerstroke hard acceleration issues.

Variable Geometry Turbocharger (VGT) Actuator and Vanes

The VGT uses movable vanes to adjust exhaust flow to the turbine, optimizing boost. Soot buildup or a failing VGT actuator can cause these vanes to stick.

- Symptoms: Turbo lag, sluggish acceleration, lack of top-end power, whistle-like noises, and sometimes an engine that enters “limp mode.” This is a primary cause of 6.0 Powerstroke lack of power.

- Diagnosis:

- VGT Actuator Test: With a diagnostic scanner, you can command the VGT actuator to cycle its vanes. Listen for smooth movement.

- Visual Inspection: Remove the turbocharger and inspect the vanes for soot buildup or corrosion.

- MAP/BARO Sensor Readings: Compare these to identify if the turbo is building adequate boost.

- Repair:

- Turbo Cleaning: Often, cleaning the VGT vanes can resolve sticking issues.

- VGT Actuator Replacement: If the actuator itself is faulty, it will need to be replaced.

- Turbo Replacement: In severe cases of damage or wear, the entire turbo may need replacement.

Boost Leaks and the MAP Sensor

Even if your turbo is working perfectly, boost leaks can prevent that pressurized air from reaching the engine. The Manifold Absolute Pressure (MAP) sensor measures this boost pressure, relaying critical information to the PCM.

- Symptoms: Reduced power, whistling or hissing sounds under acceleration, increased exhaust smoke, and poor fuel economy. All contribute to 6.0 Powerstroke hesitant acceleration.

- Diagnosis:

- Visual Inspection: Check all intercooler pipes (cold side and hot side) and boots for cracks, tears, or loose clamps.

- Smoke Test: Professional shops can perform a smoke test, injecting smoke into the intake system to pinpoint leaks.

- MAP Sensor Readings: Monitor live data from the MAP sensor. If it’s not reading adequate pressure despite the turbo spooling, it could be a leak or a faulty sensor.

- Repair: Replace damaged boots or pipes, tighten clamps. If the MAP sensor is faulty, replace it. Ensure the hose connecting the MAP sensor to the intake manifold is clean and free of cracks.

Sensor & Electrical System Diagnostics: Reading the Engine’s Mind

The 6.0 Powerstroke relies heavily on a network of sensors and modules to operate efficiently. When these components fail or provide inaccurate data, the engine’s computer (PCM) makes incorrect fueling or timing decisions, leading directly to 6.0 Powerstroke hard acceleration issues.

ICP (Injection Control Pressure) & IPR (Injection Pressure Regulator) Sensors

These two components are absolutely critical for the high-pressure oil system that actuates the injectors. The ICP sensor measures the oil pressure, and the IPR valve regulates it.

- ICP Sensor (Injection Control Pressure):

- Symptoms: Hard or no starts (especially when hot), rough idle, stalling, and significant loss of power during acceleration – a hallmark of 6.0 Powerstroke hard acceleration issues.

- Diagnosis: Monitor ICP pressure via a scanner. At idle, it should be around 500-750 PSI, increasing significantly under acceleration (up to 3,800 PSI). If pressure is low or erratic, or if you have codes like P2285, P2287, the ICP sensor or its circuit may be faulty.

- Repair: Replace the ICP sensor. Note its location: early 6.0 models (03-04) have it under the turbo; later models (05-07) have it on the passenger side valve cover.

- IPR Valve (Injection Pressure Regulator):

- Symptoms: Similar to ICP sensor issues: long crank times, stalling, surging, and severe power loss, contributing to 6.0 Powerstroke surging issues.

- Diagnosis: Monitor IPR percentage (duty cycle) with a scanner. At idle, it should be around 25-35%. If it’s consistently very high (e.g., 85%) during cranking or acceleration, the IPR valve may be stuck or there’s an oil leak in the high-pressure oil system.

- Repair: Replace the IPR valve. This is located under the turbo and can be a challenging job.

EGR (Exhaust Gas Recirculation) Valve and Cooler

The EGR system reroutes a portion of exhaust gas back into the intake to reduce NOx emissions. It’s notorious for clogging with soot in the 6.0 Powerstroke.

- Symptoms: Reduced power, hesitation during acceleration, black or white smoke, rough idle, and often a strong smell of exhaust. Can trigger codes like P0401 (EGR flow insufficient). Directly impacts smooth acceleration and causes 6.0 Powerstroke hard acceleration issues.

- Diagnosis:

- Visual Inspection: Remove and inspect the EGR valve for excessive soot buildup.

- Scanner Test: Command the EGR valve to open and close with a diagnostic tool.

- Cooler Inspection: Leaking EGR coolers can also cause issues (white smoke, coolant loss).

- Repair: Clean or replace the EGR valve. If the cooler is leaking or severely clogged, it may need to be replaced (often with an upgraded, less prone-to-failure design) or deleted (for off-road use only, consult local regulations).

FICM (Fuel Injection Control Module)

The FICM powers and controls the fuel injectors. It boosts battery voltage (12V) to approximately 48V to fire the injectors. A failing FICM leads to weak injector pulses.

- Symptoms: Hard starting (especially when cold), misfires, rough idle, overall lack of power, and often a distinct “buzzing” sound from the engine. This is a common cause of 6.0 Powerstroke lack of power.

- Diagnosis: Monitor FICM voltage with a diagnostic scanner. It should be a steady 48.0V (or very close) when the engine is running. If it drops significantly (e.g., to 30V or lower), the FICM is failing.

- Repair: Replace or repair the FICM. Many companies offer FICM repair services or upgraded units.

Exhaust System & Catalytic Converter Restrictions

An often-overlooked area when troubleshooting 6.0 Powerstroke hard acceleration issues is the exhaust system. Just as an engine needs to breathe in, it also needs to breathe out efficiently. Any restriction in the exhaust path can choke the engine and prevent proper turbo spooling.

Clogged Catalytic Converter or DPF

While later 6.0 models (primarily 2007) might have a Diesel Particulate Filter (DPF), all models have a catalytic converter. Over time, these can become clogged with soot and carbon buildup.

- Symptoms: Significant loss of power, reduced fuel economy, increased exhaust gas temperature (EGT), a smell of rotten eggs (sulfur), and sometimes a glowing catalytic converter. The engine will feel severely restricted, leading to classic 6.0 Powerstroke hard acceleration issues.

- Diagnosis:

- Backpressure Test: This is the most definitive test. A gauge is connected to the exhaust system before the catalytic converter to measure backpressure. High readings indicate a restriction.

- Temperature Differences: Measure exhaust temperature before and after the catalytic converter. A significant temperature drop across the converter can indicate a clog.

- Visual Inspection: Sometimes, a severely clogged converter can be seen by looking into it (if accessible).

- Repair: Replace the clogged catalytic converter. In some regions, DPFs can be cleaned, but often replacement is necessary. Be aware of local emissions regulations regarding aftermarket exhaust components.

Exhaust Manifold Leaks

Cracked exhaust manifolds or leaking manifold gaskets can reduce the exhaust pressure available to spin the turbo, leading to poor turbo performance.

- Symptoms: A distinct ticking or hissing sound from the engine bay, especially when cold, which might lessen as the engine warms up. Reduced turbo boost and overall power, contributing to 6.0 Powerstroke sluggish acceleration.

- Diagnosis:

- Auditory: Listen carefully around the exhaust manifolds for leaks.

- Smoke Test: Can help pinpoint small leaks.

- Visual: Look for soot stains around manifold gaskets or cracks in the manifold itself.

- Repair: Replace cracked manifolds or leaking gaskets. This can be a labor-intensive job due to tight spaces and rusted bolts.

Advanced Diagnostics & Professional Assistance

While many of the fixes for 6.0 Powerstroke hard acceleration issues can be tackled by a determined DIYer, some require specialized tools or knowledge. Knowing when to escalate to professional help can save you time, money, and frustration.

Reading Diagnostic Trouble Codes (DTCs)

Your Check Engine Light (CEL) isn’t just a warning; it’s a pointer. The first step in any diagnosis should be to read the DTCs stored in the PCM.

- OBD-II Scanner: A basic scanner can read generic P-codes. However, for a 6.0 Powerstroke, a more advanced scanner (like FORScan or an IDS system) that can read Ford-specific codes (P1xxx codes) and monitor live data is invaluable.

- Understanding Codes: Don’t just clear codes. Research what they mean. For instance, P0284 points to a Cylinder 8 Injector Contribution/Balance Fault, immediately directing your attention.

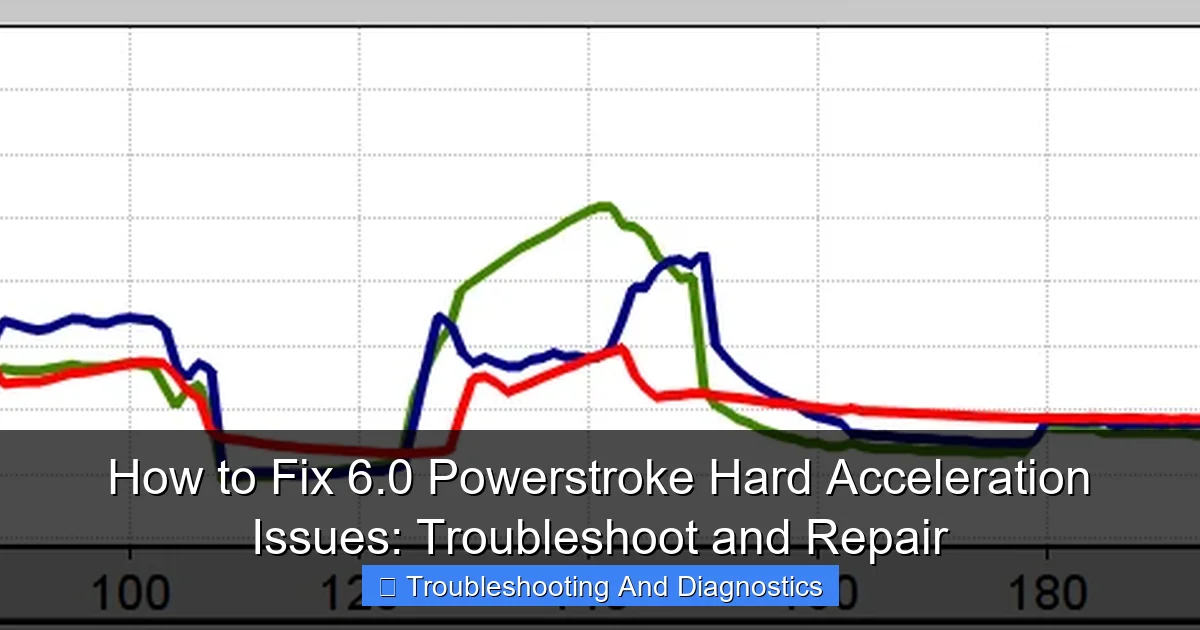

Live Data Monitoring: What to Look For

A good diagnostic scanner allows you to view real-time engine parameters. This is crucial for diagnosing intermittent or complex 6.0 Powerstroke hard acceleration issues. Here’s a table of key parameters to monitor:

| Parameter | Acronym | Target Reading (Approx.) | Significance for Hard Acceleration |

|---|---|---|---|

| Injection Control Pressure | ICP | 500-750 PSI (Idle), >2000 PSI (Accel) | Critical for injector operation. Low pressure = lack of fuel. |

| Injection Pressure Regulator Duty Cycle | IPR % | 25-35% (Idle), higher under load | Indicates how hard the IPR is working. High % with low ICP = leak. |

| Fuel Injection Control Module Voltage | FICM_V | 47.0-48.0V (key on/engine running) | Directly powers injectors. Low voltage = weak injector firing. |

| Fuel Pressure | FP | 50-65 PSI | Ensures injectors have adequate fuel supply. Low pressure = starved engine. |

| Manifold Absolute Pressure | MAP | ~14.7 PSI (KOEO), increases with boost | Measures turbo boost. Low MAP with high RPM = boost leak or turbo issue. |

| Engine Oil Temperature | EOT | Typically within 15-20°F of ECT | High EOT or large EOT/ECT split can indicate oil cooler/HPOP issues affecting ICP. |

| Exhaust Gas Recirculation (EGR) Desired/Actual | EGR_D/EGR_A | Should match closely | Mismatched values indicate sticking EGR valve. |

| Variable Geometry Turbocharger Duty Cycle | VGT_DC | Varies, 15-85% | Monitors VGT actuator movement. Erratic values can mean sticking vanes. |

When to Seek Professional Help

While troubleshooting and repairing 6.0 Powerstroke hard acceleration issues can be a rewarding DIY project, there are times when calling in a professional is the smart choice:

- Persistent or Multiple Codes: If you’re getting a cluster of seemingly unrelated codes, or codes that return immediately after clearing, a professional diagnostic technician can interpret the full picture.

- Lack of Proper Tools: High-pressure oil system diagnosis often requires specialized tools like an air test kit for the HPOP system.

- Complex Internal Engine Issues: If diagnostics point to major components like the High-Pressure Oil Pump (HPOP), cylinder head issues, or internal engine damage, it’s best left to experienced mechanics.

- Safety Concerns: If you’re uncomfortable working with high-pressure fuel or oil systems, or if the repairs involve lifting heavy components like the turbo or cab, a professional shop has the right equipment and training.

- Time & Experience: A seasoned diesel mechanic can often diagnose and fix issues much faster than someone new to the 6.0, thanks to their experience with its specific quirks.

Conclusion: Reclaiming Your 6.0 Powerstroke’s Performance

Dealing with 6.0 Powerstroke hard acceleration issues can be incredibly frustrating, but as we’ve explored, many of these problems have identifiable root causes and effective solutions. From ensuring your fuel system delivers adequate pressure to maintaining a healthy turbocharger and monitoring critical sensors, a methodical approach to diagnosis is key.

Remember, the 6.0 Powerstroke is a powerful, yet sensitive, machine. Regular maintenance, including timely oil and filter changes, is your first line of defense against many of these issues. When problems do arise, arm yourself with a good diagnostic scanner, patience, and this guide. Whether you choose to tackle the repairs yourself or seek professional assistance, understanding the potential culprits behind your 6.0 Powerstroke hard acceleration issues will empower you to make informed decisions and get your truck back to delivering the smooth, robust power it was designed for.

Don’t let a sluggish pedal keep you from enjoying your truck. With the right troubleshooting and repair steps, your 6.0 Powerstroke can accelerate confidently once again, ready for whatever the road—or the job site—throws its way.

🎥 Related Video: Ford 6.0 Powerstroke lacks power. (low boost)

📺 DieselTechRon

I had one here that is actually pretty common. When the boost or manifold absolute pressure (MAP) sensor is not responding …

Frequently Asked Questions

What are the most common causes of 6.0 Powerstroke hard acceleration issues?

Hard acceleration problems in a 6.0 Powerstroke are often linked to issues with the Fuel Injection Control Module (FICM), a faulty Variable Geometry Turbocharger (VGT), or a failing High-Pressure Oil Pump (HPOP). Other culprits can include clogged EGR valves, defective injectors, or problems with the Integrated Pressure Control (ICP) sensor.

Is it safe to drive my 6.0 Powerstroke if it’s experiencing hard acceleration?

Generally, it is not recommended to continue driving your 6.0 Powerstroke with hard acceleration issues, as it indicates a significant underlying problem. Continued operation could lead to further engine damage or potentially create an unsafe driving condition due to unpredictable power delivery or sudden loss of power.

What’s the first diagnostic step I should take for hard acceleration problems on my 6.0 Powerstroke?

The initial and most crucial step is to connect a diagnostic scan tool to check for any stored Diagnostic Trouble Codes (DTCs). Additionally, monitoring live data parameters such as FICM voltage, ICP pressure, IPR (Injector Pressure Regulator) duty cycle, and EGR valve position can provide invaluable insights into the root cause of the hard acceleration.

Can a faulty FICM directly cause hard acceleration issues in a 6.0 Powerstroke?

Yes, absolutely. The FICM (Fuel Injection Control Module) is critical for delivering proper voltage to the injectors, and if it’s failing or providing insufficient voltage (especially below 48V), the injectors won’t fire correctly. This can directly result in poor engine performance, including sluggish or hard acceleration, misfires, and rough idling.

What are some other symptoms that often accompany 6.0 Powerstroke hard acceleration issues?

Besides hard acceleration, you might experience excessive black or white smoke from the exhaust, rough idling, a noticeable decrease in fuel economy, or a check engine light illumination. These symptoms frequently point to common issues like failing injectors, a stuck VGT turbo, or problems within the EGR system contributing to the acceleration struggles.

What preventative maintenance can help avoid 6.0 Powerstroke hard acceleration issues?

Regular maintenance is key; ensure you perform timely oil and filter changes using the correct specification fluids, and routinely check your cooling system. Inspecting the EGR valve for carbon buildup and monitoring your turbocharger’s VGT operation can also help prevent common causes of hard acceleration problems.