Mastering the Technique: How to Align Your Transfer Case Motor with Ease

Have you ever experienced issues with your four-wheel drive system? One of the most common culprits is a misaligned transfer case motor. This small component plays a crucial role in shifting power between your vehicle’s axles, but it can easily become misaligned – resulting in a variety of problems. Fortunately, realigning your transfer case motor is a relatively straightforward process that you can easily do yourself with the right tools and know-how.

In this step-by-step guide, we’ll walk you through the process of aligning your transfer case motor so you can get back to enjoying your off-road adventures without any more fuss. So, grab your tools and let’s get started!

Understanding the Role of Transfer Case Motor

If you’re wondering how to align transfer case motor, it’s important to first understand its role in your vehicle. The transfer case motor is responsible for controlling the position of the transfer case, which is what distributes power to each individual wheel. This is an essential component of four-wheel drive vehicles, as it allows for better control in off-road situations and rough terrain.

The transfer case motor itself is typically controlled by the vehicle’s computer, which receives input from various sensors in the vehicle. If the transfer case motor is not properly aligned, it can cause issues with the distribution of power to the wheels, which can negatively affect the vehicle’s performance. Luckily, aligning the transfer case motor is a relatively simple process that can be done with the right tools and a bit of patience.

By following the correct steps, you can ensure that your vehicle is operating at its best and that you’re getting the most out of its four-wheel drive capabilities.

What is a Transfer Case Motor?

A transfer case motor is an essential component of a four-wheel drive vehicle that controls the transfer case’s shifting mechanism. It’s usually located on the transfer case’s exterior and is responsible for transferring torque from the transmission to the front and rear axles. The motor is responsible for engaging the four-wheel drive system and disengaging it when not needed, depending on the driving conditions.

When the transfer case motor fails, your vehicle’s four-wheel drive system may not engage, which can cause problems when driving in wet, icy, or slick conditions. To ensure your transfer case motor stays in good working order, it’s important to have it inspected and replaced regularly by a qualified mechanic. By doing so, you can maintain your vehicle’s performance, safety, and reliability on the road.

Why Alignment is Important?

Alignment is a crucial aspect of maintaining the proper functioning of a vehicle. In this regard, one of the most critical components is the transfer case motor. Essentially, the transfer case motor is responsible for transferring power from the engine to the drive train in a four-wheel-drive vehicle.

Without it, the vehicle would not be able to move, and this can cause damage to the entire system. Suppose there is a misalignment in the transfer case motor. In that case, it can cause the vehicle to lose power or even result in the drive train locking up.

Consequently, it is essential to ensure that the transfer case motor is aligned correctly. This involves a thorough inspection of the motor, including the gears and shafts. If misalignment is identified, the system must be re-aligned to ensure that it functions optimally.

Ultimately, proper alignment of the transfer case motor is crucial to the smooth operation of the four-wheel-drive system and the vehicle as a whole.

Determining the Need for Alignment

If you’re experiencing issues with your transfer case motor, the first step is determining whether it’s out of alignment. Signs of misalignment could include grinding or whirring sounds when shifting gears or a noticeable lack of power in your vehicle. To align the transfer case motor, start by checking the torque on all of the bolts and hardware associated with the motor.

If that doesn’t solve the problem, you may need to take the motor out and check the alignment of the driveshaft. Keep in mind that this process can be tricky and may require specialized tools or professional assistance. Ultimately, making sure your transfer case motor is properly aligned is crucial for keeping your vehicle running smoothly and avoiding costly repairs down the line.

So, whether you’re a seasoned mechanic or a novice DIY-er, it’s always a good idea to prioritize proper alignment when working on your transfer case motor.

Common Signs of Misaligned Transfer Case Motor

If you notice strange noises or vibrations while driving, it could be a sign of a misaligned transfer case motor that needs attention. Additionally, difficulty shifting gear or a warning light on the dashboard are other indicators that something is amiss. To determine if you need to align your transfer case motor, it’s important to consult with a professional mechanic who can run a full diagnostic and inspection.

They will be able to identify any issues with the transfer case motor and recommend the best course of action for repair. Ignoring the problem can lead to further damage and costly repairs down the line, so it’s always best to address any issues as soon as possible. Don’t hesitate to seek help if you suspect your transfer case motor is not aligned properly.

Inspection Steps to Detect Misalignment

When considering the need for alignment, there are a few key steps that can help detect misalignment in machinery. First, it’s important to conduct a visual inspection of the machinery, looking for any signs of wear or damage. This can include things like cracks or missing pieces, which can indicate misalignment.

Then, a vibration analysis can be conducted to detect any abnormal vibrations. This can be done using a handheld analyzer or through computer software. Additionally, a laser alignment tool can be used to identify any misalignment issues with precision.

By conducting these inspections, businesses can determine if misalignment is present and take the necessary steps to correct it to avoid larger problems down the line. Misalignment can cause increased wear and tear on machinery and result in costly repairs, so it’s important to address any issues as soon as possible.

Aligning Transfer Case Motor: Step-by-Step Process

If you’re wondering how to align your transfer case motor properly, we’ve got you covered! Aligning the transfer case motor isn’t as complicated as it sounds, but it does require a bit of patience and attention to detail. The first step involves removing the transfer case from the transmission and ensuring the motor’s alignment grooves are visible. Once you locate the grooves, you’ll need to align them with the transfer case’s mating grooves, ensuring the motor is level with the transfer case and working smoothly.

It’s important to take your time with this process and double-check your alignment before reassembling everything. With a little bit of practice, aligning your transfer case motor will become second nature.

Preparing the Vehicle for Alignment

When it comes to preparing your vehicle for an alignment, there are a few crucial steps you need to follow. One of these steps is aligning the transfer case motor. This process is essential to ensure that your vehicle’s power is distributed correctly to all four wheels.

To start, you’ll need to locate the transfer case motor, which is typically found under the vehicle. Once you’ve located it, remove the bolts and allow the motor to move freely. Next, attach the alignment tool to the transfer case motor and move it until it’s aligned correctly.

To ensure that the motor stays in place, re-tighten the bolts. Finally, test your vehicle on the road to make sure that everything is working correctly. By following these straightforward steps, you’ll be able to align your transfer case motor and prepare your vehicle for a successful alignment.

Removing the Transfer Case Motor

If you need to remove the transfer case motor from your vehicle, it’s essential to know how to properly align it when re-installing it. Here’s a step-by-step process to make sure your transfer case motor is aligned correctly: Start by removing any bolts or connectors that attach the motor to the transfer case.

Take the motor out carefully and inspect it for any damage or wear to the teeth or gears.

With the transfer case still in place, align the motor splines with the transfer case input. Carefully slide the motor back into place and reattach any bolts or connectors that were removed.

Double-check the alignment of the motor and transfer case by visually inspecting the connection. By taking the time to properly align the transfer case motor, you can ensure that it functions correctly and doesn’t cause any issues down the line.

So, if you’re removing or replacing your transfer case motor, make sure to follow these steps to guarantee a smooth installation process.

Positioning the Motor for Alignment

When aligning the transfer case motor, the first step is to position it correctly. The motor should be placed in such a way that it is easily accessible for alignment and installation. One effective way to do this is by attaching the motor to a floor jack and raising it to the proper height.

This provides ample room to work on the motor and ensures that it is at the ideal angle for proper alignment. It’s important to ensure that the motor is level at all times, as even a slight tilt can throw off the alignment. Once the motor is in position, it’s time to focus on aligning it properly.

With the right tools and careful attention, the motor can be aligned perfectly to ensure that it operates smoothly and effectively. By following these simple steps, you can ensure that your transfer case motor is ready for optimal performance and longevity. So, are you ready to get started on the alignment process?

Aligning the Motor by Adjusting the Mounting Bolts

When it comes to aligning the transfer case motor in your vehicle, adjusting the mounting bolts is a critical step in the process. It is essential to make sure that the motor is correctly aligned to avoid any further damage and ensure proper functioning. The first step is to locate the mounting bolts that hold the motor in place.

Once you have located them, check to see if any of them are loose or damaged. Tighten any loose bolts, and if any are damaged, replace them immediately. Next, use a floor jack or an adjustable wrench to adjust the position of the motor until it is aligned correctly.

It is essential to check the motor’s alignment using a laser alignment tool to ensure that it is perfectly aligned. Once the motor is correctly aligned, tighten all the mounting bolts and test the transfer case’s functionality. By aligning the transfer case motor, you can ensure that your vehicle runs smoothly and efficiently without any complications.

With proper alignment, you can drive confidently knowing that your vehicle is in top shape.

Reinstalling the Motor and Testing its Alignment

When it comes to reinstalling the transfer case motor and testing its alignment, there are a few key steps you’ll need to follow to ensure everything is working as it should. First, you’ll need to set the motor in place and secure it using bolts or screws. Next, you’ll need to attach any wiring or electrical connections to the motor, ensuring that everything is properly grounded and secured.

Once everything is in place, it’s time to test the motor’s alignment by running it through a series of tests and checks. This might include checking for any unusual sounds or vibrations, testing the motor’s torque and power output, and checking to ensure that the transfer case is shifting smoothly and accurately. In essence, aligning the transfer case motor is all about ensuring that everything is in sync and working together properly, so taking the time to carefully test and check everything along the way is key to achieving success.

Preventing Future Misalignments

If you’re wondering how to align your transfer case motor, there are a few things you can do to prevent misalignments in the future. First, make sure you’re using the correct size socket or wrench when tightening the bolts on your transfer case motor. Tightening them too much or using the wrong size can cause misalignments.

Additionally, be sure to inspect your transfer case and motor mounts regularly to ensure they’re in good condition and aren’t contributing to the misalignment. Finally, when installing a new transfer case motor, be sure to follow the manufacturer’s instructions carefully to avoid any potential misalignments. By taking these precautions, you can prevent future misalignments and ensure your transfer case motor is functioning properly.

Regular Maintenance and Inspection Tips

Regular maintenance and inspection of your machinery are crucial to keep them in top working condition. If you ignore your equipment’s routine maintenance, it could lead to sudden breakdowns and costly repairs, not to mention increased downtime. One of the most common issues is misalignment.

Misalignment can cause a host of problems, including vibration, overheating, reduced output, and increased wear and tear on your equipment. Regular inspection and maintenance can help prevent misalignment from occurring. It’s essential to inspect and record alignment data on your equipment regularly.

By doing this, you can identify trends indicating a need for further action. If you notice any anomalies in alignment data, it’s critical to take prompt action to correct the problem. Misalignment is like a domino effect, causing other issues that can ultimately lead to your equipment’s premature failure, resulting in unplanned downtime and costly repairs.

Remember, even a minor misalignment can severely impact your equipment’s lifespan and performance. So, make sure you follow a regular maintenance program and inspect your machinery regularly to keep them working seamlessly.

Common Causes of Misalignment and How to Avoid Them

Preventing misalignments is crucial to avoid costly repairs and downtime. One of the most common causes of misalignment is improper installation. During the installation process, it’s essential to ensure that all components are installed correctly, and the equipment is leveled correctly.

Improper alignment can also be caused by poor maintenance practices. Regular inspections and maintenance of the equipment can prevent misalignment issues from occurring. Another factor that can contribute to misalignment is environmental conditions.

Extreme temperatures, humidity, and vibration can cause machines to shift, resulting in misalignment. Implementing measures to control the environment can help reduce the risk of misalignment. Lastly, using high-quality couplings can also help prevent misalignment.

Couplings made from low-quality materials can wear out quickly and cause misalignment. Investing in good quality couplings can save time and money in the long run. By taking preventative measures, businesses can avoid misalignment issues and keep their operations running smoothly.

Conclusion

In conclusion, aligning your transfer case motor is quite simple if you follow the right steps. It’s the equivalent of playing a game of connect the dots, except instead of dots, you’re matching arrows, and instead of a beautiful masterpiece, you get a functioning four-wheel-drive system. So grab your tools and get to work, and impress your friends with your newfound alignment skills.

Who knows, maybe your next career move is to become a human GPS!”

FAQs

What is a transfer case motor and what does it do?

A transfer case motor is a component of the transfer case that engages and disengages the four-wheel-drive system. It helps to transfer power from the transmission to the front and rear axles.

What are the signs of a failing transfer case motor?

The signs of a failing transfer case motor include difficulty shifting into four-wheel drive, strange noises coming from the transfer case, and the four-wheel drive system not engaging.

How can I diagnose a problem with the transfer case motor?

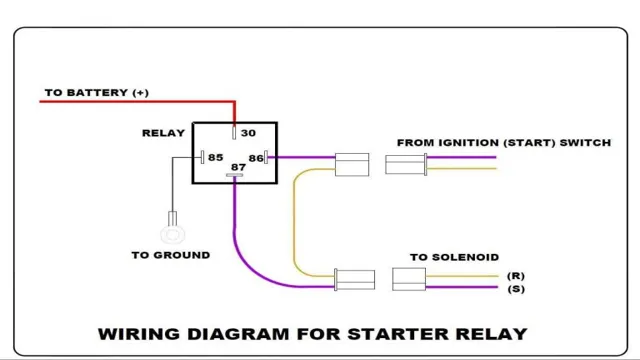

To diagnose a problem with the transfer case motor, you can check the fuse, inspect the wiring, and test the motor itself with a multimeter.

How do I align a transfer case motor?

To align a transfer case motor, you will need to loosen the mounting bolts, then adjust the position of the motor until it is lined up with the transfer case. Once aligned, tighten the mounting bolts securely.