Effortless Guide: Aligning Torque Converter to Flywheel for a Perfect Fit

Have you ever wondered how a vehicle’s torque converter and flywheel come together to ensure smooth transmission and power transfer? Aligning the torque converter to the flywheel is a crucial step in this process, and it’s essential to do it right to prevent damage to your engine and transmission. In this step-by-step guide, we’ll discuss how to align your torque converter to your flywheel and ensure your vehicle runs smoothly. So get ready to dive into the world of transmissions and learn how to align your torque converter like a pro!

Understanding the Basics

If you’re wondering how to align a torque converter to a flywheel, there are a few things you need to keep in mind. First off, it’s important to ensure that the torque converter is fully seated on the transmission input shaft before you try to align it with the flywheel. Once you’ve done that, you can begin to rotate the torque converter until it aligns with the flywheel.

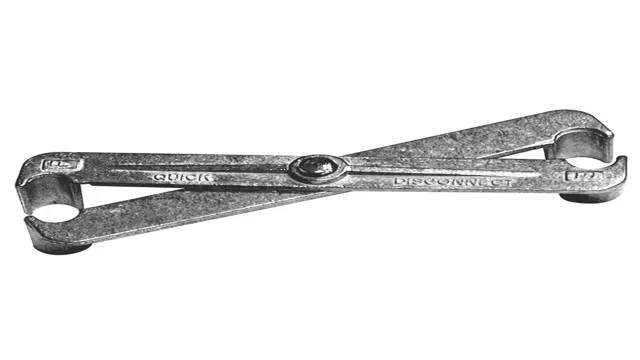

This can be a bit tricky, as you’ll need to make sure that the starter bolt holes on the flywheel line up with the torque converter mounting bolts. To help make this process a bit easier, you can use a special alignment tool that’s designed specifically for this purpose. This tool will allow you to easily rotate the torque converter and ensure that it’s properly aligned with the flywheel.

Once you’ve got everything lined up, you can tighten the torque converter mounting bolts and starter bolts to the manufacturer’s specifications, and your job is done!

What is a Torque Converter?

A torque converter is an essential component in the functioning of an automatic transmission. As the engine rotates, it generates torque, which is transferred to the wheels through the transmission. However, when the vehicle is stationary, such as when starting or idling, the engine’s rotational force is not enough for the wheels to move.

This is where the torque converter comes in. It acts as a fluid coupling between the engine and the transmission, multiplying the rotational force of the engine to the wheels. Think of it as a bicycle’s gear system.

Just like how changing gears makes it easier to ride uphill, the torque converter multiplies the engine’s torque to overcome the resistance of a stationary vehicle and efficiently transfer power to the wheels. So, the next time you drive an automatic car, remember the essential role played by the torque converter in providing smooth acceleration and power delivery while on the road.

What is a Flywheel?

In the world of engineering, a flywheel is a rotating machine part that is designed to store energy in order to aid with smooth and consistent rotary motion. It works by accumulating energy during the period when there is excess power, and then distributing this energy when there is a dip in power. Whether you’re looking at a car engine, a mechanical watch, or an electricity supply system, flywheels are an essential part of ensuring that things run smoothly.

A flywheel can be described as a “spinning battery”, collecting and storing energy then releasing it when needed. The momentum created by the flywheel helps to keep the associated machine or system turning even when the power supply isn’t perfectly consistent. Its ability to smooth out any bumps in the road of power supply makes it one of the most important machine parts available for use today.

Tools You Will Need

When aligning a torque converter to a flywheel, there are a few essential tools you’ll need to get the job done correctly. Firstly, you’ll need a torque wrench to tighten the bolts and ensure that they are tightened to the correct torque setting. Additionally, you’ll need a pry bar to move the torque converter and align it properly.

A flashlight or other light source can also be helpful to see what you’re working on, especially if the area is dark or hard to access. Finally, it’s always a good idea to have a manual handy that outlines the specific torque specifications for your make and model of vehicle. With these tools in hand, you’ll be able to properly align your torque converter to your flywheel, ensuring a smooth and efficient ride.

Torque Wrench

When it comes to DIY projects or professional repairs, having the right tools can make all the difference. One essential tool to have in your toolbox is a torque wrench. This tool is used to tighten bolts or nuts to a specific torque value, which is essential for ensuring that everything is secure and properly seated.

When choosing a torque wrench, you’ll want to consider the type of project you’ll be working on, the required torque value, and the size and design of the wrench itself. Other tools you may need to go along with your torque wrench include sockets, extensions, and adapters to ensure that you have the right size and fit for the job. It’s always a good idea to invest in high-quality tools that will last a long time and provide accurate results every time you use them.

So why not add a torque wrench to your collection of tools and take your repairs and DIY projects to the next level?

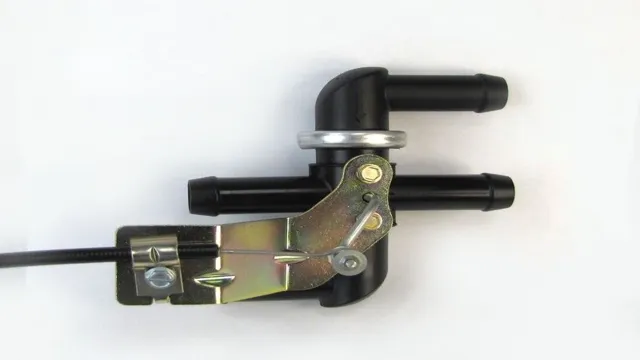

Alignment Tool or Transmission Input Shaft

If you’re planning on changing your transmission or clutch, you will need an alignment tool or a transmission input shaft. These tools will help you align the clutch disc with the pressure plate and the flywheel. Without proper alignment, your clutch won’t function correctly, and you could seriously damage your transmission.

Luckily, these tools are affordable, and they’re easy to use. Just make sure to follow the manufacturer’s instructions carefully, and take your time during the process. Remember, rushing through this job could cost you in the long run.

So, take the time to do it right, and you’ll have a smoother running car in no time.

Socket Set

If you want to tackle some DIY projects at home or even become a professional handyman, you will need to have an essential tool in your arsenal: a socket set. A socket set is a set of tools that includes a ratcheting wrench and different sizes of sockets that you can attach to it. Sockets come in various shapes and sizes to fit different types of bolts and nuts.

When buying a socket set, consider getting one that has both metric and standard sizes to cover a wide range of projects. Additionally, choose a set that is made of high-quality materials and comes in a sturdy case for easy storage. With a socket set, you can undo and tighten bolts and nuts in no time, making your DIY projects faster and easier.

So, invest in a high-quality socket set, and you will be ready to handle any project that comes your way.

Step-by-Step Guide

Aligning the torque converter to the flywheel is an important task that needs to be performed correctly in order to prevent any damage to your transmission. Here’s a step-by-step guide to help you get the job done. First, remove the transmission from your vehicle and place it on a workbench.

Next, install the torque converter onto the transmission input shaft and rotate it slowly until it is fully seated. Align the bolt holes on the torque converter to the flywheel and insert the bolts. Tighten them in a criss-cross pattern to ensure even torque distribution.

Finally, re-install the transmission and test drive your vehicle to ensure that everything is working correctly. By following these steps closely, you’ll be able to align your torque converter to your flywheel with ease and keep your transmission running smoothly.

Step 1 – Accessing the Torque Converter and Flywheel

To access the torque converter and flywheel in your vehicle, there are a few steps you need to follow. Firstly, you need to ensure that the engine is turned off and the car is on a flat surface. Once you have done this, you can begin by removing the transmission from the engine.

This may require some tools, such as a wrench, socket, or ratchet. Once you have loosened the bolts, you should be able to access the torque converter and flywheel. It’s worth noting that the torque converter is located inside the transmission, while the flywheel is attached to the engine.

When you have located these components, you can begin inspecting them for any signs of damage or wear and tear. If you notice any issues, it may be necessary to repair or replace them. It’s important to take your time and be careful when working on these components, as they are integral to the operation of your vehicle.

By following these steps and taking the necessary precautions, you can access the torque converter and flywheel with ease.

Step 2 – Aligning the Torque Converter

When it comes to aligning a torque converter, there are a few key steps to follow in order to ensure a successful installation. The second step in the process is to align the torque converter itself. This involves making sure that the converter is properly aligned with the flexplate, which is the disc that connects the engine to the transmission.

To begin this step, you’ll first want to make sure that the transmission is properly mounted in place. Next, you’ll want to carefully install the torque converter into the transmission, making sure that it slides in smoothly and easily. Once the converter is in place, you’ll want to align it with the flexplate by rotating the converter until the bolt holes line up with the holes in the flexplate.

This can be a bit tricky, but it’s important to take your time and make sure everything lines up just right. Once you’ve got everything aligned, you can go ahead and tighten up the nuts and bolts to secure the converter in place. With a little patience and attention to detail, you can align your torque converter like a pro!

Step 3 – Tightening the Bolts

When it comes to tightening the bolts, it’s essential to follow the manufacturer’s instructions for your specific equipment. This step may seem simple, but it’s crucial to ensuring that your equipment operates efficiently and safely. Start by finding the correct torque specifications for your bolts and ensure you have the correct tools to carry out this task.

The right torque settings help to ensure that the bolts are neither too tight nor too loose. If the bolts are too loose, then your equipment will be unstable, and if they are over-tightened, the threads may cross. Use a torque wrench to tighten each bolt gradually, ensuring they are tightened in the correct sequence.

Repeat the process until each bolt is correctly secured in place. Remember to periodically check the tightness of your bolts, as these can shift over time due to vibration and other factors. Taking these simple steps can help to prolong your equipment’s lifespan and keep it operating safely and efficiently.

Tips for Success

Aligning the torque converter to the flywheel is a crucial step in properly installing an automatic transmission. To begin, make sure the torque converter is properly seated on the input shaft. Then, insert two bolts into the converter and hand-tighten them.

Rotate the converter while gently pushing it towards the transmission until it aligns with the flywheel’s bolt holes. Insert and hand-tighten the remaining bolts in a star pattern to ensure even tightening. It’s important to note that forcing the converter into place can cause damage to the transmission pump or the converter itself.

In addition, not properly aligning the two components can result in transmission damage or a loss of power. Taking your time to align the torque converter to the flywheel correctly will save you costly repairs in the long run.

Check the Torque Converter and Flywheel for Damage

When inspecting your vehicle’s torque converter and flywheel, it’s important to keep a few things in mind to ensure success. Firstly, check for any signs of damage, such as cracks or excessively worn areas. Be sure to examine the torque converter thoroughly, including the stator and turbine, to ensure that they’re in good working condition.

Secondly, pay attention to the quality of the flywheel’s surface. Check for any warping or hot spots that could indicate that the flywheel needs to be resurfaced or replaced. Additionally, make sure that the flywheel’s teeth are in good condition and aren’t excessively worn or damaged.

By taking these steps, you can ensure that your torque converter and flywheel are in good condition and that your vehicle is running smoothly. Don’t let small problems go unaddressed, as they can quickly become larger and more expensive issues down the road. Remember to schedule regular maintenance to keep your vehicle operating at peak performance.

Follow the Manufacturer’s Specifications

When it comes to ensuring success in any project, following the manufacturer’s specifications is paramount. Whether you’re working with machinery, electronics or any other equipment, the manufacturer knows their product best and provides guidance on how to use it safely and effectively. Skipping over the specifications and instructions can result in damage to the equipment, injury to yourself, or even worse- accidents that put others’ lives in danger.

You don’t want to be that person who thought they knew better and ended up creating a hazardous situation. So, make it a habit to always read and follow the manufacturer’s specifications before using any equipment. Not only will it help you avoid mishaps, but it may also improve your overall productivity and efficiency.

Remember, the specifications are there for a reason – to guide you towards success.

Conclusion

In conclusion, aligning a torque converter to a flywheel may seem like a daunting task, but with the right tools and a little bit of patience, it can be done in a snap. Just remember to take your time, go slowly and methodically, and give yourself plenty of space to work. And for best results, enlist the help of an experienced mechanic or a friendly neighborhood robot assistant.

Together, you’ll have that torque converter spinning like a top in no time!”

FAQs

What is a torque converter, and how does it work?

A torque converter is a device used in automatic transmissions that transfers power from the engine to the transmission. It uses hydraulic fluid to transmit power and allows the engine to continue running even when the vehicle is stopped or idling. The torque converter works by controlling the flow of fluid between two impeller-like components, known as the pump and the turbine.

Why is it necessary to align a torque converter to the flywheel?

When installing a torque converter, it is essential to align it correctly with the flywheel. Misalignment can cause severe damage, such as cracked flex plates, damaged torque converters, and starter bending or breaking. Proper alignment ensures that the torque converter and flywheel spin in unison, allowing for smooth power transfer.

How do I know if my torque converter is misaligned?

Signs of misalignment include vibration, noise, and difficulty shifting or starting the vehicle. The engine may also stall or hesitate when coming to a stop. If you suspect misalignment, it is best to have a professional mechanic inspect the torque converter and flywheel.

Can I align the torque converter myself, or do I need to take it to a mechanic?

Aligning the torque converter requires specific tools and knowledge, so it is best to leave it to a professional mechanic. Attempting to align the torque converter yourself can result in costly damage to the transmission and other components. Don’t take any chances- take your vehicle to a trusted mechanic for proper alignment.