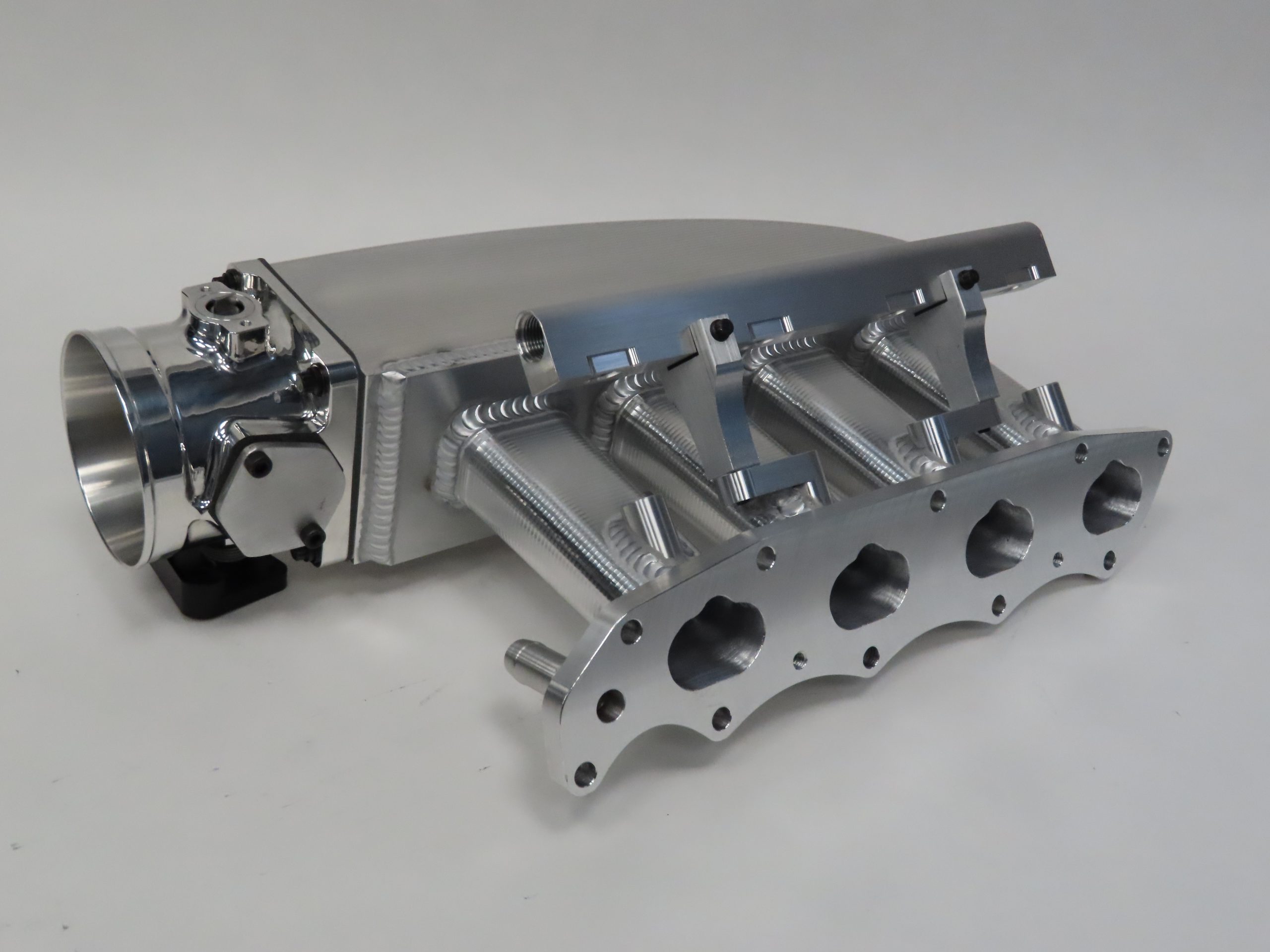

Homemade Intake Manifold : Boost Performance with DIY Fabrication

Are you a car enthusiast looking to improve the performance of your vehicle? One of the most effective ways to enhance engine power and efficiency is by installing a custom intake manifold. An intake manifold is a crucial component of the engine that distributes air and fuel to the cylinders. While there are plenty of aftermarket intake manifolds available in the market, building a homemade intake manifold can be a rewarding and cost-effective alternative for those with the technical skills and DIY spirit.

Benefits of a Homemade Intake Manifold

There are several benefits to building a homemade intake manifold:

- Customization: A homemade intake manifold allows you to tailor the design to fit your specific engine and performance goals.

- Cost-Effective: By building your own intake manifold, you can save money compared to purchasing a pre-built one.

- Performance Gains: A well-designed homemade intake manifold can improve airflow and fuel distribution, leading to increased horsepower and torque.

- Satisfaction: Building a custom intake manifold can be a fulfilling project for DIY enthusiasts and tinkerers.

Understanding Intake Manifold Basics

Before diving into the process of building a homemade intake manifold, it’s essential to understand the basic principles behind its operation. The intake manifold is responsible for delivering air and fuel to the engine’s cylinders. It consists of a series of tubes and chambers that distribute the air-fuel mixture to each cylinder. A well-designed intake manifold maximizes airflow and ensures an even distribution of the air-fuel mixture for optimal combustion.

Building Your Homemade Intake Manifold

Here’s a step-by-step guide to building your own homemade intake manifold:

Step 1: Research And Planning

Before you start building your intake manifold, research different designs and intake manifold configurations. Consider factors such as runner length, plenum volume, and inlet shape to determine the best design for your engine and performance objectives.

Step 2: Gather Materials And Tools

Once you have a design in mind, gather the necessary materials and tools for the construction process. This may include aluminum or steel tubing, flanges, gaskets, a welder, and assorted hand tools.

Step 3: Fabrication

Using your chosen design as a guide, begin fabricating the intake manifold components. This may involve cutting and shaping the tubing, welding the pieces together, and creating mounting points for sensors and injectors.

Step 4: Test Fitment And Fine-tuning

Once the intake manifold is assembled, test-fit it onto the engine to ensure proper fitment and clearance. Make any necessary adjustments to optimize the fit and alignment with the engine’s intake ports.

Step 5: Installation And Tuning

Install the homemade intake manifold onto your engine and make any final adjustments as needed. Once installed, tune the engine to optimize performance and ensure proper air-fuel ratios.

Considerations for Homemade Intake Manifold Construction

When building a homemade intake manifold, there are several important considerations to keep in mind:

- Metal Selection: Choose a material, such as aluminum or steel, that is suitable for intake manifold construction and can withstand the heat and pressure within the engine bay.

- Thermal Insulation: Consider incorporating thermal insulation or ceramic coatings to minimize heat transfer and reduce the risk of heat soak in the intake manifold.

- Flow Bench Testing: If possible, perform flow bench testing to evaluate the airflow characteristics and efficiency of your homemade intake manifold design.

- Professional Assistance: If you’re new to fabrication or unsure about certain design aspects, consider consulting with a professional or experienced fabricator for guidance.

Credit: www.hogansracingmanifolds.com

Frequently Asked Questions For Homemade Intake Manifold : Boost Performance With Diy Fabrication

What Are The Benefits Of A Homemade Intake Manifold?

Crafting your own intake manifold allows for customization, potentially improving airflow and performance.

How Can I Make A Homemade Intake Manifold?

You can create a homemade intake manifold by shaping and welding metal, following design principles.

What Materials Are Suitable For A Diy Intake Manifold?

Aluminum or steel are commonly used materials for creating a homemade intake manifold.

Is It Legal To Use A Homemade Intake Manifold On My Vehicle?

It’s crucial to check local regulations and emission laws before installing a homemade intake manifold.

Conclusion

Building a homemade intake manifold can be a challenging yet rewarding project for automotive enthusiasts seeking to enhance their vehicle’s performance. By understanding the basics of intake manifold operation and following a methodical fabrication process, you can create a custom intake manifold that meets your specific performance goals. Whether it’s for a high-performance race car or a street-driven project vehicle, a homemade intake manifold can be a valuable addition to any engine build.

Remember to always prioritize safety and quality in the fabrication process, and don’t hesitate to seek expert advice or assistance when needed. With careful planning and craftsmanship, your homemade intake manifold can be the key to unlocking added horsepower and throttle response in your vehicle.