Fuel System Diagnostic Tools for 7.3 Powerstroke: Ensure Peak Performance

Featured image for this comprehensive guide about Fuel system diagnostic tools for 7.3 Powerstroke

Image source: kimini.online

The roar of a 7.3 Powerstroke engine isn’t just a sound; it’s a testament to a legacy of power, reliability, and sheer American engineering. For countless truck enthusiasts and working professionals, this iconic diesel engine, produced by Ford from 1994.5 to 2003, represents the pinnacle of a bygone era – an era of mechanical simplicity blended with robust performance. But even the most legendary engines demand attention, especially when it comes to their intricate fuel systems. Over time, wear and tear, coupled with the complexities of diesel fuel delivery, can lead to performance issues that leave owners scratching their heads.

Imagine your trusty 7.3 struggling to start, sputtering under load, or consuming fuel at an alarming rate. These aren’t just minor annoyances; they’re distress signals from a system critical to your engine’s very operation. Pinpointing the exact cause of a fuel system problem in a 7.3 Powerstroke can feel like finding a needle in a haystack without the right equipment. That’s where a comprehensive understanding of fuel system diagnostic tools for 7.3 Powerstroke becomes not just helpful, but absolutely essential. Equipping yourself with the right tools and knowledge is the first step towards maintaining the legendary performance and longevity your 7.3 deserves, preventing minor hiccups from escalating into costly repairs, and ensuring your beast continues to run strong for decades to come.

Quick Answers to Common Questions

What is Fuel system diagnostic tools for 7.3 Powerstroke?

Fuel system diagnostic tools for 7.3 Powerstroke refers to essential knowledge and techniques that can significantly improve your understanding and results.

Why is Fuel system diagnostic tools for 7.3 Powerstroke important?

Mastering Fuel system diagnostic tools for 7.3 Powerstroke provides practical benefits and helps you achieve better outcomes in various situations.

How does Fuel system diagnostic tools for 7.3 Powerstroke work?

Fuel system diagnostic tools for 7.3 Powerstroke involves specific methods and approaches that deliver effective results when applied correctly.

When should I use Fuel system diagnostic tools for 7.3 Powerstroke?

You can apply Fuel system diagnostic tools for 7.3 Powerstroke techniques whenever you need to improve your approach or achieve better results.

What are the benefits of Fuel system diagnostic tools for 7.3 Powerstroke?

Learning Fuel system diagnostic tools for 7.3 Powerstroke offers numerous advantages including improved efficiency, better results, and practical applications.

📋 Table of Contents

- The Heartbeat of Your Beast: Understanding the 7.3 Powerstroke Fuel System

- Common Ailments: Recognizing 7.3 Powerstroke Fuel System Issues

- Your Arsenal: Essential Fuel System Diagnostic Tools for the 7.3 Powerstroke

- Diving Deeper: Advanced Diagnostic Techniques & Powerstroke-Specific Tools

- DIY vs. Pro: When to Tackle It Yourself and When to Seek Expert Help

- Beyond the Fix: Preventative Maintenance for a Resilient 7.3 Fuel System

- Common 7.3 Powerstroke Fuel System Symptoms & Diagnostic Pathways

- Conclusion: Empowering Your 7.3 Powerstroke for Years to Come

The Heartbeat of Your Beast: Understanding the 7.3 Powerstroke Fuel System

Before diving into diagnostics, it’s crucial to grasp the fundamental workings of the 7.3 Powerstroke fuel system. Unlike modern common-rail diesels, the 7.3 utilizes an indirect injection system where fuel is delivered to the injectors by a mechanical lift pump and then pressurized by the engine’s high-pressure oil pump (HPOP) system. This unique design, while robust, also introduces specific points of potential failure that require specialized diagnostic approaches.

Learn more about Fuel system diagnostic tools for 7.3 Powerstroke – Fuel System Diagnostic Tools for 7.3 Powerstroke: Ensure Peak Performance

Image source: tbwauto.com

Key Components Explained

- Fuel Tank and Lines: The starting point, containing the diesel fuel and the lines that transport it to the engine bay.

- Electric Fuel Pump (Lift Pump): Located on the frame rail (or in-tank on some models), this pump draws fuel from the tank and sends it under low pressure (typically 40-70 PSI) to the fuel filter.

- Fuel Filter Housing: A critical component that cleans the fuel, removing contaminants before it reaches the injectors. It often includes a fuel heater and a water separator.

- Fuel Rails: These deliver the filtered, low-pressure fuel to the fuel galleries within the cylinder heads, which then feed the injectors.

- Injectors: The heart of the system. In the 7.3, these are Hydraulically Actuated Electronically Controlled Unit Injectors (HEUI). They use high-pressure engine oil to atomize and inject fuel into the combustion chambers.

- High-Pressure Oil Pump (HPOP): This pump, driven by the engine, generates the immense oil pressure (up to 3,000 PSI) needed to actuate the HEUI injectors.

- Injector Pressure Regulator (IPR) Valve: Controls the output pressure of the HPOP by bleeding off excess oil pressure, thereby regulating the oil pressure available to the injectors.

- Injector Control Pressure (ICP) Sensor: Monitors the actual oil pressure in the high-pressure oil system and sends this feedback to the Powertrain Control Module (PCM).

Understanding the interplay between these components is paramount. For instance, an issue with the HPOP or IPR valve, while technically part of the *oil* system, directly impacts fuel delivery, making comprehensive **fuel system diagnostic tools for 7.3 Powerstroke** essential for accurate troubleshooting.

Common Ailments: Recognizing 7.3 Powerstroke Fuel System Issues

Even the most meticulously maintained 7.3 Powerstroke can develop fuel system issues over time. Recognizing the symptoms early can save you from more extensive damage and keep your diagnostic process focused. Many problems, if caught early, can be resolved with the right **fuel system diagnostic tools for 7.3 Powerstroke** and a bit of elbow grease.

Learn more about Fuel system diagnostic tools for 7.3 Powerstroke – Fuel System Diagnostic Tools for 7.3 Powerstroke: Ensure Peak Performance

Image source: bluesky-cogcms-prodb.cdn.imgeng.in

Symptoms to Watch For

- Hard Starting / No Start: One of the most common indicators, especially after sitting for a while or during cold weather.

- Rough Idle / Stalling: The engine struggles to maintain a steady RPM, or frequently dies.

- Loss of Power / Hesitation: Your truck doesn’t accelerate as it should, or feels sluggish under load.

- Excessive Smoke (White, Blue, or Black): The color of the smoke can offer clues about combustion issues related to fuel.

- Poor Fuel Economy: A noticeable drop in miles per gallon without changes in driving habits.

- Engine Misfires: A cylinder isn’t firing correctly, often causing a noticeable shake.

- Fuel Leaks: Visible fuel dripping or puddles, often accompanied by a strong diesel smell.

- Check Engine Light (CEL): While generic, it often points to sensor readings that are out of spec.

Typical Culprits

Many common issues can be traced back to a few key areas:

- Weak or Failing Lift Pump: Insufficient low-pressure fuel delivery to the filter housing.

- Clogged Fuel Filter: Restricts fuel flow, starving the injectors. This is a very common cause of performance issues.

- Air Intrusion in Fuel Lines: Air bubbles disrupt fuel flow and make starting difficult.

- Faulty Injectors: Worn o-rings, electrical problems (UVC harness), or internal failures can cause misfires and poor performance.

- Failing IPR Valve or ICP Sensor: These directly affect the high-pressure oil system, which in turn controls injector firing. Issues here often lead to no-start or rough running conditions.

- Compromised HPOP: While less common, a failing HPOP won’t generate enough pressure for the injectors.

- Poor Fuel Quality / Contamination: Water or debris in the fuel can damage components and clog filters.

Identifying these symptoms and potential causes is the first, crucial step in using your **fuel system diagnostic tools for 7.3 Powerstroke** effectively.

Your Arsenal: Essential Fuel System Diagnostic Tools for the 7.3 Powerstroke

When your 7.3 Powerstroke isn’t running right, having the right **fuel system diagnostic tools for 7.3 Powerstroke** can make all the difference. These tools range from simple, inexpensive items to more sophisticated electronic devices, each playing a vital role in pinpointing fuel system anomalies.

1. Basic Inspection Tools

Sometimes, the solution is right in front of you. Don’t underestimate the power of visual inspection.

- Flashlight: Essential for peering into dark engine bays to check for leaks, loose connections, or damaged hoses.

- Inspection Mirror: Helps view hard-to-reach areas, especially around the back of the engine or under the truck.

- Rags/Paper Towels: For wiping away grime to spot leaks or cleaning up spilled fuel.

- Safety Glasses and Gloves: Always prioritize safety when working with fuel and moving parts.

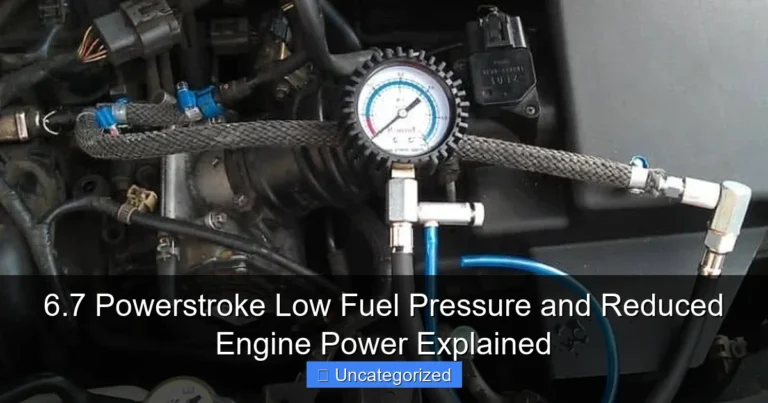

2. Fuel Pressure Gauge

This is arguably one of the most fundamental **fuel system diagnostic tools for 7.3 Powerstroke**. The low-pressure fuel system must maintain adequate pressure for the injectors to function correctly.

- Purpose: Measures the pressure of the fuel being delivered by the lift pump to the filter housing and beyond.

- How to Use: A gauge with a compatible fitting (often a Schrader valve or a direct connection into a test port) is connected to the fuel system, typically at the fuel filter housing or an aftermarket gauge port.

- What to Look For: The 7.3 Powerstroke typically requires 40-70 PSI of fuel pressure at idle. Anything below 40 PSI can indicate a weak lift pump, a clogged filter, or an air leak. Fluctuating readings can point to a failing pump or air in the system.

3. Scan Tool / OBD-II Reader with Powerstroke-Specific Capabilities

For modern vehicles, and even for the “older” 7.3, a good scan tool is indispensable. Generic OBD-II readers can read basic codes, but you’ll need one capable of communicating with Ford’s proprietary PCM data for real insights.

- Purpose: Reads diagnostic trouble codes (DTCs), monitors live sensor data (ICP, IPR, fuel pressure if equipped with an aftermarket sensor), and performs bidirectional tests (like the Injector Buzz Test or Contribution Test).

- Key Data PIDs to Monitor:

- ICP (Injector Control Pressure): Monitors the pressure of the high-pressure oil system. Should rise quickly during cranking and maintain pressure while running.

- IPR (Injector Pressure Regulator) Duty Cycle: Shows how hard the IPR valve is working to maintain ICP. A high duty cycle (e.g., above 50% at idle) can indicate an HPOP or IPR issue.

- FRP (Fuel Rail Pressure – if aftermarket sensor): While the 7.3 doesn’t have an OEM fuel rail pressure sensor, some aftermarket systems install one, providing critical low-pressure fuel data.

- RPM, Engine Load, MAF/MAP: Provides context for how the engine is operating when fuel issues occur.

- Powerstroke-Specific Tests:

- Injector Buzz Test: Electrically tests each injector’s solenoid, producing an audible “buzz.” It can identify open or shorted injector circuits or faulty injector solenoids.

- Cylinder Contribution Test: Measures the contribution of each cylinder to the overall engine power, helping pinpoint weak or non-contributing cylinders due to fuel, compression, or injector issues.

- Recommended Tools: While many generic OBD-II scanners exist, specialized tools like FORScan (with an appropriate adapter), AutoEnginuity (with Ford bundle), or professional-grade scanners like Snap-on Solus/Verus are ideal for comprehensive 7.3 Powerstroke fuel system diagnostics.

4. Multimeter

Electrical issues often mimic fuel system problems, and a multimeter is your best friend for electrical diagnostics.

- Purpose: Tests voltage, resistance, and continuity in electrical circuits, sensors, and solenoids.

- How to Use: Check for proper voltage at the lift pump, injector harness connectors, ICP sensor, and IPR valve. Test resistance of injector solenoids (if accessible and specified) and continuity of wiring.

- Key Applications: Diagnosing UVC (Under Valve Cover) harness issues, faulty ICP/IPR sensor wiring, or confirming power supply to the fuel pump.

5. Fuel System Bleed Tools / Priming Tools

After working on the fuel system, air can get trapped, leading to no-start or hard-start conditions. These tools help remove air.

- Purpose: To quickly and effectively purge air from the fuel lines and filter housing after maintenance (e.g., filter replacement, line repairs).

- Examples: Hand priming pumps or specialized vacuum pumps that can pull fuel through the system. Often, simply cycling the key on and off several times (to activate the lift pump) can help bleed the system, but a dedicated tool can expedite the process.

6. Fuel Filter Wrench and Bucket

Not strictly diagnostic, but absolutely essential for preventative maintenance that can prevent future diagnostic needs.

- Purpose: Safely remove and replace the fuel filter.

- Actionable Tip: Always have a catch bucket ready to collect spilled fuel during filter changes. A dirty fuel filter is a very common cause of fuel system issues in a 7.3 Powerstroke, so regular replacement is key.

Diving Deeper: Advanced Diagnostic Techniques & Powerstroke-Specific Tools

While the basic tools cover many scenarios, some issues in the 7.3 Powerstroke fuel system require a more specialized approach. These advanced techniques and tools provide even greater precision in identifying elusive problems.

1. High-Pressure Oil System (HPO) Diagnostics

As mentioned, the 7.3’s injectors are hydraulically actuated by engine oil. Therefore, issues in the HPO system directly impact fuel delivery.

- HPOP Output Test: A specialty tool (or a carefully crafted setup with a pressure gauge and shut-off valve) can test the actual output pressure of the HPOP. This involves blocking the HPOP output and monitoring the pressure it can generate, bypassing the IPR valve.

- IPR and ICP Electrical Testing: Beyond simply reading sensor values, advanced diagnostics might involve back-probing these sensors while the engine is running or checking their resistance and voltage signals under various conditions using a multimeter or oscilloscope.

- Air Test for HPO Leaks: This involves removing the IPR valve and injecting shop air into the HPOP system while listening for air leaks (typically from injector o-rings, standpipes, or dummy plugs). This is a critical diagnostic step for hard-start/no-start conditions related to high-pressure oil leaks.

2. Injector Performance Testing

When scan tool tests (like the buzz and contribution tests) suggest an injector issue, further investigation might be needed.

- Injector Leakage Test: Special tools can be connected to the return side of the injectors to measure individual injector fuel return rates. Excessive return indicates internal injector leakage.

- Visual Inspection of Injectors: While not a “tool” per se, physically removing injectors allows for a thorough visual inspection for signs of wear, pitting, or damage to the nozzle and O-rings. This requires specialized injector removal tools and gaskets.

3. Fuel Sample Analysis

Contaminated fuel is a silent killer of fuel systems. Sometimes, you need to literally see what’s in your fuel.

- Purpose: To identify water contamination, microbial growth (algae), or particulate matter that can clog filters and damage injectors.

- How to Do It: Draw a sample directly from the fuel tank or the fuel filter housing into a clear container. Let it sit to allow separation of water or sediment. Chemical test kits are also available for more precise analysis.

- Actionable Insight: If contamination is found, a full fuel system cleaning and potentially tank draining may be necessary, along with addressing the source of contamination.

These advanced **fuel system diagnostic tools for 7.3 Powerstroke** and techniques require more expertise and sometimes specialized equipment, but they are invaluable for resolving stubborn or intermittent fuel system problems.

DIY vs. Pro: When to Tackle It Yourself and When to Seek Expert Help

One of the biggest questions for any 7.3 Powerstroke owner is, “Can I fix this myself, or do I need a professional?” The answer often depends on your skill level, the tools you possess, and the complexity of the issue at hand. Understanding when to use your **fuel system diagnostic tools for 7.3 Powerstroke** in your own garage versus when to head to a shop is crucial.

Advantages of DIY Diagnostics and Repairs

- Cost Savings: Labor costs at a diesel shop can be substantial. Doing the work yourself can save hundreds, if not thousands, of dollars.

- Learning Experience: Every repair is an opportunity to deepen your understanding of your 7.3, building confidence and mechanical skills.

- Immediate Action: You can start diagnosing and potentially fixing the problem as soon as it arises, without waiting for shop availability.

- Personal Satisfaction: There’s a unique satisfaction in knowing you kept your beloved Powerstroke running strong with your own hands.

DIY is generally suitable for straightforward issues like fuel filter changes, lift pump replacements (if accessible), basic fuel pressure checks, and interpreting basic scan tool codes (P0000-P0999) using your **fuel system diagnostic tools for 7.3 Powerstroke**.

When to Call the Pros

There are definitely times when the smart move is to hand the keys to a qualified diesel mechanic:

- Complex, Intermittent Issues: If your diagnostic efforts yield conflicting results, or the problem is highly intermittent, a professional’s experience and advanced diagnostic equipment (like an oscilloscope for waveform analysis) can be invaluable.

- Specialized Tool Requirements: Some repairs, especially those involving the high-pressure oil system (HPOP, IPR replacement), injector removal, or extensive engine teardown, require specialty tools that are expensive and rarely used by the average DIYer.

- Time Constraints: If you rely on your truck for work and can’t afford extended downtime, a professional shop can often diagnose and repair faster.

- Safety Concerns: Working with high-pressure fuel and oil systems, especially during engine operation, carries inherent risks. If you’re uncomfortable or unsure, don’t take chances.

- Major Internal Engine Work: If diagnostics point to internal engine issues beyond the fuel system (e.g., worn pistons, camshaft problems), it’s almost always best left to a professional.

Even when you take your truck to a shop, understanding how **fuel system diagnostic tools for 7.3 Powerstroke** work and being able to communicate your observations and initial findings can greatly assist the mechanic, potentially saving you diagnostic time and money.

Beyond the Fix: Preventative Maintenance for a Resilient 7.3 Fuel System

Diagnosing and fixing a fuel system problem is only half the battle. The other, equally important half is preventing future issues through diligent preventative maintenance. A well-maintained 7.3 Powerstroke fuel system is a resilient one, capable of delivering legendary performance for hundreds of thousands of miles.

1. Regular Fuel Filter Changes

This cannot be stressed enough. A clean fuel filter is the first line of defense against contaminants and is crucial for maintaining proper fuel flow and pressure. Clogged filters are a leading cause of performance degradation and often mistaken for more complex issues.

- Actionable Tip: Replace your 7.3 Powerstroke fuel filter every 10,000-15,000 miles, or more frequently if you use questionable fuel sources or drive in dusty environments. Always use a high-quality filter from a reputable brand.

2. Use Quality Fuel and Fuel Additives

The quality of your diesel fuel directly impacts the health of your fuel system.

- Actionable Tip: Always fuel up at reputable stations. Consider using a quality diesel fuel additive, especially during colder months. These additives can improve lubricity, prevent gelling, disperse water, and clean injectors, directly extending the life of your fuel system components.

3. System Checks and Inspections

Periodically inspect your fuel system components for signs of wear or impending failure.

- Actionable Tip: During oil changes or other routine maintenance, take a few extra minutes to visually inspect fuel lines for cracks or chafing, check connections for leaks, and listen for unusual noises from the lift pump. Early detection of a small leak using your basic **fuel system diagnostic tools for 7.3 Powerstroke** (like your eyes and a flashlight) can prevent a major problem.

4. Keep Your Engine Oil Clean (for HPOP Reliance)

Since the 7.3 Powerstroke uses engine oil to actuate its HEUI injectors, the quality and cleanliness of your engine oil are paramount to fuel system health.

- Actionable Tip: Adhere to a strict engine oil change schedule using the manufacturer-recommended oil viscosity and type. Dirty or degraded oil can shorten the life of your HPOP and injectors, making them prime candidates for future diagnostic work.

5. Monitor Fuel Pressure Routinely

If you’ve invested in a permanent fuel pressure gauge or frequently use your portable **fuel system diagnostic tools for 7.3 Powerstroke**, make it a habit to check pressure regularly.

- Actionable Tip: A gradual drop in fuel pressure over time, even if still within spec, can be an early indicator of a weakening lift pump or a partially clogged filter. Catching this early allows for proactive replacement before a complete failure strands you.

By implementing these preventative measures, you not only reduce the likelihood of needing extensive diagnostic work but also ensure your 7.3 Powerstroke remains a reliable, high-performing truck for years to come.

Common 7.3 Powerstroke Fuel System Symptoms & Diagnostic Pathways

| Symptom | Potential Cause(s) | Primary Diagnostic Tools / Steps | Expected Readings / Outcomes |

|---|---|---|---|

| Hard Start / No Start | Low Fuel Pressure, Air Intrusion, Weak HPOP, Failing IPR/ICP, Bad Injectors | Fuel Pressure Gauge, Scan Tool (ICP/IPR/Buzz Test), Multimeter (UVC harness), HPO Air Test | < 40 PSI fuel pressure; Low ICP during cranking; Failed buzz test; High IPR duty cycle; Air leaks in HPO system. |

| Rough Idle / Stalling | Low Fuel Pressure, Clogged Filter, Failing Injector, Air Intrusion, IPR/ICP Issues | Fuel Pressure Gauge, Scan Tool (ICP/IPR/Contribution Test), Visual Inspection, Fuel Sample | Fluctuating fuel pressure; Erratic ICP/IPR readings; Cylinder contribution issues; Contaminated fuel. |

| Loss of Power / Hesitation | Low Fuel Pressure, Clogged Filter, Failing Injector, Weak HPOP | Fuel Pressure Gauge, Scan Tool (ICP/IPR/Contribution Test) | Low fuel pressure under load; ICP drops significantly under load; Cylinder contribution issues. |

| Excessive Smoke | Failing Injector (White/Blue), Air Intrusion (White), Clogged Air Filter (Black) | Scan Tool (Contribution Test), Visual Inspection, Fuel Sample, Injector Leakage Test | Cylinder contribution issues; White smoke with air bubbles in fuel (from clear lines); Fuel contamination. |

| Poor Fuel Economy | Clogged Filter, Failing Injectors, Low Fuel Pressure, Sensor Malfunction | Fuel Pressure Gauge, Scan Tool (Long-term fuel trims, ICP/IPR), Fuel Filter Inspection | Low fuel pressure; Out-of-spec ICP/IPR; Dirty fuel filter. |

| Check Engine Light (CEL) | Various sensor/component failures (ICP, IPR, PCM, Injector circuit) | Scan Tool (Read DTCs, Live Data) | Specific DTCs (e.g., P1211, P1212 for ICP; P127x for injector circuit). |

Conclusion: Empowering Your 7.3 Powerstroke for Years to Come

The 7.3 Powerstroke is more than just an engine; it’s a testament to enduring quality and raw power. To keep this legend roaring, understanding and maintaining its intricate fuel system is paramount. From the low-pressure lift pump to the high-pressure oil-actuated injectors, every component plays a crucial role in delivering that characteristic diesel punch.

By investing in the right fuel system diagnostic tools for 7.3 Powerstroke—from a simple fuel pressure gauge and a capable scan tool to specialty HPO air test kits—you empower yourself to quickly and accurately identify problems. Combining these tools with a keen eye for symptoms and a commitment to preventative maintenance not only saves you money on expensive shop visits but also deepens your connection with your truck. Regular fuel filter changes, quality fuel, and diligent inspections are the cornerstones of a healthy fuel system, ensuring your 7.3 continues to perform at its peak for hundreds of thousands of miles.

Don’t wait for your trusty Powerstroke to leave you stranded. Equip yourself with the knowledge and tools, stay proactive with maintenance, and your 7.3 will reward you with reliable, powerful performance for years to come. Your legacy machine deserves nothing less.

🎥 Related Video: 6.4L Power Stroke Fuel System Problems? Expert Bleeding & Diagnostic Tips

📺 Alliant Power

Is your 6.4L Power Stroke giving you fuel system headaches? This video from Alliant Power provides essential tech tips to keep …

Frequently Asked Questions

What is Fuel system diagnostic tools for 7.3 Powerstroke?

Fuel system diagnostic tools for 7.3 Powerstroke is an important topic with many practical applications and benefits.

How can Fuel system diagnostic tools for 7.3 Powerstroke help me?

Understanding Fuel system diagnostic tools for 7.3 Powerstroke can improve your knowledge and provide practical solutions.