Fixing 6.0 Powerstroke Camshaft Position Sensor Failure: Troubleshooting Tips

Featured image for this comprehensive guide about Fixing 6.0 Powerstroke camshaft position sensor failure

Image source: autotrends.org

The Ford 6.0 Powerstroke diesel engine. For many, it’s a testament to raw power and capability; for others, a source of legendary frustration. If you’re a proud (or sometimes exasperated) owner of a 6.0, you’ve likely become intimately familiar with its quirks and common issues. Among the many components that can bring this beast to its knees, the camshaft position sensor (CMP) stands out as a frequent culprit, often leading to maddening no-start conditions or erratic engine behavior.

Imagine this: You turn the key, the starter whirs, but your mighty Powerstroke simply refuses to catch, leaving you stranded. Or perhaps it starts, only to stumble, stutter, and lose power when you least expect it. These are classic signs that your 6.0 Powerstroke camshaft position sensor failure might be at play. This tiny, yet critically important, sensor is the unsung hero that tells your engine’s computer (PCM) exactly where the camshaft is in its rotation, a piece of information vital for precise fuel injection and ignition timing. When it goes rogue, your engine loses its internal compass.

Fear not, fellow Powerstroke enthusiast! While a failing CMP sensor can be a headache, diagnosing and fixing the issue is often within the realm of a dedicated DIY mechanic or a skilled professional. This comprehensive guide will walk you through everything you need to know about the 6.0 Powerstroke CMP sensor, from understanding its function to recognizing symptoms, performing accurate diagnostics, and executing a successful replacement. By the end, you’ll be equipped with the knowledge to tackle a 6.0 Powerstroke camshaft position sensor failure head-on, restoring your truck’s reliability and getting you back on the road with confidence.

Quick Answers to Common Questions

What are the common signs of a failed 6.0 Powerstroke camshaft position sensor?

A struggling engine, no-start condition, rough idle, or sudden stalling are telltale signs. You might also see a ‘Check Engine’ light with relevant diagnostic trouble codes (DTCs) related to the camshaft position sensor failure.

Can I still drive my 6.0 Powerstroke if I suspect a camshaft position sensor failure?

It’s highly advised not to drive your truck with a failing sensor, as it can cause unexpected stalls or prevent starting altogether. Addressing the camshaft position sensor failure immediately is crucial for your safety and the engine’s health.

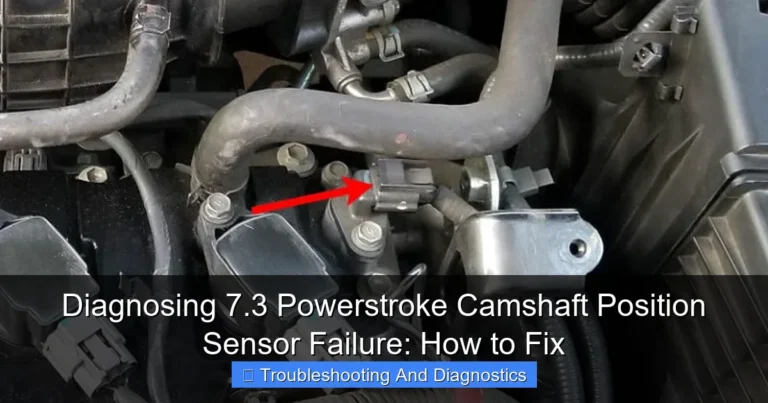

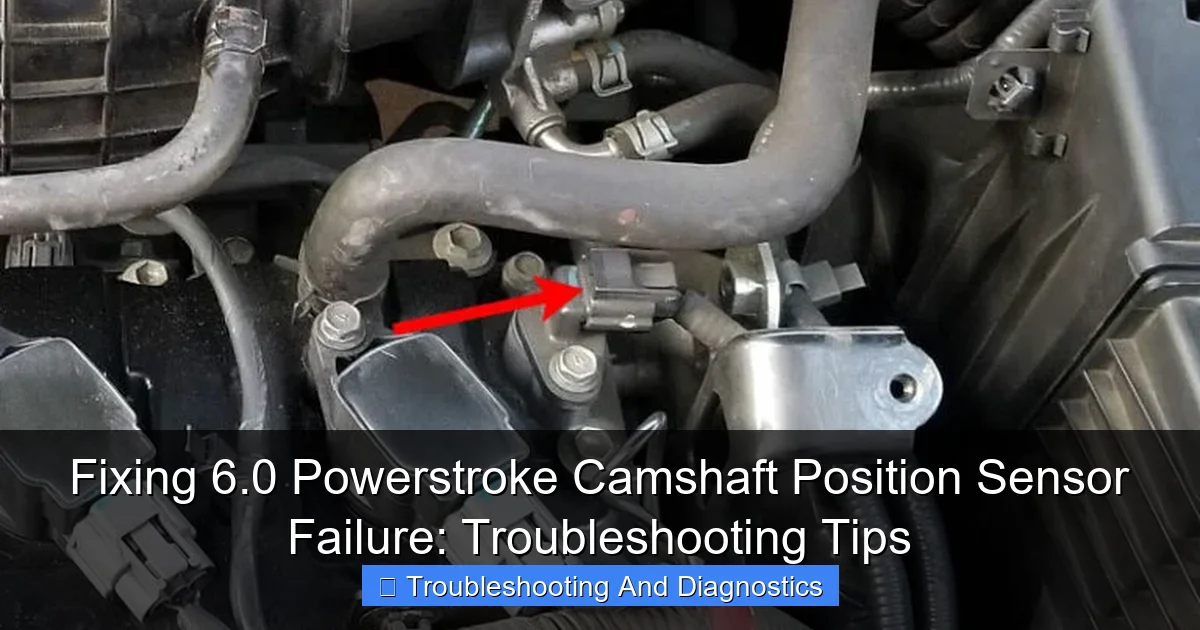

Where exactly is the 6.0 Powerstroke camshaft position sensor located?

The camshaft position sensor on the 6.0 Powerstroke is typically found on the front of the engine, usually near the high-pressure oil pump cover. It’s relatively accessible, making the task of fixing 6.0 Powerstroke camshaft position sensor failure a bit easier.

Is fixing 6.0 Powerstroke camshaft position sensor failure a difficult DIY job?

For most DIYers with basic mechanical skills, replacing the 6.0 Powerstroke camshaft position sensor is a straightforward job. It doesn’t require specialized tools beyond common wrenches and sockets, making fixing this failure quite manageable.

What’s the very first thing I should do if I suspect a 6.0 Powerstroke camshaft position sensor failure?

Your first step should be to connect an OBD-II scanner to read any diagnostic trouble codes (DTCs). This will confirm if the issue points to the camshaft position sensor, guiding your next steps in fixing 6.0 Powerstroke camshaft position sensor failure.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Camshaft Position Sensor (CMP)

- Recognizing the Symptoms of a Failing 6.0 Powerstroke CMP Sensor

- Diagnosing 6.0 Powerstroke CMP Sensor Failure: Step-by-Step

- The Replacement Process: How to Fix a Failing 6.0 Powerstroke CMP Sensor

- Preventing Future 6.0 Powerstroke CMP Sensor Issues & Best Practices

- Common 6.0 Powerstroke CMP Sensor DTCs and Their Meanings

- Conclusion

Understanding the 6.0 Powerstroke Camshaft Position Sensor (CMP)

Before we dive into troubleshooting, it’s essential to grasp what the camshaft position sensor does and why it’s so critical for the intricate operation of your 6.0 Powerstroke.

Learn more about Fixing 6.0 Powerstroke camshaft position sensor failure – Fixing 6.0 Powerstroke Camshaft Position Sensor Failure: Troubleshooting Tips

Image source: themotorguy.com

What Does the CMP Sensor Do?

The camshaft position sensor, often abbreviated as CMP, is a magnetic sensor designed to monitor the rotational speed and position of the engine’s camshaft. The camshaft, in turn, controls the opening and closing of the engine’s intake and exhaust valves. The CMP sensor sends a signal to the engine’s Powertrain Control Module (PCM), which uses this information in conjunction with data from the crankshaft position sensor (CKP) to determine the precise timing for fuel injection, valve actuation, and other critical engine functions. Think of it as one half of the engine’s internal GPS system.

| Symptom / Diagnostic Code (DTC) | Probable Cause / Diagnosis | Troubleshooting & Recommended Fix |

|---|---|---|

| P0340 / P0341 (Camshaft Position Sensor Circuit Malfunction) | Most commonly, a failed CPS. Also possible: damaged wiring harness, poor connector contact, or faulty PCM. | Visually inspect CPS wiring and connector for damage. Test CPS output signal with an oscilloscope or monitor RPM on a scan tool during cranking. Replace CPS (approx. 30-60 min DIY). |

| Long Crank, No Start (Engine cranks normally, but won’t fire) | Intermittent or complete loss of CPS signal, preventing the PCM from recognizing engine rotation and fueling. Often no immediate DTC. | Monitor Engine RPM via scan tool while cranking. If RPM shows 0 or erratic/missing signal, suspect CPS failure. Replace CPS and clear any pending codes. |

| Engine Stalls Intermittently, Rough Idle, or Sudden Power Loss | CPS signal dropping out intermittently, often due to heat, vibration, or internal sensor defect. Symptoms may worsen when warm. | Drive vehicle until symptoms occur. Monitor live data for sudden RPM drops. Check for chafed wires or loose connections to the CPS. Replace CPS with a quality OEM-spec part. |

| No 5V Reference or Signal Output at CPS Connector | Open circuit in wiring to CPS, short to ground, or faulty PCM providing reference voltage. | With key on, engine off, check for 5V reference and ground at the CPS connector using a multimeter. If missing, trace wiring back to PCM or check PCM itself. |

| Post-Replacement Checks / Preventative Maintenance | Ensuring the repair was successful and using reliable components to prevent future failures. | Always use a genuine Ford/Motorcraft or high-quality aftermarket CPS. Clear all DTCs. Start engine, confirm smooth operation, and perform a short test drive to ensure no codes return (estimated part cost: $50-$150). |

Why is it So Critical for the 6.0?

The 6.0 Powerstroke utilizes a sophisticated High-Pressure Oil Pump (HPOP) and an Injector Control Pressure (ICP) system to operate its Hydraulic Electronic Unit Injectors (HEUI). This system relies heavily on extremely precise timing to deliver fuel efficiently and powerfully. If the PCM doesn’t receive accurate or consistent data from the CMP sensor, it struggles to synchronize fuel injection and valve events, leading to a cascade of problems. Without a clear signal from the CMP, the PCM essentially loses its ability to fire the injectors at the correct moment, often resulting in a 6.0 Powerstroke no-start condition.

Common 6.0 Powerstroke CMP Sensor Issues

Like many components on the 6.0 Powerstroke, the CMP sensor can be susceptible to failure due to a combination of factors:

- Heat and Vibration: The engine bay of a diesel truck generates immense heat and vibration, which can degrade the sensor’s internal electronics and wiring over time.

- Wiring Harness Issues: The wiring leading to the sensor can chafe, fray, or develop intermittent connections, mimicking a sensor failure.

- Contamination: Metal debris or oil sludge can interfere with the sensor’s magnetic signal.

- Sensor Age and Quality: OEM sensors sometimes had design flaws, and aftermarket sensors can vary wildly in quality. Opting for a genuine Ford or high-quality aftermarket part is crucial during replacement.

Recognizing the Symptoms of a Failing 6.0 Powerstroke CMP Sensor

Identifying the symptoms of a failing 6.0 Powerstroke CMP sensor is the first step toward a successful diagnosis and repair. While some signs can be attributed to other issues, a combination of these strongly points to a CMP problem.

Learn more about Fixing 6.0 Powerstroke camshaft position sensor failure – Fixing 6.0 Powerstroke Camshaft Position Sensor Failure: Troubleshooting Tips

Image source: sensormass.com

Classic No-Start Condition

This is arguably the most common and frustrating symptom. Your engine will crank vigorously, often sounding strong, but it simply won’t fire up. The starter engages, the engine turns over, but there’s no combustion. This happens because the PCM isn’t getting the necessary camshaft position data to time the fuel injection, making it impossible for the engine to ignite the fuel-air mixture. This is a tell-tale sign of a severe 6.0 Powerstroke camshaft position sensor failure.

Rough Idle or Stalling

If your truck does manage to start, a failing CMP sensor can cause an extremely rough idle. The engine might shake violently, sound erratic, and struggle to maintain a consistent RPM. In some cases, it might even stall unexpectedly, especially after warming up or when coming to a stop. This indicates the PCM is receiving intermittent or incorrect signals from the sensor.

Reduced Engine Performance and Loss of Power

When the CMP sensor is sending inconsistent data, the PCM enters a “limp mode” or struggles to optimize fuel delivery. This results in a noticeable reduction in engine power, poor acceleration, and a general lack of responsiveness. Your once-powerful 6.0 Powerstroke will feel sluggish and underpowered.

Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs)

Almost inevitably, a failing CMP sensor will trigger the Check Engine Light on your dashboard. More importantly, it will store specific Diagnostic Trouble Codes (DTCs) in the PCM’s memory. These codes are invaluable for narrowing down the problem. Common codes associated with a faulty 6.0 Powerstroke CMP sensor include:

- P0340: Camshaft Position Sensor Circuit Malfunction

- P0341: Camshaft Position Sensor Circuit Range/Performance

- P0342: Camshaft Position Sensor Circuit Low Input

- P0343: Camshaft Position Sensor Circuit High Input

- P0344: Camshaft Position Sensor Circuit Intermittent

Always start your diagnostic process by scanning for these codes with an OBD-II scanner.

Diagnosing 6.0 Powerstroke CMP Sensor Failure: Step-by-Step

Accurate diagnosis is paramount when dealing with a potential 6.0 Powerstroke camshaft position sensor failure. Avoid the common mistake of simply replacing the sensor without proper testing, as other issues can mimic the same symptoms.

1. Visual Inspection

Begin by visually inspecting the CMP sensor and its wiring harness. The sensor is located at the front of the engine, usually near the harmonic balancer, accessible from the front of the vehicle. Look for:

- Damaged Wiring: Check for frayed wires, cracked insulation, or signs of rodent damage.

- Corroded or Loose Connector: Ensure the electrical connector is securely seated and free from corrosion, dirt, or oil.

- Physical Damage to Sensor: While rare, look for any cracks or impact damage to the sensor housing.

2. Checking for Diagnostic Trouble Codes (DTCs)

As mentioned, this is your first and most critical step. Connect an OBD-II scanner to your truck’s diagnostic port. Read and note down any stored DTCs. While codes like P0340 directly point to the CMP sensor, other codes might indicate related issues (e.g., wiring problems, PCM issues).

3. Live Data Monitoring (Crucial for 6.0 Powerstroke)

This is where an advanced OBD-II scanner capable of displaying live data comes in handy, especially for a 6.0 Powerstroke diagnostic. During a cranking no-start condition:

- Monitor RPM: Observe the RPM reading while cranking. If the RPM gauge shows zero or very low RPMs (e.g., less than 50 RPM), it’s a strong indicator that either the CMP or CKP sensor (or their circuits) is not sending a signal to the PCM. A healthy 6.0 should show around 150-200 RPM while cranking.

- CMP and CKP Correlation: Some advanced scanners allow you to view the signals from both the camshaft position sensor and crankshaft position sensor. These signals should be present and correlate properly. If one is missing or erratic, you’ve found your culprit.

Remember, the 6.0 Powerstroke requires a minimum cranking RPM (typically 150-200 RPM) and valid CMP/CKP signals to command fuel injection.

4. Electrical Testing (Voltage and Resistance)

While live data is often more definitive for intermittent issues, basic electrical tests can confirm circuit integrity. You’ll need a multimeter for this:

- Disconnect Battery: Always disconnect the battery before performing electrical tests to prevent short circuits.

- Check for Reference Voltage: With the ignition ON (engine OFF), check the sensor connector for the correct reference voltage (usually 5V or 12V, depending on the specific sensor design – consult your service manual).

- Check for Ground: Verify a good ground connection at the sensor connector.

- Signal Wire Test: Testing the signal wire directly can be tricky without an oscilloscope. However, if reference voltage and ground are present, but the sensor isn’t producing an RPM signal during cranking, it points to internal sensor failure or a wiring issue on the signal line.

Be cautious: resistance tests on the sensor itself are often unreliable as internal failures can be intermittent or specific to operating conditions.

5. Wiggle Test

If you suspect an intermittent connection, perform a “wiggle test.” With the engine running (if it starts) or while cranking, gently wiggle the wiring harness and connector leading to the CMP sensor. If the engine stumbles, stalls, or changes its behavior, it indicates a loose connection or damaged wiring.

The Replacement Process: How to Fix a Failing 6.0 Powerstroke CMP Sensor

Once you’ve confidently diagnosed a 6.0 Powerstroke camshaft position sensor failure, the replacement process is relatively straightforward for most DIY mechanics.

Tools and Parts You’ll Need

- New 6.0 Powerstroke CMP sensor (preferably OEM or a high-quality aftermarket brand like Standard Motor Products, Bosch, or Alliant Power).

- Ratchet and appropriate sockets (usually 8mm or 10mm for the retaining bolt).

- Flathead screwdriver (for prying/disconnecting if needed).

- Dielectric grease.

- Clean rag.

- Gloves.

- Safety glasses.

Locating the CMP Sensor

The CMP sensor on the 6.0 Powerstroke is located at the front of the engine, just above the harmonic balancer. It’s usually mounted directly into the timing cover. Depending on your truck’s configuration and accessories, you might need to remove some components for better access, such as portions of the fan shroud or even the fan itself, though often it’s accessible without major disassembly.

Step-by-Step Replacement Guide

- Safety First: Ensure the engine is cool. Disconnect both negative battery terminals to prevent accidental starting or electrical shorts.

- Gain Access: If necessary, remove any obstructions hindering access to the sensor. This may involve moving hoses or part of the fan shroud.

- Disconnect Electrical Connector: Carefully unclip or slide off the electrical connector from the old CMP sensor. Be gentle, as plastic connectors can become brittle with age and heat.

- Remove Retaining Bolt: Using your ratchet and appropriate socket, remove the single bolt that holds the CMP sensor in place.

- Extract Old Sensor: Gently pull or wiggle the old sensor out of its bore. It might be slightly stiff due to the O-ring seal. If it’s stuck, a gentle pry with a flathead screwdriver against the mounting flange (be careful not to damage the engine block) can help.

- Inspect and Clean: Examine the old sensor for any unusual wear or debris. Clean the mounting bore thoroughly with a clean rag to ensure the new sensor seats properly and seals well.

- Prepare New Sensor: Apply a small amount of dielectric grease to the O-ring of the new CMP sensor. This aids in installation and helps maintain a good seal.

- Install New Sensor: Insert the new sensor into the bore, ensuring it’s fully seated. Reinstall the retaining bolt and tighten it snugly (do not overtighten, as the housing is often plastic).

- Reconnect Electrical Connector: Firmly reattach the electrical connector until it clicks into place.

- Reassemble and Reconnect: Reinstall any components you removed for access. Reconnect both negative battery terminals.

- Clear Codes and Test: Use your OBD-II scanner to clear any stored DTCs. Start the engine and listen for proper operation. Take your truck for a test drive, monitoring for normal acceleration, idle, and no return of the Check Engine Light.

Post-Replacement Checks

After replacing the CMP sensor, it’s a good practice to:

- Monitor Live Data: If your scanner allows, re-check RPM readings during cranking and running to ensure a consistent signal is now being sent.

- Listen for Engine Smoothness: Pay attention to the engine’s idle and overall running quality. It should be noticeably smoother if the CMP was the issue.

- Check for Leaks: Ensure there are no oil leaks around the new sensor’s mounting point.

Preventing Future 6.0 Powerstroke CMP Sensor Issues & Best Practices

While complete prevention of component failure is impossible, there are best practices you can follow to minimize the chances of a recurring 6.0 Powerstroke camshaft position sensor failure.

Opt for Quality Replacement Parts

When it comes to sensors, especially for critical engine functions, don’t skimp on quality. Invest in a genuine Ford OEM CMP sensor or a reputable aftermarket brand known for its reliability and direct fit. Generic, cheap sensors are often a false economy, failing prematurely and leading to more headaches.

Regular Maintenance and Wiring Harness Inspection

Maintain your 6.0 Powerstroke diligently. Regular oil changes and keeping the engine bay clean can help reduce overall stress on components. Periodically inspect the wiring harness leading to the CMP sensor and other critical sensors for signs of chafing, rubbing, or damage. Secure loose wiring with zip ties or loom to prevent vibration-induced wear.

Addressing Other Potential Issues

Sometimes, a CMP sensor failure can be symptomatic of a larger problem. For example, excessive engine vibration due to worn motor mounts could prematurely wear out sensors. Ensure your engine is otherwise in good health. Also, if your truck experiences frequent high-temperature operation, consider upgrading cooling components to reduce overall engine bay heat.

Professional Diagnosis for Complex Issues

While this guide empowers you to tackle many issues, if you’ve followed all diagnostic steps and are still facing problems, or if multiple codes are present, don’t hesitate to seek professional help. A qualified diesel mechanic with specialized 6.0 Powerstroke diagnostic tools and experience can quickly pinpoint elusive problems, saving you time, frustration, and potentially costly misdiagnoses.

Common 6.0 Powerstroke CMP Sensor DTCs and Their Meanings

Understanding the specific Diagnostic Trouble Codes (DTCs) related to the 6.0 Powerstroke CMP sensor is crucial for accurate troubleshooting. Here’s a brief breakdown of the most common codes you might encounter:

| DTC (Diagnostic Trouble Code) | Description and Potential Cause |

|---|---|

| P0340 | Camshaft Position Sensor Circuit Malfunction: This is a generic code indicating that the PCM has detected an issue with the CMP sensor circuit. It could mean a faulty sensor, open or shorted wiring, or a problem with the PCM itself. |

| P0341 | Camshaft Position Sensor Circuit Range/Performance: The PCM is receiving a signal from the CMP sensor, but the signal’s characteristics (e.g., frequency, amplitude) are not within the expected range, suggesting an intermittent fault or a sensor sending incorrect data. |

| P0342 | Camshaft Position Sensor Circuit Low Input: The voltage signal from the CMP sensor circuit is consistently lower than expected. This could point to a short to ground in the wiring, a faulty sensor producing a weak signal, or high resistance in the circuit. |

| P0343 | Camshaft Position Sensor Circuit High Input: Conversely, this code indicates the voltage signal from the CMP sensor circuit is consistently higher than expected. Possible causes include a short to voltage in the wiring or a faulty sensor internally shorted. |

| P0344 | Camshaft Position Sensor Circuit Intermittent: This code suggests that the CMP sensor signal is intermittently lost or erratic. This is often the hardest to diagnose as the problem comes and goes, possibly due to loose connections, heat-related sensor failure, or wiring fatigue. |

Always remember that while these codes point to the CMP circuit, they don’t always definitively mean the sensor itself is bad. Thorough diagnostic steps, especially live data analysis, are vital to confirm the root cause of any 6.0 Powerstroke camshaft position sensor failure.

Conclusion

The 6.0 Powerstroke camshaft position sensor failure might seem daunting, especially when your truck is stuck in a no-start condition. However, by understanding the sensor’s role, recognizing the classic symptoms, and following a methodical diagnostic approach, you can effectively pinpoint and resolve the issue. Whether it’s the dreaded P0340 code or an unexplained rough idle, the key is not to jump to conclusions but to systematically test and confirm the fault.

Empowered with the knowledge from this guide, you now have the tools to tackle this common 6.0 Powerstroke diagnostic challenge. Remember to prioritize quality replacement parts, inspect wiring diligently, and don’t shy away from professional help when needed. By taking these steps, you’ll not only fix the immediate problem but also contribute to the long-term reliability and performance of your beloved 6.0 Powerstroke, ensuring it continues to serve you faithfully on the road ahead.

🎥 Related Video: No FICM sync? Cam and Crank Position sensor info #powerstroke #powerstrokenation #powerstrokelife

📺 Agape Love Automotive

Frequently Asked Questions

What are the common symptoms of a 6.0 Powerstroke camshaft position sensor failure?

Symptoms often include extended cranking, no-start conditions, rough idling, or sudden engine stalls while driving. You might also experience reduced engine power, poor fuel economy, or the illumination of the Check Engine Light with related trouble codes (e.g., P0340, P0341).

Where is the camshaft position sensor (CPS) located on a 6.0 Powerstroke engine?

The camshaft position sensor on a 6.0 Powerstroke is located at the front of the engine, on the passenger side, positioned behind the cooling fan and belt. It is typically mounted on the timing cover and can be somewhat challenging to access due to its location.

How can I test if my 6.0 Powerstroke camshaft position sensor is truly faulty?

While diagnostic trouble codes are a strong indicator, a thorough test usually involves checking the sensor’s signal output with an oscilloscope or monitoring engine RPM during cranking using a scan tool. A healthy sensor should produce a consistent square wave signal as the engine turns over.

Is it safe to drive my 6.0 Powerstroke with a bad camshaft position sensor?

It is generally not recommended to drive with a faulty camshaft position sensor, especially if it’s causing stalling or no-start conditions. A failing sensor can lead to unpredictable engine behavior, making your vehicle unreliable and potentially unsafe to operate.

What are the common causes for a 6.0 Powerstroke camshaft position sensor to fail?

Common causes for failure include exposure to extreme engine heat, which can degrade internal components, and general wear and tear over time. Electrical issues like damaged wiring or poor connections within the sensor’s circuit can also lead to intermittent or complete failure.

Are there any other components that can cause similar symptoms to a failing 6.0 Powerstroke CPS?

Yes, several other components can mimic a failing 6.0 Powerstroke camshaft position sensor, such as a faulty crankshaft position sensor, a weak high-pressure oil pump (HPOP), or even a damaged FICM (Fuel Injection Control Module). Always perform thorough diagnostics to rule out other potential issues before replacing the CPS.