Diagnosing Ford 6.0 Powerstroke Overheating Issues: How to Prevent Damage

Featured image for this comprehensive guide about Diagnosing Ford 6.0 Powerstroke overheating issues

Image source: up.picr.de

Diagnosing Ford 6.0 Powerstroke Overheating Issues: How to Prevent Damage

Few phrases strike more fear into the heart of a Ford truck owner than “my 6.0 Powerstroke is overheating.” The legendary 6.0L Powerstroke engine, while capable of immense power and torque, has a well-documented history of cooling system vulnerabilities that can lead to catastrophic failure if not addressed promptly and correctly. If you’ve found yourself staring at that rising temperature gauge or, worse, seeing steam billow from under the hood, you know the urgency of the situation. Ignoring these signs is a direct path to costly repairs, including blown head gaskets or even a completely seized engine.

The good news? Many common Ford 6.0 Powerstroke overheating issues are identifiable and preventable, provided you know what to look for and how to diagnose them. This comprehensive guide will arm you with the knowledge to pinpoint the root cause of your engine’s heat problems, from the most common culprits to the more obscure challenges. We’ll delve into the intricacies of the 6.0 Powerstroke cooling system, offer actionable diagnostic steps, and provide strategies to not only fix current issues but also prevent future overheating catastrophes. Your trusty Powerstroke deserves the best care, and understanding its cooling system is paramount to its longevity.

Join us as we navigate the complex world of diagnosing Ford 6.0 Powerstroke overheating issues, ensuring your truck stays cool, reliable, and on the road for years to come. By understanding the symptoms, performing the right tests, and implementing preventative measures, you can transform your overheating headache into a well-running, powerful machine.

Quick Answers to Common Questions

What are the first signs of a Ford 6.0 Powerstroke overheating?

Keep an eye out for your temperature gauge climbing rapidly, steam escaping from under the hood, or your coolant degas bottle overflowing. These are critical clues when diagnosing Ford 6.0 Powerstroke overheating issues.

What’s often the root cause of 6.0 Powerstroke overheating?

The primary suspect is frequently a clogged oil cooler, which then prevents the EGR cooler from receiving proper coolant flow. Addressing this initial failure point is key to correctly diagnosing Ford 6.0 Powerstroke overheating issues.

Can I safely drive my 6.0 Powerstroke if it starts overheating?

Absolutely not! Pull over immediately and shut off the engine to prevent catastrophic and expensive damage. Ignoring the temperature gauge can quickly turn a minor problem into a major repair when diagnosing Ford 6.0 Powerstroke overheating issues.

What’s the easiest way to start diagnosing Ford 6.0 Powerstroke overheating issues myself?

Begin by checking your coolant levels and inspecting the degas bottle for any signs of bubbling or sludge. These simple visual checks can offer immediate insights into potential problems.

Besides the oil cooler, what other common culprits cause these overheating problems?

While the oil cooler is a prime suspect, a failed fan clutch, a sticking thermostat, or even issues with the water pump can also lead to overheating. A thorough diagnostic process considers all these possibilities.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Cooling System: A Foundation for Diagnosis

- Common Culprits: Top Causes of 6.0 Powerstroke Overheating

- Early Warning Signs & Initial Diagnostic Steps

- Advanced Diagnostics: Diving Deeper into 6.0 Powerstroke Overheating

- Preventing Future Overheating: Maintenance & Upgrade Strategies

- When to Seek Professional Help and Why

- Conclusion: Stay Cool, Drive On

Understanding the 6.0 Powerstroke Cooling System: A Foundation for Diagnosis

Before we dive into specific problems, it’s crucial to understand the unique architecture of the Ford 6.0 Powerstroke cooling system. Unlike simpler engines, the 6.0 uses coolant for more than just engine temperature regulation; it also cools the engine oil and the Exhaust Gas Recirculation (EGR) system. This integrated design, while efficient in theory, creates several critical failure points that can quickly lead to 6.0 Powerstroke overheating.

Learn more about Diagnosing Ford 6.0 Powerstroke overheating issues – Diagnosing Ford 6.0 Powerstroke Overheating Issues: How to Prevent Damage

Image source: s32667.pcdn.co

The system comprises several key components:

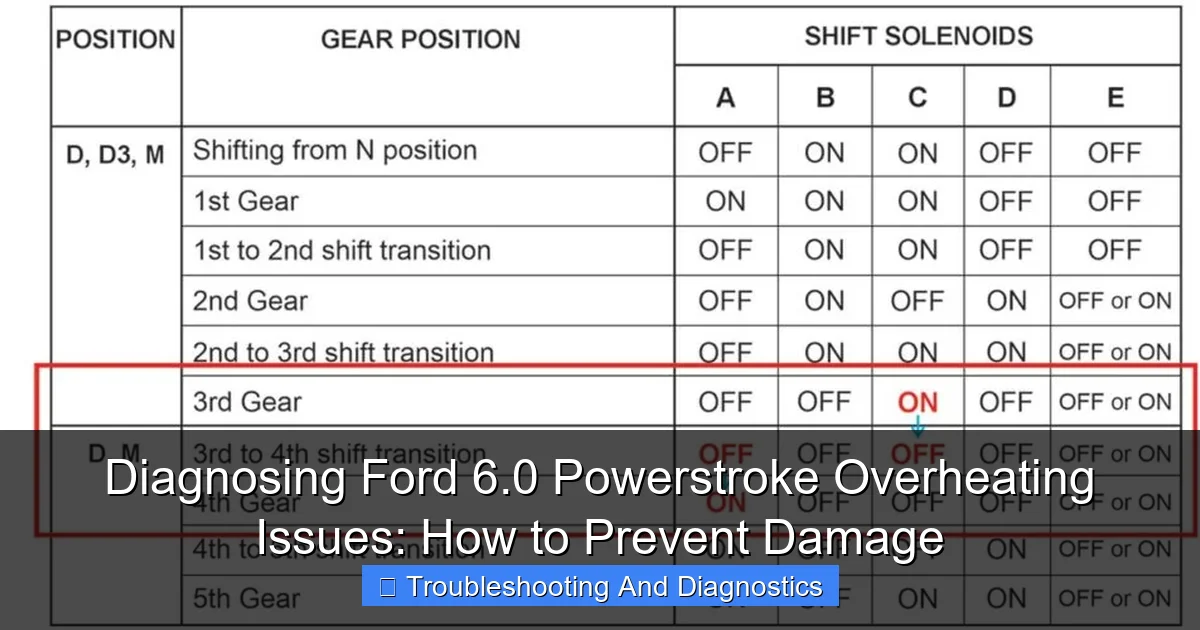

| Symptom/Observation | Likely Cause(s) | Diagnostic Test/Expected Reading | Notes/Impact |

|---|---|---|---|

| High EOT-ECT Delta (Oil Temp vs. Coolant Temp) | Clogged Oil Cooler | Monitor EOT vs. ECT via OBD-II scanner at 65+ mph, warmed up. Delta > 15-20°F unloaded. | Primary cause of EGR cooler failure and overall engine stress. Crucial to address. |

| Coolant loss, white smoke from exhaust, degas bottle bubbling | EGR Cooler Failure | Cooling system pressure test. Inspect EGR valve/manifold for coolant. Exhaust gas in coolant test. | Hot exhaust gases entering coolant system cause rapid overheating and pressure buildup. |

| Excessive coolant pressure, degas bottle overflow (boiling over) | Blown Head Gaskets or Cracked Head | Cylinder contribution test, exhaust gas in coolant test, compression/leak-down test. | Severe issue, often a secondary failure from repeated overheating or high boost. Costly repair. |

| Slow warm-up, intermittent overheating under load | Failed Thermostat | Monitor ECT; thermostat should open between 190-205°F. Check radiator temperature variance. | Relatively inexpensive part, but can lead to engine damage if left unresolved. |

| Engine overheats at idle or low speeds; fan runs constantly/loudly | Clogged Radiator or Stuck Fan Clutch | Visually inspect radiator fins for debris. Test fan clutch engagement (should roar when hot and engaged). | Restricted airflow or insufficient cooling fan operation reduces heat dissipation. |

- Radiator: Dissipates heat from the coolant.

- Water Pump: Circulates coolant throughout the engine.

- Thermostat: Regulates engine operating temperature by controlling coolant flow.

- Coolant Hoses: Transport coolant between components.

- Degas Bottle (Coolant Reservoir): Stores excess coolant and allows for expansion. This is often the first place to observe symptoms of a problem.

- Engine Oil Cooler (EOC): A critical component located under the intake manifold, it uses engine coolant to cool the engine oil.

- EGR Cooler: Cools hot exhaust gases before they are recirculated into the intake manifold. This component is notorious for failures.

- Cooling Fan & Fan Clutch: Provides additional airflow across the radiator, especially at low speeds or while idling.

- Sensors: Engine Coolant Temperature (ECT) and Engine Oil Temperature (EOT) sensors provide vital data to the engine control unit (ECU).

The interconnected nature of the oil cooler, EGR cooler, and engine block means that a failure in one area can quickly cascade, leading to a general Ford 6.0 Powerstroke overheating condition. For instance, a clogged oil cooler restricts coolant flow to the EGR cooler, which can then fail and introduce exhaust gases into the cooling system, leading to further overheating and potential damage to other components like head gaskets. This complex interaction makes accurate diagnosis crucial.

Common Culprits: Top Causes of 6.0 Powerstroke Overheating

When your 6.0 starts to run hot, a handful of issues are statistically more likely to be the cause. Understanding these common failure points is the first step in diagnosing Ford 6.0 Powerstroke overheating issues.

Learn more about Diagnosing Ford 6.0 Powerstroke overheating issues – Diagnosing Ford 6.0 Powerstroke Overheating Issues: How to Prevent Damage

Image source: s32667.pcdn.co

1. Clogged Engine Oil Cooler (EOC)

The EOC is arguably the most notorious component in the 6.0’s cooling system. Over time, casting sand and silicate dropout from conventional green coolant can accumulate inside the narrow passages of the EOC. This internal clogging restricts coolant flow, leading to two primary problems:

- High Engine Oil Temperature (EOT): The oil can’t be adequately cooled, leading to higher-than-normal oil temperatures.

- Reduced Coolant Flow to EGR Cooler: Because the EGR cooler relies on the same coolant circuit, a clogged EOC starves the EGR cooler of necessary coolant, causing it to overheat and fail.

A significant indicator of a clogged EOC is a large “Delta T” – the difference between your EOT and ECT. If, after 15-20 minutes of highway driving, your EOT is consistently more than 15 degrees Fahrenheit higher than your ECT (e.g., EOT 215°F, ECT 200°F), you likely have a clogged oil cooler. If the difference exceeds 25 degrees, replacement is highly recommended.

2. EGR Cooler Failure

The EGR cooler failure is another extremely common and damaging issue. When the EOC is clogged, the EGR cooler operates at much higher temperatures, causing its internal tubes to crack and leak. Once cracked, exhaust gases enter the cooling system, leading to:

- "Coolant Puking" from the Degas Bottle: Exhaust gases displace coolant, forcing it out of the degas bottle.

- Rapid Loss of Coolant: The system loses coolant as it’s expelled, exacerbating the overheating.

- Increased System Pressure: The exhaust gases pressurize the cooling system beyond its design limits.

If you’re repeatedly adding coolant, seeing steam or fluid escaping the degas bottle cap, or noticing unusually high pressure in the coolant hoses, an EGR cooler failure is a strong suspect. While an EGR delete kit can permanently resolve this issue (check local emissions laws), a quality aftermarket EGR cooler is also an option.

3. Blown Head Gaskets

Often, blown head gaskets are a secondary failure, resulting from prolonged or severe 6.0 Powerstroke overheating caused by a clogged oil cooler and failed EGR cooler. However, they can also fail independently due to excessive cylinder pressures or improper torque on head bolts. Symptoms are similar to an EGR cooler failure:

- Coolant Puking: Exhaust gases enter the cooling system.

- Loss of Power: Compression leaks.

- White Smoke from Exhaust: If coolant is entering the combustion chamber.

Diagnosing head gaskets definitively often requires specialized tools like a block tester (for exhaust gas in coolant) or a cooling system pressure test.

4. Water Pump Failure

While less common than the above, a failing water pump can certainly lead to overheating. Symptoms include:

- Lack of Coolant Circulation: Hot spots in the engine.

- Noise: A grinding or whining sound from the front of the engine.

- Leakage: Coolant leaking from the weep hole on the water pump housing.

Visually inspect the pump for leaks and ensure the belt is tight and in good condition.

5. Radiator and Cooling Fan Issues

A clogged or damaged radiator can reduce its heat exchange capacity. External debris (leaves, bugs) or internal corrosion can both cause issues. Similarly, a faulty cooling fan clutch will prevent the fan from engaging properly, leading to overheating, especially at idle or low speeds, or when towing. Check for proper fan engagement when the engine is hot and the AC is on.

6. Thermostat Malfunctions

A stuck-closed thermostat prevents coolant from circulating to the radiator, causing rapid overheating. A stuck-open thermostat, while not causing overheating, will prevent the engine from reaching operating temperature, which can also cause efficiency issues. Symptoms of a faulty thermostat include rapid temperature swings or a consistently high-running engine.

Early Warning Signs & Initial Diagnostic Steps

Catching Ford 6.0 Powerstroke overheating issues early can save you thousands in repairs. Pay close attention to these warning signs and perform these initial checks.

Key Symptoms to Watch For:

- "Coolant Puking" from Degas Bottle: Coolant overflowing or bubbling out of the reservoir. This is a tell-tale sign of exhaust gases in the cooling system.

- Constantly Low Coolant Level: If you’re frequently topping off the degas bottle, you have a leak or are losing coolant somewhere.

- Rising Temperature Gauge: The most obvious sign. Don’t ignore it!

- Sweet Smell of Coolant: Indicates an external leak.

- Steam from Under the Hood: Usually a sign of a significant leak or boiling coolant.

- Excessive Pressure in Coolant Hoses: Hoses feel rock-hard even when the engine is not extremely hot.

- Poor Heater Performance: Indicates low coolant level or circulation issues.

- Check Engine Light (CEL): Could be triggered by a sensor reading out of range.

Initial Diagnostic Steps:

- Visual Inspection:

- Check the degas bottle for proper coolant level (when cold). Look for residue or signs of overflow.

- Inspect all coolant hoses for cracks, leaks, or swelling.

- Look for visible coolant leaks around the radiator, water pump, and engine block.

- Examine the radiator fins for blockages (leaves, dirt).

- Check the drive belt for the water pump and cooling fan for proper tension and wear.

- Monitor Temperature Gauges (EOT/ECT): If you have an OBD-II scanner or a monitoring device (like an Edge Insight or Forscan), actively monitor your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT). This “Delta T” test is critical for diagnosing a clogged oil cooler.

- Degas Bottle Pressure Test: With the engine cold, remove the cap from the degas bottle. Start the engine. If you immediately see bubbles or “puking” coolant, it’s a strong indicator of exhaust gas entering the system (EGR cooler or head gaskets).

- Feel the Hoses: When the engine is at operating temperature, carefully feel the upper and lower radiator hoses. They should be firm, but not rock-hard, and both should be hot. A cold lower hose with a hot upper hose could indicate a stuck thermostat.

Advanced Diagnostics: Diving Deeper into 6.0 Powerstroke Overheating

If the initial checks don’t pinpoint the problem, it’s time for more advanced diagnostic tools and procedures. These methods are crucial for accurate Powerstroke diagnostic work.

1. Cooling System Pressure Test

This test involves attaching a specialized pump to the degas bottle and pressurizing the cooling system to its operating pressure (typically 16-20 psi). Monitor the pressure gauge for at least 30 minutes. A rapid drop in pressure indicates a leak, which can then be visually searched for. This helps identify external leaks that might not be obvious, or slow internal leaks.

2. Exhaust Gas in Coolant Test (Block Tester)

A chemical "block tester" kit can definitively determine if exhaust gases are present in your coolant. This kit contains a blue liquid that changes color (typically to yellow) when exposed to combustion gases. You use a bulb to draw air from the degas bottle through the liquid. This is invaluable for confirming EGR cooler failure or blown head gaskets.

3. Coolant Flow Test

Some technicians can perform a coolant flow test using specialized equipment to measure the actual flow rate through various parts of the cooling system. This can directly identify restrictions, such as a severely clogged oil cooler or radiator.

4. Infrared Thermometer (IR Gun)

An IR gun can be useful for checking surface temperatures of different components. You can compare the temperature of various points on the radiator, hoses, and engine block to identify localized hot spots or blockages. For example, a cold spot on the radiator with the engine hot indicates a clogged section.

5. Cylinder Contribution Test

While not directly a cooling system test, a cylinder contribution test (performed with a diagnostic scanner) can sometimes indirectly point to blown head gaskets. If a cylinder consistently shows low contribution, it might indicate a loss of compression due to a head gasket leak. This is less common but worth noting.

6. Oil Analysis

An engine oil analysis can reveal the presence of coolant in the oil, indicating an internal leak from the oil cooler or head gaskets. Conversely, coolant analysis can show traces of oil if there’s an oil-to-coolant leak.

| Potential Cause | Primary Symptoms | Key Diagnostic Test(s) |

|---|---|---|

| Clogged Engine Oil Cooler (EOC) | High Delta T (EOT > ECT by >15-25°F); Often leads to EGR cooler failure. | Monitor EOT/ECT (e.g., Forscan, Edge Insight). |

| EGR Cooler Failure | Coolant "puking" from degas bottle; Rapid coolant loss; Excessive degas bottle pressure. | Exhaust gas in coolant test (block tester); Visual inspection (hard to see directly). |

| Blown Head Gaskets | Coolant "puking" from degas bottle (often more severe); Loss of power; White smoke. | Exhaust gas in coolant test; Cooling system pressure test; Compression test. |

| Faulty Water Pump | Engine overheating; Grinding/whining noise; Coolant leak from weep hole. | Visual inspection; Listen for noises; Coolant circulation check. |

| Stuck Thermostat | Rapid overheating (stuck closed); Engine not reaching temp (stuck open); Erratic temperature swings. | Feel radiator hoses (upper hot, lower cold = stuck closed); Monitor ECT. |

| Radiator/Fan Clutch Issues | Overheating at idle/low speed or when towing (fan clutch); General overheating (radiator). | Visual inspection of radiator (debris); Check fan clutch engagement (when hot, A/C on). |

Preventing Future Overheating: Maintenance & Upgrade Strategies

Once you’ve successfully diagnosed and repaired your Ford 6.0 Powerstroke overheating issues, the next critical step is to implement strategies to prevent recurrence. "Bulletproofing" a 6.0 Powerstroke isn’t just about performance; it’s fundamentally about addressing the inherent weaknesses in the cooling and oil systems to ensure reliability.

Key Preventative Measures & Upgrades:

- Regular Coolant Flushes and Quality Coolant:

- Perform regular coolant flushes (every 30,000-50,000 miles, or as recommended).

- Use only Ford-approved gold coolant (Motorcraft Gold or equivalent) or a reputable Extended Life Coolant (ELC) that meets Ford specifications. Avoid mixing coolant types.

- If switching to an ELC, ensure a thorough flush is performed to remove all traces of old coolant and silicates.

- Install a Coolant Filter: A coolant filter system is arguably one of the most cost-effective preventative measures. It removes casting sand and other debris from the cooling system, preventing it from clogging the new oil cooler and other critical passages.

- Upgrade Engine Oil Cooler (EOC): If replacing the EOC, consider a reputable aftermarket unit with larger passages or a design less prone to clogging. Ensure the replacement includes a complete flush of the entire cooling system to remove debris that could clog the new cooler.

- Address the EGR System:

- EGR Delete: For off-road use or in areas without strict emissions testing, an EGR delete kit permanently removes the problematic EGR cooler, eliminating a major source of 6.0 Powerstroke overheating.

- Upgraded EGR Cooler: If an EGR delete isn’t an option (due to emissions laws), install a high-quality aftermarket EGR cooler, preferably one with a larger or more robust design.

- Monitor EOT/ECT Constantly: Invest in an OBD-II monitor (e.g., Edge Insight CTS3, Banks iDash, or Forscan on a smartphone/laptop) to continuously monitor your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT). This allows you to catch Delta T issues early, before they lead to major failures.

- Check Your Fan Clutch: A dying fan clutch can lead to overheating, especially when towing or in hot weather. Test it regularly and replace if it shows signs of weakness.

- Replace Thermostat Proactively: A relatively inexpensive part, replacing your thermostat as part of routine maintenance can prevent a headache down the road.

- Consider Head Studs (for high-performance or heavy-duty use): While expensive, upgrading to ARP head studs is a common “bulletproofing” modification. The factory head bolts can stretch under high cylinder pressures, leading to blown head gaskets. Studs provide more consistent clamping force.

Proactive maintenance and strategic upgrades are the best defense against Ford 6.0 Powerstroke overheating issues. Investing a little now can save you significantly later.

When to Seek Professional Help and Why

While this guide provides extensive information on diagnosing Ford 6.0 Powerstroke overheating issues, there comes a point where professional intervention is necessary. Knowing your limits can save you time, money, and further damage to your engine.

Reasons to Call a Professional:

- Lack of Proper Tools: Many advanced diagnostic steps (e.g., pressure testing, block testing, advanced scanner analysis) require specialized tools that the average DIYer may not possess.

- Complexity of the Repair: Jobs like oil cooler replacement (which requires removing the intake manifold), EGR cooler replacement, or especially head gasket issues are very labor-intensive and require specific torque sequences, specialized gaskets, and a deep understanding of the engine’s mechanics.

- Inability to Pinpoint the Problem: If you’ve gone through all the diagnostic steps and still can’t definitively identify the root cause, a professional Ford Powerstroke specialist will likely have more experience with the nuances of these engines.

- Risk of Further Damage: Guessing at a diagnosis or performing a repair incorrectly can lead to more severe and expensive engine damage. For instance, improper bleeding of the cooling system after a repair can still cause overheating.

- Time Constraints: Some repairs can take days to complete, even for an experienced mechanic. If you rely on your truck daily, professional help might be the fastest route to getting it back on the road.

- Warranty Considerations: If your truck is still under a warranty (even an extended powertrain warranty), performing DIY repairs might void it. Always check with your dealer or warranty provider first.

A reputable shop specializing in Powerstroke diesels will have trained technicians, the correct diagnostic equipment (like Ford’s IDS system), and access to genuine Ford parts or high-quality aftermarket equivalents. They can accurately diagnose the problem, perform the repair efficiently, and often offer a warranty on their work. While it’s an investment, the peace of mind and assurance of a correctly done job are invaluable when dealing with an engine as complex and temperamental as the 6.0 Powerstroke.

Conclusion: Stay Cool, Drive On

The Ford 6.0 Powerstroke is a formidable engine, but its Achilles’ heel often lies within its cooling system. By now, you should have a much clearer understanding of the common causes of 6.0 Powerstroke overheating, the tell-tale symptoms to watch for, and the precise diagnostic steps needed to identify the root cause. From monitoring your Delta T to performing a block test, accurate diagnosis is the cornerstone of effective repair.

Remember, prompt action is critical. Ignoring that rising temperature gauge or the tell-tale "puking" from the degas bottle can quickly escalate a manageable repair into a complete engine overhaul. By implementing proactive maintenance strategies – such as regular coolant flushes, installing a coolant filter, and judiciously considering upgrades like an improved oil cooler or EGR solution – you can significantly bolster your engine’s reliability and longevity.

Whether you’re tackling the repair yourself or entrusting your truck to a Powerstroke specialist, the knowledge gained from this guide empowers you to make informed decisions. Keep your Ford 6.0 Powerstroke cooling system in top shape, and you’ll enjoy many more miles of powerful, reliable driving. Stay vigilant, stay proactive, and keep that Powerstroke cool!

🎥 Related Video: Bad EGR cooler or head gasket

📺 BulletProofDiesel

Frequently Asked Questions

How do I know if my Ford 6.0 Powerstroke is overheating?

The most obvious sign is your engine temperature gauge climbing into the red zone or a “CHECK GAUGE” warning light illuminating on your dashboard. Other indicators include steam from under the hood, a sweet smell of burning coolant, or a noticeable loss of engine power while driving.

What are the most common causes of 6.0 Powerstroke overheating?

Many issues can lead to a Ford 6.0 Powerstroke overheating, with the most frequent culprits being a clogged oil cooler, a failed EGR cooler, or a malfunctioning fan clutch. A faulty thermostat or compromised head gaskets due to excessive pressure can also contribute significantly to the problem.

What are the first steps to diagnose an overheating Ford 6.0 Powerstroke?

Begin by safely pulling over and allowing the engine to cool down completely, then check the coolant level in the degas bottle and inspect for any visible leaks around hoses or the radiator. Also, verify that the fan clutch is engaging properly and that there are no obstructions blocking airflow through the radiator fins.

Are there specific diagnostic tests or tools for Ford 6.0 Powerstroke overheating?

Yes, a crucial diagnostic is monitoring the Engine Coolant Temperature (ECT) and Engine Oil Temperature (EOT) delta using a scan tool; a spread greater than 15 degrees Fahrenheit at operating temperature often indicates a clogged oil cooler. A coolant pressure test and an exhaust gas in coolant test can also pinpoint issues like head gasket failure or a leaking EGR cooler in your Ford 6.0 Powerstroke.

What should I do immediately if my Ford 6.0 Powerstroke starts to overheat?

Safely pull off the road and turn off the engine as soon as possible to prevent severe damage to critical components. Do not attempt to open the radiator cap or degas bottle when the engine is hot, as pressurized coolant can cause serious burns. Allow the vehicle to cool completely before attempting any inspection or adding fluids.

How can I prevent future overheating issues with my Ford 6.0 Powerstroke?

Regular maintenance, including timely coolant flushes with the correct extended life coolant, is critical for your 6.0 Powerstroke. Proactively monitoring your ECT/EOT delta, replacing the oil cooler with an updated version, and considering an aftermarket EGR cooler can significantly reduce the risk of future overheating problems.