Diagnosing 6.0 Powerstroke Water Pump Failure: Fixing Cooling Problems

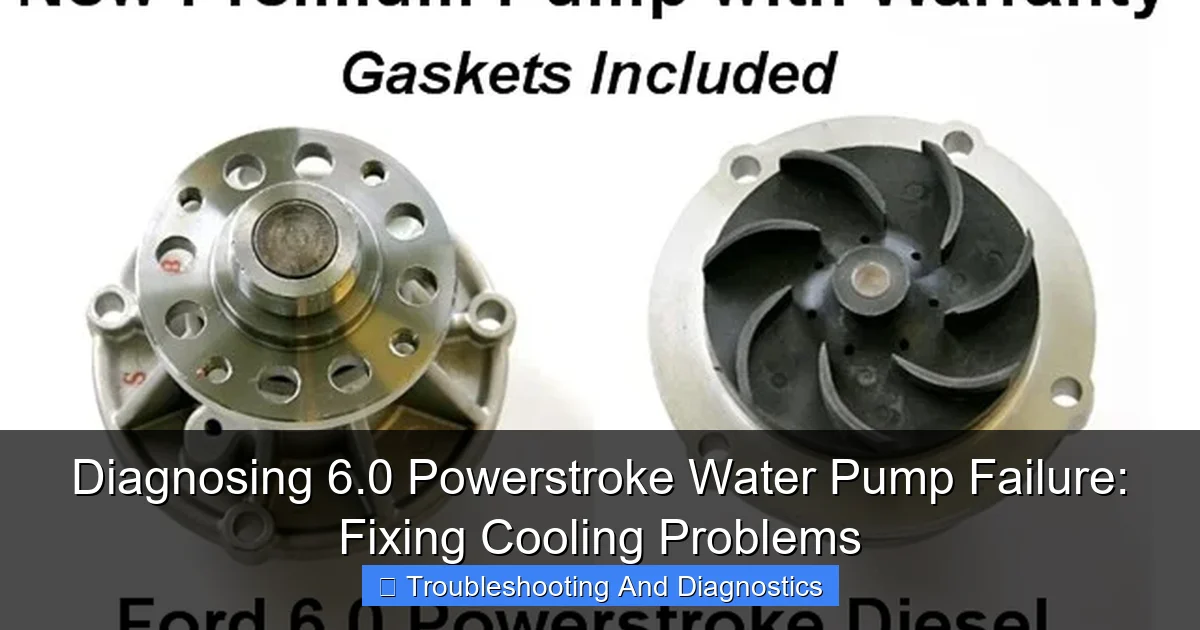

Featured image for this comprehensive guide about Diagnosing 6.0 Powerstroke water pump failure

Image source: international-t444e-water-pump.com

The Ford 6.0 Powerstroke engine, a legendary powerhouse for many a heavy-duty truck, is known for its incredible torque and robust capabilities. However, even the toughest engines have their Achilles’ heel, and for the 6.0, the cooling system has often been a point of contention. Among the various components that contribute to the 6.0’s thermal management, the water pump plays a silently critical role. It’s the heart that circulates coolant, ensuring your engine stays within optimal operating temperatures.

When this vital component begins to falter, it can rapidly lead to a cascade of problems, from minor inconveniences to severe engine damage. Overheating is not just an annoyance; it’s a direct threat to the longevity and performance of your diesel engine, potentially leading to blown head gaskets, cracked cylinder heads, and other costly repairs. Understanding the subtle and not-so-subtle signs of a failing water pump is paramount for any 6.0 Powerstroke owner.

This comprehensive guide is designed to equip you with the knowledge and actionable steps needed for diagnosing 6.0 Powerstroke water pump failure. We’ll delve deep into the common water pump symptoms 6.0 Powerstroke owners experience, walk you through a detailed diagnostic process, and help you differentiate water pump issues from other prevalent 6.0 Powerstroke cooling problems. By the end, you’ll be well-prepared to identify the issue and take the necessary steps to fix 6.0 Powerstroke water pump issues effectively, safeguarding your investment and keeping your truck on the road.

Quick Answers to Common Questions

What are the first signs of a 6.0 Powerstroke water pump failure?

The most common tell-tale signs are engine overheating, a noticeable coolant leak, and a rapidly dropping coolant reservoir level. Don’t ignore these crucial warnings!

Where should I look for a coolant leak if my 6.0 Powerstroke water pump is failing?

Check for puddles or drips on the ground directly beneath the front of your engine. Also, visually inspect the water pump itself for pink/red crusty residue, especially around the weep hole.

Can a 6.0 Powerstroke water pump failure cause any strange noises?

Absolutely! A failing water pump can produce grinding, squealing, or whining noises from the front of the engine as its bearings wear out. Listen carefully for these unusual sounds.

My 6.0 Powerstroke is running hot, but I don’t see a visible leak. Could it still be a water pump issue?

Yes, it’s possible! The impeller inside the water pump can corrode or break apart, leading to poor coolant circulation and overheating without an external leak. A failing thermostat could also be a culprit, but don’t rule out the water pump.

How critical is it to address a 6.0 Powerstroke water pump failure quickly?

It’s very critical! A failed water pump can quickly lead to severe engine overheating, which can cause significant and costly damage to your 6.0 Powerstroke engine. Early diagnosis and repair are essential to prevent further problems.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Cooling System and Its Vulnerabilities

- Early Warning Signs and Symptoms of 6.0 Powerstroke Water Pump Failure

- The Step-by-Step Diagnostic Process for 6.0 Powerstroke Water Pump Failure

- Differentiating Water Pump Failure from Other 6.0 Cooling Problems

- The Repair Process: What to Expect When Fixing Your 6.0 Powerstroke Water Pump

- Preventing Future 6.0 Powerstroke Water Pump Issues and Maintaining Your Cooling System

- Common 6.0 Powerstroke Cooling Issues and Their Primary Indicators

- Conclusion

Understanding the 6.0 Powerstroke Cooling System and Its Vulnerabilities

Before we dive into diagnosing a specific component, it’s essential to appreciate the intricate design of the 6.0 Powerstroke’s cooling system. Unlike simpler engines, the 6.0 features a complex architecture involving multiple heat exchangers, including the engine oil cooler (EOC) and the exhaust gas recirculation (EGR) cooler, all relying on a consistent flow of coolant. This system is designed for high performance but can be sensitive to imbalances or failures.

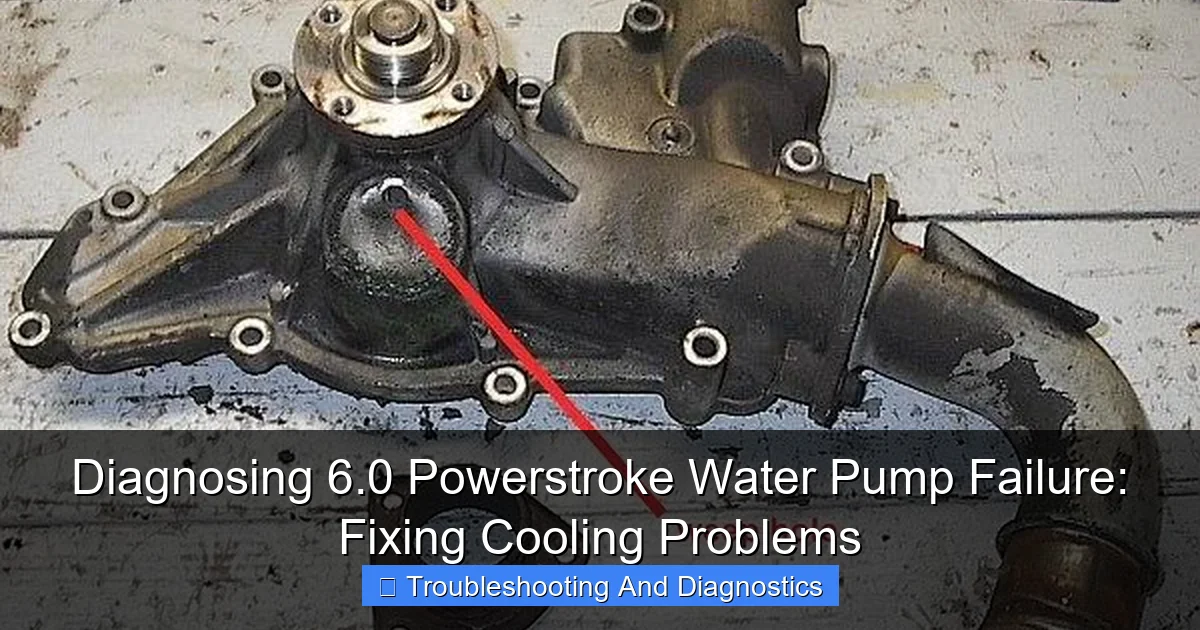

Learn more about Diagnosing 6.0 Powerstroke water pump failure – Diagnosing 6.0 Powerstroke Water Pump Failure: Fixing Cooling Problems

Image source: static.superdutypsd.com

The water pump is the central force behind this elaborate system. Mounted on the front of the engine and driven by the serpentine belt, its impeller blades draw hot coolant from the engine and push it through the radiator for cooling, then back into the engine to absorb more heat. A properly functioning water pump ensures a continuous and adequate flow rate, maintaining the engine’s temperature balance. The 6.0 Powerstroke, being a high-output diesel, generates significant heat, making its cooling system, and especially the water pump, work incredibly hard. Over time, wear and tear, manufacturing defects, or improper coolant maintenance can lead to a 6.0 Powerstroke water pump failure.

| Symptom/Observation | Likely Water Pump Related Cause | Diagnostic Action |

|---|---|---|

| **Engine Overheating** (high temp gauge, warning light) | Insufficient coolant circulation due to failed impeller, bearing seizure, or belt slippage. | Check coolant level; observe coolant flow in degas bottle (should be strong stream); scan for high ECT (Engine Coolant Temperature). |

| **Coolant Leaks** (front of engine, especially near pump) | Worn bearing and/or seal failure, allowing coolant to escape from the weep hole or housing. | Visually inspect the water pump weep hole (on pump underside); perform a cooling system pressure test. |

| **Squealing, Grinding, or Growling Noise** (from front accessory drive) | Failing water pump bearing; worn out or damaged internal components. | Use a mechanic’s stethoscope to pinpoint noise source; check for excessive pulley play with belt removed. |

| **No/Weak Coolant Flow in Degas Bottle** (with engine running, cool) | Severely corroded, broken, or dislodged water pump impeller. | Remove degas cap (carefully, when cool) and observe flow. Lack of flow strongly indicates impeller issue. |

| **Excessive Play in Water Pump Pulley** | Critically worn water pump bearing, leading to instability and potential failure. | With the serpentine belt removed, grasp the pulley and check for side-to-side or in-and-out movement. |

The Role of the Water Pump in 6.0 Thermal Management

- Coolant Circulation: The primary function is to circulate coolant through the engine block, cylinder heads, radiator, heater core, and various coolers.

- Temperature Regulation: By moving coolant efficiently, it ensures heat is dissipated effectively, preventing overheating.

- Support for Critical Components: The EGR and oil coolers rely heavily on this circulation to perform their functions, directly impacting engine health and emissions.

When the water pump begins to fail, this critical circulation is compromised, leading to a host of problems that can quickly escalate. Recognizing these early signs is the first step in effective diagnosis and repair.

Early Warning Signs and Symptoms of 6.0 Powerstroke Water Pump Failure

Catching 6.0 Powerstroke water pump failure early can save you significant time and money. While some symptoms are obvious, others can be subtle and easily mistaken for other issues. Pay close attention to these common water pump symptoms 6.0 Powerstroke owners often encounter.

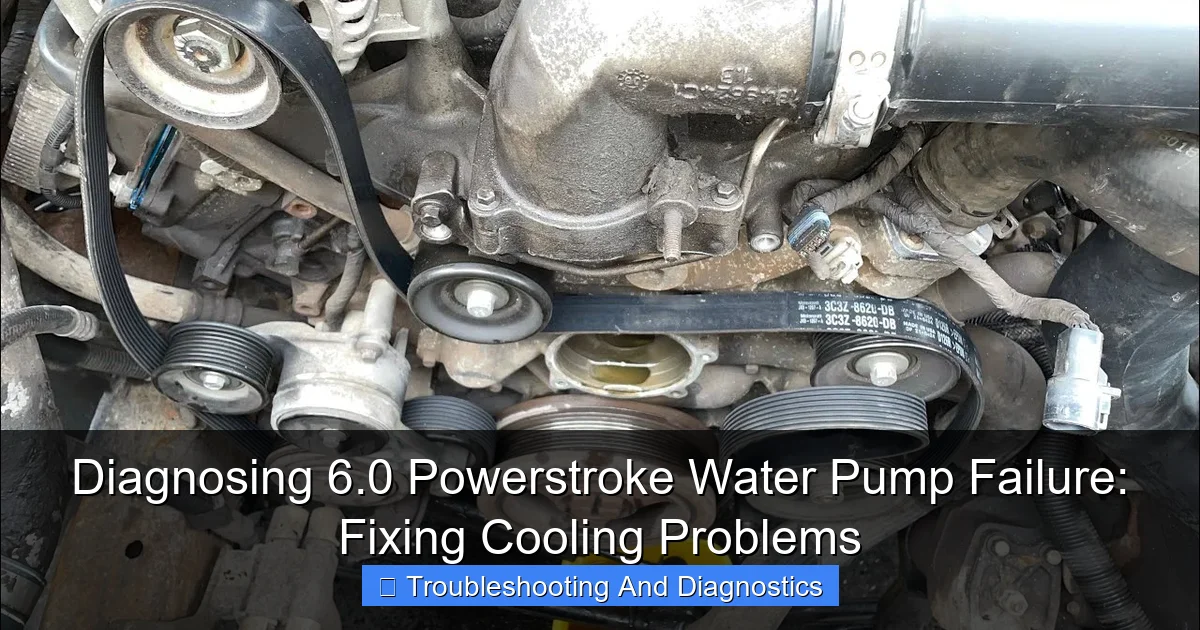

Learn more about Diagnosing 6.0 Powerstroke water pump failure – Diagnosing 6.0 Powerstroke Water Pump Failure: Fixing Cooling Problems

Image source: i.ytimg.com

Overheating Engine

This is arguably the most common and alarming symptom. If your temperature gauge starts creeping into the red zone, especially during heavy loads, towing, or extended idle, a failing water pump is a prime suspect. Without sufficient coolant circulation, the engine cannot shed heat effectively, leading to:

- Temperature gauge rising above normal operating range (typically 190-210°F).

- Steam emanating from under the hood.

- A sweet, sickly smell of burning coolant.

- The engine entering ‘limp mode’ to prevent catastrophic damage.

While other issues like a clogged radiator or faulty fan clutch can cause overheating, a rapidly increasing temperature often points to a severe flow restriction or complete pump failure.

Coolant Leaks

A visible coolant leak is another tell-tale sign of a failing water pump. The pump housing has a “weep hole” designed to allow a small amount of coolant to escape if the internal seal begins to fail. This is an early warning system.

- Puddle under your truck: Look for puddles of green, pink, or orange liquid (depending on your coolant type) under the front of the vehicle.

- Stains on the water pump housing: Examine the pump for dried coolant residue or active drips, particularly around the weep hole (often located on the underside of the pump body, near the pulley shaft).

- Coolant levels dropping: If you’re constantly topping off your degas bottle, but see no other obvious external leaks, the water pump’s internal seal might be compromised, leading to slow, evaporation-prone leaks.

Squealing or Grinding Noises

The water pump’s shaft rides on bearings, and like any bearing, they can wear out. When this happens, you might hear distinct noises from the front of your engine.

- Squealing: A high-pitched squeal, often most noticeable at start-up or when the engine is cold, can indicate a failing bearing or a loose serpentine belt due to bearing drag. This sound usually intensifies with engine RPM.

- Grinding: As the bearings deteriorate further, the squeal can turn into a rougher grinding sound, indicating severe internal damage to the pump. This noise is typically constant and directly correlates with the pump’s rotation.

Using a mechanic’s stethoscope (or even a long screwdriver handle to your ear) can help pinpoint the source of the noise to the water pump area.

Decreased Heater Performance

If your truck’s heater isn’t blowing hot air as effectively as it used to, or only blows warm air intermittently, it could indicate insufficient coolant circulation. The heater core relies on hot engine coolant to warm the cabin. A weakened water pump might not be able to push enough hot coolant through the heater core, especially at idle or lower RPMs, leading to reduced cabin heating.

Visible Impeller Damage or Corrosion (Advanced Stages)

In severe cases of 6.0 Powerstroke water pump failure, the impeller blades themselves can become corroded, eroded, or even break off. While you usually can’t see the impeller without removing the pump, certain signs might point to it:

- Coolant contamination: If you see small flakes or chunks of material in your degas bottle or when draining coolant, it could be impeller fragments.

- Intermittent overheating: If the impeller is partially damaged, the pump might work sometimes but struggle under load, leading to inconsistent temperatures.

Corrosion of the impeller is often a result of using incorrect coolant types or neglecting coolant flushes, leading to cavitation and material degradation.

The Step-by-Step Diagnostic Process for 6.0 Powerstroke Water Pump Failure

When faced with suspected 6.0 Powerstroke cooling problems, a systematic approach is crucial. Here’s how to go about diagnosing 6.0 Powerstroke water pump issues methodically.

1. Visual Inspection: The First Line of Defense

Always start with a thorough visual check.

- Check Coolant Level: Ensure the degas bottle (coolant reservoir) is at the proper level. Low coolant can mimic pump failure symptoms.

- Inspect for Leaks: Look around the water pump housing, hoses, and under the truck for any signs of coolant leaks, especially from the water pump’s weep hole. Use a flashlight to get a good view.

- Examine the Serpentine Belt: A loose, worn, or damaged serpentine belt can prevent the water pump from turning efficiently, leading to poor circulation. Check for cracks, fraying, or excessive play.

- Check Radiator Fins: Ensure the radiator fins aren’t blocked by debris (leaves, bugs) or severely bent, which can impede airflow.

2. Pressure Testing the Cooling System

A cooling system pressure tester is an invaluable tool for pinpointing leaks.

- Procedure: Connect the pressure tester to the degas bottle and pump it up to the specified pressure (refer to your owner’s manual or a service manual, typically 15-18 PSI for the 6.0).

- Observation: Monitor the gauge. If the pressure drops, there’s a leak. Systematically inspect all hoses, connections, the radiator, and most importantly, the water pump. A steady drip from the weep hole under pressure confirms a water pump seal failure.

- No External Leaks? If pressure drops but you see no external leaks, suspect internal leaks like an EGR cooler or head gasket issue.

3. Checking for Coolant Circulation

This test helps determine if the pump is actually moving coolant.

- Warm-up and “Squeeze Test”: With the engine warmed up and at operating temperature, carefully feel the upper and lower radiator hoses. The upper hose (coming from the thermostat housing) should be hot and firm. The lower hose (going into the water pump) should also be warm/hot. A significant temperature difference or a very soft, easily collapsible lower hose could indicate poor circulation.

- Degas Bottle Flow: With the engine running at idle and the cap off the degas bottle (be careful of hot coolant!), look for a steady stream of coolant returning into the bottle. Some 6.0s have a small hose that returns coolant to the bottle. No flow, or very weak flow, can suggest a failing water pump impeller.

4. Listening for Abnormal Noises

As mentioned earlier, unusual noises are a strong indicator.

- Engine Running: With the engine idling, listen closely from different positions around the front of the engine.

- Stethoscope/Hose Trick: Use a mechanic’s stethoscope or a long hose held to your ear (and the other end on the water pump housing) to isolate any grinding, squealing, or whining noises directly to the pump.

5. Inspecting the Water Pump Weep Hole

This is often the most definitive visual sign for a failed seal.

- Location: The weep hole is usually a small hole on the underside of the water pump housing, below the shaft.

- Evidence: Any signs of dried coolant residue, fresh coolant drips, or a steady stream of coolant from this hole confirm that the internal seal has failed, indicating it’s time to replace the water pump.

6. Using a Scan Tool for Overheating Codes

While not directly diagnosing the water pump, a scan tool can reveal valuable information if the engine is overheating.

- DTCs: Look for Diagnostic Trouble Codes (DTCs) related to engine temperature, such as P0217 (Engine Over Temperature Condition).

- Live Data: Monitor Engine Coolant Temperature (ECT) and Engine Oil Temperature (EOT) live data. While a high EOT/ECT delta (difference) usually points to an oil cooler issue, a general rapid rise in ECT without corresponding EOT rise (or vice versa, depending on where the heat is accumulating) can sometimes indirectly suggest a flow problem if other components are ruled out.

Differentiating Water Pump Failure from Other 6.0 Cooling Problems

The 6.0 Powerstroke is notorious for several 6.0 Powerstroke cooling problems, making accurate diagnosis crucial. It’s easy to misattribute symptoms, leading to unnecessary repairs. Here’s how to differentiate a failing water pump from other common cooling system culprits.

EGR Cooler Failure

Often confused with other overheating issues.

- Symptoms: White smoke from the exhaust (especially on startup or acceleration), unexplained coolant loss (with no external leaks), coolant “puking” from the degas bottle, gurgling sounds from the degas bottle.

- Differentiation: While an EGR cooler failure can cause overheating and coolant loss, it typically doesn’t produce external leaks from the water pump or specific mechanical noises from the pump itself. The exhaust smoke is a key differentiator.

Oil Cooler Clogging

A very common and significant issue for the 6.0.

- Symptoms: The most definitive symptom is a high delta between Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT). If, after 30 minutes of highway driving, your EOT is consistently 15-20 degrees Fahrenheit or more higher than your ECT, your oil cooler is likely clogged. Other symptoms include sludgy coolant in the degas bottle, slow warm-up of the engine coolant, and eventual overheating.

- Differentiation: A clogged oil cooler primarily affects the EOT/ECT delta, whereas a water pump failure will more directly affect overall coolant flow, leading to rapid ECT increases and potentially external leaks/noises.

Thermostat Malfunction

A simple component that can cause big headaches.

- Symptoms: Engine taking a very long time to warm up (stuck open), or overheating rapidly and consistently (stuck closed). Inconsistent temperature readings.

- Differentiation: A thermostat issue directly impacts temperature regulation but usually doesn’t involve external leaks from the water pump or the specific mechanical noises associated with a failing pump bearing.

Radiator Obstruction or Damage

The primary heat exchanger can also fail.

- Symptoms: Overheating, especially at higher speeds or under load. Visible external leaks from the radiator core, bent or clogged external fins reducing airflow. Cool spots on the radiator (checked with an IR thermometer) indicating internal blockage.

- Differentiation: Radiator issues focus on the heat exchange process itself or external leaks from the core, not the circulation provided by the water pump.

Fan Clutch Issues

The engine fan is crucial for cooling at low speeds.

- Symptoms: Overheating at idle or low speeds, but temperatures drop at higher speeds when ram air provides cooling. A loud roar from the fan that doesn’t subside (if stuck engaged) or no roar at all when it should engage (if failed disengaged).

- Differentiation: A fan clutch issue is speed-dependent for its overheating symptoms and doesn’t present with water pump leaks or mechanical noises.

The Repair Process: What to Expect When Fixing Your 6.0 Powerstroke Water Pump

Once you’ve confidently diagnosed a 6.0 Powerstroke water pump failure, the next step is to fix 6.0 Powerstroke water pump. This can be a DIY project for the mechanically inclined, or best left to a professional. Here’s an overview of what the repair entails.

DIY vs. Professional Repair

- DIY: If you have experience with engine work, the necessary tools (including a torque wrench, specific sockets, and a cooling system flush kit), and a good service manual, replacing a 6.0 Powerstroke water pump is certainly achievable. It requires patience and attention to detail.

- Professional: If you’re uncomfortable with complex engine repairs, lack the tools, or are short on time, taking your truck to a reputable diesel mechanic is the best course of action. They have specialized tools, diagnostic equipment, and experience with 6.0 Powerstrokes.

Tools and Parts Needed (DIY)

- New 6.0 Powerstroke water pump (OEM or high-quality aftermarket).

- New water pump gasket(s) and O-rings.

- RTV sealant (specified for coolant systems).

- New serpentine belt (recommended, as you’ll be removing the old one).

- Coolant flush chemical.

- Sufficient amount of the correct type of engine coolant (Ford Motorcraft Gold or compatible ELC).

- Distilled water.

- Various sockets, wrenches, ratchets, extensions.

- Drain pan, funnel, clean buckets.

- Torque wrench.

- Scraper for old gasket material.

- Hose clamp pliers.

Basic Repair Steps (Overview)

- Drain Coolant: Properly drain the entire cooling system into a clean container for disposal or reuse if it’s fresh.

- Remove Serpentine Belt: Relieve tension and remove the serpentine belt.

- Remove Components: Carefully remove any components obstructing access to the water pump (e.g., fan shroud, fan clutch, possibly alternator or idler pulleys).

- Disconnect Hoses: Detach all hoses connected to the water pump.

- Remove Water Pump: Unbolt the water pump from the engine block. Be prepared for residual coolant to spill.

- Clean Mounting Surface: Thoroughly clean all old gasket material and residue from the engine block mounting surface. This is critical for a leak-free seal.

- Install New Pump: Apply a thin, even bead of RTV sealant (if specified by the new pump’s instructions) to the new gasket, position it on the new pump, and carefully install the new pump, torquing bolts to factory specifications in the correct sequence.

- Reinstall Components: Reattach hoses, serpentine belt, and any other removed components.

- Refill and Bleed Cooling System: Refill the system with a 50/50 mix of approved coolant and distilled water. Start the engine with the degas bottle cap off, allowing air to escape. Monitor the coolant level and add more as needed until the system is fully bled. Drive the truck and recheck levels after it cools.

- Check for Leaks: After running the engine and bleeding the system, carefully check for any new leaks around the water pump area.

Critical Best Practices

- Flush the System: Before installing the new pump, it’s highly recommended to perform a thorough cooling system flush, especially if the old coolant was contaminated or if you suspect sludge from an oil cooler issue. This ensures the new pump isn’t exposed to old contaminants.

- Use Proper Coolant: Always use the correct type of coolant for your 6.0 Powerstroke (Ford Motorcraft Gold or equivalent ELC coolant). Mixing coolant types or using incompatible coolants can lead to corrosion and premature component failure.

- Torque Specs: Do not overtighten or undertighten water pump bolts. Use a torque wrench and follow factory specifications precisely.

Preventing Future 6.0 Powerstroke Water Pump Issues and Maintaining Your Cooling System

Preventative maintenance is key to avoiding future 6.0 Powerstroke water pump failure and other 6.0 Powerstroke cooling problems. A proactive approach extends the life of your entire cooling system and, by extension, your engine.

Regular Coolant Flushes and Maintenance

This is arguably the most important preventative measure.

- Schedule: Follow Ford’s recommended coolant flush intervals (typically every 3-5 years or 60,000-100,000 miles, but always check your specific manual).

- Benefits: Regular flushing removes corrosive acids, sediment, and contaminants that can degrade seals, corrode impellers, and clog passages within the water pump and other cooling components.

Using Quality Coolant and Distilled Water

The type of coolant and water you use makes a significant difference.

- Correct Coolant: Always use the specified coolant for your 6.0 Powerstroke (e.g., Ford Motorcraft Gold or a compatible extended-life coolant). Never mix different types of coolants.

- Distilled Water: When mixing concentrated coolant, always use distilled water. Tap water contains minerals that can cause scale buildup and contribute to corrosion within the cooling system, including the water pump’s impeller.

Inspecting Belts and Hoses Regularly

These components directly impact water pump performance.

- Check Condition: Periodically inspect the serpentine belt for cracks, fraying, or excessive wear. Ensure it has proper tension.

- Hose Integrity: Examine all radiator and heater hoses for cracks, bulges, or softness, which can indicate impending failure.

Monitoring Engine Temperatures

Being aware of your engine’s thermal performance can help catch issues early.

- Dash Gauge: Pay attention to your dashboard temperature gauge.

- Aftermarket Monitors: Consider investing in an aftermarket monitor (like an Edge Insight or similar) that can display live EOT and ECT data. This provides a much more precise picture of your cooling system’s health and can alert you to issues like a climbing EOT/ECT delta long before the dash gauge moves.

Addressing Minor Leaks Promptly

Don’t ignore small drips or coolant residue.

- Early Intervention: A minor leak from the water pump’s weep hole, a hose, or a connection should be addressed immediately. Small leaks can quickly become major ones and lead to significant coolant loss and potential overheating.

Common 6.0 Powerstroke Cooling Issues and Their Primary Indicators

To help solidify your understanding and assist in diagnosing 6.0 Powerstroke water pump issues versus other problems, here’s a quick reference table:

| Cooling System Component | Primary Symptoms | Key Differentiating Factor |

|---|---|---|

| Water Pump | Overheating, coolant leaks at weep hole, squealing or grinding noise from pump, decreased cabin heat. | Weep hole leak, specific mechanical noise from pump housing. |

| EGR Cooler | White smoke from exhaust (sweet smell), unexplained coolant loss (no external leak), coolant “puking” from degas bottle. | Exhaust smoke, no external leak, P040X codes possible. |

| Oil Cooler | High EOT/ECT delta (>15-20°F), sludgy coolant in degas bottle, slow coolant warm-up. | Significant EOT/ECT temperature difference (requires monitoring tool). |

| Thermostat | Engine taking very long to warm up (stuck open), or rapid, consistent overheating (stuck closed), inconsistent temperature readings. | Direct impact on engine warm-up time and stable operating temperature. |

| Fan Clutch | Overheating at idle or low speeds (improves at highway speeds), loud fan roar that doesn’t subside or no engagement when hot. | Specific to low speed/idle overheating, noticeable fan noise change. |

| Radiator | Overheating (especially under load), visible external leaks, low coolant flow, cold spots on radiator. | External leaks from core, visual damage to fins, or internal blockages. |

Conclusion

The 6.0 Powerstroke is a formidable engine, but like any complex machine, it demands attention to its vital systems. The water pump, though often overlooked until it fails, is an absolute cornerstone of its cooling system. Understanding the various water pump symptoms 6.0 Powerstroke owners should watch for, and having a systematic approach to diagnosing 6.0 Powerstroke water pump failure, empowers you to act decisively.

Whether you choose to tackle the repair yourself or enlist the help of a professional, swift and accurate diagnosis of 6.0 Powerstroke cooling problems, particularly those related to the water pump, is crucial. Ignoring the early signs can lead to far more severe and costly engine damage. By staying vigilant, performing regular maintenance, and addressing issues promptly, you can significantly extend the life of your 6.0 Powerstroke and keep it running strong for years to come. Don’t let a failing water pump leave you stranded; equip yourself with knowledge and take control of your truck’s health.

🎥 Related Video: Fixing 6.0L Pattern Failures – Episode 4: Water Pump

📺 BulletProofDiesel

Our video series with Diesel World Magazine continues – this time, we look at the water pump in the 6.0L – which has a plastic …

Frequently Asked Questions

What are the common symptoms of a 6.0 Powerstroke water pump failure?

The most noticeable symptoms include engine overheating, especially under load or at idle, and a visible coolant leak from the front of the engine, often near the accessory belts. You might also hear a grinding, squealing, or whining noise from the water pump area as its bearings begin to fail.

How can I confirm if my 6.0 Powerstroke water pump has failed?

A visual inspection for coolant leaks around the water pump housing, particularly from the weep hole, is crucial. You can also check for excessive play in the water pump pulley by gently wiggling it, and observe coolant circulation in the degas bottle to ensure proper flow.

Is water pump failure a common issue on the 6.0 Powerstroke engine?

While not as notorious as some other 6.0 Powerstroke issues, water pump failure is a known wear item that can occur due to age, mileage, or a faulty component. Regular coolant maintenance and timely replacement are important for preventing such failures.

What are the potential causes of a 6.0 Powerstroke water pump failure?

Common causes include worn-out internal bearings, a leaking shaft seal, or a corroded impeller. These issues can be exacerbated by neglected coolant changes, which can lead to contaminants and premature wear on the water pump’s components.

Can I still drive my 6.0 Powerstroke if I suspect a water pump failure?

It is strongly advised not to drive your 6.0 Powerstroke with a suspected water pump failure. Continuing to drive can quickly lead to severe engine overheating, causing catastrophic and expensive damage such as blown head gaskets, a cracked block, or damaged cylinder heads.

What diagnostic methods are best for identifying a 6.0 Powerstroke water pump problem?

Start with a thorough visual inspection for coolant leaks and signs of bearing play in the pulley. A cooling system pressure test can help pinpoint external leaks, and monitoring engine temperatures with an OBD-II scanner can confirm overheating patterns linked to the water pump.