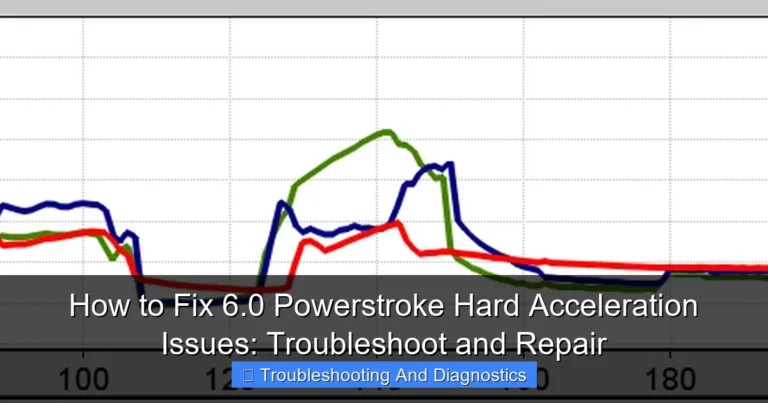

Diagnosing 6.0 Powerstroke High Exhaust Gas Temperature: Causes and Fixes

Featured image for this comprehensive guide about Diagnosing 6.0 Powerstroke high exhaust gas temperature

Image source: nesstech.co.in

The roar of a 6.0 Powerstroke engine is music to many diesel enthusiasts’ ears, signifying raw power and reliability. However, even the most robust engines have their Achilles’ heel, and for the 6.0 Powerstroke, keeping an eye on exhaust gas temperature (EGT) is paramount. A sudden or sustained surge in EGT can be more than just a warning light; it’s a distress signal from your engine, indicating underlying issues that could lead to catastrophic failure if left unaddressed. Understanding and promptly diagnosing 6.0 Powerstroke high exhaust gas temperature is not just good practice; it’s essential for the longevity and performance of your truck.

High EGT in a diesel engine, especially the sophisticated 6.0 Powerstroke, signifies that the combustion process is producing excessive heat, or that this heat isn’t being managed properly. This isn’t just about uncomfortable cabin temperatures; it’s about the very integrity of critical engine components. From melting pistons and cracking cylinder heads to destroying turbochargers and catalytic converters, the consequences of ignoring elevated EGT can be financially devastating. This comprehensive guide will arm you with the knowledge to understand, identify, and address the common causes of high EGT in your 6.0 Powerstroke, ensuring your beloved truck stays on the road for years to come.

Whether you’re a seasoned diesel mechanic or a truck owner looking to be more proactive in maintaining your vehicle, this post is designed to walk you through the complexities of 6.0 Powerstroke EGT issues. We’ll delve into the science behind EGT, explore the tell-tale symptoms, uncover the most frequent culprits, and provide actionable, step-by-step diagnostic and repair strategies. Get ready to gain the insights needed to protect your investment and keep your 6.0 Powerstroke running cool and strong.

Quick Answers to Common Questions

What are the main signs I might have high exhaust gas temperature on my 6.0 Powerstroke?

You might notice reduced power, poor fuel economy, a hotter-than-usual engine compartment, or even a burning smell. An EGT gauge, if installed, will directly show elevated readings, often exceeding safe limits during normal driving or towing.

Why is my 6.0 Powerstroke experiencing high exhaust gas temperature?

Common culprits for a high exhaust gas temperature on a 6.0 Powerstroke include issues with the Exhaust Gas Recirculation (EGR) system, a failing turbocharger, clogged injectors, or even a restricted exhaust. Each of these can lead to inefficient combustion and increased heat.

Is high exhaust gas temperature dangerous for my 6.0 Powerstroke?

Absolutely! Consistently high exhaust gas temperature can cause severe damage to critical components like the turbocharger, exhaust valves, and even melt pistons. It’s a clear sign of an underlying problem that needs immediate attention to prevent costly repairs.

What’s the very first thing I should check when diagnosing high exhaust gas temperature?

A great starting point for diagnosing high exhaust gas temperature is to check for any diagnostic trouble codes (DTCs) using an OBD-II scanner. Also, visually inspect your exhaust system for any obvious restrictions or leaks, and ensure your air filter isn’t clogged.

Can I continue driving my 6.0 Powerstroke if I suspect high exhaust gas temperature?

It’s strongly advised not to continue driving with suspected high exhaust gas temperature for extended periods. This can quickly escalate minor issues into catastrophic engine failure. Address the problem promptly to protect your investment.

📋 Table of Contents

- Understanding Exhaust Gas Temperature (EGT) and Its Critical Role in the 6.0 Powerstroke

- Recognizing the Warning Signs: Symptoms of High EGT in Your 6.0 Powerstroke

- Uncovering the Root Causes: Why Your 6.0 Powerstroke EGT is Soaring

- A Systematic Approach: Step-by-Step Diagnosis of High EGT Issues

- Fixing and Preventing: Comprehensive Solutions for High EGT in Your 6.0 Powerstroke

- Conclusion: Keeping Your 6.0 Powerstroke Cool and Running Strong

Understanding Exhaust Gas Temperature (EGT) and Its Critical Role in the 6.0 Powerstroke

Exhaust Gas Temperature (EGT) is a measurement of the temperature of the exhaust gases exiting the combustion chambers of your engine. In a diesel engine like the 6.0 Powerstroke, EGT is a direct indicator of the efficiency of the combustion process and the thermal load on various engine components. Monitoring EGT is crucial because diesel engines operate under high compression and generate significant heat, especially under load.

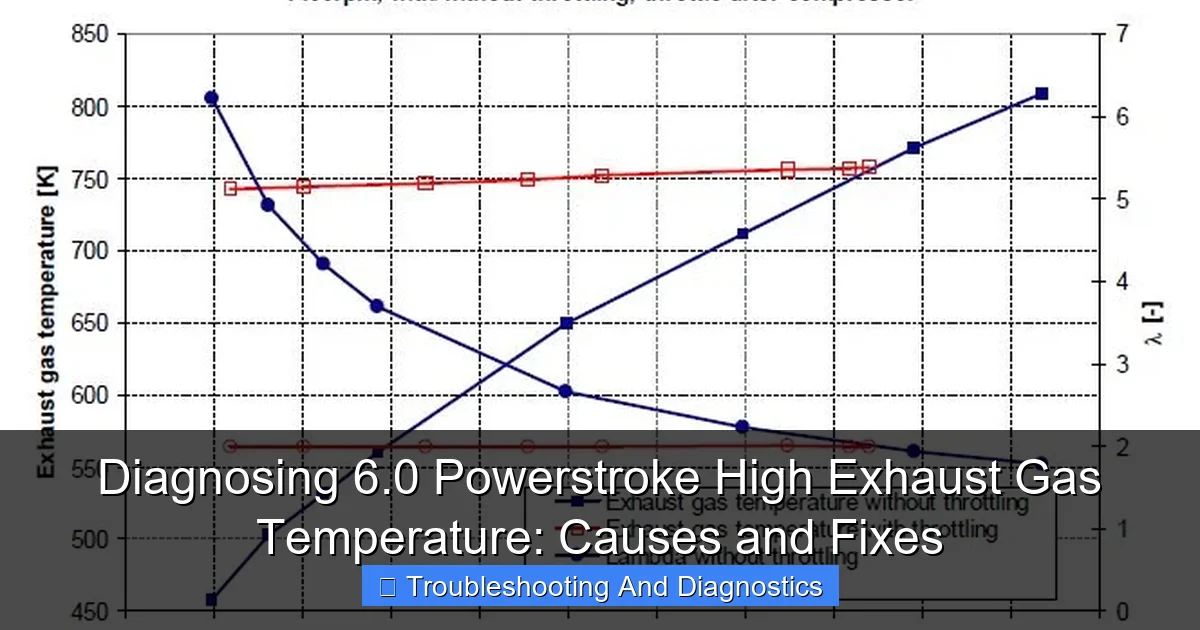

Learn more about Diagnosing 6.0 Powerstroke high exhaust gas temperature – Diagnosing 6.0 Powerstroke High Exhaust Gas Temperature: Causes and Fixes

Image source: vert-certification.eu

Why EGT Matters So Much for Your 6.0 Powerstroke

The 6.0 Powerstroke is known for its robust design, but also for its sensitivity to certain operating conditions. High EGT can lead to a cascade of problems, impacting everything from fuel efficiency to engine longevity. Sustained high temperatures can cause material fatigue and failure in components designed to withstand only certain heat limits. For instance, the ceramic turbine housing of the variable geometry turbocharger (VGT) can crack, piston crowns can melt, and exhaust valves can warp, leading to significant engine damage.

| Symptom/Observation | Potential Cause | Diagnostic Action |

|---|---|---|

| Sustained EGTs > 1250°F (675°C) under load | Over-fueling, under-boosting, excessive exhaust restriction, faulty EGT sensor | Monitor MAP, BARO, EBP, FICM, and injector data via scan tool. Check for related DTCs. Verify EGT sensor accuracy. |

| Black or excessive smoke, reduced power, high EGTs | Failed fuel injector(s), restricted air intake/filter, sticking VGT turbo vanes, low fuel pressure | Perform cylinder contribution test. Inspect air filter. Check fuel pressure (idle/WOT). Inspect turbo for binding/carbon. |

| Check Engine Light (CEL) with codes like P0299 (Underboost) or P0401 (EGR Flow Insufficient) | VGT turbocharger issues, exhaust leaks, clogged EGR cooler/valve, boost leaks | Diagnose turbo control system (VGT solenoid/actuator). Inspect exhaust for leaks. Clean/replace EGR components. Perform boost leak test. |

| High EGTs during heavy towing or sustained climbs, poor throttle response | Restricted exhaust system (e.g., clogged catalytic converter), tuner calibration issues, excessive load for vehicle setup | Inspect exhaust for restrictions (e.g., backpressure test). Review aftermarket tuner settings. Ensure proper gearing/load management. |

| Coolant loss or overheating symptoms accompanying high EGTs | EGR cooler leak (internal or external), blown head gasket, restricted coolant flow | Pressure test cooling system. Perform EGR cooler bypass test. Check for exhaust gases in coolant or coolant in exhaust/oil. |

Normal EGT ranges for a stock 6.0 Powerstroke typically hover between 600-900°F (315-480°C) during cruising and light acceleration, and can briefly peak up to 1200-1300°F (650-705°C) during heavy towing or hard acceleration. However, sustained temperatures above 1350°F (730°C) are generally considered dangerous and require immediate attention. Aftermarket gauges are often installed by owners to provide real-time EGT readings, as factory instrumentation typically doesn’t include a dedicated EGT gauge.

The Dangers of Sustained High EGT

- Turbocharger Damage: The VGT turbocharger is highly susceptible to extreme heat. High EGT can cause the turbine housing to crack, damage the seals, or seize the VGT unison ring, leading to boost issues and further EGT problems.

- Piston Damage: Excessive heat can melt the aluminum piston crowns, particularly around the injector spray pattern, leading to reduced compression, oil consumption, and severe engine damage.

- Valve Damage: Exhaust valves operate in a high-temperature environment. Sustained high EGT can cause valves to warp, burn, or lose their seating integrity, resulting in compression loss and misfires.

- Catalytic Converter & DPF Issues: If your 6.0 Powerstroke is equipped with a catalytic converter (and/or a DPF in later applications), extremely high EGT can damage the internal matrix, leading to blockages and further restriction.

- Head Gasket Issues: While high coolant temperature is more directly related to head gasket failure, the overall thermal stress from sustained high EGT can contribute to the weakening of cylinder head bolts and gaskets, increasing the risk of failure.

- Reduced Engine Life: In general, running any engine consistently at the upper limits of its thermal tolerance will accelerate wear and significantly shorten its overall lifespan.

Recognizing the Warning Signs: Symptoms of High EGT in Your 6.0 Powerstroke

Before you even hook up a diagnostic tool, your 6.0 Powerstroke will often exhibit symptoms that point towards elevated EGT. Being observant and understanding these signs can help you identify a problem early, potentially saving you from costly repairs. The most obvious indicator, of course, is an aftermarket EGT gauge displaying readings consistently above normal operating ranges, especially during periods of light load.

Learn more about Diagnosing 6.0 Powerstroke high exhaust gas temperature – Diagnosing 6.0 Powerstroke High Exhaust Gas Temperature: Causes and Fixes

Image source: i0.wp.com

Common Symptoms to Watch For:

- Visible Exhaust Smoke:

- Black Smoke: Often indicates an overly rich fuel mixture, meaning too much fuel for the available air. This incomplete combustion directly leads to higher EGT.

- White Smoke (especially during acceleration/under load): Can indicate fuel not burning completely, possibly due to injector issues or a lack of cylinder compression, both of which can contribute to higher combustion temperatures or unburnt fuel heating up in the exhaust.

- Loss of Power or Poor Acceleration: When EGT is too high, the engine’s computer (PCM) may de-fuel the engine to protect components, resulting in a noticeable reduction in power and sluggish acceleration. You might feel the truck “pulling back” under heavy throttle.

- Excessive Heat Under the Hood: While normal operation generates heat, an unusually hot engine bay, especially after light use, could suggest the engine is running hotter than it should be, affecting all systems, including exhaust.

- Unusual Engine Noises:

- Knocking or Pinging: Could indicate severe pre-ignition or detonation due to hot spots, often linked to extremely high combustion temperatures.

- Turbo Whine (excessive): While turbos do whine, an unusually loud or different pitch of whine might indicate the turbocharger is being overworked or damaged by heat.

- Poor Fuel Economy: An engine running rich (too much fuel) to compensate for other issues that cause high EGT will inherently consume more fuel.

- Check Engine Light (CEL) Illumination: While not specific to EGT, various sensor failures or system malfunctions that lead to high EGT can trigger a CEL. A scan tool will be necessary to retrieve Diagnostic Trouble Codes (DTCs).

- Unusual Odors: A distinct smell of unburnt fuel or an overly rich exhaust smell can indicate combustion issues that contribute to high EGT.

It’s important to note that many of these symptoms can overlap with other engine problems. However, when observed in conjunction with high EGT readings (if you have a gauge), they collectively point towards a critical need for diagnosing 6.0 Powerstroke high exhaust gas temperature problems.

Uncovering the Root Causes: Why Your 6.0 Powerstroke EGT is Soaring

Diagnosing 6.0 Powerstroke high exhaust gas temperature requires a systematic approach, as numerous factors can contribute to the problem. Fundamentally, high EGT is caused by either too much fuel for the available air (rich condition), restricted exhaust flow, or inefficiencies in the combustion or cooling process. Let’s break down the most common culprits.

Fuel System Issues

The fuel system is often at the heart of high EGT in a 6.0 Powerstroke because improper fueling directly impacts combustion efficiency.

- Clogged Fuel Filters: Restricted fuel flow due to dirty filters (both the frame-mounted and engine-mounted filters) can lead to insufficient fuel pressure at the injectors, causing them to spray inefficiently or not deliver enough fuel for complete combustion.

- Faulty Fuel Injectors:

- Sticking/Worn Injectors: A common issue on the 6.0 Powerstroke. Injectors that are “stuck open” or have a poor spray pattern can dump too much fuel into the cylinder, leading to incomplete combustion and high EGT, often accompanied by black smoke.

- Clogged Injectors: Conversely, partially clogged injectors might not deliver enough fuel or spray it unevenly, leading to misfires and inefficient burning.

- Low Fuel Pressure (HFCM, FICM, Standpipes/Dummy Plugs): The High-Pressure Fuel Pump (HPFP) system relies on a consistent supply of low-pressure fuel. Issues with the Horizontal Fuel Conditioning Module (HFCM) or the Fuel Injection Control Module (FICM) voltage can indirectly affect injector performance and lead to combustion issues and increased EGT. Leaks in the standpipes or dummy plugs within the cylinder heads can also cause low oil pressure to the injectors, impairing their function.

- Fuel Quality: Poor quality fuel or contaminated fuel can burn inefficiently, raising EGT.

Air System Restrictions & Turbocharger Malfunctions

The engine needs a precise amount of clean air to burn fuel efficiently. Any restriction or malfunction here will inevitably raise EGT.

- Clogged Air Filter: A dirty air filter restricts airflow into the turbocharger, leading to an air-starved engine and a rich condition, which is a classic cause of high EGT.

- Boost Leaks: Leaks in the intercooler pipes, boots, or CAC (Charge Air Cooler) itself allow pressurized air to escape, meaning less air reaches the engine. This creates a rich condition and results in high EGT.

- Turbocharger Issues (VGT Actuator/Unison Ring): The 6.0 Powerstroke’s variable geometry turbocharger (VGT) is designed to optimize boost across the RPM range.

- Sticking VGT Unison Ring: Carbon buildup can cause the unison ring to stick, preventing the turbo from efficiently spooling up or maintaining boost. This leads to insufficient air and a rich condition, causing EGT to climb.

- Faulty VGT Solenoid/Actuator: A malfunctioning solenoid or electronic actuator can prevent the VGT vanes from moving correctly, similar to a stuck unison ring.

EGR System Malfunctions

The Exhaust Gas Recirculation (EGR) system helps reduce NOx emissions, but when it fails, it can drastically impact engine performance and EGT.

- Stuck Open EGR Valve: If the EGR valve gets stuck in the open position, it will continuously route exhaust gases back into the intake manifold, even when not required. This displaces fresh, oxygen-rich air with hot, inert exhaust gas, leading to a lean burn, loss of power, and significantly higher EGT.

- Clogged EGR Cooler: The EGR cooler is designed to cool exhaust gases before they re-enter the engine. If it’s clogged with soot, it restricts exhaust flow and can cause the EGR valve to receive hotter than normal gases, impacting its operation or leading to internal leaks and coolant consumption, which can also affect overall thermal management.

Exhaust System Restrictions

Anything that impedes the free flow of exhaust gases out of the engine will increase back pressure and raise EGT.

- Clogged Catalytic Converter: The catalytic converter can become clogged with soot or partially melt if the engine has been running rich for an extended period. This creates a significant restriction, trapping hot exhaust gases and causing EGT to rise dramatically.

- Aftermarket Exhaust Systems: While generally designed for better flow, some poorly designed aftermarket systems or damaged components within them can create restrictions.

Sensor Malfunctions

The PCM relies on accurate data from various sensors to manage fuel delivery and air intake. Faulty sensors can lead to incorrect calculations and contribute to high EGT.

- EGT Sensor Malfunction: While the sensor itself doesn’t cause high EGT, a faulty EGT sensor could provide inaccurate readings, causing the PCM to incorrectly de-fuel or, worse, giving you a false sense of security while actual EGTs are dangerously high.

- MAP (Manifold Absolute Pressure) Sensor & MAF (Mass Air Flow) Sensor: These sensors measure air density and flow. A dirty or faulty MAP/MAF sensor can provide incorrect air readings, leading the PCM to inject the wrong amount of fuel, causing a rich condition and high EGT.

- IAT (Intake Air Temperature) Sensor: Incorrect temperature readings can impact fuel calculations.

A Systematic Approach: Step-by-Step Diagnosis of High EGT Issues

When faced with diagnosing 6.0 Powerstroke high exhaust gas temperature, a logical, step-by-step approach is critical. Rushing to replace parts without proper diagnosis can be expensive and frustrating.

Step 1: Initial Visual Inspection and Basic Checks

Start with the simple things. They often yield the quickest solutions.

- Check Fluid Levels: Ensure coolant and oil levels are correct. While not a direct EGT cause, low fluids can cause overall engine overheating, which can indirectly contribute to EGT.

- Inspect Air Filter: Remove and check the air filter for excessive dirt or blockage. Replace if necessary.

- Examine Charge Air Cooler (CAC) Boots and Pipes: Look for cracks, tears, or loose clamps. A common source of boost leaks. Squeeze the boots to feel for integrity.

- Listen for Leaks: With the engine running, listen for any hissing sounds indicative of boost or exhaust leaks.

- Observe Exhaust Smoke: Note the color and consistency of exhaust smoke.

Step 2: Utilize a Diagnostic Scan Tool (Essential for 6.0 Powerstroke)

A capable scan tool (like FORScan, AutoEnginuity, or a high-end professional scanner) is invaluable for diagnosing 6.0 Powerstroke high exhaust gas temperature. It allows you to read Diagnostic Trouble Codes (DTCs) and, crucially, monitor live data.

Key Parameters to Monitor (Live Data):

- EGT (Exhaust Gas Temperature): If equipped with an aftermarket sensor or if the PCM monitors it, observe real-time EGT values.

- MAP (Manifold Absolute Pressure): Compare actual boost pressure to desired boost pressure. A significant difference often indicates boost leaks or turbo issues.

- MAF (Mass Air Flow): Check for realistic airflow values. A dirty MAF can read low.

- Fuel Pressure (Low Pressure Side): Crucial for the 6.0 Powerstroke. Ideally, you want to see ~50-70 PSI at idle and under load. Drops below 45 PSI are problematic.

- ICP (Injection Control Pressure) & IPR (Injection Pressure Regulator) Duty Cycle: ICP should build quickly and consistently. High IPR duty cycle (above 70%) to maintain ICP can indicate leaks in the high-pressure oil system (dummy plugs, standpipes, HPOP).

- FICM (Fuel Injection Control Module) Voltage: Ensure FICM main power is consistently at or above 48V. Lower voltage can cause injectors to fire inefficiently.

- EGR Valve Position/Duty Cycle: Monitor if the EGR valve is opening and closing as commanded. Perform a functional test if available.

- Injector Contribution Test: Many scan tools can perform an injector contribution test to identify weak or dead cylinders, which can contribute to uneven combustion and high EGT.

Data Table: Sample 6.0 Powerstroke Diagnostic Parameters (Approximate Values)

| Parameter | Normal Idle Range | Normal Under Load (WOT) Range | Potential High EGT Implication |

|---|---|---|---|

| EGT (Post-Turbo) | 600-900°F (315-480°C) | 1100-1300°F (590-705°C) | Sustained >1350°F: Critical danger |

| Low-Pressure Fuel Pressure | 45-70 PSI | 45-70 PSI | <45 PSI: Fuel starvation, injector issues |

| MAP Sensor (Boost) | 0-1 PSI (relative to atmosphere) | 20-28 PSI | Low/no boost: Air starvation, rich burn |

| FICM Voltage | 47.5-49.0 V | 47.5-49.0 V | <45V: Injector misfire/poor performance |

| ICP Pressure | 500-750 PSI | 2500-4000 PSI | Low/slow to build: HPO system issue |

| IPR Duty Cycle | 20-30% | 60-80% | Consistently >70%: HPO system leak |

| EGR Valve Position | 0-5% (closed) | 10-70% (open, variable) | Stuck open: Excessive exhaust recirculation |

Step 3: Component-Specific Testing

- Fuel Pressure Test (Manual Gauge): While a scan tool can read the sensor, a mechanical fuel pressure gauge directly connected to the fuel rail provides the most accurate reading of actual low-pressure fuel delivery. This is crucial for diagnosing 6.0 Powerstroke high exhaust gas temperature related to fueling.

- Injector Buzz Test/Contribution Test: Use your scan tool to perform these tests. A buzz test can identify injectors that are not responding, while a contribution test helps pinpoint weak or dead cylinders.

- Turbocharger VGT Actuator Test: If your scan tool allows, command the VGT actuator through its full range of motion. Listen for smooth operation and observe boost readings. A sticky unison ring might be felt as resistance or heard as grinding.

- EGR Valve Removal/Inspection: If live data suggests an issue, physically remove and inspect the EGR valve for carbon buildup or if it’s stuck open/closed.

- Boost Leak Test: This involves pressurizing the intake system (usually after the turbo and before the engine) with compressed air and listening for leaks with soapy water. This is vital for finding those hidden boost leaks.

- Exhaust Back Pressure Test: If a clogged catalytic converter is suspected, an exhaust back pressure test (usually done by tapping into an EGT port before the cat) can confirm if there’s excessive restriction.

Fixing and Preventing: Comprehensive Solutions for High EGT in Your 6.0 Powerstroke

Once you’ve successfully completed diagnosing 6.0 Powerstroke high exhaust gas temperature and pinpointed the cause, it’s time for the fix. Addressing these issues not only resolves the immediate EGT problem but also contributes to the overall health and longevity of your engine. Prevention is key to avoiding recurrence.

Addressing the Root Causes:

- Fuel System Repairs:

- Replace Fuel Filters: Adhere to Ford’s recommended service intervals (10,000-15,000 miles or 6 months) for both the frame-mounted and engine-mounted filters. Use quality OEM or equivalent filters.

- Injector Replacement/Repair: If faulty injectors are identified, they must be replaced. Consider genuine Ford OEM injectors or reputable remanufactured units for best results. Address the underlying cause of injector failure if possible (e.g., low fuel pressure, poor quality fuel).

- Address Low Fuel Pressure: This could involve replacing the HFCM pump, checking for clogged screens in the fuel tank, or addressing issues with standpipes/dummy plugs if they are leaking.

- Air System & Turbocharger Fixes:

- Replace Air Filter: Use a high-quality filter designed for your 6.0 Powerstroke.

- Repair Boost Leaks: Replace cracked CAC boots, tighten clamps, or repair/replace a leaky intercooler.

- Turbocharger Service/Replacement: If the VGT unison ring is sticky, a turbo cleaning service can often resolve the issue. If the VGT solenoid or actuator is faulty, it will need replacement. In severe cases of damage, the turbocharger itself may need to be replaced.

- EGR System Solutions:

- EGR Valve Cleaning/Replacement: A carbon-fouled EGR valve can often be cleaned. If it’s internally faulty, it will need to be replaced.

- EGR Cooler Repair/Replacement: If the cooler is clogged, it can be flushed, or if it’s leaking, it must be replaced. Upgraded aftermarket EGR coolers are available that are more resistant to failure.

- EGR Delete (Off-Road Use Only): In some regions and for off-road use only, an EGR delete kit can be installed. This removes the entire EGR system, eliminating potential failure points and often reducing EGT. However, this is illegal for on-road use in most jurisdictions due to emissions regulations.

- Exhaust System Repairs:

- Catalytic Converter Replacement: If the catalytic converter is confirmed to be clogged, it must be replaced to restore proper exhaust flow.

- Sensor Replacements:

- Replace Faulty Sensors: If the EGT sensor, MAP, MAF, or IAT sensors are providing inaccurate readings, replace them with OEM or high-quality aftermarket equivalents.

Preventative Measures and Best Practices:

Preventing high EGT in your 6.0 Powerstroke is far easier and cheaper than fixing it. Regular maintenance and mindful driving are your best defense.

- Adhere to Strict Maintenance Schedules:

- Fuel Filters: Replace every 10,000-15,000 miles. This is arguably the most critical maintenance item for the 6.0.

- Air Filters: Inspect regularly and replace as needed, typically every 15,000-30,000 miles or annually.

- Oil Changes: Use quality synthetic oil and adhere to recommended intervals (5,000-7,500 miles). Clean oil helps the turbo and injectors.

- Coolant System: Flush and refill with the correct Ford-specified coolant every 50,000-100,000 miles.

- Install an Aftermarket EGT Gauge: This is a highly recommended modification for any 6.0 Powerstroke owner, especially if you tow or have performance modifications. It provides real-time data, allowing you to react quickly to rising temperatures before damage occurs.

- Monitor Driving Habits:

- Cool Down Turbo: After periods of heavy load or high-speed driving, allow the engine to idle for a few minutes before shutting it off. This allows the turbocharger to cool down slowly, preventing oil coking and prolonging its life.

- Avoid “Lugging” the Engine: Operating at low RPMs under heavy load can cause EGT to climb rapidly. Downshift to keep RPMs in a more efficient range (e.g., 2000-2500 RPM for towing).

- Consider Quality Performance Tuning (with caution): If you opt for aftermarket tunes, choose reputable tuners known for safe and effective programming. Aggressive tunes without proper supporting modifications or monitoring can significantly increase EGT. Always monitor EGT carefully with any tune.

- Use Fuel Additives: High-quality diesel fuel additives can help keep injectors clean, improve lubricity, and reduce carbon buildup in the EGR system, all contributing to more efficient combustion and lower EGT.

Conclusion: Keeping Your 6.0 Powerstroke Cool and Running Strong

Diagnosing 6.0 Powerstroke high exhaust gas temperature is a critical skill for any owner of this powerful diesel engine. High EGT is not merely an inconvenience; it’s a severe warning that, if ignored, can lead to devastating engine damage, costing you thousands in repairs. By understanding the underlying causes—from simple clogged filters to complex injector or turbocharger issues—and employing a systematic diagnostic approach, you can pinpoint and address the problem effectively.

Remember, prevention is always better than cure. Adhering to strict maintenance schedules, installing an aftermarket EGT gauge for real-time monitoring, and adopting mindful driving habits are your best defenses against soaring EGT. Your 6.0 Powerstroke is a formidable machine, and with the right care and attention to its exhaust gas temperatures, it will continue to serve you faithfully, delivering power and reliability for countless miles to come. Stay vigilant, stay informed, and keep your Powerstroke running cool.

🎥 Related Video: 🚨 DPF Blockage Alert: Faulty Exhaust Temperature Sensor Detected 🚨 💨 #ytshorts #car #ford #dpf

📺 Life Behind Cars

Where is the front airbag crash sensor on a Alfa Romeo Giulietta Lusso Jtdm-2 Diesel 2011 1956cc.

Frequently Asked Questions

What are the common symptoms of high exhaust gas temperature (EGT) in a 6.0 Powerstroke?

Symptoms can include a noticeable loss of power, reduced fuel economy, and a strong smell of exhaust. You might also observe excessive black smoke from the tailpipe, especially under acceleration or heavy load.

Why is my 6.0 Powerstroke experiencing high EGT, and what are the main causes?

Common causes for high EGT in a 6.0 Powerstroke include a restricted exhaust system (like a clogged catalytic converter), faulty fuel injectors, or a failing turbocharger. Issues with the EGR system, such as a sticking EGR valve, can also contribute to elevated temperatures.

How can high exhaust gas temperature impact my 6.0 Powerstroke engine?

Sustained high EGT can severely damage critical engine components, including the turbocharger, exhaust manifold, and even the cylinder heads. It can lead to premature wear, cracking, and ultimately, costly engine failures if not addressed promptly.

What is a normal operating range for 6.0 Powerstroke EGTs, and how can I monitor them?

Typically, normal unloaded cruising EGTs should be below 800-900°F, while under heavy load, they might peak between 1200-1350°F briefly. You can monitor EGTs using an aftermarket EGT gauge with a thermocouple installed pre-turbo.

What are the typical fixes for resolving high exhaust gas temperature issues in a 6.0 Powerstroke?

Resolving high EGT often involves inspecting and potentially replacing components like restricted exhaust parts (catalytic converter/DPF), faulty fuel injectors, or the turbocharger. Cleaning or replacing the EGR valve and cooler can also be a crucial step.

Can I continue to drive my 6.0 Powerstroke if I suspect it has high EGT?

It is not recommended to continue driving your 6.0 Powerstroke with suspected high EGT, as it can quickly lead to severe and expensive engine damage. If you notice symptoms, reduce load, drive conservatively, and have the issue diagnosed and repaired as soon as possible.