Diagnosing 6.0 Powerstroke Fuel Pressure Regulator Issues: Quick Solutions

Featured image for this comprehensive guide about Diagnosing 6.0 Powerstroke fuel pressure regulator issues

Image source: cruzetalk.com

The roar of a 6.0 Powerstroke engine is a symphony to many truck enthusiasts, but sometimes that powerful hum can turn into a troublesome grumble. If you own a Ford truck equipped with the legendary, albeit sometimes infamous, 6.0 Powerstroke diesel engine, you’re likely familiar with its quirks. While these engines are capable of incredible performance and longevity when properly maintained, they also have a reputation for specific issues that, if not addressed promptly, can lead to significant headaches. Among the most critical components that can throw a wrench into your truck’s smooth operation is the fuel pressure regulator (FPR).

A failing 6.0 Powerstroke fuel pressure regulator can manifest in a range of frustrating symptoms, from frustrating hard starts and rough idling to a noticeable loss of power and even a complete no-start condition. Diagnosing these issues quickly and accurately isn’t just about getting your truck back on the road; it’s about preventing further damage to other, more expensive components within your complex 6.0 Powerstroke fuel system. This comprehensive guide will equip you with the knowledge and actionable steps needed to confidently diagnose and understand 6.0 Powerstroke fuel pressure regulator issues, helping you keep your beast running strong and reliable.

Whether you’re a seasoned DIY mechanic or just starting to dive into the intricacies of your diesel truck, understanding the function of the FPR and how to identify its failures is a crucial skill. We’ll break down the symptoms, walk you through diagnostic procedures, and even help you differentiate FPR problems from other common 6.0 Powerstroke fuel problems. Get ready to arm yourself with the insights needed to conquer those pesky 6.0 Powerstroke fuel issues once and for all.

Quick Answers to Common Questions

What are the common symptoms of a failing 6.0 Powerstroke fuel pressure regulator?

You might notice hard starting (especially when warm), rough idle, lack of power, or even stalling. These are classic signs that your 6.0 Powerstroke fuel pressure regulator might be struggling.

How do I check the fuel pressure on my 6.0 Powerstroke to diagnose regulator issues?

You’ll need a fuel pressure gauge that connects to the Schrader valve on the secondary fuel filter housing. Connect it and monitor the pressure while the engine is running to assess your 6.0 Powerstroke fuel pressure regulator’s performance.

What’s the ideal fuel pressure for a healthy 6.0 Powerstroke?

Ideally, your 6.0 Powerstroke should maintain around 45-70 PSI at idle. If it consistently drops below 40 PSI, your fuel pressure regulator or another fuel system component definitely needs attention.

Can a bad 6.0 Powerstroke fuel pressure regulator cause issues beyond just starting?

Absolutely! A faulty 6.0 Powerstroke fuel pressure regulator can lead to decreased power under load, poor throttle response, and even misfires, making your truck feel sluggish and unreliable.

Are there any quick visual checks I can do for my 6.0 Powerstroke fuel pressure regulator?

While a fuel pressure gauge is the most definitive tool, you can visually inspect the regulator (located on the secondary fuel filter housing) for any obvious fuel leaks or damage. A clean, dry area is a good start, but a proper pressure test is crucial for diagnosing 6.0 Powerstroke fuel pressure regulator issues.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Fuel System and the FPR’s Role

- Common Symptoms of a Failing 6.0 Powerstroke Fuel Pressure Regulator

- Step-by-Step Diagnostic Procedures for 6.0 Powerstroke FPR Issues

- Differentiating FPR Issues from Other 6.0 Fuel System Problems

- Solutions and Preventative Measures for 6.0 Powerstroke Fuel Pressure Regulator Problems

- DIY vs. Professional Help: When to Call the Experts for Your 6.0 Powerstroke

- Conclusion: Empowering Your 6.0 Powerstroke for the Long Haul

Understanding the 6.0 Powerstroke Fuel System and the FPR’s Role

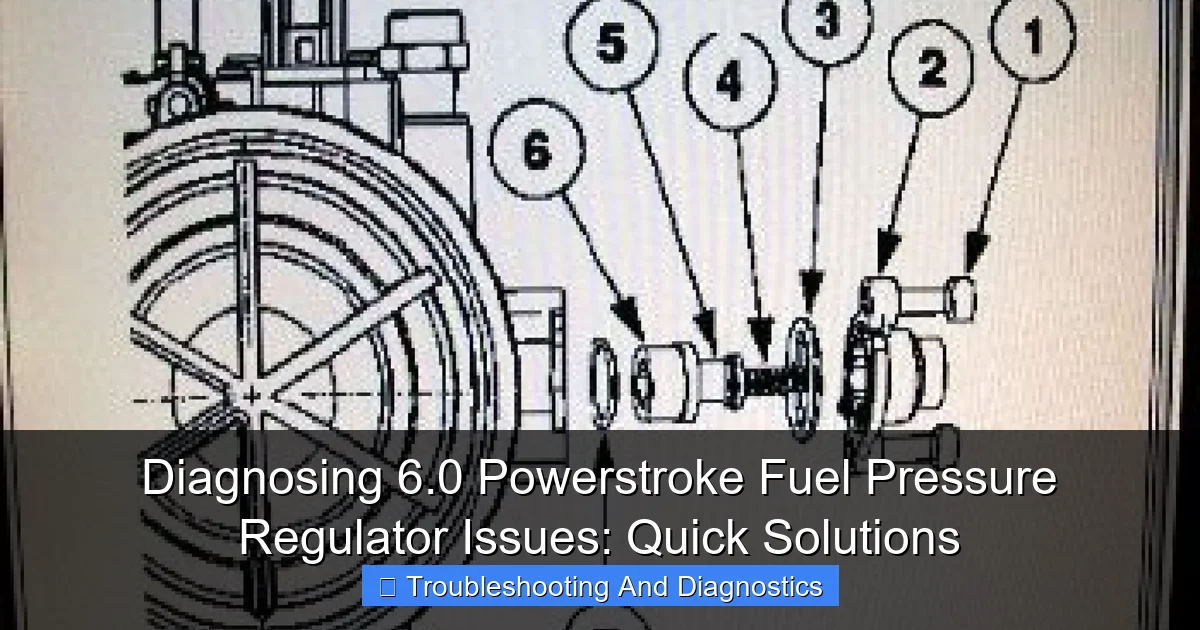

Before we can effectively diagnose a problem, it’s essential to understand how the system is designed to work. The 6.0 Powerstroke fuel system is a sophisticated network designed to deliver precisely metered, high-pressure fuel to the injectors. Unlike some simpler diesel engines, the 6.0 Powerstroke utilizes an HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, which relies on high-pressure oil to actuate the fuel injectors. However, the fuel delivery aspect is just as critical, and this is where the fuel pressure regulator plays its vital role.

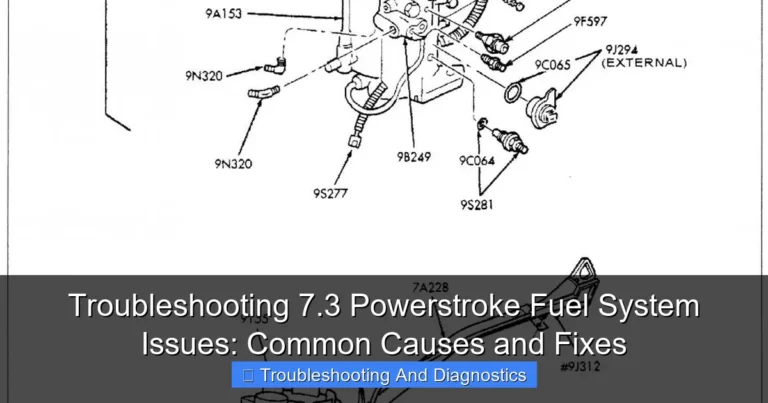

Learn more about Diagnosing 6.0 Powerstroke fuel pressure regulator issues – Diagnosing 6.0 Powerstroke Fuel Pressure Regulator Issues: Quick Solutions

Image source: diagraminfo.com

How the 6.0 Fuel System Works

Fuel in a 6.0 Powerstroke starts its journey from the tank, passes through a primary filter, and is then drawn by a low-pressure fuel pump (often frame-mounted) to the secondary fuel filter housing on top of the engine. After filtration, the fuel enters a manifold that supplies the injectors. It’s at this point that the FPR valve 6.0 Powerstroke comes into play. The system is designed to maintain a constant, optimal fuel pressure for the injectors, typically around 45-60 PSI. Any excess fuel is then returned to the tank.

| Diagnostic Parameter / Symptom | Normal / Expected Range | Indication of Faulty FPR |

|---|---|---|

| Key On Engine Off (KOEO) Fuel Pressure | 45-55 PSI (holds for >30 seconds) | <40 PSI, or rapid pressure drop after priming. |

| Engine Idling Fuel Pressure | 45-55 PSI (stable) | <45 PSI, erratic fluctuation, or significant drop. |

| Wide Open Throttle (WOT) Fuel Pressure | Maintains 50-70 PSI | Drops significantly (<45 PSI) or cannot reach target pressure under load. |

| Engine Performance | Smooth acceleration, good power | Lack of power, poor acceleration, rough idle, bucking under load. |

| Starting Characteristics | Starts quickly, no excessive cranking | Hard start, prolonged cranking, no-start condition. |

The Critical Function of the Fuel Pressure Regulator (FPR)

The fuel pressure regulator (FPR) in your 6.0 Powerstroke is an often-overlooked but absolutely crucial component. Its primary function is to maintain consistent fuel pressure within the secondary fuel filter housing, ensuring that the injectors always have enough fuel at the correct pressure to operate efficiently. This is paramount for proper combustion, optimal engine performance, and preventing damage to the injectors. The FPR is essentially a spring-loaded diaphragm valve that senses fuel pressure and opens or closes to either allow more fuel into the system or return excess fuel to the tank, thereby regulating the pressure. A failing 6.0 Powerstroke FPR can lead to either too much or too little fuel pressure, both of which are detrimental to engine health and performance.

Common Symptoms of a Failing 6.0 Powerstroke Fuel Pressure Regulator

Recognizing the symptoms of a faulty 6.0 Powerstroke fuel pressure regulator is the first step toward effective diagnosis and repair. These symptoms often mimic other fuel system or engine problems, making accurate identification critical. Pay close attention to how your truck behaves, especially during startup and under load.

Learn more about Diagnosing 6.0 Powerstroke fuel pressure regulator issues – Diagnosing 6.0 Powerstroke Fuel Pressure Regulator Issues: Quick Solutions

Image source: i.ytimg.com

Key Indicators of FPR Failure

- Hard Starts, Especially When Cold or After Sitting: This is one of the most common and frustrating symptoms. If your 6.0 Powerstroke cranks excessively before starting, or struggles to fire up after being parked for a while, a faulty FPR could be losing fuel prime, allowing pressure to bleed off when the engine is off.

- Rough Idle or Stalling: An inconsistent or unstable idle can indicate that the engine isn’t receiving a steady supply of fuel at the correct pressure. The engine might shake, stumble, or even stall, particularly when cold. This is a classic sign of an issue with the FPR valve 6.0 Powerstroke.

- Loss of Power or Poor Acceleration: When the FPR can’t maintain adequate fuel pressure, the injectors won’t deliver enough fuel, leading to a noticeable decrease in power, sluggish acceleration, and difficulty climbing hills or towing. Your truck might feel like it’s “bogging down.” This is a significant indicator of fuel pressure issues 6.0 Powerstroke.

- Excessive Smoke (Black or White): While black smoke often points to too much fuel and white smoke to unburnt fuel (or coolant), inconsistent fuel pressure from a failing FPR can contribute to both. Poor fuel atomization due to incorrect pressure can lead to incomplete combustion.

- Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs): While not always specific to the FPR, a failing FPR can trigger various fuel system-related codes. Common codes might include P0087 (Fuel Rail/System Pressure – Too Low), P0088 (Fuel Rail/System Pressure – Too High), or other general fuel system performance codes. It’s crucial to pull these codes with an OBD-II scanner.

- Engine Misfires or Hesitation: Similar to a rough idle, an engine that misfires or hesitates under acceleration indicates inconsistent fuel delivery, which can directly stem from an inability of the 6.0 Powerstroke fuel pressure regulator to maintain stable pressure.

If you’re experiencing one or more of these symptoms, it’s time to delve deeper into diagnosing the health of your 6.0 Powerstroke fuel pressure regulator.

Step-by-Step Diagnostic Procedures for 6.0 Powerstroke FPR Issues

Accurately diagnosing 6.0 Powerstroke fuel pressure regulator issues requires a methodical approach. The most definitive way to test the FPR is to directly measure the fuel pressure within the system. This section will guide you through the process, providing actionable steps and insights.

Tools Needed for Fuel Pressure Testing

- Fuel Pressure Gauge Kit: Specific for diesel, capable of reading 0-100+ PSI. Ensure it has the correct fittings for your 6.0 Powerstroke fuel filter housing.

- OBD-II Scanner: Capable of reading live data and pulling diagnostic trouble codes (DTCs).

- Basic Hand Tools: Wrenches, screwdrivers, etc., for accessing the fuel filter housing.

- Shop Rags: For containing any spilled fuel.

- Safety Glasses and Gloves: Always prioritize safety when working with fuel.

Performing the Fuel Pressure Test

This is the most critical step in diagnosing 6.0 Powerstroke fuel problems. The 6.0 Powerstroke fuel pressure test will tell you exactly what’s happening with the fuel pressure.

- Depressurize the Fuel System: Before disconnecting any fuel lines, it’s wise to depressurize the system. You can do this by removing the fuel pump relay or fuse and then cranking the engine for a few seconds until it dies.

- Locate the Secondary Fuel Filter Housing: This is on top of the engine, usually toward the front passenger side.

- Connect the Fuel Pressure Gauge: There should be a Schrader valve or a test port on the secondary fuel filter housing. Remove the cap and carefully attach your fuel pressure gauge. Ensure a tight, leak-free connection.

- Reinstall Fuel Pump Relay/Fuse: If you removed it in step 1.

- Cycle the Key (KOEO – Key On, Engine Off): Turn the ignition key to the “ON” position (do not start the engine). The fuel pump should prime for a few seconds. Observe the pressure reading on your gauge. It should build and then hold steady.

- Start the Engine and Monitor Pressure at Idle: Start the 6.0 Powerstroke and let it idle. Note the fuel pressure reading. A healthy 6.0 Powerstroke should typically show 45-60 PSI at idle.

- Test Under Load (Optional, but Recommended): If safe to do so, drive the truck and observe the fuel pressure under various load conditions (acceleration, highway cruising, uphill). The pressure should remain stable and within the recommended range. A significant drop in pressure under load is a strong indicator of a failing 6.0 Powerstroke fuel pressure regulator or a weak fuel pump.

- Check for Pressure Bleed-Off: After turning off the engine, observe how quickly the fuel pressure drops. A rapid drop to zero could indicate a leaking FPR or a check valve issue in the fuel pump, leading to hard starts 6.0 Powerstroke after sitting.

Interpreting Your Fuel Pressure Readings

Understanding what your gauge readings mean is key to 6.0 Powerstroke fuel system troubleshooting:

- Consistently Low Pressure (below 45 PSI): This is a strong indicator of a failing fuel pressure regulator 6.0 Powerstroke that is stuck open or a weak fuel pump not delivering enough volume.

- Intermittent Low Pressure, Especially Under Load: Points towards an FPR that struggles to maintain pressure when demand increases, or a fuel pump that can’t keep up.

- Fluctuating Pressure: Erratic readings can suggest a sticky FPR valve or debris in the system.

- Pressure Bleed-Off: If pressure drops significantly after the engine is off, the FPR might not be holding prime, leading to extended cranking.

- Consistently High Pressure (above 65 PSI): Less common, but can indicate an FPR that is stuck closed, preventing excess fuel from returning to the tank.

Data Table: Expected 6.0 Powerstroke Fuel Pressure Readings

Here’s a quick reference for ideal fuel pressure values in a healthy 6.0 Powerstroke:

| Condition | Expected Fuel Pressure (PSI) | Potential Issue (if outside range) |

|---|---|---|

| Key On, Engine Off (KOEO) Prime | 45-60 | Low: Fuel Pump, Clogged Filter, FPR High: Stuck FPR |

| Engine Idling | 45-60 | Low: Fuel Pump, Clogged Filter, FPR High: Stuck FPR |

| Under Load (Driving) | 45-60 (should remain stable) | Drop: Weak Fuel Pump, Clogged Filter, FPR Fluctuation: Sticking FPR |

| Engine Off (Pressure Hold) | Should hold for at least 30-60 seconds before slow bleed-off | Rapid Drop: Leaking FPR, Check Valve in Fuel Pump |

Differentiating FPR Issues from Other 6.0 Fuel System Problems

The 6.0 Powerstroke fuel system is complex, and many components can cause similar symptoms to a faulty FPR. It’s crucial to accurately pinpoint the problem to avoid unnecessary parts replacement and wasted effort. Here’s how to distinguish an FPR issue from other common 6.0 Powerstroke fuel problems.

Fuel Pump Failure

A weak or failing fuel pump will also cause low fuel pressure, leading to symptoms like hard starts, loss of power, and rough idle. However, a failing fuel pump typically produces consistently low pressure across all conditions, and often drops even further under load, whereas an FPR might show slightly better pressure at idle but struggle to hold it. If your fuel pressure is low, and your FPR is new or known good, the fuel pump is the next likely suspect. You can often hear a healthy fuel pump prime when you turn the key to the ‘on’ position.

Clogged Fuel Filters

The 6.0 Powerstroke has two fuel filters: a primary (frame-mounted) and a secondary (on-engine). Clogged filters restrict fuel flow, leading to low fuel pressure and similar performance issues. The key difference here is that a new FPR won’t fix a clogged filter. Always ensure your fuel filters are changed regularly according to Ford’s maintenance schedule, typically every 10,000-15,000 miles. If your fuel pressure is low and you haven’t changed filters recently, start there.

Injector Issues

Failing fuel injectors can cause rough idle, misfires, loss of power, and excessive smoke. However, injector issues generally won’t present with consistently low fuel pressure at the test port if the FPR and fuel pump are healthy. If your fuel pressure test passes, but you still have engine performance problems, look to the injectors. An OBD-II scanner capable of reading injector contribution tests can help here.

Stiction in HPOP/Injectors

The 6.0 Powerstroke uses high-pressure oil to actuate its injectors. If the High-Pressure Oil Pump (HPOP) is failing or if the injectors themselves suffer from “stiction” (oil-related sticking), you’ll experience hard starts (especially hot), rough idle, and loss of power. Again, a fuel pressure test will typically show good fuel pressure, indicating the fuel delivery side is fine, but the oil side (and thus injector firing) is the problem. Live data monitoring of ICP (Injector Control Pressure) and IPR (Injector Pressure Regulator) is crucial for diagnosing these issues.

By systematically checking your fuel pressure, considering recent maintenance, and using an OBD-II scanner, you can effectively narrow down whether your symptoms point specifically to the 6.0 Powerstroke fuel pressure regulator or another part of the complex fuel and oil system.

Solutions and Preventative Measures for 6.0 Powerstroke Fuel Pressure Regulator Problems

Once you’ve confidently diagnosed a faulty 6.0 Powerstroke fuel pressure regulator, the solution typically involves replacement. However, understanding the causes and taking preventative measures can extend the life of your new FPR and the entire 6.0 Powerstroke fuel system.

FPR Replacement

Replacing the 6.0 Powerstroke fuel pressure regulator is a relatively straightforward job for a moderately skilled DIY mechanic. The FPR is located within the secondary fuel filter housing. Many aftermarket kits offer upgraded springs or designs to maintain more consistent fuel pressure, often preferred over stock replacements. Be sure to use quality OEM or reputable aftermarket parts for the best longevity.

Steps for Replacement (General Overview):

- Gather Tools: Basic sockets, wrenches, rags, and a new FPR kit.

- Depressurize System: Remove fuel pump fuse/relay and crank engine.

- Remove Secondary Fuel Filter Cap: Use a large socket to unscrew the cap.

- Remove Fuel Filter: Lift out the filter element.

- Access the FPR: The FPR is typically held in place by a snap ring or a small bolt. Consult your service manual for the exact procedure.

- Remove Old FPR: Carefully extract the old regulator. Be mindful of any O-rings or springs.

- Install New FPR: Lubricate new O-rings with clean diesel fuel or assembly lube. Install the new regulator, ensuring it’s seated correctly. Reinstall any retaining clips or bolts.

- Reinstall Fuel Filter and Cap: Ensure new O-rings are used for the filter cap.

- Prime System: Cycle the key several times (KOEO) to allow the fuel pump to prime the system and build pressure.

- Start Engine: Check for leaks and verify proper operation. Conduct another fuel pressure test to confirm proper pressure.

Upgraded FPR Kits

Many 6.0 Powerstroke owners opt for upgraded FPR valve 6.0 Powerstroke kits. These often include a stiffer spring to maintain a higher, more consistent fuel pressure, which can improve injector longevity and engine performance. Maintaining a consistent 55-60 PSI is generally considered ideal for these engines. Research reputable brands known for their 6.0 Powerstroke fuel system troubleshooting solutions.

Preventative Measures

- Regular Fuel Filter Changes: This is paramount. Clogged filters stress the entire fuel system, including the FPR. Follow your manufacturer’s recommended service intervals for both primary and secondary fuel filters, or even shorten them if you use lower-quality fuel or operate in dusty environments.

- Use Quality Fuel: Dirty or contaminated fuel is a leading cause of fuel system component failure. Source your diesel from reputable stations.

- Consider Fuel Additives: High-quality diesel fuel additives can help keep your fuel system clean, lubricate components, and prevent gelling in cold weather. Look for additives that boast cetane improvement and injector cleaning properties.

- Monitor Fuel Pressure Periodically: If you’ve had FPR issues in the past, or if your truck has high mileage, consider periodic fuel pressure checks as part of your maintenance routine. This proactive approach can catch a failing fuel pressure regulator 6.0 Powerstroke before it causes significant problems.

By staying proactive and addressing symptoms promptly, you can significantly reduce the likelihood of encountering severe 6.0 Powerstroke fuel pressure regulator issues and keep your truck running smoothly for years to come.

DIY vs. Professional Help: When to Call the Experts for Your 6.0 Powerstroke

Diagnosing and repairing 6.0 Powerstroke fuel pressure regulator issues can range from a relatively simple DIY task to a complex diagnostic challenge. Knowing when to roll up your sleeves and when to seek professional assistance is crucial for your truck’s health and your wallet.

When to Tackle it Yourself

If you’re comfortable with basic automotive repairs, have a decent set of tools, and are willing to invest in a quality fuel pressure gauge, diagnosing and replacing a 6.0 Powerstroke fuel pressure regulator is often within reach. The physical replacement process, as outlined above, is not overly complicated. If your fuel pressure test clearly indicates an FPR issue (e.g., consistently low pressure that stabilizes after FPR replacement), and you’re confident in following instructions, DIY is a viable option. Many experienced 6.0 Powerstroke owners perform this maintenance themselves, saving on labor costs.

This is especially true for replacing the FPR as a preventative measure or an upgrade. If you’re simply swapping out an old, potentially weakened FPR for a new, upgraded unit, and your existing symptoms are minor (like slight hard starting), then a DIY approach is very reasonable.

When to Seek Professional Help

There are several scenarios where calling a qualified diesel mechanic is the smarter choice:

- Uncertain Diagnostics: If your fuel pressure test results are ambiguous, or if the symptoms persist after replacing the FPR, it’s time to call in an expert. Misdiagnosis can lead to replacing expensive, unnecessary parts. A professional will have specialized diagnostic equipment and in-depth knowledge of 6.0 Powerstroke fuel system troubleshooting.

- Complex Co-occurring Issues: If your truck is showing multiple, seemingly unrelated symptoms (e.g., low fuel pressure, HPOP codes, and transmission issues), a professional can effectively diagnose the root cause and identify any co-occurring problems.

- Lack of Proper Tools or Experience: Don’t attempt a repair if you don’t have the right tools or the confidence to perform the job safely and correctly. Improper installation can lead to leaks, further damage, or even a fire hazard.

- Time Constraints: If you rely on your truck daily and cannot afford downtime for learning and troubleshooting, a professional can get the job done faster and more reliably.

- Warranty Concerns: If your truck is still under warranty, performing DIY repairs might void certain coverages. Always check your warranty terms.

- Safety Concerns: Working with fuel and high-pressure systems carries inherent risks. If you’re uncomfortable with any aspect of the repair, prioritize your safety and seek professional help.

Ultimately, the decision to go DIY or professional depends on your skill level, available tools, comfort with the diagnostic process, and the complexity of the issues. For critical components like the fuel pressure regulator 6.0 Powerstroke, ensuring the repair is done correctly is paramount to your truck’s long-term reliability and performance. A few extra dollars spent on professional diagnosis can save you significantly more in potential future repairs caused by incorrect DIY attempts.

Conclusion: Empowering Your 6.0 Powerstroke for the Long Haul

The 6.0 Powerstroke diesel engine, for all its legendary power and undeniable presence, demands attention and understanding from its owners. Navigating common issues, particularly those stemming from the fuel pressure regulator, is a rite of passage for many enthusiasts. By diligently applying the diagnostic steps and insights provided in this comprehensive guide, you are now better equipped to identify, troubleshoot, and resolve 6.0 Powerstroke fuel pressure regulator issues with confidence.

Remember, a healthy 6.0 Powerstroke fuel system is the backbone of your truck’s performance and longevity. From recognizing the subtle cues of a 6.0 Powerstroke hard start or a persistent 6.0 Powerstroke rough idle, to performing a precise fuel pressure test 6.0 Powerstroke, each step brings you closer to maintaining optimal engine health. Regular maintenance, particularly timely fuel filter changes, and a proactive approach to monitoring your truck’s behavior are your best defenses against costly breakdowns and frustrating downtime.

Don’t let the reputation of the 6.0 deter you. With the right knowledge and a methodical approach to diagnosing 6.0 Powerstroke fuel problems, you can ensure your truck remains a reliable workhorse and a source of pride for years to come. Whether you choose to tackle these repairs yourself or seek expert professional assistance, understanding the nuances of your 6.0 Powerstroke fuel pressure regulator is a powerful asset in your diesel ownership journey. Keep that engine humming smoothly, and enjoy the power and capability your 6.0 Powerstroke was built to deliver.

🎥 Related Video: Checking fuel pressure on the Ford 6.0 powerstroke

📺 DieselTechRon

With this video I try to show how and explain the importance of keeping the fuel pressure up to save your injectors or testing for …

Frequently Asked Questions

What are the common symptoms of a faulty 6.0 Powerstroke fuel pressure regulator?

A failing 6.0 Powerstroke fuel pressure regulator (FPR) often causes hard starting, especially when warm, and a noticeable lack of power or poor acceleration. You might also experience a rough idle, engine stalling, or a general feeling of hesitation during driving.

How do I test my 6.0 Powerstroke fuel pressure regulator to confirm it’s faulty?

The most effective way is to connect a fuel pressure gauge to the test port on the fuel filter housing. Monitor the pressure at key-on-engine-off (KOEO) and while the engine is running under various loads. A consistent low pressure, or significant fluctuations, typically indicates a problem with the 6.0 Powerstroke fuel pressure regulator.

What are the correct fuel pressure readings I should see when diagnosing my 6.0 Powerstroke fuel pressure regulator?

For a healthy 6.0 Powerstroke, you should typically see around 50-60 PSI at key-on-engine-off (KOEO). While the engine is running, the pressure should maintain a consistent range of 45-55 PSI. Pressures consistently below 45 PSI are a strong indicator of a failing fuel pressure regulator.

Where is the 6.0 Powerstroke fuel pressure regulator located, and is it also called the “blue spring”?

The fuel pressure regulator on a 6.0 Powerstroke is housed within the fuel filter housing, typically on the back or side. The “blue spring” is actually a common aftermarket upgrade kit that replaces the original spring inside the FPR housing to increase and stabilize fuel pressure, not the entire regulator itself.

What usually causes 6.0 Powerstroke fuel pressure regulator failures, and how can I prevent them?

Failures are often caused by wear and tear on the internal spring or plunger, as well as contamination from dirty fuel passing through. Ensuring you use high-quality fuel filters and change them regularly according to the manufacturer’s schedule can significantly extend the life of your 6.0 Powerstroke fuel pressure regulator.

Do I need special tools to diagnose 6.0 Powerstroke fuel pressure regulator problems myself?

A dedicated fuel pressure gauge with the correct adapter for the 6.0 Powerstroke fuel filter housing test port is essential. While not strictly necessary for basic pressure checks, a diagnostic scan tool that can read actual and desired fuel pressure can provide a more comprehensive diagnosis of your 6.0 Powerstroke fuel pressure regulator issues.