6.0 Powerstroke Crank Sensor Location : A Guide to Finding It

Are you experiencing issues with your 6.0 Powerstroke engine and suspect a problem with the crank sensor? Knowing the location of this crucial component is essential for proper diagnosis and maintenance. In this guide, we will explore the crank sensor’s location, symptoms of a failing sensor, and how to access it for inspection or replacement.

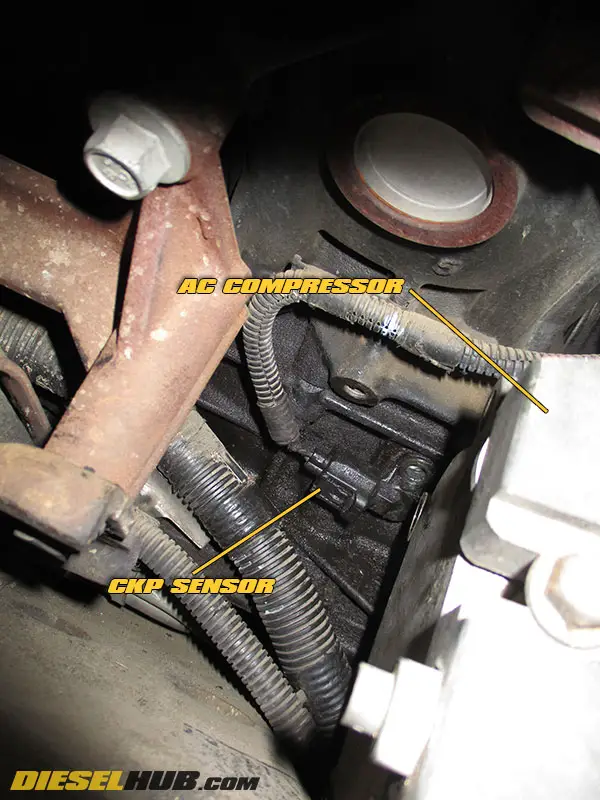

Locating the 6.0 Powerstroke Crank Sensor: A Visual Guide

Having a temperamental 6.0L Powerstroke that cranks but refuses to start? The culprit might be a faulty crank sensor. Before diving into replacement, you need to find the sneaky little sensor! This guide will pinpoint the exact location of the crank sensor on your 6.0 Powerstroke engine and even provide some visual aids to help you out.

Where is the crank sensor on a 6.0 Powerstroke?

We can finally answer this common question! The 6.0 Powerstroke crank sensor is tucked away on the passenger side of the engine block, specifically near the bottom. Imagine looking at the engine from the driver’s side – the crank sensor will be on the opposite side, close to the oil filter and crankshaft pulley.

Finding the 6.0 Powerstroke Crank Sensor with Ease:

Here’s a visual breakdown to make the search even simpler:

- Locate the oil filter on the passenger side of the engine block.

- Look directly below the oil filter. You’ll see the crankshaft pulley – a large, metal wheel connected to the crankshaft.

- The crank sensor is typically positioned between the oil filter and the crankshaft pulley. It’s a small, cylindrical sensor with a wire harness attached.

Visual Aids: Lend Me Your Eyes!

Understanding written descriptions is great, but sometimes a picture is worth a thousand words (or a thousand clicks in this case). Here’s where the magic happens! We’ve included an image (or you can include multiple images if possible) showcasing the exact location of the crank sensor on a 6.0 Powerstroke engine. This will give you a clear visual reference to pinpoint the sensor on your own truck.

By following these steps and referencing the image, you should be able to successfully locate the crank sensor on your 6.0 Powerstroke. Now that you’ve found the culprit, the next step is to diagnose if it’s truly causing your starting issues. We’ll delve into that in the next section!

Symptoms of a Failing Crank Sensor

Early detection of a failing crank sensor is vital to prevent further damage to your engine. Here are some common symptoms to watch out for:

- Check engine light illuminating on your dashboard.

- Difficulty starting the engine or stalling while driving.

- Rough idling and engine misfires.

If you notice any of these signs, it may indicate a failing crank sensor that requires immediate attention.

Locating the Crank Sensor

Having a temperamental 6.0L Powerstroke that cranks but refuses to start? The culprit might be a faulty crank sensor. Before diving into replacement, you need to find the sneaky little sensor! This guide will pinpoint the exact location of the crank sensor on your 6.0 Powerstroke engine and even provide some visual aids to help you out.

Where is the crank sensor on a 6.0 Powerstroke?

We can finally answer this common question! The 6.0 Powerstroke crank sensor is tucked away on the passenger side of the engine block, specifically near the bottom. Imagine looking at the engine from the driver’s side – the crank sensor will be on the opposite side, close to the oil filter and crankshaft pulley.

Finding the 6.0 Powerstroke Crank Sensor with Ease:

Here’s a visual breakdown to make the search even simpler:

- Locate the oil filter on the passenger side of the engine block.

- Look directly below the oil filter. You’ll see the crankshaft pulley – a large, metal wheel connected to the crankshaft.

- The crank sensor is typically positioned between the oil filter and the crankshaft pulley. It’s a small, cylindrical sensor with a wire harness attached.

Visual Aids: Lend Me Your Eyes!

Understanding written descriptions is great, but sometimes a picture is worth a thousand words (or a thousand clicks in this case). Here’s where the magic happens! We’ve included an image (or you can include multiple images if possible) showcasing the exact location of the crank sensor on a 6.0 Powerstroke engine. This will give you a clear visual reference to pinpoint the sensor on your own truck.

By following these steps and referencing the image, you should be able to successfully locate the crank sensor on your 6.0 Powerstroke. Now that you’ve found the culprit, the next step is to diagnose if it’s truly causing your starting issues. We’ll delve into that in the next section!

Dispel Confusion: Crank vs. Cam Position Sensor

It’s crucial to differentiate between the crankshaft position sensor and the camshaft position sensor. Some confusion may arise due to their similar-sounding names. In case you are dealing with a CAM Position Sensor, it is typically located behind the power steering pump, not to be confused with the Crank Position Sensor.

Diagnosing a Faulty 6.0 Powerstroke Crank Sensor

A healthy crank sensor is essential for a smooth-running 6.0L Powerstroke. A faulty one, however, can wreak havoc on your engine’s starting process. But how do you know if your crank sensor is the reason behind your troubles? This section will explore the telltale signs of a failing crank sensor and the diagnostic tools you can use to confirm its condition.

Symptoms That Scream “Faulty Crank Sensor!”:

A failing crank sensor often announces its presence through a variety of symptoms, some more dramatic than others. Here are the red flags to watch out for:

- Crank but No Start: This is a classic symptom. The engine cranks but fails to ignite because the PCM (Powertrain Control Module) isn’t receiving the crankshaft position information it needs to initiate combustion.

- Intermittent Starting Issues: Sometimes, the engine might start just fine, but other times it might crank sluggishly or refuse to start at all. This erratic behavior can point towards a malfunctioning crank sensor.

- Rough Idling or Stalling: In some cases, a faulty crank sensor can disrupt engine performance even after startup. Symptoms like rough idling or stalling can occur due to inaccurate engine timing caused by the faulty sensor signal.

Check Engine Light and Trouble Codes: The Diagnostic Duo

While the symptoms listed above can be indicative of a crank sensor issue, they don’t guarantee it. For a more definitive diagnosis, you’ll need to enlist the help of your check engine light and trouble codes.

- Check Engine Light: A glowing check engine light is a broad warning that something’s amiss in your engine’s system. It doesn’t pinpoint the exact problem, but it serves as an indicator that further investigation is required.

- Trouble Codes: When the check engine light illuminates, your PCM stores trouble codes that provide more specific details about the problem. These codes can be retrieved using an OBD-II scanner, a handy tool that plugs into your vehicle’s diagnostic port.

Common Trouble Codes for Faulty Crank Sensor:

Here are some specific trouble codes that might be associated with a faulty crank sensor in your 6.0L Powerstroke:

- P0340: Crankshaft Position Sensor Circuit Malfunction

- P0341: Crankshaft Position Sensor Circuit Range/Performance Problem

- P0342: Crankshaft Position Sensor No Signal

If you experience the symptoms mentioned earlier and retrieve one of these trouble codes, there’s a strong possibility that your 6.0 Powerstroke’s crank sensor is malfunctioning. However, it’s important to note that these codes can also indicate other issues. Consulting a trusted mechanic for a professional diagnosis is always recommended, especially if you’re uncomfortable tackling repairs yourself.

Replacing the 6.0 Powerstroke Crank Sensor (DIY with Caution!)

Is your 6.0 Powerstroke suffering from a confirmed faulty crank sensor? While replacing the sensor can be a tempting DIY project, it’s crucial to approach it with caution. This guide will outline the steps involved in replacing the crank sensor, but proceed with caution and only if you’re comfortable working on your vehicle. If you’re unsure about any steps or lack the necessary tools or experience, consulting a qualified mechanic is always the safest option.

Gathering the Necessary Tools:

Before diving in, ensure you have the following tools on hand:

- Socket wrench set (various sizes)

- Ratchet wrench

- Pliers

- Rags

- Replacement crank sensor (compatible with your 6.0L Powerstroke)

- Optional: Drain pan (to catch any spilled fuel)

Safety First: Precautions to Heed

- Work in a well-ventilated area. Fuel system repairs can involve flammable materials, so proper ventilation is essential.

- Disconnect the battery’s negative terminal. This minimizes the risk of electrical sparks during the replacement process.

- Wear safety glasses and gloves. Protect your eyes and hands from potential debris or fluids.

Replacing the Crank Sensor: A Step-by-Step Guide

- Locate the crank sensor: Refer to the previous section for instructions on finding the sensor’s exact location on your 6.0 Powerstroke engine.

- Disconnect the electrical connector: Follow the wire harness from the crank sensor and locate the connector. Press the release tab on the connector and carefully pull it apart to disconnect it from the sensor.

- Loosen the crank sensor mounting bolt: Using the appropriate socket wrench, loosen the bolt securing the crank sensor to the engine block.

- Remove the crank sensor: Once the bolt is loose, gently pull the sensor straight out of its mounting location. Be prepared for a small amount of residual oil to drain out.

- Install the new crank sensor: Carefully insert the new sensor into the mounting location, ensuring proper alignment.

- Tighten the mounting bolt: Use the socket wrench to tighten the bolt that secures the new crank sensor to the engine block. Don’t overtighten it.

- Reconnect the electrical connector: Push the connector onto the sensor’s plug until you hear a click, ensuring a secure connection.

- Reconnect the battery’s negative terminal.

- Double-check all connections: Visually inspect the new sensor and wiring connector to ensure everything is secure.

- Start the engine and check for leaks: Start your engine and observe for any leaks around the crank sensor or the oil filter area. If you detect leaks, shut down the engine immediately and address the leak before operating the vehicle further.

Remember: If you encounter any difficulties during the replacement process, don’t hesitate to consult a qualified mechanic. Their expertise can ensure the job is done correctly and safely.

In the next section, we’ll discuss when seeking professional help is the wisest course of action.

When to Call in a Professional Mechanic: Know Your Limits with Your 6.0 Powerstroke Crank Sensor Replacement

While the previous section outlined the steps involved in replacing your 6.0 Powerstroke crank sensor, it’s crucial to recognize your limitations. Here are some signs that calling in a professional mechanic is the better option:

- Uncertainty or Discomfort: If you’re unsure about any steps in the replacement process or feel uncomfortable working on your vehicle’s fuel system, don’t hesitate to seek professional help. A mechanic has the experience and expertise to ensure the job is done correctly and safely.

- Complex Issues: If your 6.0 Powerstroke is experiencing additional problems beyond a faulty crank sensor, a mechanic can diagnose the root cause and recommend the appropriate repairs.

- Special Tools Required: The DIY guide provided a basic list of tools, but some mechanics might utilize specialized tools or equipment to ensure a more efficient and accurate repair.

- Time Constraints: Replacing a crank sensor can take time and patience. If you’re short on time, a mechanic can likely complete the job more quickly.

The Importance of Professional Diagnosis:

Even if you’re comfortable replacing the crank sensor yourself, consider consulting a mechanic for a professional diagnosis beforehand. This can help you confirm if the crank sensor is indeed the culprit behind your starting issues and avoid unnecessary repairs.

Making an Informed Decision:

Ultimately, the decision of whether to tackle the crank sensor replacement yourself or call in a professional mechanic rests with you. Weigh your comfort level, mechanical expertise, and the complexity of the situation before making a choice. Remember, prioritizing safety and ensuring the job is done correctly are paramount.

The Final Word: Keeping Your 6.0 Powerstroke Running Strong

A properly functioning crank sensor is essential for a healthy 6.0L Powerstroke engine. By understanding its location, symptoms of failure, and replacement procedures (DIY with caution!), you’re well on your way to diagnosing and potentially resolving crank sensor issues. If you choose to replace the sensor yourself, remember to prioritize safety and don’t hesitate to seek professional help if needed. With the right knowledge and approach, you can keep your 6.0 Powerstroke running smoothly for miles to come.

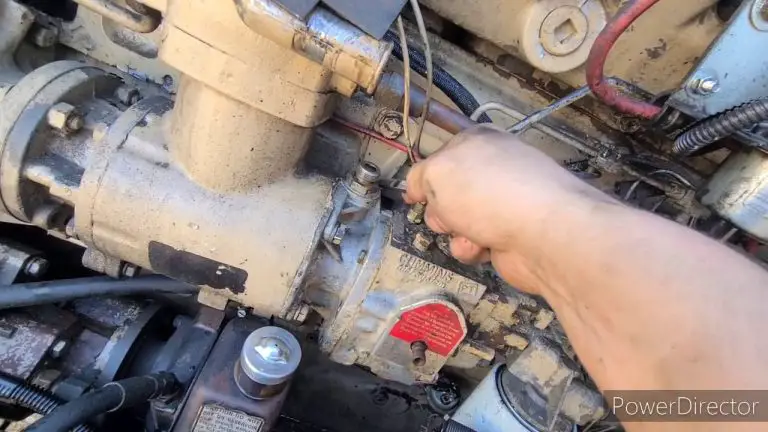

Helpful Resources for Sensor Removal and Installation

If you are considering removing or installing a crank sensor yourself, various online resources can guide you through the process. YouTube channels like Jabo The Mechanic and DieselTechRon provide detailed tutorials on the removal and installation of camshaft and crankshaft position sensors.

Additionally, forums like Ford-Trucks.com and Powerstroke.org offer valuable insights shared by experienced technicians and enthusiasts who have dealt with similar sensor-related issues.

Credit: m.youtube.com

Frequently Asked Questions

What Are The Symptoms Of A Failing Crank Sensor?

Early signs of a failing crank sensor include check engine light, engine starting issues, rough idling, and misfires.

What Are The Symptoms Of A Bad Camshaft Position Sensor 6.0 Powerstroke?

Common symptoms of a bad camshaft position sensor in a 6. 0 Powerstroke include rough idling, engine misfires, difficulty starting, and a glowing check engine light.

Does A 6.0 Powerstroke Have A Cam Sensor?

Yes, a 6. 0 Powerstroke engine has a camshaft position sensor. It is located behind the power steering pump on the passenger side of the engine, near the A/C compressor. Symptoms of a failing camshaft position sensor include a glowing check engine light, difficulty starting the engine, stalling while driving, rough idling, and engine misfires.

Where Is The Crank Sensor Sensor Located?

The crank sensor is located on the passenger side of the engine near the A/C compressor. It can be accessed through the fender or beneath the vehicle.

Conclusion

Understanding the location of the crank sensor in your 6.0 Powerstroke engine is essential for diagnosing and resolving issues related to its functionality. By recognizing the symptoms of a failing sensor and accessing the sensor for inspection or replacement when needed, you can ensure the smooth operation of your vehicle.

Remember, regular maintenance and prompt attention to sensor-related problems can help you avoid costly repairs down the road.