Maximize Your Turbo Boost: Step-by-Step Guide on How to Calibrate VGT Turbo Actuator

As the owner of a turbocharged vehicle, you already know the importance of keeping your turbo in top-notch condition. Keeping your vehicle’s turbocharger in good condition not only ensures that your car runs at peak performance, but it also helps to extend the life and durability of your turbo. One essential component to keep an eye on is your VGT turbo actuator.

An actuator is a mechanical device that is responsible for precisely regulating the flow of air that moves through your engine. However, as with any mechanical component, it can fall out of calibration over time, leading to suboptimal performance. Fortunately, calibrating your VGT turbo actuator is a relatively simple process when you know what you’re doing.

In this step-by-step guide, we’ll walk you through the process of calibrating your VGT turbo actuator, ensuring that your car continues to run at peak performance.

Introduction

Calibrating a VGT turbo actuator can be a daunting task, especially if you have never done it before. However, it’s essential to ensure that your engine is running smoothly and efficiently. To start the process, you will need to locate the actuator and check for any physical damages or wear and tear.

After that, you will need to disconnect the actuator and connect it to the special tool for calibration. Be sure to follow the instructions provided in the manual and adjust the actuator as required until you achieve the desired results. Once done, you can reconnect the actuator, start your engine, and test drive to ensure that everything is working as it should.

By following these steps, you can calibrate your VGT turbo actuator with ease and enhance the performance of your engine. Remember, regular calibration is crucial to ensuring the longevity and efficiency of your vehicle.

Understanding VGT Turbo Actuators

VGT Turbo Actuators VGT or Variable Geometry Turbochargers are designed to provide an excellent balance between fuel efficiency and performance. These turbochargers have a unique design that allows the vanes to change their angle of attack, which alters the air’s flow to the engine. To control the VGT, the turbo actuator comes into play.

The Turbo Actuator is positioned on top of the VGT cartridge and is responsible for positioning the vanes to control airflow and exhaust gas recirculation. It precisely regulates the vane angle to optimize engine performance, improve fuel economy, decrease emissions, and meet stringent emissions regulations. The VGT turbo actuator is essentially a small electric motor that functions like a stepper motor.

As engine load and speed fluctuate, the vehicle’s ECU signals the actuator to adjust the vane angle to maintain optimal engine performance. VGT turbo actuators are essential components that play a crucial role in the performance and efficiency of today’s modern diesel engines.

Why Calibrate VGT Turbo Actuators?

Calibrating VGT turbo actuators is an essential task in maintaining the performance of your vehicle’s engine. The turbocharger system plays a crucial role in boosting the engine’s power output, and the actuator is responsible for controlling the turbo vanes’ position and regulating the exhaust gas flow. Over time, the turbo actuator may become worn or damaged, leading to diminished engine performance and reduced fuel efficiency.

By having your VGT turbo actuator calibrated, you’ll ensure that it operates within its ideal range and that your engine runs smoothly and efficiently. Not only will this help reduce the risk of engine damage, but it will also improve your vehicle’s overall performance.

Tools and Materials Needed

If you’re wondering how to calibrate a VGT turbo actuator, the first step is to gather all the necessary tools and materials. You will need a diagnostic scanner, a laptop with appropriate software, and a torque wrench. Next, you’ll need to locate the turbo actuator and remove it from the turbocharger housing.

Once removed, you can proceed to calibrate it by connecting it to the diagnostic scanner and laptop. This will allow you to input the correct calibration values and ensure proper function. Finally, after calibration is complete, reattach the turbo actuator to the turbocharger housing and torque it down to the manufacturer’s specifications.

Remember, proper calibration of your VGT turbo actuator is essential for optimal performance and fuel efficiency. Don’t hesitate to seek the help of a professional if you’re uncertain about any step of the process.

Scan Tool

When it comes to diagnosing problems with your car, a scan tool can be an invaluable resource. But before you start using one, you need to make sure you have the right tools and materials on hand. The first thing you’ll need is the scan tool itself.

There are a variety of scan tools available on the market, so it’s important to choose one that’s appropriate for your make and model of car. You’ll also need a laptop or other device to use the scan tool with. Some scan tools come with built-in screens, but many connect to a laptop or tablet via USB or Bluetooth.

Finally, you’ll need a reliable internet connection to download updates and access the most current diagnostic information. By having all of these tools and materials on hand, you’ll be able to diagnose and fix any issues with your car quickly and efficiently.

VGT Turbo Actuator Adjustment Tool

Are you facing issues with the VGT turbo actuator in your vehicle? If yes, then fear not, because there’s a simple solution that can help you get the actuator in perfect working condition – the VGT Turbo Actuator Adjustment Tool. To use this tool, you’ll need a few tools and materials like a wrench, socket set, pliers, and a turbo actuator adjustment tool. This tool is designed to make it easy for you to adjust the VGT turbo actuator to the correct position, preventing over- or under-boosting in the engine.

With this tool, you can easily make small adjustments to get the perfect boost levels for your vehicle. Using this tool can also help to improve the fuel efficiency of your vehicle while reducing emissions. So, if you’re experiencing any issues with your VGT turbo actuator, it’s time to invest in a VGT Turbo Actuator Adjustment Tool – your vehicle will thank you for it!

Service Manual or Technical Bulletin

When you have a technical issue with one of your tools or machinery, the first place to turn to is the service manual or technical bulletin. These resources provide detailed instructions on how to fix the problem and prevent it from happening again in the future. However, before you can start repairing, you need to make sure you have all the necessary tools and materials.

This can include anything from basic hand tools like screwdrivers and pliers to more specialized equipment like multimeters or torque wrenches. It’s important to have everything you need before starting the repair to avoid delays or potential safety hazards. Make sure you read through the entire service manual or technical bulletin beforehand to ensure you have everything you need.

By doing this and preparing properly, you can save time and money by making the repair yourself and avoiding the cost of having a professional do it for you.

Calibrating VGT Turbo Actuator

If you’re having issues with your VGT turbo actuator, one solution might be to calibrate it. Calibration ensures that the actuator is properly adjusted and functioning optimally. To begin, start by removing the actuator from the turbocharger.

Then, connect the actuator to a specialized testing device and run through the calibration process as directed by the manufacturer. The process typically involves adjusting the actuator until it is within the recommended position range, which is specified by the manufacturer. Once the calibration is complete, reinstall the actuator onto your turbocharger and test it for proper function.

Keep in mind that proper calibration is crucial for optimal performance, so be sure to follow the manufacturer’s instructions and recommendations carefully. With a properly calibrated VGT turbo actuator, you can expect improved engine performance and better fuel economy.

Step 1: Disconnect the Battery

When it comes to calibrating the VGT turbo actuator, the first step is to disconnect the battery. This is a crucial safety measure that ensures no electrical currents are running through the system while you’re working on it. Failure to disconnect the battery could cause serious harm or even death due to the high voltage present in the system.

Once you’ve disconnected the battery, you can proceed with calibrating the VGT turbo actuator to improve the engine’s performance and ensure it’s running smoothly. Calibrating the VGT turbo actuator involves fine-tuning the position of the actuator to optimize boost delivery and improve engine response. This is an essential task for any mechanic or DIY enthusiast looking to get the most out of their vehicle.

So, if you’re looking to improve your engine’s performance and prevent any potential hazards, be sure to disconnect the battery before starting the calibration process.

Step 2: Remove the Turbo Actuator

When calibrating your VGT turbo actuator, the next step after disconnecting the electrical connector is to remove the actuator itself. This step involves unbolting the actuator from the turbocharger housing and carefully sliding it out of the way to gain access to the turbine control valve. It’s essential to handle the actuator with care and keep it in a clean, safe place to avoid damage or contamination.

Additionally, take note of the actuator’s position and orientation before removal. Reinstalling it back in the same position ensures accurate calibration and prevents any issues with performance or operation. Remember to take your time and follow the manufacturer’s instructions for best results.

By performing a VGT turbo actuator calibration, you’ll improve your engine’s efficiency and power output, ensuring maximum performance and reducing overall maintenance costs for your vehicle.

Step 3: Inspect the Actuator and Turbocharger

When it comes to calibrating your VGT turbo actuator, inspecting the actuator and turbocharger is an essential step. The actuator is responsible for controlling the turbocharger’s boost pressure, which impacts the engine’s power and efficiency. Start by examining the actuator for any signs of damage, including cracks or corrosion.

Next, check the linkage and mounting bracket for wear or looseness which can affect performance. While inspecting the turbocharger, be on the lookout for excessive oil or debris in the intake system, as this can indicate a failing oil seal or clogged air filter. By thoroughly examining both the actuator and turbocharger, you can ensure that your VGT turbo actuator is accurately calibrated and functioning efficiently.

This can lead to improved engine performance, fuel economy and a smoother ride.

Step 4: Install the VGT Turbo Actuator Adjustment Tool

If you’re looking to calibrate your VGT Turbo Actuator, the fourth step in the process is to install the VGT Turbo Actuator Adjustment Tool. This tool is crucial in ensuring that your VGT Turbo Actuator is correctly calibrated. It will allow you to adjust the position of the turbine vanes in the turbocharger to optimize engine performance.

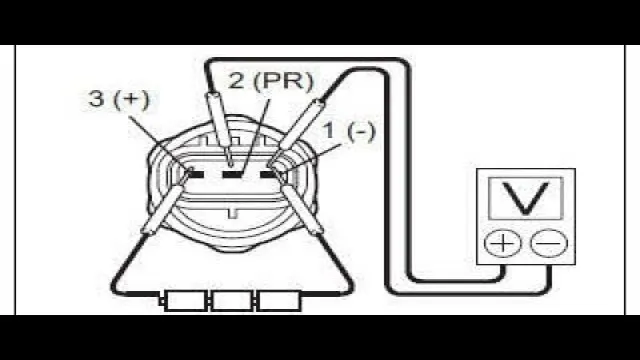

Installing the VGT Turbo Actuator Adjustment Tool is relatively easy. Begin by removing the connector that attaches the actuator to the turbocharger. Then, insert the adjustment tool in its place and connect the adjustment tool to the actuator.

Once this is done, carefully adjust the actuator so that it aligns with the turbocharger. It’s crucial to ensure that the actuator is calibrated correctly to prevent damage to the engine or the turbocharger. Misalignment can cause the vanes to be positioned improperly, leading to excessive exhaust gas temperatures, which can ultimately lead to engine failure.

By following the right calibration procedures and ensuring that the VGT Turbo Actuator Adjustment Tool is installed correctly, you can improve your engine’s power and efficiency. With the right tools and attention to detail, calibrating your VGT Turbo Actuator is a straightforward process that can make a significant difference in your vehicle’s performance.

Step 5: Follow the Calibration Procedure as Per the Manufacturer’s Instructions

Calibrating VGT Turbo Actuator Calibrating a VGT turbo actuator is a critical step in ensuring your vehicle runs smoothly and efficiently. Before beginning the calibration process, it’s important to read the manufacturer’s instructions carefully to understand the specific requirements for your VGT turbo actuator. Once you have a good understanding of the instructions, you can begin the calibration process.

The first step is to disconnect the VGT turbo actuator from the ECU. This ensures that the actuator doesn’t receive any signals during the calibration process. Next, you’ll need to adjust the actuator to the correct position, as indicated in the manufacturer’s instructions.

This may require the use of specialized tools, so be sure to have everything you need on hand before you start. Once you’ve adjusted the actuator, you’ll need to connect it to the ECU and follow any further instructions provided by the manufacturer. At this point, you should test the VGT turbo actuator to ensure it’s functioning correctly.

You can do this by engaging the turbo boost, monitoring the actuator’s performance, and addressing any issues that arise. Calibrating your VGT turbo actuator is a necessary step in maintaining the longevity and performance of your vehicle. By carefully following the manufacturer’s instructions and taking the time to test the actuator, you can ensure that your vehicle is running smoothly and is performing efficiently.

With a properly calibrated VGT turbo actuator, you can enjoy a smoother ride, improved fuel efficiency, and a longer lifespan for your vehicle.

Testing the Calibration

Calibrating a VGT turbo actuator is a process that may seem complicated at first, but with proper guidance, it can be done quickly and efficiently. After installation, the next step is to test the calibration to ensure that it is correctly set. One way to do this is by using a diagnostic tool to connect to the actuator and monitor its response to commands.

Another method is to manually send voltage signals to the actuator to see how it responds. It is important to take note of the actual position of the actuator compared to the requested position and make adjustments accordingly. A properly calibrated VGT turbo actuator should respond quickly and smoothly to commands, with little to no lag or hesitation.

By taking the time to test the calibration, you can be confident that your VGT turbo actuator is functioning optimally, which can improve performance and fuel efficiency while reducing wear and tear on your engine.

Step 1: Clear the Trouble Codes

When it comes to testing the calibration of your vehicle, the first step is to clear any trouble codes that may be present. These codes can often lead to confused and inaccurate readings, causing unnecessary frustration and wasted time. Clearing these codes will allow you to start fresh and make more accurate readings.

But how do you know if the calibration is accurate in the first place? One way is to test it against a known standard, such as a factory specification or a reference meter. This will give you a baseline to compare your readings against and ensure that you are getting accurate results. Additionally, monitoring your vehicle’s performance over time can help you detect any inconsistencies or issues in the calibration.

By paying attention to these details and taking the time to test and monitor your calibration, you can ensure that your vehicle is running smoothly and efficiently.

Step 2: Road Test

After the calibration of the vehicle’s ADAS system, the next step is to road test it. This process is crucial to ensure that the calibration is accurate and that the system operates as intended. During the road test, a technician will simulate various driving conditions, such as different speeds, weather conditions, and road types, to test the functionality of the ADAS system.

They will also verify that the system is aligned with the camera and sensor’s correct positions, and that the calibration meets safety guidelines. The road test process is important as it identifies any problems with the system before it’s too late. For example, if a technician does not perform accurate calibration, the ADAS system could malfunction when it encounters unexpected obstacles, such as a sudden lane change.

This can result in serious accidents, injuries, or even fatalities. By testing the calibration, technicians can prevent these issues and ensure the safety of drivers and passengers on the road. In conclusion, the road test is a crucial step in the ADAS calibration process.

It ensures that the system is calibrated correctly and that it operates as intended. It also helps detect any issues with the system before it’s too late, which can prevent accidents and safety risks. Overall, the calibration and road test process should only be performed by experienced and certified technicians to ensure the safety of all road users.

Conclusion

In summary, calibrating your VGT turbo actuator can be a complex process, but with the right tools and knowledge, it’s a cinch! You’ll be revving your engine and hitting the open road in no time. Remember, a well-calibrated VGT turbo actuator is like giving your vehicle a gym membership – it’ll be stronger, more efficient, and able to tackle any challenge that comes its way. So go ahead, don your mechanic’s hat, and get to work – your turbo (and your vehicle) will thank you!”

Importance of Proper Calibrating VGT Turbo Actuator

Proper calibration of the VGT turbo actuator is crucial for the efficient performance of a diesel engine. Testing the calibration of the actuator is an important step to ensure it is set up correctly and operating at optimal levels. A poorly calibrated actuator can result in reduced fuel efficiency, excessive emissions, and even engine damage.

During testing, the technician will verify that the actuator is responding accurately to the signals from the engine control unit. They will also check that the actuator is operating within the manufacturer’s specifications and ensure that the correct vacuum and electrical connections are in place. By properly testing and calibrating the VGT turbo actuator, diesel engine owners can rest assured that they are getting the most out of their vehicle and protecting it from potential damage.

Don’t overlook the importance of proper calibration, it could save you time, money, and headaches in the long run.

Always Consult Service Manual or Technical Bulletin

When it comes to testing the calibration of your equipment, it is important to remember to always consult the service manual or technical bulletin. These resources will outline the proper procedures for testing the calibration of your specific device. Testing the calibration is necessary to ensure accurate measurements and reliable data.

It is recommended to perform calibrations on a regular basis, especially if the equipment has undergone any repairs or maintenance. Inaccurate measurements can lead to errors in data analysis and potentially costly mistakes. So, always refer to the manual or technical bulletin for the proper steps to testing and maintaining the calibration of your equipment.

FAQs

What is a VGT turbo actuator and why is it important in engine performance?

A VGT (Variable Geometry Turbocharger) turbo actuator is a critical component of the engine’s turbocharger system. It regulates the flow of exhaust gases into the turbocharger, controlling the boost pressure and engine power output.

How can I tell if my VGT turbo actuator is faulty?

Symptoms of a faulty VGT turbo actuator can include sluggish acceleration, loss of power and increased fuel consumption. You may also experience warning lights appearing on the dashboard or abnormal engine noises.

Can a faulty VGT turbo actuator damage other engine components?

Yes, a faulty VGT turbo actuator can cause damage to other engine components if left unchecked for too long. The increased stress on the engine can cause premature wear and tear on the turbocharger, leading to costly repairs.

How often should I calibrate my VGT turbo actuator?

The frequency of VGT turbo actuator calibration depends on the manufacturer’s recommendations. Typically, it should be done every 50,000 to 100,000 miles or as specified in the vehicle’s owner’s manual. It’s important to schedule regular maintenance appointments with a qualified mechanic to keep your VGT turbo actuator functioning properly.