7.3 Powerstroke No-Start Troubleshooting Guide: Common Solutions

Featured image for this comprehensive guide about 7.3 Powerstroke no-start troubleshooting guide

Image source: static8.depositphotos.com

7.3 Powerstroke No-Start Troubleshooting Guide: Common Solutions

Few engines command the respect and admiration of the 7.3 Powerstroke. Renowned for its legendary durability, robust performance, and relatively straightforward design, it remains a beloved workhorse for countless truck owners. However, even the most bulletproof engines can experience a dreaded no-start condition. Picture this: you turn the key, hear the starter whir, but your trusted 7.3 Powerstroke won’t start. The silence that follows can be deafening, and the frustration, immediate.

A 7.3 Powerstroke no-start can stem from a variety of issues, ranging from simple fuel delivery problems to complex electrical or high-pressure oil system failures. The good news? Many common no-start scenarios can be diagnosed and resolved with a bit of patience and the right approach. This comprehensive guide is designed to equip you with the knowledge and actionable steps needed to troubleshoot your 7.3 Powerstroke cranking no start situation, helping you pinpoint the problem and get back on the road.

Whether you’re a seasoned diesel mechanic or a passionate DIYer, understanding the common culprits behind a 7.3 Powerstroke no-start is crucial. We’ll delve into the vital systems of your engine, providing a step-by-step approach to diagnosing and, hopefully, fixing your truck. Let’s rev up our troubleshooting engines and get your 7.3 Powerstroke roaring back to life!

Quick Answers to Common Questions

My 7.3 Powerstroke cranks but won’t start – where do I even begin?

If your 7.3 Powerstroke cranks over strongly but won’t fire up, start by checking your fuel filter and confirming you’re getting fuel pressure to the engine. Often, a clogged filter or a failing fuel pump is the first place to look.

What if my 7.3 Powerstroke doesn’t crank at all?

First, check your battery terminals for corrosion and ensure both batteries are fully charged; the 7.3 Powerstroke needs strong voltage to operate its glow plugs and fuel system. If the batteries are good, inspect the starter and its main connections.

Could a sensor be preventing my 7.3 Powerstroke from starting?

Absolutely! A faulty Camshaft Position Sensor (CPS) is a very common cause of a no-start condition for your 7.3 Powerstroke. It’s often a good idea to keep a spare on hand, as they can fail suddenly.

My 7.3 Powerstroke only starts when it’s cold, but not when warm. What’s up?

This often points to issues with your High-Pressure Oil Pump (HPOP) system, specifically a failing ICP (Injector Control Pressure) sensor or IPR (Injector Pressure Regulator) valve. These components are crucial for proper fuel injection when the engine is warm.

Is there a simple, quick check I can do before getting too deep into troubleshooting my 7.3 Powerstroke?

Yes, always ensure you have enough fuel in the tank and check for any blown fuses related to the fuel pump or PCM in your 7.3 Powerstroke. These basic checks often get overlooked but can instantly solve a no-start problem.

📋 Table of Contents

The Foundation: Battery, Fuel, and Basic Checks

Before diving into complex diagnostics, always start with the basics. Many a 7.3 Powerstroke no-start has been solved by addressing these fundamental components.

Learn more about 7.3 Powerstroke no-start troubleshooting guide – 7.3 Powerstroke No-Start Troubleshooting Guide: Common Solutions

Image source: drodd.com

Battery Health is Paramount

A diesel engine requires significant cranking power, especially the 7.3 Powerstroke. Even if your starter is turning the engine over, insufficient battery voltage or amperage can prevent it from starting. The glow plug system alone draws a substantial amount of current.

| No-Start Symptom | Most Common Cause(s) | Diagnostic & Verification | Likelihood / Notes |

|---|---|---|---|

| Cranks, No Start (Cold, No Smoke) | Fuel delivery issue (low pressure, air in fuel, clogged filter), Glow Plug Relay (GPR) / Glow Plugs. | Check fuel pressure (should be 40-70 psi), test GPR for voltage output, check glow plug resistance. | ~25% of cold no-starts. GPR failure is extremely common below 30°F. |

| Cranks, No Start (Hot, Long Crank) | High-Pressure Oil Pump (HPOP) issues, ICP sensor, IPR valve, or low oil in reservoir. | Monitor ICP (needs 500+ psi to start), check IPR duty cycle (KOEO), inspect HPOP reservoir level. | ~35% of hot no-starts. HPOP/IPR/ICP related failures are very common wear items. |

| Cranks, No Start (But Smokes) | Injector issues (worn, sticking), poor compression, Cam Position Sensor (CMP) signal erratic. | Perform cylinder contribution test (if scanner allows), compression test, check CMP signal/replace sensor (common part). | ~15% of no-starts. Often indicates underlying mechanical or timing issues. |

| No Crank, No Start | Dead battery, faulty starter, bad battery cables/connections, ignition switch. | Load test battery, check voltage drop across cables, jump starter solenoid, test ignition switch continuity. | ~20% of all no-starts. Very common after sitting or in cold weather. |

| Cranks Slowly, No Start | Weak battery, corroded battery cables, failing starter motor. | Load test battery, clean and inspect all battery/starter cable connections, test starter current draw. | ~10% of no-starts. Often precedes a complete “no crank” condition. |

- Check Battery Voltage: A fully charged battery should read around 12.6 volts. Anything below 12.4 volts can indicate a weak battery.

- Load Test: A simple voltage check isn’t enough. Batteries can show good surface voltage but fail under load. Take your batteries to an auto parts store for a free load test or use a dedicated load tester.

- Terminal Connections: Inspect battery terminals for corrosion and ensure they are clean and tight. Loose or corroded connections can drastically reduce current flow.

- Alternator Check: While not a direct no-start cause, a failing alternator can lead to undercharged batteries over time, resulting in a no-start.

Did you know? On average, a healthy 7.3 Powerstroke battery should be able to crank the engine at least 150-200 RPM for the engine to build enough oil pressure to fire.

Fuel – The Lifeblood of Your Diesel

It sounds obvious, but you’d be surprised how often a 7.3 Powerstroke no-start is simply due to a lack of fuel, or contaminated fuel.

- Fuel Level: Ensure your tank isn’t empty. The fuel gauge can sometimes be inaccurate.

- Fuel Quality: Diesel fuel can gel in extreme cold, or become contaminated with water. If you suspect contaminated fuel, draining and refilling with fresh, treated diesel is crucial.

- Listen for the Fuel Pump: When you turn the key to the “ON” position (before cranking), you should hear a hum from the electric fuel pump for a few seconds. If you don’t hear it, this is a strong indicator of a fuel pump issue, a blown fuse, or a bad relay.

Air Intake and Filters

While less common for a complete no-start, a severely restricted air filter can make starting difficult, especially in cold weather. Ensure your air filter is clean and there are no obstructions in the intake path.

Diving Deeper: Fuel Delivery System Failures

If your basic checks pass, it’s time to investigate the fuel delivery system more thoroughly. Problems here are a very common cause of a 7.3 Powerstroke no-start.

Learn more about 7.3 Powerstroke no-start troubleshooting guide – 7.3 Powerstroke No-Start Troubleshooting Guide: Common Solutions

Image source: wonder007.com.tw

Fuel Pump Issues

The electric fuel pump supplies low-pressure fuel to the injectors. If it fails, no fuel gets to the engine.

- Test Fuel Pump Relay/Fuse: Check the fuse box for the fuel pump fuse and swap the relay with a known good one (e.g., the horn relay) to test.

- Test Fuel Pump Output: Disconnect the fuel line before the fuel filter housing and direct it into a clear container. Have someone briefly cycle the key to “ON.” You should see a strong, steady stream of fuel. Lack of flow or weak flow points to a faulty pump or blockage.

Fuel Filter & Heater Problems

A clogged fuel filter is one of the most common reasons for a 7.3 Powerstroke won’t start. These engines are sensitive to fuel flow restrictions.

- Replace Fuel Filter: If you haven’t replaced it recently, start here. It’s an inexpensive and often effective fix. Ensure the O-rings are properly seated.

- Fuel Bowl Heater: In colder climates, a failed fuel bowl heater can lead to fuel gelling in the filter housing. A shorted heater can also blow the fuse for the fuel pump, leading to a no-start. Disconnecting the heater element (if the fuse keeps blowing) can isolate this issue.

Air in the Fuel System

Diesel engines don’t tolerate air in the fuel lines. This can happen after running out of fuel, replacing filters, or from leaky O-rings.

- Bleeding the System: After replacing filters or running out of fuel, cycle the key several times for 30 seconds each to allow the fuel pump to push air out and fill the fuel bowl. You might need to crank the engine in short bursts to help it along.

- Check for Leaks: Inspect all fuel lines for signs of leaks or cracked hoses that could be allowing air to enter.

Fuel Pressure Regulator

Located on the fuel bowl, the fuel pressure regulator maintains correct fuel pressure to the injectors. A faulty regulator can lead to low fuel pressure, preventing the engine from starting or running poorly.

High-Pressure Oil System & Injection Components

The 7.3 Powerstroke utilizes a HEUI (Hydraulically Actuated Electronic Unit Injection) system, meaning high-pressure oil is critical for firing the injectors. Problems in this system are a very common reason for a 7.3 Powerstroke no-start.

ICP (Injection Control Pressure) Sensor

The ICP sensor monitors the pressure in the high-pressure oil system. If it fails or sends an incorrect signal to the PCM, the PCM won’t command the injectors to fire, resulting in a 7.3 Powerstroke no-start. Symptoms often include long crank times, rough idle, or no start at all. Sometimes, simply unplugging the ICP sensor can allow the truck to start (PCM defaults to a pre-programmed value), indicating a faulty sensor.

IPR (Injection Pressure Regulator) Valve

The IPR valve controls the amount of oil sent to the injectors, directly regulating the ICP. A stuck open or faulty IPR valve will prevent the high-pressure oil pump from building sufficient pressure to fire the injectors.

- Symptoms: Extended cranking, no start, or stalling.

- Diagnostic Tip: A scan tool showing low ICP during cranking, even with a good HPOP, can point to a failing IPR.

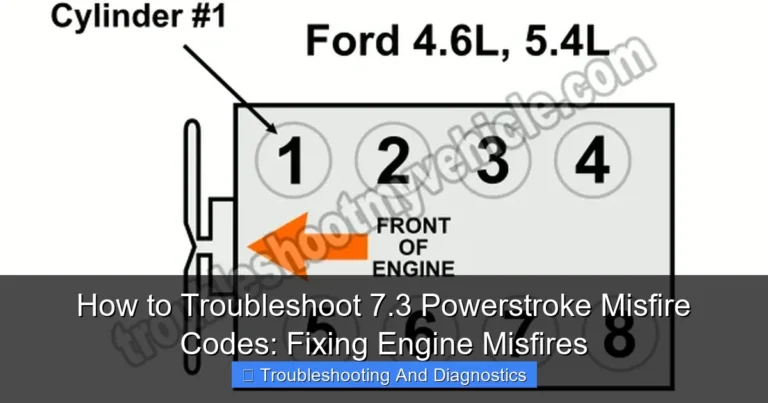

UVCH (Under Valve Cover Harness) & Injectors

The UVCH is a common failure point for the 7.3 Powerstroke. It provides power and control signals to the injectors and glow plugs. Heat cycling can cause the connector pins to loosen or burn, leading to open circuits.

- Symptoms: Misfires, rough idle, or a complete 7.3 Powerstroke no-start.

- Checking: Often, the truck will start but run very rough, or not at all. A “buzz test” with a diagnostic tool can identify faulty injectors or open circuits in the UVCH.

Individual Injectors: While less common for a total no-start, a severely faulty injector (e.g., sticking open) can compromise the high-pressure oil system, leading to insufficient pressure for other injectors to fire.

HPOP (High-Pressure Oil Pump)

The HPOP is the heart of the HEUI system. Its job is to generate the high oil pressure (typically 500 PSI minimum for starting) needed to activate the injectors. A failing HPOP, though less common than IPR or ICP issues, can absolutely cause a 7.3 Powerstroke no-start.

- Symptoms: No or very low ICP during cranking, even with a good IPR and healthy oil level.

- Testing: This typically requires specialized diagnostic tools to monitor ICP and engine oil pressure (EOP) simultaneously.

Electrical & Sensor Woes: The Brains of the Operation

Modern diesels rely heavily on electronic signals. Malfunctions in sensors or control modules can severely impact starting.

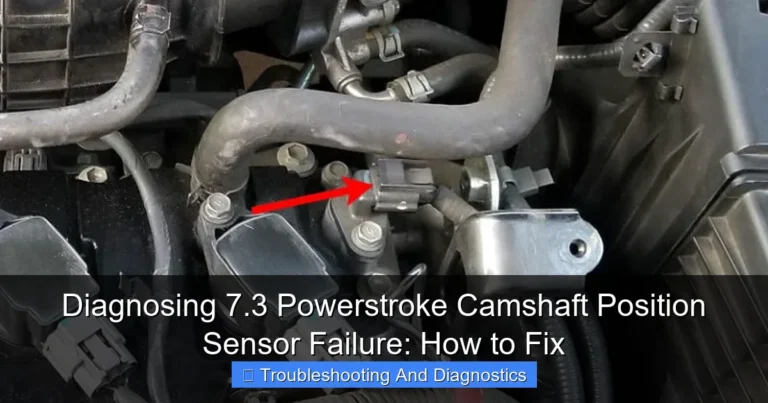

CPS (Camshaft Position Sensor)

The CPS tells the PCM the exact position of the crankshaft, which is vital for injector timing. A failing or failed CPS is a notorious cause of a 7.3 Powerstroke no-start, often without any other warning signs. Your engine will crank, but never fire.

- Symptoms: Sudden stalling, no start, or intermittent no-start conditions. Often, the tachometer won’t move while cranking if the CPS is bad.

- Replacement: This is a relatively inexpensive and easy part to replace. It’s often recommended to carry a spare, especially on older 7.3 Powerstroke trucks.

FICM (Fuel Injection Control Module)

The FICM boosts the 12-volt battery voltage to 48 volts, which is necessary to fire the injectors. If the FICM output voltage is low (below 45 volts while cranking), the injectors won’t fire correctly, leading to a hard start or a 7.3 Powerstroke no-start.

- Testing: You can test FICM voltage with a multimeter at specific test points, or with a diagnostic scan tool.

PCM (Powertrain Control Module) Issues

The PCM is the brain of your engine. While rare, a faulty PCM can lead to a 7.3 Powerstroke no-start, manifesting in a variety of ways, including no communication with a scan tool, or incorrect commands to other components. This is usually diagnosed after ruling out all other possibilities.

Wiring Harnesses and Fuses

A damaged wire or blown fuse can interrupt power or signal to critical components. Always check relevant fuses (fuel pump, PCM, FICM, glow plug relay, etc.) in your under-hood fuse box and under the dash. Inspect visible wiring harnesses for signs of rodent damage, chafing, or corrosion.

Cold Start Specifics: Glow Plugs and Relays

While not strictly a “no-start” if the engine is warm, a failure in the glow plug system is a prime suspect for a 7.3 Powerstroke no-start in cold weather.

Glow Plug System – Essential for Cold Starts

Glow plugs heat the combustion chambers to aid ignition in cold temperatures. Without them, the diesel fuel won’t ignite effectively when it’s cold. Below roughly 40-50°F (4-10°C), a healthy glow plug system is usually critical for starting.

Glow Plug Relay (GPR) Failure

The GPR (also known as the glow plug controller or solenoid) supplies power to all eight glow plugs. It’s a high-amperage component and a common failure point.

- Symptoms: Long crank times in cold weather, excessive white smoke after starting, or a complete 7.3 Powerstroke no-start when temperatures drop.

- Testing GPR: With a multimeter, check for 12 volts at both large terminals on the GPR for about 10-30 seconds after turning the key to “ON” (engine off) in cold weather. If you have 12V on one side but not the other, the GPR is likely faulty.

Testing Glow Plugs

Individual glow plugs can also fail. While one or two bad glow plugs might allow starting, multiple failures will make starting difficult or impossible in cold weather.

- Method: Disconnect the wire from each glow plug. Using an ohmmeter, check the resistance between the glow plug terminal and a good ground. A reading of 0.6 to 2.0 ohms is typically good. An open circuit (OL or infinite resistance) indicates a bad glow plug.

Note: Some later 7.3L engines (specifically some California emissions trucks) used an AIH (Air Intake Heater) system instead of, or in addition to, glow plugs. Check your specific vehicle’s configuration.

Advanced Diagnostics and Next Steps

If you’ve gone through the basics and still have a 7.3 Powerstroke no-start, it’s time to get a bit more technical.

Reading Diagnostic Trouble Codes (DTCs)

A diagnostic scan tool (OBD-II scanner capable of reading diesel-specific codes) is invaluable for troubleshooting a 7.3 Powerstroke no-start. DTCs can point you directly to a faulty sensor or system.

- Generic vs. Enhanced Scanners: While a generic OBD-II scanner can read some codes, an enhanced scanner (like Forscan, AutoEnginuity, or high-end shop tools) can read manufacturer-specific codes and monitor live data from sensors (ICP, IPR duty cycle, FICM voltage, etc.), which is crucial for HEUI diagnostics.

- Interpreting Codes: Don’t just replace the part the code points to. Use the code as a guide and perform further tests to confirm the diagnosis. For example, an ICP sensor code might mean the sensor is bad, or it might mean the IPR isn’t building pressure, causing the ICP to read low.

Common Symptoms and Potential Causes Summary

Here’s a quick reference table to help categorize your 7.3 Powerstroke no-start symptoms:

| Symptom | Most Common Potential Causes | Key Diagnostic Steps |

|---|---|---|

| Engine cranks, but very slowly | Weak batteries, poor battery connections, bad starter | Load test batteries, clean terminals, check starter draw |

| Engine cranks normally, no start (any temperature) | CPS sensor, ICP sensor, IPR valve, fuel pump, no fuel, FICM failure | Scan for codes, check fuel pressure, monitor ICP/FICM voltage, check fuel pump operation, try unplugging ICP |

| Engine cranks normally, no start (cold temps only) | Glow plug relay (GPR), bad glow plugs, weak batteries, fuel gelling | Test GPR, test glow plugs, ensure proper cold weather fuel, load test batteries |

| Engine starts, then immediately dies | Air in fuel system, low fuel pressure, failing ICP sensor, weak FICM | Bleed fuel system, check fuel pressure, monitor ICP/FICM voltage |

| Engine cranks, white/blue smoke, no start | Low compression, bad injectors, insufficient high-pressure oil (HPOP, IPR, leaks) | Perform compression test (last resort), buzz test injectors, monitor ICP pressure while cranking |

Professional Help

If you’ve exhausted your DIY options or lack the specialized tools, don’t hesitate to consult a qualified diesel mechanic. A professional shop will have access to advanced diagnostic equipment and the expertise to quickly identify and resolve complex issues, saving you time and potential further damage.

Preventative Maintenance

The best way to avoid a 7.3 Powerstroke no-start is through regular preventative maintenance. This includes:

- Regularly replacing fuel and air filters.

- Testing and maintaining battery health.

- Monitoring engine fluids, especially oil level and quality (critical for the HEUI system).

- Addressing minor issues promptly before they escalate.

Conclusion

A 7.3 Powerstroke no-start can be a frustrating experience, but with a systematic approach and the knowledge provided in this guide, you’re well-equipped to tackle most common issues. From the simple checks of battery and fuel to the more intricate diagnostics of the high-pressure oil and electrical systems, understanding your 7.3 Powerstroke’s starting issues is the first step towards a solution.

Remember, patience and methodical testing are your best friends. Many fixes are straightforward, and even if it leads to a professional, you’ll be able to communicate much more effectively about the symptoms and what you’ve already tried. Keep your beloved 7.3 Powerstroke running strong – it’s an engine built to last, and with the right care, it will continue to serve you faithfully for years to come. Happy troubleshooting!

🎥 Related Video: Obs 7.3 crank no start

📺 Jairus Broyles

Frequently Asked Questions

My 7.3 Powerstroke won’t start, what’s the first thing I should check?

Start your troubleshooting by checking the battery and its connections. A low or dead battery is a common culprit and can prevent proper cranking or power the Glow Plug Control Module (GPCM).

My 7.3 Powerstroke cranks but won’t fire up, what could be the problem?

If your 7.3 Powerstroke cranks vigorously but doesn’t start, it often points to a fuel delivery issue, air in the fuel system, or a lack of proper injection pressure. Ensure you have fuel in the tank, check the fuel filter, and listen for the “harvester pump” (electric fuel pump) to prime when you turn the key.

Could a bad sensor prevent my 7.3 Powerstroke from starting?

Absolutely. The Camshaft Position Sensor (CPS) is a very common failure point on the 7.3 Powerstroke and can cause a no-start condition even if the engine cranks fine. The Injector Control Pressure (ICP) sensor or Injector Pressure Regulator (IPR) valve can also prevent the engine from building enough high-pressure oil to fire the injectors.

My 7.3 Powerstroke struggles to start when it’s cold. What should I investigate?

Cold start issues on a 7.3 Powerstroke are often related to the glow plug system or fuel gelling. Test your glow plugs and the Glow Plug Control Module (GPCM) for proper operation. Also, ensure you’re using winterized fuel or an anti-gel additive in colder temperatures.

My 7.3 Powerstroke isn’t cranking at all, what are the likely causes?

If your 7.3 Powerstroke doesn’t crank, the first suspects are a completely dead battery or a faulty starter motor. Also, check your battery terminals for corrosion and verify the neutral safety switch is functioning correctly, as it can prevent the starter from engaging.

My 7.3 Powerstroke won’t start after I changed the fuel filter or ran out of fuel. What do I do?

After a fuel filter change or running out of fuel, you likely have air in the fuel system. Cycle the key to the “on” position for 30 seconds several times to allow the fuel pump to prime and push air back to the tank. It may take several cranking attempts to purge all the air from the system completely.