7.3 Powerstroke Injector Specifications: Everything You Need to Know

Featured image for this comprehensive guide about 7.3 Powerstroke injector specifications

Image source: static8.depositphotos.com

The 7.3 Powerstroke engine isn’t just a workhorse; it’s a legend. For nearly a decade, from 1994.5 to 2003, this turbocharged direct-injection diesel engine powered millions of Ford trucks and E-series vans, earning a reputation for incredible durability, reliability, and sheer pulling power. Even today, decades after its production ceased, thousands of these magnificent machines are still on the road, hauling, working, and turning heads. But like any complex piece of machinery, the 7.3L Powerstroke relies on its intricate components to deliver that legendary performance, and none are quite as critical as its fuel injectors.

The injectors are the heart of the 7.3L’s fuel delivery system, precisely metering and atomizing fuel into the combustion chambers under immense pressure. They dictate everything from horsepower and torque to fuel efficiency and exhaust emissions. Understanding the nuances of these vital components – from their fundamental design to their specific codes and capabilities – is paramount for any 7.3L owner, whether you’re performing routine maintenance, troubleshooting a performance issue, or planning a serious power upgrade. Delving into the world of 7.3 Powerstroke injector specifications is not just about technical knowledge; it’s about preserving the legacy and maximizing the potential of your beloved truck.

In this comprehensive guide, we’ll peel back the layers of the 7.3L Powerstroke’s fuel injection system. We’ll explore the groundbreaking HEUI technology, differentiate between the various injector types, decode the cryptic injector codes, discuss common problems and solutions, and navigate the exciting realm of injector upgrades. By the end, you’ll have a profound understanding of 7.3 Powerstroke injector specifications, empowering you to make informed decisions that will keep your Powerstroke roaring strong for many more miles to come.

Quick Answers to Common Questions

What are the factory 7.3 Powerstroke injector specifications?

Most 1999.5-2003 7.3L Powerstrokes came with AD code injectors, which are 140cc/B-code (single shot) for better emissions. Earlier 1994.5-1999 models often had AB or AA injectors, which were split shot designs with different 7.3 Powerstroke injector specifications.

How do I know which 7.3 Powerstroke injector size is right for me?

Your ideal 7.3 Powerstroke injector specifications depend on your goals: towing, daily driving, or maximum power. Consider what you use your truck for and consult with a reputable tuner to match the injector size to your needs and other modifications.

What do the injector codes (like AD or AB) on my 7.3 Powerstroke mean?

These codes designate the specific internal 7.3 Powerstroke injector specifications, including the nozzle type, plunger and barrel size, and whether it’s a single-shot or split-shot design. They are crucial for identifying your injectors and ensuring proper replacements or upgrades.

Do I need a custom tune for upgraded 7.3 Powerstroke injector specifications?

Absolutely! Upgrading your 7.3 Powerstroke injector specifications almost always requires a custom tune to ensure proper fuel delivery, prevent engine damage, and maximize performance. Without it, your truck won’t run correctly, if at all.

What’s a common “mild upgrade” for 7.3 Powerstroke injector specifications?

For a good balance of power and drivability without major supporting mods, many owners opt for 160/30 or 160/80 7.3 Powerstroke injector specifications. These offer a noticeable power bump while still being manageable for daily driving and light towing with a good tune.

📋 Table of Contents

- Understanding the 7.3L Powerstroke HEUI System

- 7.3 Powerstroke Injector Types: Single Shot vs. Split Shot

- Decoding 7.3 Powerstroke Injector Codes and Specifications

- Common 7.3 Powerstroke Injector Problems and Troubleshooting

- Upgrading Your 7.3 Powerstroke Injectors

- Maintaining Your 7.3 Powerstroke Injectors for Longevity

- Conclusion

Understanding the 7.3L Powerstroke HEUI System

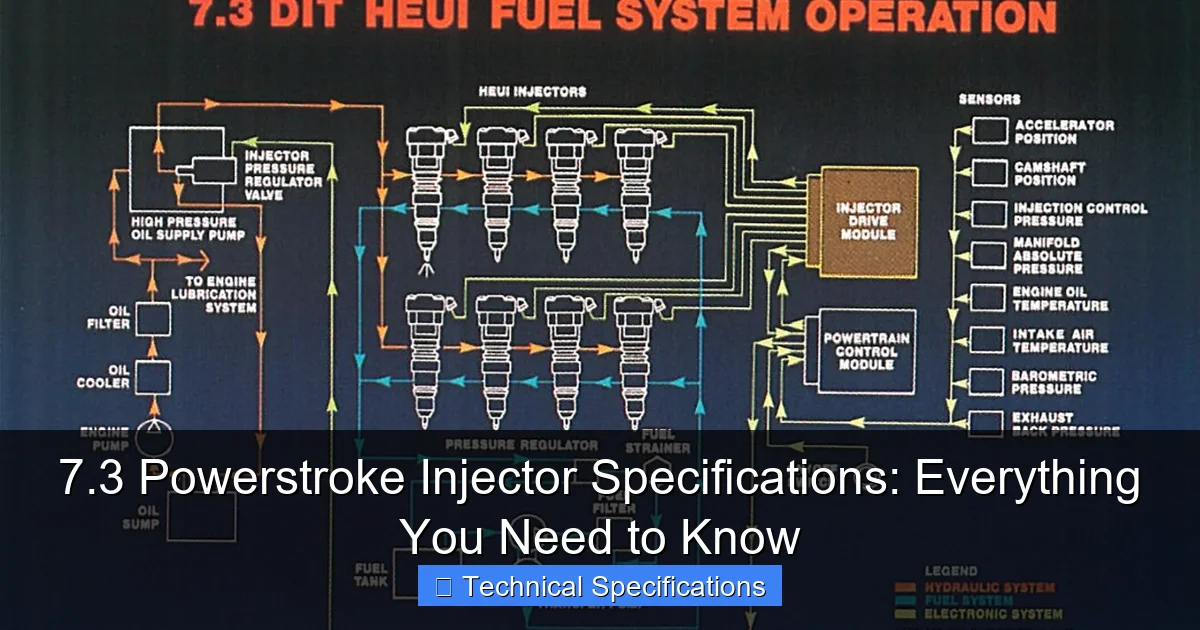

Before we dive deep into the specific details of the injectors, it’s essential to grasp the innovative system that powers them: the Hydraulically Actuated Electronically Controlled Unit Injector, or HEUI system. Developed by Caterpillar and Navistar, this technology was revolutionary for its time, offering significant advantages over previous mechanical injection systems.

Learn more about 7.3 Powerstroke injector specifications – 7.3 Powerstroke Injector Specifications: Everything You Need to Know

Image source: lh5.googleusercontent.com

How HEUI Works: A Synergy of Oil and Fuel

Unlike conventional fuel systems where a high-pressure fuel pump directly pressurizes the fuel for injection, the HEUI system uses engine oil to actuate the fuel injectors. Here’s a simplified breakdown:

| Injector Designation | Flow Rate (cc/min) | Nozzle Size / Configuration | Common Application / Power Level (Approx. HP) |

|---|---|---|---|

| OEM AB Code | ~120 | Stock (7-hole) | 1994.5-1997 Stock Replacement (~250-275 HP) |

| OEM AD Code | ~140 | Stock (7-hole) | 1999.5-2003 Stock Replacement (~275-300 HP) |

| 160/0 (Stock Nozzle) | 160 | Stock equivalent | Mild Towing / Street Performance (~350-375 HP) |

| 160/30 (30% Over) | 160 | 30% over stock | Performance Street / Light Hauling (~375-400 HP) |

| 205/80 (80% Over) | 205 | 80% over stock | Aggressive Performance / Hot Rod (~450-500 HP) |

| 238/100 (100% Over) | 238 | 100% over stock | Competition / Extreme Performance (~500+ HP) |

- High-Pressure Oil Pump (HPOP): The heart of the HEUI system, the HPOP, driven by the engine, pressurizes engine oil to incredibly high levels, often exceeding 3,000 PSI (pounds per square inch), and sometimes reaching up to 3,600 PSI in later models.

- High-Pressure Oil Rails: This pressurized oil is then sent through a series of internal passages and external tubes to the oil rails, which sit on top of the cylinder heads and feed the injectors.

- Injectors: Each injector contains a intensifier piston and a poppet valve. When the Powertrain Control Module (PCM) commands an injector to fire, a solenoid on the top of the injector is energized. This opens a valve, allowing the high-pressure oil from the rail to enter the injector.

- Injection Event: The high-pressure oil acts on the intensifier piston, which in turn acts on a smaller plunger in the fuel side of the injector. Due to the difference in piston surface areas, this intensifies the fuel pressure inside the injector to an astonishing 20,000 to 24,000 PSI – far higher than the oil pressure. This ultra-high-pressure fuel is then forced through the nozzle, creating a finely atomized spray into the combustion chamber.

- Fuel Supply: Meanwhile, a separate low-pressure fuel pump delivers fuel from the tank to the fuel galleries within the cylinder heads, which constantly feed the injectors with fresh fuel at a lower pressure (around 45-65 PSI).

This ingenious design allows for extremely precise control over injection timing, duration, and pressure, leading to better combustion, reduced emissions, and improved performance compared to its predecessors. However, it also means that the health of your engine oil directly impacts the performance of your injectors, making oil quality and change intervals critically important for the longevity of your HEUI system.

7.3 Powerstroke Injector Types: Single Shot vs. Split Shot

Not all 7.3L Powerstroke injectors are created equal. Over its production run, Ford, in conjunction with Navistar, evolved the injector design to meet changing emissions standards and improve engine refinement. The primary distinction lies between “single shot” and “split shot” injectors.

Learn more about 7.3 Powerstroke injector specifications – 7.3 Powerstroke Injector Specifications: Everything You Need to Know

Image source: img.freepik.com

The Evolution of Injectors: From Simplicity to Sophistication

The early 7.3L Powerstroke engines, specifically those produced from 1994.5 to early 1997, utilized single shot injectors. As the name suggests, these injectors deliver their entire fuel charge in one continuous squirt or “shot” into the cylinder. While effective and powerful, this single injection event could be somewhat noisy and contributed to higher NOx emissions due to the rapid and complete combustion.

Responding to stricter emissions regulations and the desire for a quieter, smoother running engine, Ford introduced split shot injectors in the late 1997 model year, becoming standard from 1999 to 2003. Split shot injectors are characterized by a two-stage injection event:

- Pilot Injection: A small amount of fuel is injected very early in the combustion cycle. This “pilot” charge ignites and begins the combustion process, effectively pre-heating the cylinder.

- Main Injection: Following the pilot shot, the larger, main fuel charge is injected. This second shot ignites more smoothly and completely thanks to the pilot injection.

The benefits of split shot technology were significant. It dramatically reduced the characteristic diesel “clatter” (often referred to as NVH – Noise, Vibration, and Harshness) and helped lower harmful emissions, particularly NOx. It also allowed for more precise control over the combustion event, contributing to a smoother power delivery.

Identifying Your Injector Type and Its Implications

Generally, the easiest way to determine your injector type is by your truck’s model year:

- 1994.5 – Early 1997: Likely equipped with single shot injectors.

- Late 1997 – 2003: Likely equipped with split shot injectors.

While you can sometimes visually distinguish them by the appearance of the solenoid, the most reliable method is to check the injector body for its specific code, which we’ll discuss next. It’s crucial to know your injector type, especially when replacing or upgrading. Installing split shots in an engine originally designed for single shots (or vice-versa) without a proper PCM tune will lead to severe performance issues, potential engine damage, and incorrect emissions output.

Decoding 7.3 Powerstroke Injector Codes and Specifications

Every 7.3L Powerstroke injector has a unique alphanumeric code stamped on its body, typically on the solenoid. These codes are not just random letters; they provide vital information about the injector’s design, flow rate, and intended application. Understanding these codes is key to correctly identifying your current injectors and making informed decisions about replacements or upgrades.

The Alphabet Soup of Injector Codes

The most common 7.3 Powerstroke injector specifications codes you’ll encounter are AA, AB, AD, AC, AE, and AF. Each code corresponds to a specific design and flow rate, expressed in cubic centimeters (cc) per 1,000 strokes.

Here’s a breakdown of common 7.3 Powerstroke injector specifications and codes:

| Injector Code | Year Range (Approx.) | Type | Flow Rate (cc @ 1000 Strokes) | Application/Notes |

|---|---|---|---|---|

| AA | 1994.5 – 1997 (Early) | Single Shot | 90 cc | Standard for early 7.3L Powerstrokes. Excellent for towing and daily driving. |

| AB | 1994.5 – 1997 (Early) | Single Shot | 90 cc | Similar to AA, often found in California emissions models. |

| AD | 1999 – 2003 (Late) | Split Shot | 140 cc | Standard for most 1999-2003 7.3L Powerstrokes. Good balance of power and economy. |

| AE | 1999 – 2003 (Late) | Split Shot | 140 cc | Similar to AD, often found in California emissions models. |

| AC | 1999 – 2003 (Specific models) | Split Shot | 135-140 cc | Commonly found in some California models or specific fleet applications. Functionally similar to AD/AE. |

| AF | 1999 – 2003 (Specific models) | Split Shot | 160 cc | Less common, often referred to as “Large AD” or “Early Excursion AD” injector. Provides a slight power bump over standard ADs. |

Understanding Flow Rate (cc): The cubic centimeter (cc) rating indicates the total volume of fuel the injector can deliver per 1,000 strokes of the intensifier piston. A higher cc rating means the injector can flow more fuel. This is a critical metric for performance applications. When people talk about “bigger injectors,” they’re referring to higher cc ratings.

The Importance of Matching Injectors and PCM Tune

It’s crucial to understand that simply swapping in injectors with different 7.3 Powerstroke injector specifications without adjusting your truck’s Powertrain Control Module (PCM) tune can lead to serious issues. The PCM is programmed to expect a certain amount of fuel delivery from your specific injector type. If you install injectors with a higher flow rate, for example, the PCM will still command them to fire based on the old specifications, resulting in too much fuel, excessive smoke, poor performance, and potentially even engine damage.

This is especially true when transitioning between single shot and split shot injectors. Their fundamental injection characteristics are so different that a single shot PCM cannot correctly control a split shot injector and vice versa. Always ensure that any injector change is accompanied by an appropriate custom tune from a reputable tuner.

Common 7.3 Powerstroke Injector Problems and Troubleshooting

Even with their robust design, 7.3 Powerstroke injectors are not immune to issues. Given their critical role and the harsh environment they operate in, problems can arise, often leading to noticeable symptoms. Early detection and proper troubleshooting can save you from more extensive and costly repairs.

Symptoms of Failing Injectors

Identifying a failing injector can be challenging, as many symptoms can overlap with other engine problems. However, here are some tell-tale signs to look out for:

- Rough Idle/Misfires: One of the most common symptoms. The engine might shake, stumble, or run unevenly, especially at idle.

- Loss of Power: A noticeable decrease in acceleration or overall engine strength, particularly under load.

- Excessive Smoke:

- White/Grey Smoke: Often indicates unburnt fuel, especially noticeable when cold or at idle.

- Blue Smoke: Can suggest oil burning, possibly due to worn injector O-rings allowing oil into the combustion chamber.

- Black Smoke: Could indicate over-fueling, where the injectors are delivering too much fuel for the available air, or a problem with the PCM tune.

- Hard Starting: Especially when the engine is hot. “Hot start no-start” is a classic symptom of poor quality high-pressure oil (HPOP) or worn injector O-rings allowing oil to bleed off.

- Increased Fuel Consumption: If injectors are leaking or not atomizing fuel correctly, efficiency suffers.

- Injector “Stiction”: A common term for injectors sticking due to carbon buildup or contaminants within the injector spool valve, often causing a rough idle or misfire when cold, which sometimes clears up as the engine warms.

- Diesel “Knock” or “Clatter”: While the 7.3L naturally has some diesel noise, an unusually loud or irregular knocking can point to an injector issue.

Root Causes of Injector Failure

Understanding why injectors fail is crucial for preventing future issues and effectively troubleshooting current ones:

- Worn O-rings: The injectors use several O-rings to seal against the cylinder head and the high-pressure oil rail. Over time, these O-rings can harden, crack, or degrade from heat and oil exposure, leading to leaks. This can cause high-pressure oil to escape, affecting injector actuation pressure, or allow fuel and oil to mix (creating “fuel in oil” or “oil in fuel” issues).

- Stiction: As mentioned, this is a common issue with HEUI injectors. Carbon and varnish deposits from degraded engine oil can cause the internal spool valve (which directs high-pressure oil) to stick, preventing proper injector operation. Poor oil quality and extended oil change intervals are major contributors.

- Electrical Issues: The injector solenoids are electronic components. They can fail due to internal shorts, breaks in the winding, or corrosion in the electrical connectors. Problems with the injector wiring harness (Under Valve Cover Harness or UVCH) are also common.

- Contaminated Fuel: Water or debris in the fuel can damage the precision components within the injector nozzle, leading to poor spray patterns or blockages.

- Injector Wear: Over hundreds of thousands of miles, the internal components simply wear out, reducing efficiency and leading to leaks or improper operation.

Basic Troubleshooting Steps

If you suspect an injector issue, here’s a logical troubleshooting path:

- Check Oil and Fuel Levels/Quality: Ensure your oil is at the correct level, not overly dirty, and free of fuel contamination. Verify your fuel filters are not clogged.

- Listen for the Injector Buzz Test: With a capable scan tool, you can command an “injector buzz test.” This cycles the solenoids rapidly, creating an audible buzz from each injector. A missing or weak buzz indicates an electrical issue or a stuck solenoid.

- Use an OBD-II Scanner for Codes: A P02XX code (e.g., P0261, P0264, P0267, etc.) specifically points to an injector circuit malfunction in a particular cylinder. Other codes like P1316 (IDM DTCs Detected) indicate issues with the Injector Driver Module.

- Perform a Cylinder Contribution Test: Many scan tools can perform a “contribution test” which analyzes engine RPM changes when individual cylinders are deactivated. A cylinder that shows little to no change in RPM when deactivated likely has a non-contributing or weakly contributing injector.

- Visual Inspection: Look for oil leaks around the valve cover gasket or signs of fuel in the valley. Check the UVCH connections for looseness or burn marks.

While these steps can help pinpoint a faulty injector, professional diagnosis is often recommended, especially before investing in new injectors.

Upgrading Your 7.3 Powerstroke Injectors

For many 7.3L owners, simply maintaining the stock **7.3 Powerstroke injector specifications** isn’t enough. The desire for more power, better towing capability, or improved fuel efficiency often leads to considering injector upgrades. This is a popular modification, but it requires careful planning and a holistic approach.

Why Upgrade Your Injectors?

- Increased Horsepower and Torque: The primary reason for most upgrades. More fuel means more power, especially when combined with increased air (turbo upgrades) and proper tuning.

- Better Towing Performance: Larger injectors can provide the extra grunt needed to pull heavy loads more easily, reducing strain on the engine.

- Replacing Worn Stock Units: If your original injectors are failing, upgrading rather than simply replacing with stock units offers a chance to improve performance at the same time.

- Optimized for Other Modifications: If you’ve upgraded your turbo, HPOP, or intercooler, larger injectors are often necessary to fully utilize the potential of those modifications.

Types of Upgrade Injectors

Injector upgrades typically fall into a few categories, defined by how much fuel they can flow:

- Stock Replacement: These injectors match the original 7.3 Powerstroke injector specifications for your truck. They are ideal for those who want to restore factory performance without modifications.

- “Stage” Injectors (e.g., Stage 1, Stage 2, Stage 3): These are usually rebuilt stock injectors with larger nozzles and sometimes other internal modifications to increase flow rate. They are often described by two numbers:

- The first number is the overall flow rate in cc (e.g., 160cc, 205cc, 238cc).

- The second number is the nozzle size in percentage over stock (e.g., 30%, 80%, 100%). A 205/80 injector, for instance, flows 205cc of fuel through a nozzle that’s 80% larger than stock.

Common examples include:

- 160/30: A mild upgrade, often considered a good balance for daily driving and light towing, providing a noticeable power bump without excessive smoke.

- 205/80 or 238/100: More aggressive upgrades for serious power, requiring substantial supporting modifications.

- Hybrid Injectors: These are custom-built injectors that often combine components from different 7.3L injectors (e.g., a stock body with a larger intensifier piston from an AD injector and a larger nozzle). They are designed to deliver more fuel while requiring less high-pressure oil volume than a similarly flowing “Stage” injector. This can be beneficial for high-power applications where the HPOP might otherwise be a limiting factor.

Crucial Considerations for Upgrades

Upgrading injectors is rarely a standalone modification. To safely and effectively harness the increased power, several other components must be considered:

- Custom Tuning: This is NON-NEGOTIABLE. Any change in injector 7.3 Powerstroke injector specifications from stock, especially flow rate or type (single vs. split shot), requires a custom tune for your PCM. Without it, your truck will run poorly, smoke excessively, and could be damaged.

- Fuel System Upgrades: Larger injectors demand more fuel flow. Your stock fuel pump might not be able to keep up, leading to fuel pressure drops. Consider an upgraded fuel pump (e.g., an electric pump like AirDog or FASS, or a regulated return system) and larger fuel lines.

- Turbocharger Upgrade: More fuel requires more air for complete combustion. The stock turbocharger, especially the Garrett TP38 or early GTP38, can quickly become a bottleneck with larger injectors, leading to high Exhaust Gas Temperatures (EGTs) and excessive smoke. An upgraded turbo (e.g., a larger GTP38R, SXE, or larger frame turbo) is often necessary.

- High-Pressure Oil Pump (HPOP): While hybrid injectors are designed to be more efficient with HPOP volume, larger injectors in general will demand more high-pressure oil. For aggressive upgrades, a larger displacement HPOP (like an Adrenaline, Stealth, or a dual HPOP setup) might be necessary to maintain sufficient oil pressure under full load.

- Transmission Upgrades: The increased power from larger injectors can quickly overwhelm a stock 4R100 automatic transmission. If you plan on significant power increases and heavy use, a built transmission with upgraded clutches, valve body, and torque converter is highly recommended to prevent premature failure.

- Monitoring Gauges: Always install aftermarket gauges to monitor vital engine parameters, including EGTs, boost pressure, fuel pressure, and HPOP pressure. This allows you to keep an eye on your engine’s health and prevent damage.

Choosing the right injectors and supporting modifications depends entirely on your power goals, budget, and intended use for the truck. Research thoroughly and consult with reputable performance shops or tuners before making a decision.

Maintaining Your 7.3 Powerstroke Injectors for Longevity

The best way to avoid expensive injector repairs and ensure your 7.3L Powerstroke continues to perform reliably is through proactive and diligent maintenance. The HEUI system, with its reliance on engine oil for injector actuation, has specific needs that differentiate it from other diesel engines.

The Role of Oil Quality: The Lifeblood of Your Injectors

As we’ve discussed, high-pressure engine oil directly actuates your injectors. This means that oil quality is paramount. It’s not just lubricating; it’s also a hydraulic fluid. Poor quality or degraded oil can lead to a host of problems:

- Stiction: This is arguably the most common issue directly related to oil. As oil breaks down, it forms carbon and varnish deposits that can accumulate in the tight tolerances of the injector spool valve, causing it to stick.

- Accelerated Wear: Contaminated or thin oil provides less protection for the internal moving parts of the injectors and the HPOP, leading to premature wear.

- Reduced Performance: If the oil can’t maintain proper viscosity or pressure, injector actuation will be compromised, leading to poor spray patterns and reduced power.

Actionable Tips for Oil Maintenance:

- Use the Correct Oil Specification: Always use oil that meets the correct diesel engine oil classification (e.g., CI-4 Plus, CJ-4, or CK-4). While older specifications are being superseded, ensure the oil you choose is suitable for a high-pressure common rail or HEUI system. Consult your owner’s manual or a reputable diesel mechanic for the best recommendation.

- Frequent Oil Changes: The 7.3L holds a lot of oil (15 quarts!), but its HEUI system is hard on it. Stick to strict oil change intervals, typically every 3,000-5,000 miles or less, especially if you tow heavily or operate in harsh conditions. Don’t push it.

- Consider Synthetic Oil: While not strictly required, many owners report better cold starting, reduced stiction, and extended oil life with high-quality synthetic diesel oils. Synthetics generally have better thermal stability and resistance to breakdown.

- Monitor Oil Level: Consistently check your oil level. Low oil levels can lead to cavitation in the HPOP and insufficient pressure for injector actuation.

The Importance of Fuel Quality and Filtration

While oil gets most of the attention for HEUI injectors, fuel quality and filtration are equally critical for the longevity of the injector nozzles and internal components that handle the fuel itself.

- High-Quality Diesel Fuel: Always fill up at reputable fuel stations. Cheap or questionable fuel sources can contain excessive water, sediment, or other contaminants that can wreak havoc on your injectors.

- Regular Fuel Filter Changes: The fuel filter is your primary defense against fuel contamination. Change your fuel filter at or before the recommended intervals, typically every 10,000-15,000 miles, or more frequently if you get questionable fuel.

- Aftermarket Fuel Filtration: Consider adding an aftermarket fuel filter/water separator system. These systems often offer much finer filtration than stock and better water separation capabilities, providing an extra layer of protection for your expensive injectors.

Fuel Additives: A Controversial but Potentially Beneficial Topic

The use of fuel additives is a widely debated topic among diesel owners. However, certain additives can genuinely benefit your 7.3 Powerstroke injectors, especially with modern Ultra-Low Sulfur Diesel (ULSD).

- Lubricity Additives: ULSD, while cleaner burning, has significantly reduced lubricity compared to older diesel fuels. This can lead to increased wear on fuel system components, including the injectors. A good lubricity additive can help restore this lost lubrication.

- Cetane Boosters: Higher cetane numbers generally lead to easier cold starts, smoother running, and potentially better fuel economy due to more complete combustion.

- Stiction-Specific Additives: For trucks experiencing stiction issues, there are oil additives specifically designed to clean and free up the internal components of HEUI injectors. These are often used as a “flush” or long-term maintenance treatment.

Always research additives carefully and choose reputable brands. Avoid products that make exaggerated claims or contain questionable ingredients.

Monitoring and Early Detection

Pay close attention to your truck’s behavior. Any changes in engine sound, exhaust color, idle quality, or power output should be investigated promptly. Early detection of a failing injector can prevent it from causing further damage to other cylinders or the overall engine. Addressing issues as soon as they arise is far less costly than waiting for a complete breakdown.

Conclusion

The 7.3 Powerstroke injector specifications are far more than just technical data; they are the key to understanding the heart of one of the most beloved diesel engines ever produced. From the ingenious HEUI system that actuates them with high-pressure oil to the subtle yet significant differences between single shot and split shot designs, each aspect plays a crucial role in your truck’s performance and longevity. Decoding injector codes, understanding flow rates, and recognizing the signs of failure are essential skills for any 7.3L owner.

Whether you’re meticulously maintaining your stock setup, troubleshooting a persistent rough idle, or planning a formidable power upgrade, a deep understanding of your 7.3 Powerstroke injectors is non-negotiable. Proactive maintenance, including rigorous oil and fuel filtration, along with thoughtful consideration of upgrades and their necessary supporting modifications, will ensure your legendary 7.3L Powerstroke continues to perform at its peak for hundreds of thousands of miles to come. Invest in knowledge, invest in quality parts, and your 7.3L will reward you with unwavering reliability and performance.

🎥 Related Video: All You Need To Know About HEUI Fuel Injectors! – Understanding 6.0 & 7.3 Powerstroke Injectors

📺 KC TURBOS

6.0 and 7.3 Powerstroke fuel injectors can be a little confusing. how do they work? What size nozzle should I get? How much …

Frequently Asked Questions

What are the stock 7.3 Powerstroke injector specifications?

The stock 7.3 Powerstroke injectors vary by model year and often by specific production runs. Common stock codes include AD (found in early 99 and older), AE (late 99-03), and AB (94.5-97), each having specific flow rates and internal designs. These injectors are designed for optimal factory performance and emissions compliance.

What are the common upgrade options for 7.3 Powerstroke injectors?

Common upgrade options for 7.3 Powerstroke injectors involve increasing the nozzle size and/or the internal plunger/barrel size, often referred to as “stage” injectors or by their CC rating. Popular choices range from 160cc to 238cc or larger, designed for increased horsepower and torque, often requiring supporting modifications like a larger turbo and custom tuning.

What are the signs that my 7.3 Powerstroke injectors need replacing?

Common signs of failing 7.3 Powerstroke injectors include rough idle, excessive smoke (especially blue or white smoke), poor fuel economy, loss of power, and hard starting. A professional diagnostic test, such as a cylinder contribution test, can help pinpoint specific problematic injectors needing replacement.

What is the difference between AD and AE 7.3 Powerstroke injectors?

AD and AE are common codes found on 7.3 Powerstroke injectors, primarily denoting different internal components and fuel delivery characteristics. AE injectors typically came in later models (late 99-03) and are often preferred for their slightly larger poppet valve, offering better flow potential and a more desirable spray pattern compared to the AD type (early 99 and older).

How do I choose the correct 7.3 Powerstroke injector size for my application?

Choosing the right 7.3 Powerstroke injector size depends on your power goals, supporting modifications, and desired driving characteristics. For mild upgrades, 160cc or 180cc injectors are common, while higher horsepower builds may require 205cc, 238cc, or even larger injectors with appropriate fuel system upgrades, turbo, and custom tuning.

Are 7.3 Powerstroke injectors compatible across all model years?

While many 7.3 Powerstroke injectors are physically interchangeable, there are important differences in external connectors (like the single-shot vs. split-shot firing order) and internal specifications between early (94.5-97) and late (99-03) model years. Using injectors not specifically designed for your model year, or without proper tuning, can lead to performance issues or engine damage.