7.3 Powerstroke High-Pressure Oil Pump Symptoms: A Comprehensive Guide

The 7.3 Powerstroke engine, a stalwart in the world of diesel engines, has gained a well-deserved reputation for its exceptional power and reliability. Ford truck owners have come to appreciate its robust performance, making it a preferred choice for heavy-duty tasks. At the heart of this legendary engine lies a critical component – the high-pressure oil pump. This pump plays a vital role in maintaining the engine’s optimal functioning by supplying high-pressure oil to ensure efficient fuel injection and lubrication.

However, like any mechanical part, the high-pressure oil pump is prone to wear and tear over time. Identifying the symptoms of a faulty pump becomes crucial for maintaining the engine’s performance and avoiding potential damage. In this comprehensive guide, we will explore the various warning signs that indicate a malfunctioning high-pressure oil pump in the 7.3 Powerstroke engine. By understanding these symptoms, you can take prompt action and seek appropriate repairs, safeguarding your engine’s longevity and preserving its optimal performance.

What are the pressure ranges that determine the performance of injectors with different levels of ICP?

Different pressure ranges of Injection Control Pressure (ICP) are crucial in determining the performance of injectors with varying capacities. – To achieve exceptional performance with injectors below 250cc, maintaining an ICP of 2800+ psi is vital. – A moderate ICP of 2400 psi can still produce acceptable results, though not optimal. – Mediocre performance is expected at 2200 psi, where full injector potential may not be realized, impacting driveability with increased smoke. – If ICP drops below 1900 psi, a new or aftermarket High-Pressure Oil Pump (HPOP) may be necessary. Lower ICP levels may result in sluggish performance and excessive smoke with larger injectors.

Signs Of A 7.3 Powerstroke High Pressure Oil Pump

Recognizing the symptoms of a faulty high-pressure oil pump in a 7.3 Powerstroke engine holds immense significance for several reasons. Firstly, the high-pressure oil pump is a critical component responsible for maintaining proper fuel injection and lubrication within the engine system. When it malfunctions, it can lead to serious performance issues and potentially cause severe damage to the engine.

By being aware of the symptoms associated with a faulty high-pressure oil pump, owners and mechanics can proactively address the problem before it escalates. This early detection can save considerable time, money, and effort by preventing further damage and reducing the risk of costly repairs or engine failure.

Moreover, recognizing these symptoms allows for timely maintenance or replacement of the high-pressure oil pump, ensuring the engine operates at its optimal level. This, in turn, leads to improved fuel efficiency, enhanced performance, and an extended lifespan for the engine.

What should be done if an overheating symptom is noticed?

If you notice this symptom, it’s best to take your vehicle to a professional mechanic as soon as possible.

What can cause overheating in an engine?

An issue with the coolant system can cause overheating, and so can a faulty HPOP.

What are the potential symptoms of an overheating engine?

The temperature pressure gauge needle usually rests halfway when everything’s running properly. When the needle starts rising toward the red zone, it shows that the engine’s temperature is too high. A warning light on the dash may also appear, pointing to an overheating engine.

How does a faulty HPOP contribute to an overheating engine?

A faulty HPOP can contribute to overheating because oil circulating at low pressure does not have the same cooling properties as oil moving at optimum pressure.

What are the potential consequences of an overheating engine?

Overheating can cause severe, expensive damage to the engine.

How can I use a scan tool to measure the ICP (Injection Control Pressure) of the HPOP?

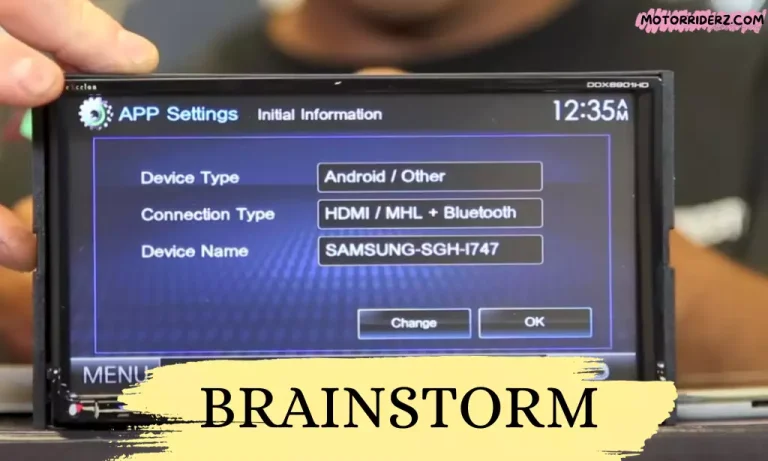

To use a scan tool to measure the Injection Control Pressure (ICP) of the High-Pressure Oil Pump (HPOP), start by connecting the scan tool to the OBD port of the vehicle. Access the ‘datastream’ function on the scan tool and look for the sensor values. Navigate through the values until you locate the ICP (or injection control pressure) parameter, which represents the oil pressure of the HPOP. It is essential to note that if your vehicle is equipped with additional components like a performance ‘box’ (such as the ‘Edge EZ’ or ‘Banks Six Gun’) or a modification like a ’10k mod’ that interferes with the ICP sensor signal, you may need to remove these modifications temporarily. This ensures that the scan tool receives accurate data from the ICP sensor. When monitoring the ICP on the scan tool, ensure that the unit of measurement is in pounds per square inch (psi). Some scan tools may display ICP in kilopascals (kPa), which can be converted to psi using the conversion factor 1 kPa = 0.145 psi. For example, 19,310 kPa would be equivalent to approximately 2800 psi. To test the HPOP’s output, set the vehicle’s performance chip to its highest setting and perform a road test on the interstate while monitoring the ICP value on the scan tool. Accelerate from around 60 mph to 90 mph at full throttle. During this acceleration, observe how the ICP spikes rapidly to a certain pressure (e.g., 2800-3000 psi) and then gradually decreases. The stabilization point of the ICP after reaching its peak pressure can provide insights into the condition of your HPOP.

How can I test the HPOP output without a scan tool?

To assess the High-Pressure Oil Pump (HPOP) output without the use of a scan tool, you can create a makeshift setup with a mechanical gauge. Start by visiting a local hydraulic supply shop to have a mechanical gauge assembled.

This gauge should include a high-pressure hose (around 40 inches long) rated for at least 3000 psi working pressure, fittings, and a quality 0-3500 psi liquid-filled gauge. The setup requires specific components, such as a #5 “male boss” 90-degree fitting and a #6 female JIC swivel fitting crimped onto the hose. To connect the gauge to the vehicle, remove a bronze plug from the cylinder head using a 5/8″ wrench and install the 90-degree fitting into the hole. Ensure the fitting is securely attached and oriented away from any nearby components before connecting the hose.

Once the mechanical gauge is connected, route the hose away from any moving parts or electrical components, ensuring it is securely positioned. For testing purposes, you can lay the gauge under the windshield wiper and conduct tests while driving. Make sure to monitor the gauge for any pressure irregularities and leaks during testing. This makeshift mechanical setup provides a practical way to test the HPOP output without the need for a scan tool, enabling you to diagnose and troubleshoot potential issues effectively.

Decreased Engine Power

A failing high-pressure oil pump in a 7.3 Powerstroke engine can have a significant impact on the engine’s power output. This component is responsible for supplying pressurized oil to the fuel injectors, ensuring proper atomization and combustion. When the pump begins to fail, it may struggle to deliver the required amount of oil at the correct pressure, leading to a noticeable decrease in engine power.

Impact on Acceleration

Acceleration is one of the key performance aspects affected by a failing high-pressure oil pump. As the pump fails to deliver adequate oil pressure to the fuel injectors, the combustion process becomes compromised. This can result in sluggish acceleration, as the engine struggles to generate the necessary power to propel the vehicle forward quickly.

Decreased Towing Capacity

Towing capacity, another crucial aspect for truck owners, can be severely impacted by a failing high-pressure oil pump. When towing heavy loads, the engine relies on optimal fuel injection and combustion to generate the required power. A faulty oil pump disrupts this process, leading to reduced power output and decreased towing capacity. The engine may struggle to maintain speed on inclines or fail to deliver the necessary torque, compromising the vehicle’s towing capabilities.

Overall Performance Implications

A failing high-pressure oil pump can have a cascading effect on the overall performance of the 7.3 Powerstroke engine. In addition to reduced power, it may cause rough idling, misfires, and increased exhaust smoke. The engine may exhibit hesitation or stumbling during acceleration, and the overall fuel efficiency can suffer as well. Ignoring these symptoms and continuing to operate with a faulty pump can lead to more severe damage and potentially expensive repairs.

Hard Starting and Rough Idle Due to Faulty High-Pressure Oil Pump

A faulty high-pressure oil pump in an engine can lead to various issues, including difficulty starting the engine and a rough idle. This component plays a crucial role in supplying oil at high pressure to operate the fuel injectors and lubricate critical engine parts. When it malfunctions, it can result in inadequate oil pressure, causing the following symptoms:

1. Extended Cranking Time: One of the primary indications of a faulty high-pressure oil pump is an increased cranking time during engine startup. As the pump fails to deliver sufficient oil pressure, it takes longer for the engine to build up the necessary fuel pressure for combustion. The extended cranking time can be characterized by the engine turning over for an excessive period before it finally starts.

2. Difficulty Starting the Engine: Inadequate oil pressure caused by a faulty high-pressure oil pump can make it challenging to start the engine. The lack of sufficient pressure hinders the proper functioning of the fuel injectors, which rely on high-pressure oil to atomize and deliver the fuel into the combustion chamber. As a result, the engine may struggle to ignite the fuel-air mixture effectively, leading to repeated failed attempts to start the engine.

3. Rough Idle: When the high-pressure oil pump fails to deliver enough oil pressure, it can result in a rough idle. The fuel injectors may not operate optimally, leading to an inconsistent fuel delivery pattern. This can cause irregular combustion, resulting in a rough and unstable idle. The engine may exhibit symptoms such as shaking, fluctuating RPMs, and a noticeable lack of smoothness during idling.

4. Stalling or Misfires: In severe cases, a faulty high-pressure oil pump can cause the engine to stall or experience misfires. Inadequate oil pressure can disrupt the fuel injection process, leading to incomplete combustion in the cylinders. This can cause the engine to lose power, hesitate, or even stall completely. Misfires may occur as a result of the inconsistent fuel delivery, leading to rough running and potential damage to the engine’s components over time.

Hesitation and Stalling Due to Failing High-Pressure Oil Pump

A failing high-pressure oil pump can contribute to hesitation and stalling during acceleration in an engine. This component is responsible for supplying pressurized oil to the fuel injectors, allowing them to deliver fuel to the combustion chamber with precision and timing. When the high-pressure oil pump malfunctions, it can lead to insufficient oil pressure, resulting in the following issues:

1. Hesitation During Acceleration: Inadequate oil pressure caused by a failing high-pressure oil pump can lead to hesitation during acceleration. The fuel injectors rely on high-pressure oil to atomize the fuel and provide an optimal air-fuel mixture for combustion. If the oil pressure is insufficient, the fuel delivery may be inconsistent or delayed. As a result, the engine may hesitate or experience a noticeable delay in responding to the accelerator pedal inputs during acceleration. This hesitation can lead to a lack of power and a jerky driving experience.

2. Stalling: Insufficient oil pressure can also contribute to stalling of the engine. The fuel injectors require adequate oil pressure to operate properly and deliver fuel in a precise manner. When the oil pressure is too low, the fuel injection process can be disrupted, leading to incomplete combustion. This can cause the engine to lose power abruptly and stall. Stalling often occurs when the engine is idling or during low-speed maneuvers, such as coming to a stop or when transitioning from deceleration to acceleration.

Connection between Insufficient Oil Pressure and Engine Misfires:

Insufficient oil pressure resulting from a failing high-pressure oil pump can also contribute to engine misfires. Engine misfires occur when the air-fuel mixture in one or more cylinders fails to ignite properly. Inadequate oil pressure can disrupt the fuel injection process, leading to incomplete combustion. When the fuel is not injected properly or in the correct timing, it can result in misfires.

Misfires can cause a range of symptoms, including rough running, loss of power, and abnormal engine sounds. The engine may shake or vibrate, and there may be a noticeable lack of smoothness during operation. Over time, frequent misfires can lead to damage to the engine’s components, such as the spark plugs, cylinders, and exhaust system.

Engine Misfires Due to Faulty High-Pressure Oil Pump

A faulty high-pressure oil pump can contribute to engine misfires, which occur when the air-fuel mixture in one or more cylinders fails to ignite properly. The high-pressure oil pump plays a crucial role in supplying pressurized oil to the fuel injectors, ensuring precise fuel delivery and combustion. When the pump malfunctions, it can result in insufficient oil pressure, leading to the following issues:

1. Incomplete Fuel Injection: A failing high-pressure oil pump may not deliver enough oil pressure to the fuel injectors. This can lead to incomplete fuel injection, causing the air-fuel mixture to be imbalanced or inadequate in the affected cylinders. The insufficient fuel delivery can result in misfires, where the fuel does not ignite or ignites improperly, leading to a disruption in the combustion process.

2. Rough Running: Misfires caused by a faulty high-pressure oil pump can result in rough running of the engine. The affected cylinders may not be firing consistently, leading to a loss of smoothness during operation. The engine may exhibit symptoms such as vibrations, shaking, or a noticeable lack of power. The rough running can be especially prominent during acceleration or at higher speeds.

3. Loss of Power: Engine misfires caused by inadequate oil pressure can also result in a loss of power. When one or more cylinders fail to ignite properly, the combustion process is compromised, leading to reduced power output. The engine may feel sluggish and struggle to accelerate or maintain speed. The loss of power can negatively impact the vehicle’s overall performance and responsiveness.

4. Check Engine Light Illumination: A faulty high-pressure oil pump and the resulting misfires can trigger the vehicle’s onboard diagnostic system, causing the check engine light to illuminate on the dashboard. The engine control unit (ECU) monitors various parameters and sensors to detect abnormalities in the engine’s operation. When misfires occur, the ECU detects the irregularities in the combustion process and registers a fault code, leading to the activation of the check engine light.

Oil Leaks Due to Failing High-Pressure Oil Pump

A failing high-pressure oil pump can contribute to oil leaks in the engine bay. The high-pressure oil pump is responsible for supplying pressurized oil to various engine components, such as the fuel injectors and other critical parts. When the pump malfunctions, it can result in several issues that can lead to oil leaks:

1. Seal Failure: The high-pressure oil pump contains seals and gaskets that help maintain a tight seal between the pump and other engine components. Over time, these seals can deteriorate or become damaged, especially if the pump is failing or experiencing excessive wear. As a result, oil can start to leak from the pump, leading to potential oil leaks in the engine bay.

2. Increased Oil Pressure: A failing high-pressure oil pump may cause a sudden increase in oil pressure. This excessive pressure can strain the seals and gaskets throughout the engine, potentially causing them to fail and leading to oil leaks. The increased pressure can also cause oil to find alternative paths of escape, such as through worn seals or improperly sealed connections, resulting in leaks.

How does a faulty high pressure oil pump affect power at high RPMs?

A faulty high pressure oil pump (HPOP) can significantly impact the power and speed of a vehicle at higher RPMs. Typically, the HPOP is connected to the crankshaft, and when you apply extra pressure on the accelerator, the crankshaft rotates faster, leading to an increase in RPMs. As a result, the HPOP also spins faster, generating higher oil pressure.

In a properly functioning HPOP, the increased oil pressure allows for more fuel to be forced into the combustion chamber. This higher fuel volume leads to greater power and speed of the vehicle. However, when the HPOP is faulty and fails to effectively increase the oil pressure, it hinders the process of forcing more fuel into the combustion chamber.

As a consequence, if the HPOP struggles to boost the oil pressure, you will not observe a noticeable increase in power and speed at higher RPMs. The insufficient oil pressure fails to push adequate fuel into the combustion chamber, thereby limiting the vehicle’s ability to generate the desired power and achieve higher speeds.

What does a whining or whirring noise from the engine indicate?

A whining or whirring noise from the engine can serve as an indication that there might be an issue with the oil pump. This noise could also suggest that the High-Pressure Oil Pump (HPOP) is nearing the end of its lifespan. When certain engine components are faulty, they tend to produce a whining or whirring sound. If this noise becomes more pronounced as you accelerate, it is likely originating from the oil pump. This is due to the connection between the HPOP and the crankshaft. As the crankshaft rotates faster, the pump has to work harder, leading to increased noise levels in a malfunctioning engine.

Potential Locations of Oil Leaks and Impact on Engine Performance and Safety:

Oil leaks caused by a failing high-pressure oil pump can occur in various locations within the engine bay. Common areas where oil leaks may manifest include:

1. High-Pressure Oil Pump Area: As mentioned earlier, failing seals and gaskets within the high-pressure oil pump itself can result in oil leaks. This can lead to the oil escaping from the pump housing and dripping onto surrounding components or pooling in the engine bay.

2. Fuel Injector Connections: The high-pressure oil pump supplies oil to the fuel injectors, and these connections can be potential areas for oil leaks. If the connections between the pump and the injectors are not properly sealed, oil can seep out, leading to leaks and potential engine performance issues.

3. Hoses and Fittings: The high-pressure oil pump is connected to various hoses and fittings that distribute the pressurized oil throughout the engine. If these hoses or fittings become damaged, loose, or worn out, oil leaks can occur at these points. Common areas to check include the connections between the pump and the hoses, as well as the fittings throughout the system.

The impact of oil leaks on engine performance and safety can be significant. Here are some potential consequences:

- Engine Performance Issues: Oil leaks can result in a loss of oil pressure and reduced lubrication to critical engine components. This can lead to increased friction, wear, and potential damage to engine parts. Reduced oil pressure can also affect the performance of the high-pressure oil pump itself, exacerbating the initial problem and potentially leading to further malfunctions.

- Decreased Engine Efficiency: Oil leaks can lead to a loss of oil, resulting in insufficient lubrication and increased friction within the engine. This can reduce engine efficiency and lead to decreased fuel economy. The engine may also experience decreased power output and performance.

- Safety Concerns: Oil leaks in the engine bay can pose safety hazards. Oil dripping onto hot engine components can cause smoke or even a fire if it comes into contact with ignition sources. Oil on the ground beneath the vehicle can create slippery conditions, increasing the risk of accidents.

Increased Fuel Consumption Due to Faulty High-Pressure Oil Pump

A faulty high-pressure oil pump can contribute to increased fuel consumption in an engine. The high-pressure oil pump plays a critical role in supplying pressurized oil to the fuel injectors, which are responsible for delivering fuel into the combustion chamber. When the pump malfunctions, it can result in inadequate oil pressure, leading to the following issues that can impact fuel efficiency:

1. Inefficient Fuel Combustion: Insufficient oil pressure caused by a faulty high-pressure oil pump can lead to inefficient fuel combustion. The fuel injectors rely on high-pressure oil to atomize the fuel into a fine mist, allowing for optimal mixing with air in the combustion chamber. When the oil pressure is inadequate, the fuel spray may be less precise, resulting in uneven or incomplete mixing with air. This inefficient fuel combustion can lead to reduced fuel efficiency and increased fuel consumption.

2. Imbalanced Air-Fuel Ratio: Inadequate oil pressure can also impact the air-fuel ratio, which refers to the ratio of air to fuel in the combustion process. When the oil pressure is low, the fuel delivery may become imbalanced, with either too much or too little fuel being injected into the combustion chamber. This can disrupt the ideal air-fuel ratio required for efficient combustion. An imbalanced air-fuel ratio can lead to incomplete fuel combustion, resulting in wasted fuel and increased fuel consumption.

3. Compensation from Engine Management System: In response to inadequate oil pressure, the engine management system may attempt to compensate by increasing the fuel injection duration or adjusting other parameters. This compensation is intended to ensure that enough fuel reaches the combustion chamber for ignition. However, this can lead to excessive fuel being injected, resulting in a richer fuel mixture. Rich fuel mixtures tend to burn less efficiently, leading to increased fuel consumption.

4. Reduced Engine Performance: A failing high-pressure oil pump can negatively affect engine performance, leading to increased fuel consumption. Inefficient fuel combustion and imbalanced air-fuel ratios can result in reduced power output, requiring the driver to apply more throttle to achieve the desired performance. The increased throttle demand leads to higher fuel consumption.

Illuminated Check Engine Light Due to Failing High-Pressure Oil Pump

A failing high-pressure oil pump can trigger the check engine light to illuminate on the vehicle’s dashboard. The check engine light is part of the onboard diagnostic system, which monitors various parameters and sensors to detect abnormalities in the engine’s operation. When the high-pressure oil pump malfunctions, it can lead to specific issues that result in the activation of the check engine light.

1. Insufficient Oil Pressure: A failing high-pressure oil pump may result in insufficient oil pressure within the engine. This can be due to pump failure, worn components, or oil leaks. The engine control unit (ECU) detects this decrease in oil pressure through various sensors and registers it as an abnormality. As a result, the ECU can trigger the check engine light to inform the driver of the issue.

2. Diagnostic Trouble Codes (DTCs) Related to Oil Pressure Issues: When the check engine light illuminates due to oil pressure issues caused by a failing high-pressure oil pump, specific diagnostic trouble codes (DTCs) may be stored in the vehicle’s ECU. These DTCs provide a starting point for technicians to diagnose the problem more accurately. Common DTCs related to oil pressure issues include:

- P0521: Engine Oil Pressure Sensor/Switch Range/Performance

- P0522: Engine Oil Pressure Sensor/Switch Low Voltage

- P0523: Engine Oil Pressure Sensor/Switch High Voltage

- P0524: Engine Oil Pressure Too Low

- P0525: Engine Oil Temperature Sensor/Switch Circuit Malfunction

These DTCs indicate different aspects of oil pressure problems and help guide the diagnostic process. They provide information about the specific nature of the oil pressure issue, such as a faulty sensor, low voltage, high voltage, or excessively low oil pressure. By retrieving these codes using a diagnostic tool, a qualified mechanic can gain insights into the nature of the problem and focus their efforts on the relevant components.

What are the different pressure levels that indicate the condition of the HPOP?

The condition of the High-Pressure Oil Pump (HPOP) can be determined by monitoring specific pressure levels. – If the HPOP can consistently maintain a pressure of 2800+ psi in the Injection Control Pressure (ICP) system, injectors with a capacity of 250cc or less will function exceptionally well. – A pressure level of 2400 psi is considered acceptable, although not optimal. – A pressure of 2200 psi indicates a mediocre condition, where full injector performance may not be achieved. However, installing larger injectors may still increase power output, though driveability issues such as excessive smoke may arise. – If the pressure drops below 1900 psi, it is recommended to consider replacing the HPOP with a new or aftermarket unit. In this scenario, using larger injectors may result in sluggish truck performance and excessive smoke emissions.

How can I test the performance of my HPOP (High-Pressure Oil Pump)?

To test the performance of your HPOP (High-Pressure Oil Pump), you can follow these steps: 1. Obtain access to a scan tool that can be connected to your truck’s OBD (On-Board Diagnostics) connector. Navigate to the ‘datastream’ function on the scan tool and locate the sensor values. Look specifically for the ICP (Injection Control Pressure) parameter as it represents your HPOP’s oil pressure. Ensure that the unit displayed for ICP is in psi (pounds per square inch) and not in volts. 2. Set the chip in its highest setting and drive your truck on the interstate with someone monitoring the ICP value on the scan tool. Begin driving at around 60mph and accelerate by flooring the pedal, maintaining full throttle from approximately 60-90mph. During this acceleration, observe if the truck can sustain an ICP reading of 2800 psi or higher. 3. If you do not have access to a scan tool, visit a local hydraulic supply house to have a mechanical gauge made for testing. The mechanical gauge can also measure the ICP accurately. 4. It is important to note that if your truck can consistently maintain an ICP of 2800 psi or more, it indicates that your HPOP is operating exceptionally well. This level of performance is especially beneficial for injectors with a capacity of 250cc or less, as they will function optimally under such conditions.

What equipment do I need to create a mechanical gauge for testing the HPOP?

To create a mechanical gauge for testing the HPOP, you will need several specific pieces of equipment. Begin by acquiring a high-pressure hose rated for at least 3000psi working pressure (with a burst rating of 12k psi). The hose should be approximately 40 inches long and come with a quality 0-3500psi liquid-filled gauge already attached at one end. In addition to the high-pressure hose and gauge, you will require fittings to connect the hose to the HPOP. Look for a #6 female JIC swivel fitting crimped onto the opposite end of the gauge. You will also need a specific individual fitting to screw into the HPOP – specifically, a 90-degree fitting with a #5 “male boss” on one end and a #6 male JIC on the other. This fitting is commonly labeled as 5MB-6MJ90 by hydraulic supply shops. As you install the fitting into the HPOP, it’s important to use a 5/8″ wrench to remove and replace any existing bronze plugs on the cylinder head with the 90-degree fitting. Make sure to tighten the fitting securely, but avoid over-tightening to prevent damage. When routing the hose, take care to avoid areas with moving parts and electrically conductive components like batteries or relays. For temporary testing purposes, you can simply run the hose up through the cowl towards the windshield, securing the gauge under a windshield wiper for easy monitoring while driving and testing the system under different conditions.

What steps are involved in setting up and using a mechanical gauge to test the HPOP?

To set up and use a mechanical gauge for testing the High-Pressure Oil Pump (HPOP), you will follow these steps: 1. Obtain a mechanical gauge: If you do not have access to a scan tool, visit a local hydraulic supply store to have a mechanical gauge made for you. The gauge should include a high-pressure hose, fittings, and a quality liquid-filled gauge rated from 0-3500psi. 2. Select the right hose: The hose required for this setup should be approximately 40 inches long, have a working pressure rating of at least 3000psi (with a burst rating of 12,000 psi), and feature a #6 female JIC swivel fitting crimped onto one end. 3. Get the necessary fittings: You will need a specialized fitting to connect the hose to the cylinder head. This fitting should be a 90-degree fitting with a #5 “male boss” on one end and a #6 male JIC on the other. For example, this fitting might be labeled as 5MB-6MJ90 at the hydraulic shop. 4. Install the fitting: With the engine turned off, remove one of the bronze-colored plugs on top of the cylinder head using a 5/8″ wrench. Install the 90-degree fitting into the hole, ensuring the jamb nut on the O-ring side is tightened to secure the fitting in place. 5. Route the hose: Route the hose away from any moving parts or electrical components that could cause interference. Guide the hose up through the cowl towards the windshield for easy access during testing. 6. Test the HPOP: With the mechanical gauge set up, you can now test the HPOP by driving the vehicle as needed. Monitor the gauge readings while operating the vehicle under different conditions to assess the performance of the pump accurately.

Conclusion

It is important to recognize the key symptoms of a faulty high-pressure oil pump in a 7.3 Powerstroke engine, including hard starting, rough idle, hesitation, stalling, engine misfires, and potential oil leaks. Early detection and timely repair are crucial to prevent further damage to the engine and associated components.They have the expertise and diagnostic tools to accurately diagnose the issue and perform the necessary repairs or replacement of the high-pressure oil pump. Taking prompt action will ensure the optimal performance and longevity of your engine.