7.3 Powerstroke Fuel Injector Flow Rate: Everything You Need to Know

Featured image for this comprehensive guide about 7.3 Powerstroke fuel injector flow rate

Image source: thumb.photo-ac.com

The iconic Ford 7.3 Powerstroke diesel engine holds a legendary status among truck enthusiasts and heavy-duty workers alike. Renowned for its unparalleled durability, simplicity, and workhorse capabilities, this engine powered Ford Super Duty trucks and vans for over a decade. But like any high-performance machine, its heart relies on a finely tuned system – and when it comes to fuel delivery, nothing is more critical than the 7.3 Powerstroke fuel injector flow rate.

Understanding your injectors and their specific flow rates isn’t just for mechanics or performance junkies. It’s essential knowledge for anyone who owns, operates, or plans to upgrade a 7.3 Powerstroke. From maximizing horsepower and torque to ensuring optimal fuel economy and extending engine life, the precise amount of fuel injected into each cylinder at the right time makes all the difference. Get it wrong, and you could face rough idles, excessive smoke, reduced power, or even catastrophic engine damage. Get it right, and your beloved 7.3 will continue to run strong for hundreds of thousands of miles.

In this comprehensive guide, we’ll dive deep into the world of 7.3 Powerstroke fuel injector flow rates. We’ll explore how these vital components work, decode the mysterious numbers and codes associated with them, discuss factors that influence their performance, and equip you with the knowledge to make informed decisions, whether you’re troubleshooting an issue or planning a performance upgrade. Prepare to unlock the full potential of your 7.3 Powerstroke!

Quick Answers to Common Questions

What exactly is 7.3 Powerstroke fuel injector flow rate?

It’s the amount of fuel your injectors can deliver into your engine’s cylinders over a specific time, typically measured in cubic centimeters (cc) or pounds per hour (lbs/hr). This 7.3 Powerstroke fuel injector flow rate is crucial for determining how much power your engine can make and how efficiently it runs.

Why should I care about my 7.3 Powerstroke fuel injector flow rate?

Understanding your 7.3 Powerstroke fuel injector flow rate is key to optimizing performance and fuel economy. The right flow rate ensures proper combustion, preventing issues like poor mileage, excessive smoke, or even engine damage.

How does a different 7.3 Powerstroke fuel injector flow rate affect my truck’s power?

A higher 7.3 Powerstroke fuel injector flow rate generally means more fuel can be delivered, allowing for more horsepower potential when properly tuned. Conversely, an incorrect or insufficient flow rate can severely limit your engine’s output and responsiveness.

What are the signs of a bad or incorrect 7.3 Powerstroke fuel injector flow rate?

You might notice symptoms like excessive black or white smoke, poor fuel economy, rough idle, loss of power, or difficulty starting. These often point to injectors not delivering fuel at their optimal 7.3 Powerstroke fuel injector flow rate.

Can I upgrade my 7.3 Powerstroke fuel injector flow rate for more power?

Absolutely! Many 7.3 Powerstroke owners upgrade to injectors with a higher 7.3 Powerstroke fuel injector flow rate to unlock significant power gains. However, this often requires complimentary modifications like a better fuel pump and custom tuning for safe and effective results.

📋 Table of Contents

- Understanding the 7.3 Powerstroke Fuel System: The Heart of Your Diesel

- Decoding 7.3 Powerstroke Injector Codes and Stock Flow Rates

- Factors Influencing 7.3 Powerstroke Fuel Injector Flow Rate

- Upgrading Your 7.3 Powerstroke Injectors: Performance & Flow

- Troubleshooting & Maintaining Optimal 7.3 Powerstroke Injector Flow

- The Impact of Correct 7.3 Powerstroke Fuel Injector Flow Rate on Performance

- Common 7.3 Powerstroke Injector Specifications

- The Impact of Correct 7.3 Powerstroke Fuel Injector Flow Rate on Performance

- Conclusion

Understanding the 7.3 Powerstroke Fuel System: The Heart of Your Diesel

To truly appreciate the significance of 7.3 Powerstroke fuel injector flow rate, we first need to understand the unique system that drives these injectors. The 7.3 Powerstroke utilizes a Hydraulically Actuated Electronically Controlled Unit Injector (HEUI) system, a sophisticated design that sets it apart from many other diesel engines.

Learn more about 7.3 Powerstroke fuel injector flow rate – 7.3 Powerstroke Fuel Injector Flow Rate: Everything You Need to Know

Image source: thumbs.dreamstime.com

How HEUI Works: A Quick Dive

Unlike common rail systems that use a single high-pressure pump for all injectors, the HEUI system employs a High-Pressure Oil Pump (HPOP) to generate incredibly high oil pressure, which is then directed to each individual injector. Inside each injector, this high-pressure oil acts on an intensifier piston, which in turn amplifies the pressure on the fuel, forcing it out through the injector nozzle into the combustion chamber. This unique method allows for very precise control over injection timing and duration, crucial for optimizing combustion and meeting emissions standards.

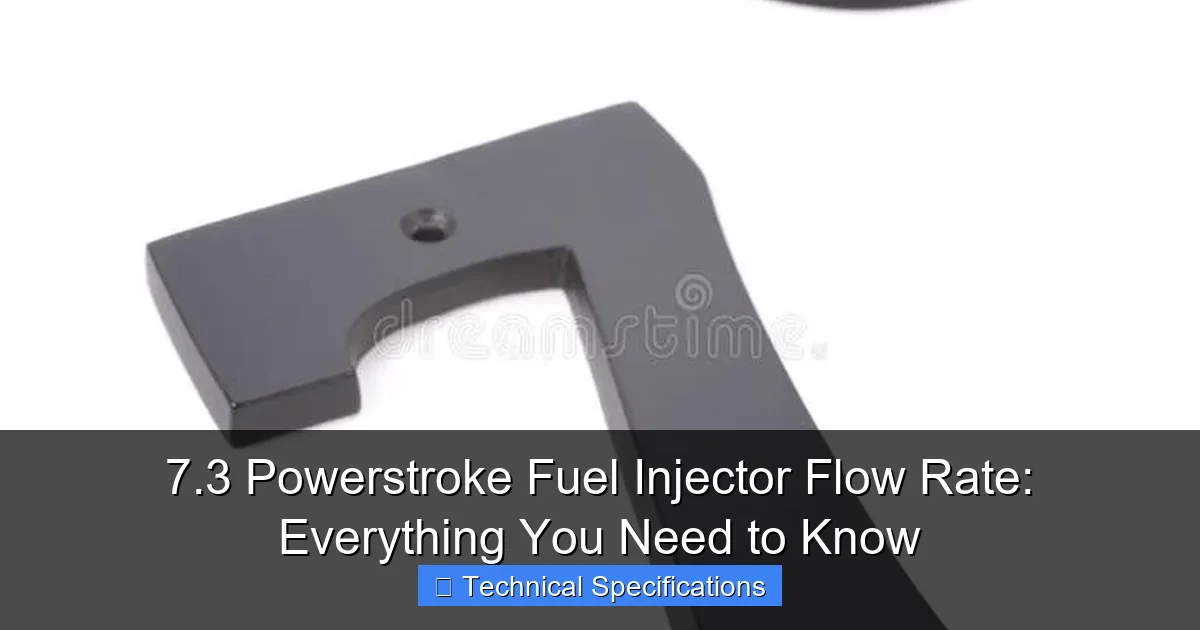

| Injector Type/Size | Flow Rate (cc/min) | Nozzle Size (% Over Stock) | Estimated HP Support (approx.) |

|---|---|---|---|

| Stock AD (99-03) | ~130-135 | 0% (Stock) | 275-325 HP |

| 160/0 (Stage 1) | 160 | 0% (Stock) | 350-375 HP |

| 180/30 (Stage 1.5) | 180 | 30% Over | 400-425 HP |

| 200/30 (Stage 2) | 200 | 30% Over | 450-475 HP |

| 238/80 (Stage 3) | 238 | 80% Over | 500-550 HP |

The system comprises several key components:

- Low-Pressure Fuel System: Delivers fuel from the tank to the fuel filter and then to the cylinder heads, where the injectors reside.

- High-Pressure Oil Pump (HPOP): Generates the incredibly high oil pressure (up to 3,000+ PSI) needed to actuate the injectors.

- Injector Pressure Regulator (IPR) Valve: Controls the HPOP output pressure, regulating the amount of oil sent to the injectors.

- Injector Control Pressure (ICP) Sensor: Monitors the actual oil pressure delivered to the injectors, providing feedback to the PCM.

- Fuel Injectors: The stars of our show, responsible for atomizing and injecting fuel into the cylinders.

- Powertrain Control Module (PCM): The “brain” of the engine, which electronically controls the IPR valve and injector firing based on sensor inputs.

Why Injector Flow Rate is Paramount

The 7.3 Powerstroke fuel injector flow rate refers to the volume of fuel that an injector can deliver within a specific timeframe, typically measured in cubic centimeters per 1,000 strokes (cc/1k strokes) or simply cubic centimeters (cc). This flow rate is not just a number; it’s a critical factor that directly influences:

- Engine Power Output: More fuel (up to a certain point, with proper air and timing) means more power. Each injector must deliver sufficient fuel for combustion.

- Fuel Economy: Incorrect flow rates, especially if varied across cylinders, can lead to inefficient combustion and wasted fuel.

- Emissions: Proper atomization and precise fuel delivery reduce harmful emissions and black smoke.

- Engine Smoothness and Driveability: Consistent flow rates across all cylinders ensure smooth idling and consistent power delivery.

- Engine Longevity: Imbalanced fuel delivery can lead to excessive heat in certain cylinders, potentially causing premature wear or damage.

In essence, the fuel injector flow rate is the lifeblood of your 7.3 Powerstroke‘s performance and health. Maintaining optimal and consistent flow is key to a happy, long-lasting engine.

Decoding 7.3 Powerstroke Injector Codes and Stock Flow Rates

Navigating the world of 7.3 Powerstroke injectors can seem daunting due to various codes and specifications. However, understanding these codes is crucial for identifying your current injectors and making informed decisions about replacements or upgrades. The factory installed different injectors depending on the year and emissions regulations.

Learn more about 7.3 Powerstroke fuel injector flow rate – 7.3 Powerstroke Fuel Injector Flow Rate: Everything You Need to Know

Image source: i.etsystatic.com

The OEM Injector Landscape: AD, AE, AB, AC Codes

Ford used several different injector codes during the 7.3 Powerstroke‘s production run. The most common and widely discussed are the AD and AE code injectors, with AC codes being specific to California emissions models, and AB codes being less common early variants.

- AD Code Injectors: These were typically found in the early 1994.5-1997 7.3 Powerstroke engines. They are known for their relatively smaller flow rate, commonly around 120-130cc (cubic centimeters). While smaller, they were well-suited for the power levels and emissions standards of their era and are incredibly durable.

- AE Code Injectors: Introduced in the late 1997.5-2003 7.3 Powerstroke models, these are often referred to as “split-shot” injectors. They have a two-stage injection event (a small pilot injection followed by the main injection) designed to reduce noise and emissions. Their typical flow rate is around 140-145cc. These are arguably the most common and popular OEM injectors due to their balance of performance and efficiency.

- AC Code Injectors: Exclusively found in California emissions 7.3 Powerstroke trucks, these are also split-shot injectors. Their flow rate is generally slightly higher than AE codes, sometimes reaching up to 150cc, to meet stricter state emissions standards.

- AB Code Injectors: Less common, these were found in some very early 1994.5-1995 models and are single-shot injectors, similar to ADs but with potentially minor variations in flow.

It’s important to remember that these “cc” ratings are nominal. Real-world 7.3 Powerstroke fuel injector flow rate can vary slightly even within the same batch of OEM injectors due to manufacturing tolerances and wear. When purchasing rebuilt or new stock injectors, reputable suppliers will often specify their tested flow rates.

What Do the Numbers Mean? Understanding cc/min

When you see ratings like “140cc” or “160/0” or “238/80” for aftermarket injectors, it can be a bit confusing. Let’s break it down:

- “cc” (Cubic Centimeters): This is the most basic measure and refers to the total volume of fuel the injector can flow per 1,000 strokes (or effectively, its maximum fuel delivery capacity at a given pressure and duration). So, a 160cc injector can deliver 160 cubic centimeters of fuel under specific test conditions.

- “160/0” or “238/80”: These advanced ratings for aftermarket 7.3 Powerstroke injectors typically indicate two things:

- First Number (e.g., 160, 238): Represents the overall fuel delivery capacity of the injector’s plunger and barrel assembly, measured in cubic centimeters. This is the main indicator of how much fuel the injector can physically flow.

- Second Number (e.g., 0, 80): Represents the size of the nozzle holes, usually in microns.

- A “/0” or “stock” nozzle means the injector uses a factory-sized nozzle with no modifications.

- A “/30“, “/80“, or “/100” indicates an aftermarket nozzle that has been bored out to a larger size (e.g., 30% over stock, 80% over stock, etc.). Larger nozzles allow for better fuel atomization and can flow more fuel at a given pressure, which is crucial for high-performance applications.

Understanding these distinctions is vital, as a larger capacity (first number) without a corresponding larger nozzle (second number) might not deliver fuel efficiently, and vice-versa. Proper matching is key to maximizing your 7.3 Powerstroke fuel injector flow rate for performance and efficiency.

Factors Influencing 7.3 Powerstroke Fuel Injector Flow Rate

The advertised or initial 7.3 Powerstroke fuel injector flow rate is just one piece of the puzzle. Over time, and due to various operational factors, the actual flow rate can degrade, fluctuate, or become inconsistent across cylinders. Understanding these influences is key to maintaining peak performance and diagnosing issues.

Injector Age and Wear

Just like any mechanical component, 7.3 Powerstroke injectors wear out. The internal components—the plunger, barrel, intensifier piston, and especially the nozzle—are subject to immense pressures and friction. Over hundreds of thousands of miles, this wear can lead to:

- Reduced Flow: Internal leakage past worn plungers or barrels can reduce the effective fuel pressure, leading to less fuel injected.

- Poor Atomization: Worn or eroded nozzle holes can cause the fuel spray pattern to become irregular or “dribble” instead of atomizing finely, leading to incomplete combustion and excessive smoke.

- Sticking Injectors: Deposits or wear can cause the internal components to stick, leading to an injector that is either partially open or closed, dramatically affecting fuel injector flow rate.

Fuel Quality and Contaminants

The quality of your diesel fuel directly impacts injector health. Diesel fuel, especially ultra-low sulfur diesel (ULSD), can sometimes lack the lubricity of older formulations. Additionally, contaminants are a major threat:

- Water Contamination: Water in fuel can cause rust and corrosion inside the precise internal components of the injectors, leading to sticking or physical damage.

- Particulate Matter: Even microscopic dirt particles can score the internal surfaces of the injector, creating internal leaks and reducing efficiency. Clogged fuel filters are a common culprit here.

- Biofuel Issues: Some biodiesel blends can be more prone to creating deposits or attracting water if not properly handled, potentially fouling injectors.

High-Pressure Oil Pump (HPOP) Health

Remember, the 7.3 Powerstroke uses high-pressure oil to actuate its injectors. If your HPOP is weak, worn, or failing, it won’t be able to generate or maintain the necessary oil pressure (typically 500-3000 PSI depending on demand). This directly translates to insufficient pressure acting on the injector’s intensifier piston, resulting in:

- Reduced 7.3 Powerstroke fuel injector flow rate: Less oil pressure means less force on the fuel, leading to less fuel injected per stroke.

- Delayed Injection: The injectors may not fire precisely when commanded.

- Hard Starts (especially when hot): A weak HPOP often struggles most when the oil is hot and thinner.

A healthy HPOP is absolutely crucial for consistent and optimal 7.3 Powerstroke fuel injector flow rate.

Friction Modifiers and Additives

While not a direct factor in the physical flow rate capacity of the injector, the use of quality fuel additives can indirectly influence how well your injectors perform and maintain their optimal 7.3 Powerstroke fuel injector flow rate over time. Additives can:

- Clean Deposits: Detergent additives can help remove carbon and varnish deposits from injector nozzles and internal components, restoring spray patterns and flow.

- Increase Lubricity: Some additives improve the lubricity of ULSD, reducing wear on injector parts.

- Disperse Water: Certain formulations help emulsify or disperse water, preventing it from settling and causing damage.

Regular use of a high-quality diesel fuel additive can be a proactive measure to preserve your 7.3 Powerstroke fuel injector flow rate.

Upgrading Your 7.3 Powerstroke Injectors: Performance & Flow

For many 7.3 Powerstroke owners, the desire for more power, better towing capability, or improved throttle response eventually leads them to consider upgrading their fuel injectors. This is where understanding 7.3 Powerstroke fuel injector flow rate becomes critical for making the right choices.

When to Consider an Upgrade

You might consider upgrading your 7.3 Powerstroke injectors if:

- Seeking More Power: The most common reason. Larger injectors are foundational for significant horsepower and torque gains.

- Towing Heavy Loads: Increased fuel delivery helps maintain power and EGTs (Exhaust Gas Temperatures) when pulling heavy trailers.

- Replacing Failing Stock Injectors: If your OEM injectors are dying, it’s an opportune time to consider an upgrade.

- Building a Performance Truck: For racing, sled pulling, or just a powerful street truck, upgraded injectors are a must.

Common Upgrade Options: From 160/0 to 238/80 and Beyond

Aftermarket 7.3 Powerstroke injectors are typically categorized by their “cc” rating (fuel delivery volume) and nozzle size. Here’s a look at common upgrade stages:

- 160/0 (Stock-ish): These are often rebuilt stock AE code injectors with a slightly higher flow rate or just a very good balance. They offer a mild bump in power and are great for refreshed stock performance.

- 160/30: This indicates 160cc of fuel with a 30% over stock nozzle. A popular choice for a mild performance boost, offering better atomization and a noticeable power increase without requiring extensive supporting modifications. Often referred to as “Stage 1” or “mild street” injectors.

- 180/0 or 180/30: Stepping up in capacity. The 180cc injectors provide a solid power bump. If paired with a 30% nozzle, they offer excellent response. These are often used as “tow” injectors due to their good balance of power and manageable EGTs.

- 205/30 or 205/80: These injectors enter the serious performance territory. The 205cc capacity with larger nozzles can push significant power. At this level, an upgraded HPOP and turbo are highly recommended.

- 238/80 or 238/100: Often considered “Stage 2” or “hot street/race” injectors. The 238cc capacity with 80% or 100% over stock nozzles can deliver tremendous amounts of fuel. These will absolutely require a high-output HPOP (like an Adrenaline or Terminator HPOP), a larger aftermarket turbocharger, and custom tuning.

- Beyond 238cc: Injectors like 250/100, 300/200, or even larger are for dedicated competition trucks. These require extensive engine modifications, including upgraded pushrods, valve springs, fuel systems, and highly specialized tuning.

Each step up in 7.3 Powerstroke fuel injector flow rate comes with increased performance potential but also greater demands on other engine components.

Matching Components: HPOP, Turbo, and Tuning

Upgrading your 7.3 Powerstroke fuel injector flow rate is rarely a standalone modification. To properly utilize the increased fuel, you need:

- High-Pressure Oil Pump (HPOP): Larger injectors demand more high-pressure oil volume. Stock HPOPs can typically support up to around 180cc injectors reasonably well, but for anything larger than 200cc, an upgraded HPOP (e.g., a “Baby Swamps,” Adrenaline, or Terminator HPOP) is essential to maintain proper ICP (Injector Control Pressure).

- Turbocharger: More fuel requires more air to burn efficiently. The stock turbocharger on a 7.3 Powerstroke is limited and can quickly become a bottleneck, leading to high EGTs and excessive smoke with larger injectors. An upgraded turbo (e.g., a 38R or S300 variant) is crucial for managing EGTs and making power.

- Custom Tuning: This is arguably the most critical component. The PCM needs to be reprogrammed to correctly manage the new injector’s flow rate, timing, and duration. Off-the-shelf tunes will not suffice for upgraded injectors; custom tuning from a reputable diesel tuner is non-negotiable for safety, performance, and longevity.

Neglecting these supporting modifications can lead to poor performance, excessive smoke, high EGTs, and potentially engine damage, even with brand-new, high-flow injectors.

Troubleshooting & Maintaining Optimal 7.3 Powerstroke Injector Flow

Even the most robust 7.3 Powerstroke injectors require attention and maintenance. Recognizing the signs of trouble and knowing how to address them can save you significant headaches and money in the long run. Maintaining consistent 7.3 Powerstroke fuel injector flow rate is key to engine health.

Signs of Poor Injector Flow

If your 7.3 Powerstroke fuel injector flow rate is compromised, your truck will often tell you in unmistakable ways. Look out for these common symptoms:

- Rough Idle or Engine Misfire: One of the most common signs. If an injector isn’t flowing correctly, that cylinder won’t contribute evenly to engine operation.

- Excessive Smoke (especially black or white): Black smoke indicates unburnt fuel (too much fuel for the air, or poor atomization). White smoke can indicate incomplete combustion due to insufficient heat or misfiring, sometimes related to coolant or fuel issues.

- Loss of Power and Poor Acceleration: A direct consequence of insufficient fuel delivery.

- Decreased Fuel Economy: Inconsistent or incorrect 7.3 Powerstroke fuel injector flow rate leads to inefficient combustion and wasted fuel.

- Hard Starting (especially when warm): Can indicate low HPOP pressure, which directly impacts injector firing and flow.

- Increased Engine Noise/Knocking: Improperly firing injectors can cause a distinct knocking sound, sometimes referred to as “injector knock.”

- High EGTs (Exhaust Gas Temperatures): If fuel isn’t burning efficiently, it can continue to burn in the exhaust manifold, significantly raising EGTs.

Diagnostic Steps and Tools

When symptoms arise, a systematic approach is best:

- Check for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner capable of reading diesel-specific codes. Codes like P1316 (IDM DTCs Detected), P1211 (ICP not Controllable), P02XX (Cylinder Contribution/Balance Faults) are common for injector issues.

- Perform a Buzz Test: This diagnostic test uses a scanner to command each injector to “buzz” or click. A healthy buzz indicates the electrical circuit and injector coil are working. A missing or weak buzz can point to an electrical issue or a dead injector coil.

- Perform a Contribution Test: Also done with a scanner, this test monitors engine RPM changes as individual cylinders are disabled. A cylinder that doesn’t cause a significant RPM drop is likely underperforming due to poor 7.3 Powerstroke fuel injector flow rate, compression, or other issues.

- Monitor ICP (Injector Control Pressure) and IPR (Injector Pressure Regulator) Duty Cycle: With a live data scanner, monitor ICP at idle, under load, and during hard acceleration. If ICP drops significantly below desired levels, your HPOP or IPR valve might be failing, directly affecting injector flow.

- Fuel Pressure Test: Low fuel pressure to the heads can starve the injectors, limiting their flow. A fuel pressure gauge is essential for checking this.

- Oil Analysis: A used oil analysis can sometimes reveal excessive fuel in the oil, indicating leaking injectors or O-rings.

Maintenance Tips for Longevity

Proactive maintenance is the best defense against injector problems:

- Use High-Quality Fuel Filters: Replace your fuel filter regularly, as per manufacturer recommendations (or more frequently if using questionable fuel). A clean fuel filter is paramount for preventing contaminants from reaching your injectors.

- Regular Oil Changes with Proper Oil: Since the HEUI system uses engine oil to actuate the injectors, the quality and cleanliness of your oil are just as important as your fuel. Use a high-quality diesel-rated oil and stick to your change intervals.

- Utilize Quality Fuel Additives: As mentioned earlier, good fuel additives can clean injectors, add lubricity, and disperse water, all contributing to healthy 7.3 Powerstroke fuel injector flow rate.

- Monitor Your Truck: Pay attention to changes in how your truck runs. Early detection of symptoms can prevent minor issues from becoming major repairs.

- Address HPOP/IPR Issues Promptly: If you suspect HPOP or IPR problems, address them immediately. A failing HPOP puts immense stress on injectors.

The Impact of Correct 7.3 Powerstroke Fuel Injector Flow Rate on Performance

The saying “you get what you put in” holds particularly true for the 7.3 Powerstroke fuel injector flow rate. Optimal and consistent flow is not just about avoiding problems; it’s about unlocking the full potential of your legendary diesel engine.

Power and Torque Gains

The most immediate and noticeable benefit of a correct and balanced 7.3 Powerstroke fuel injector flow rate is in raw power and torque. When each injector delivers the precise amount of fuel it’s supposed to, at the right time and with optimal atomization:

- Maximized Combustion Efficiency: Every drop of fuel burns completely, converting more energy into rotational force.

- Consistent Cylinder Contribution: All eight cylinders pull their weight evenly, leading to a smoother, more powerful engine feel.

- Improved Throttle Response: Precise fuel delivery means the engine responds more quickly and smoothly to accelerator input.

For upgraded injectors, correctly matching their larger fuel injector flow rate with adequate air (turbo) and a proper tune can yield substantial horsepower gains, transforming your 7.3 Powerstroke into a true beast.

Fuel Economy and Emissions

It might seem counterintuitive, but efficient fuel delivery is directly linked to better fuel economy and reduced emissions. When the 7.3 Powerstroke fuel injector flow rate is accurate:

- Less Wasted Fuel: No excessive or insufficient fueling means you’re only using the fuel necessary for the commanded power. Leaking or dribbling injectors can waste a significant amount of fuel.

- Cleaner Burn: Optimal atomization and timing lead to a more complete combustion cycle, which significantly reduces unburnt fuel (black smoke) and harmful particulate matter emissions. This is particularly relevant for maintaining compliance with emissions standards.

While an upgraded engine might consume more fuel under heavy load, a properly tuned system with optimal 7.3 Powerstroke fuel injector flow rate can often achieve better fuel efficiency than a malfunctioning stock setup under normal driving conditions.

Engine Health and Longevity

Perhaps the most critical, yet often overlooked, impact of correct 7.3 Powerstroke fuel injector flow rate is on the long-term health and durability of your engine. The 7.3 is known for its longevity, and proper fuel delivery is a cornerstone of that reputation:

- Even Cylinder Loading: When all injectors flow equally, each cylinder carries its fair share of the load, preventing over-stressing of individual pistons, connecting rods, and bearings.

- Managed EGTs: Efficient combustion keeps exhaust gas temperatures in check. High EGTs are a major killer of turbos and engines, leading to component failure. Correct fuel flow ensures fuel burns in the cylinder, not in the exhaust.

- Reduced Carbon Buildup: Proper atomization and complete combustion minimize carbon deposits on pistons, valves, and in the exhaust system, which can otherwise lead to sticky rings, reduced compression, and premature wear.

- Protection Against Wash-Down: Leaking or “stuck open” injectors can excessively fuel a cylinder, washing down the cylinder walls with raw diesel. This strips away the lubricating oil film, leading to rapid cylinder and piston ring wear, often resulting in engine failure.

Investing in quality injectors, proper supporting modifications, and diligent maintenance of your 7.3 Powerstroke fuel injector flow rate is an investment in the hundreds of thousands of miles your truck still has to offer.

Common 7.3 Powerstroke Injector Specifications

Here’s a table summarizing common 7.3 Powerstroke fuel injector flow rates and their typical applications:

| Injector Type/Code | Approx. Flow Rate (cc) | Nozzle Configuration | Typical Application/Notes |

|---|---|---|---|

| OEM AD Code | 120-130 | Single Shot / Stock | 1994.5-1997 7.3 Powerstroke, Early “Obsessed” body style trucks |

| OEM AE Code | 140-145 | Split Shot / Stock | 1997.5-2003 7.3 Powerstroke, Most common factory injector |

| OEM AC Code | 145-150 | Split Shot / Stock | California Emissions 7.3 Powerstroke models only |

| Aftermarket 160/0 | 160 | Split Shot / Stock Nozzle | Mild performance upgrade, reliable, good for towing. Often called “Stage 1” or “Stock+” |

| Aftermarket 160/30 | 160 | Split Shot / 30% Over Nozzle | Improved atomization and power, good daily driver, light towing. |

| Aftermarket 180/0 or 180/30 | 180 | Split Shot / Stock or 30% Over Nozzle | Strong performance upgrade, popular for towing, good with upgraded HPOP. |

| Aftermarket 205/30 or 205/80 | 205 | Split Shot / 30% or 80% Over Nozzle | Serious performance, requires upgraded HPOP, turbo, and custom tuning. |

| Aftermarket 238/80 or 238/100 | 238 | Split Shot / 80% or 100% Over Nozzle | High performance, requires high-output HPOP, larger turbo, and custom tuning. |

Note: “Split Shot” refers to the two-stage injection event common in later 7.3L injectors. Early AD codes are “Single Shot.” Flow rates are approximate and can vary between manufacturers and rebuilders. Always verify specifications with your supplier.

The Impact of Correct 7.3 Powerstroke Fuel Injector Flow Rate on Performance

The saying “you get what you put in” holds particularly true for the 7.3 Powerstroke fuel injector flow rate. Optimal and consistent flow is not just about avoiding problems; it’s about unlocking the full potential of your legendary diesel engine.

Power and Torque Gains

The most immediate and noticeable benefit of a correct and balanced 7.3 Powerstroke fuel injector flow rate is in raw power and torque. When each injector delivers the precise amount of fuel it’s supposed to, at the right time and with optimal atomization:

- Maximized Combustion Efficiency: Every drop of fuel burns completely, converting more energy into rotational force.

- Consistent Cylinder Contribution: All eight cylinders pull their weight evenly, leading to a smoother, more powerful engine feel.

- Improved Throttle Response: Precise fuel delivery means the engine responds more quickly and smoothly to accelerator input.

For upgraded injectors, correctly matching their larger fuel injector flow rate with adequate air (turbo) and a proper tune can yield substantial horsepower gains, transforming your 7.3 Powerstroke into a true beast.

Fuel Economy and Emissions

It might seem counterintuitive, but efficient fuel delivery is directly linked to better fuel economy and reduced emissions. When the 7.3 Powerstroke fuel injector flow rate is accurate:

- Less Wasted Fuel: No excessive or insufficient fueling means you’re only using the fuel necessary for the commanded power. Leaking or dribbling injectors can waste a significant amount of fuel.

- Cleaner Burn: Optimal atomization and timing lead to a more complete combustion cycle, which significantly reduces unburnt fuel (black smoke) and harmful particulate matter emissions. This is particularly relevant for maintaining compliance with emissions standards.

While an upgraded engine might consume more fuel under heavy load, a properly tuned system with optimal 7.3 Powerstroke fuel injector flow rate can often achieve better fuel efficiency than a malfunctioning stock setup under normal driving conditions.

Engine Health and Longevity

Perhaps the most critical, yet often overlooked, impact of correct 7.3 Powerstroke fuel injector flow rate is on the long-term health and durability of your engine. The 7.3 is known for its longevity, and proper fuel delivery is a cornerstone of that reputation:

- Even Cylinder Loading: When all injectors flow equally, each cylinder carries its fair share of the load, preventing over-stressing of individual pistons, connecting rods, and bearings.

- Managed EGTs: Efficient combustion keeps exhaust gas temperatures in check. High EGTs are a major killer of turbos and engines, leading to component failure. Correct fuel flow ensures fuel burns in the cylinder, not in the exhaust.

- Reduced Carbon Buildup: Proper atomization and complete combustion minimize carbon deposits on pistons, valves, and in the exhaust system, which can otherwise lead to sticky rings, reduced compression, and premature wear.

- Protection Against Wash-Down: Leaking or “stuck open” injectors can excessively fuel a cylinder, washing down the cylinder walls with raw diesel. This strips away the lubricating oil film, leading to rapid cylinder and piston ring wear, often resulting in engine failure.

Investing in quality injectors, proper supporting modifications, and diligent maintenance of your 7.3 Powerstroke fuel injector flow rate is an investment in the hundreds of thousands of miles your truck still has to offer.

Conclusion

The 7.3 Powerstroke fuel injector flow rate is far more than just a technical specification; it’s a fundamental aspect of your engine’s performance, efficiency, and longevity. From the original AD and AE code injectors that powered millions of trucks to the advanced aftermarket options that redefine power, understanding how these components deliver fuel is paramount for any 7.3 Powerstroke owner.

Whether you’re troubleshooting a rough idle, chasing higher horsepower, or simply aiming to keep your workhorse running strong for decades to come, paying attention to your injectors and their flow rates will yield significant dividends. Remember the critical role of the HEUI system, the importance of supporting modifications when upgrading, and the invaluable practice of regular maintenance. By staying informed and making educated decisions about your 7.3 Powerstroke injectors, you’re ensuring that the legendary roar of your diesel truck remains as strong and reliable as ever.

🎥 Related Video: Diesel Injector Torch Test!

📺 Virtual Motivation

Frequently Asked Questions

What is the stock 7.3 Powerstroke fuel injector flow rate?

The stock 7.3 Powerstroke fuel injector flow rate typically varies by year and application, but a common size for many 7.3L engines is around 140cc. These injectors are designed to deliver sufficient fuel for the factory power levels and emissions standards.

Why would I want to upgrade my 7.3 Powerstroke fuel injector flow rate?

Upgrading your 7.3 Powerstroke fuel injector flow rate is primarily done to support increased horsepower and torque output. When you add other performance modifications like larger turbochargers, custom tuning, or high-flow air intakes, the stock injectors may become a limiting factor in fuel delivery.

How do I choose the right 7.3 Powerstroke fuel injector flow rate for my truck?

Choosing the right 7.3 Powerstroke fuel injector flow rate depends heavily on your performance goals and the other modifications on your truck. It’s crucial to match the injector size with your turbocharger, high-pressure oil pump (HPOP) capacity, and custom tuning to ensure optimal performance and avoid issues.

What are common upgraded 7.3 Powerstroke fuel injector flow rates?

Common upgraded 7.3 Powerstroke fuel injector flow rates range significantly, often starting from 160cc, 180cc, or 200cc, and going much higher for heavily modified trucks. The “AD” or “AC” codes (referring to the internal components) are often combined with the flow rate, like “160/80” indicating a 160cc flow with an 80% nozzle size increase.

Does increasing the fuel injector flow rate affect my 7.3 Powerstroke’s horsepower?

Yes, increasing the 7.3 Powerstroke fuel injector flow rate directly enables higher horsepower and torque potential. Larger injectors allow the engine to receive more fuel, which, when combined with adequate air, proper tuning, and other supporting modifications, translates to a significant bump in power output.

What other modifications are recommended when upgrading my 7.3 Powerstroke’s fuel injector flow rate?

When upgrading your 7.3 Powerstroke fuel injector flow rate, it is highly recommended to also upgrade your high-pressure oil pump (HPOP) and custom tune your PCM. Additional common upgrades include a larger turbocharger, a high-flow intake, and an improved exhaust system to maximize the benefits of the new injectors.