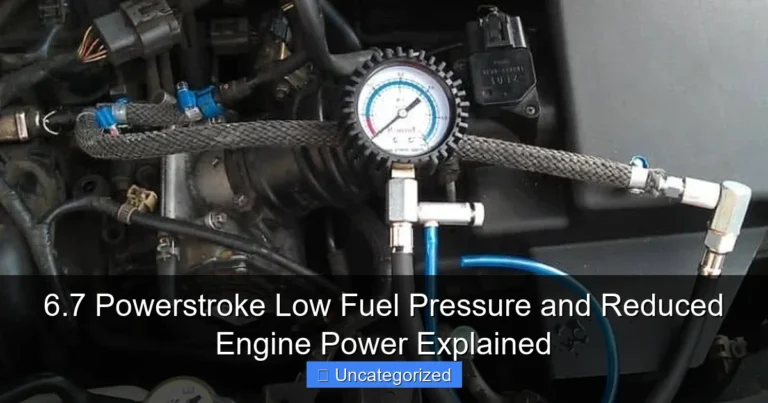

7.3 Powerstroke EGR Valve Testing Equipment: Diagnose and Fix EGR Issues

Featured image for this comprehensive guide about 7.3 Powerstroke EGR valve testing equipment

Image source: images.pexels.com

The legendary 7.3 Powerstroke engine holds a special place in the hearts of diesel enthusiasts. Known for its incredible durability, reliability, and sheer power, this workhorse has powered countless Ford trucks through millions of miles. However, like any complex machinery, even the most robust engines can develop issues over time. When performance falters, or the dreaded check engine light illuminates, many owners immediately jump to emissions components, often searching for 7.3 Powerstroke EGR valve testing equipment.

Here’s where we need to clear the air: the factory-original 7.3 Powerstroke engine, manufactured from 1994.5 to 2003, did NOT come equipped with an Exhaust Gas Recirculation (EGR) valve system. That’s right – a key difference from later Powerstroke generations! This crucial distinction means that if you’re experiencing symptoms and suspect an EGR valve issue, you’re likely misdiagnosing the problem or confusing your 7.3 with a newer model. But don’t despair! While you won’t be testing an EGR valve on your stock 7.3, understanding the tools and techniques for diagnosing its actual common issues is absolutely vital. This comprehensive guide will equip you with the knowledge to identify, test, and fix the real culprits behind your 7.3 Powerstroke’s performance woes, saving you time, money, and frustration.

Quick Answers to Common Questions

Why do I even need specific 7.3 Powerstroke EGR valve testing equipment?

You need it to accurately diagnose if your EGR valve is the culprit behind engine performance issues, rather than just guessing. It saves time and prevents unnecessary parts replacement, ensuring you fix the right problem.

What exactly does 7.3 Powerstroke EGR valve testing equipment do?

This specialized equipment helps you check for proper valve operation, common failures like sticking or blockage, and overall electrical integrity. It pinpoints exactly where the problem lies within your EGR system.

Can’t I just visually inspect my 7.3 Powerstroke EGR valve without any testing equipment?

While a visual check might reveal severe carbon buildup, it won’t tell you if the valve is actuating correctly or if the internal electronics are failing. Dedicated 7.3 Powerstroke EGR valve testing equipment provides a much more thorough and accurate diagnosis.

What symptoms suggest I should use 7.3 Powerstroke EGR valve testing equipment?

If your truck is experiencing rough idling, poor acceleration, a “check engine” light with EGR-related codes, or increased emissions, it’s definitely time to break out the 7.3 Powerstroke EGR valve testing equipment.

Is using 7.3 Powerstroke EGR valve testing equipment complicated for a DIYer?

Not necessarily! Many modern tools are user-friendly, offering guided tests and clear readouts, making 7.3 Powerstroke EGR valve testing equipment accessible for both pros and advanced DIY enthusiasts.

📋 Table of Contents

- The 7.3 Powerstroke and the EGR Myth: What You Need to Know

- Why Owners Search for “7.3 Powerstroke EGR Valve Testing Equipment”: Common Misdiagnoses

- Essential Diagnostic Tools for 7.3 Powerstroke Performance Issues

- Specific Tests and Procedures for Common 7.3 Powerstroke Symptoms

- Maintaining Your 7.3 Powerstroke’s Emission-Related Components (No EGR!)

- Choosing the Right Diagnostic Equipment: What to Look For

- Conclusion: Empowering Your 7.3 Powerstroke Diagnosis

The 7.3 Powerstroke and the EGR Myth: What You Need to Know

Let’s address the elephant in the room upfront. If you own a factory-stock 7.3 Powerstroke, searching for 7.3 Powerstroke EGR valve testing equipment is a wild goose chase. The 7.3 Powerstroke was developed before stringent EPA emissions regulations mandated EGR systems on diesel light trucks. Ford introduced the EGR system on the 6.0 Powerstroke and subsequent engines, but not on the venerable 7.3L. This is often seen as a blessing by many 7.3 owners, as EGR systems are frequently a source of maintenance headaches and costly repairs in other diesel engines.

Learn more about 7.3 Powerstroke EGR valve testing equipment – 7.3 Powerstroke EGR Valve Testing Equipment: Diagnose and Fix EGR Issues

Image source: farm3.staticflickr.com

So, why are so many people searching for “7.3 Powerstroke EGR valve testing equipment”? There are a few key reasons:

- Confusion with Newer Models: Owners of multiple Powerstroke generations might mistakenly assume all later engines share the same emissions components.

- Aftermarket Modifications: While rare, some highly customized 7.3 builds or industrial applications might have aftermarket EGR systems. However, this is not standard. More commonly, people install “EGR delete” kits on later engines and might conflate that with maintenance on a 7.3.

- Misdiagnosis of Symptoms: Many symptoms commonly associated with a failing EGR valve (like rough idle, loss of power, excessive smoke, poor fuel economy, or a check engine light) can also be caused by other components on a 7.3 Powerstroke.

Understanding this fundamental truth is the first step towards accurate diagnosis and effective repair for your truck. Instead of focusing on a non-existent part, we’ll shift our attention to the actual components that commonly fail and the essential tools to test them.

| Equipment Type | Primary Diagnostic Function | Relevance/Application (7.3L Context) | Typical Cost Range (USD) |

|---|---|---|---|

| Enhanced OBD-II Scan Tool | Read DTCs, monitor live data (MAP, IAT, EBP), perform sensor tests. | Essential for general engine health and diagnosing any emissions-related issues or performance problems; foundational for all electronic diagnostics. | $150 – $1,500+ |

| Smoke Machine (Leak Detector) | Detect leaks in intake, exhaust, vacuum lines, and other sealed systems. | Crucial for identifying pre-turbo exhaust leaks or intake manifold leaks that impact engine performance and fuel efficiency. | $100 – $500+ |

| Digital Multimeter (DMM) | Test voltage, resistance, and continuity of electrical circuits, sensors, and actuators. | Indispensable for checking wiring integrity, verifying sensor outputs (e.g., MAP, EBP), and power supply to control modules. | $30 – $200 |

| Vacuum/Pressure Gauge Kit | Measure vacuum levels, turbo boost pressure, and fuel pressure. | Essential for diagnosing issues with turbocharger control, fuel delivery, and verifying general engine vacuum integrity. | $50 – $250 |

| Exhaust Backpressure Tester | Measure exhaust system restriction (e.g., clogged catalytic converter, muffler, DPF – if aftermarket). | Helps diagnose significant power loss or engine sluggishness due to exhaust blockage, affecting overall engine efficiency. | $40 – $150 |

Why Owners Search for “7.3 Powerstroke EGR Valve Testing Equipment”: Common Misdiagnoses

Since the 7.3 Powerstroke doesn’t have an EGR valve, the symptoms that lead owners to search for 7.3 Powerstroke EGR valve testing equipment are actually pointing to other potential issues. Recognizing these symptoms and understanding their true origins is paramount. Here are some of the most common issues that get mistakenly attributed to an EGR valve on a 7.3L, along with their more likely culprits:

Learn more about 7.3 Powerstroke EGR valve testing equipment – 7.3 Powerstroke EGR Valve Testing Equipment: Diagnose and Fix EGR Issues

Image source: openclipart.org

Rough Idle or Stalling

A rough or erratic idle, or even frequent stalling, can be incredibly frustrating. On a 7.3L, this is rarely an EGR issue. Instead, look for:

- Injector Control Pressure (ICP) Sensor: A failing ICP sensor or its wiring can send incorrect pressure readings, leading to poor fuel atomization and rough running.

- Injector Pressure Regulator (IPR) Valve: The IPR valve controls the oil pressure going to the injectors. A sticking or failing IPR can cause significant drivability problems.

- Camshaft Position Sensor (CPS): A weak or failing CPS is a notorious cause of rough idle, stalling, and even no-start conditions on the 7.3L.

- Faulty Injectors: Worn or damaged fuel injectors can also cause misfires and rough idle.

Loss of Power or Poor Acceleration

If your once-mighty 7.3 feels sluggish and lacks its characteristic grunt, it’s a clear sign something is amiss. Again, not an EGR problem. Consider these:

- Turbocharger Issues: A sticking wastegate, damaged turbo vanes, or a boost leak can severely impact power output.

- Mass Air Flow (MAF) Sensor: An accumulation of dirt on the MAF sensor can lead to incorrect air-fuel mixture calculations, resulting in reduced power.

- Fuel Delivery Problems: A weak fuel pump, clogged fuel filter, or issues with the fuel pressure regulator can starve the engine of fuel.

- Exhaust Back Pressure (EBP) Sensor: While not an EGR, a faulty EBP sensor can cause the PCM to make incorrect adjustments, impacting performance.

Excessive Smoke (Black, Blue, or White)

Different smoke colors indicate different problems, none of which are typically related to an EGR valve on a 7.3L:

- Black Smoke: Often points to incomplete combustion, possibly due to over-fueling (faulty injectors), insufficient air (boost leak, dirty air filter), or ICP/IPR issues.

- Blue Smoke: Indicates burning oil, usually due to worn piston rings, valve seals, or issues within the turbocharger.

- White Smoke: Can suggest unburnt fuel (injector issues, low compression) or, more ominously, coolant burning (head gasket, cracked head).

Poor Fuel Economy

A sudden drop in miles per gallon can be a symptom of various underlying issues, not just a problem with an EGR valve:

- Fuel System Leaks: Obvious, but easily overlooked.

- Sensor Malfunctions: Faulty MAF, EBP, or ICP sensors can cause the engine to run inefficiently.

- Restricted Air Flow: Clogged air filter.

- Dragging Brakes or Driveline Issues: While not engine-related, these can severely impact fuel economy.

By understanding these common misdiagnoses, you can redirect your efforts towards the actual troubleshooting process for your 7.3 Powerstroke.

Essential Diagnostic Tools for 7.3 Powerstroke Performance Issues

Instead of searching for 7.3 Powerstroke EGR valve testing equipment, invest in these crucial diagnostic tools. They are indispensable for any 7.3 Powerstroke owner looking to accurately pinpoint and resolve engine performance problems.

1. OBD-II Scan Tool (Specific for 7.3 Powerstroke)

A generic OBD-II scanner is a good start, but for in-depth diagnosis of a 7.3 Powerstroke, you need a tool that can communicate with Ford’s Enhanced Powertrain Control Module (PCM).

- Capabilities: Reads/clears Diagnostic Trouble Codes (DTCs), monitors live data streams (e.g., ICP, IPR duty cycle, EBP, MAF, fuel pressure, oil temperature, coolant temperature, boost pressure), performs injector buzz tests, and sometimes allows for specific sensor tests.

- Recommended Tools: While professional-grade tools like Ford IDS or AutoEnginuity are excellent, more affordable and highly capable options for enthusiasts include FORScan (with a compatible ELM327 adapter) or dedicated Powerstroke scan tools like the AE Scan Tool.

- Why it’s essential: Live data is your window into what your engine’s sensors are truly reporting. Identifying values outside of specification is often the quickest way to diagnose a problem. An injector buzz test can quickly tell you if your injectors are physically responding to commands from the PCM.

2. Multimeter (Digital Volt-Ohm Meter – DVOM)

No serious diagnostic work can be done without a quality multimeter. This tool is fundamental for checking electrical circuits, sensor outputs, and continuity.

- Capabilities: Measures voltage (AC/DC), resistance (ohms), and continuity. Some advanced models also measure amperage, frequency, and duty cycle.

- Applications:

- Testing sensor reference voltage (5V, 12V).

- Checking sensor output voltage (e.g., MAF, EBP, ICP).

- Verifying circuit continuity (open wires, short circuits).

- Testing the resistance of components like glow plugs or solenoids.

- Checking battery and charging system voltage.

- Why it’s essential: Many 7.3 Powerstroke issues stem from electrical problems – faulty sensors, corroded wiring, or poor connections. A multimeter allows you to trace these issues directly.

- Capabilities: Measures static and dynamic fuel pressure at the fuel bowl.

- Required Readings: A healthy 7.3 should maintain around 60-70 PSI of fuel pressure at idle and under load. Anything significantly lower indicates a problem.

- Applications: Diagnosing a weak fuel pump, clogged fuel filter, restricted fuel lines, or a failing fuel pressure regulator.

- Why it’s essential: Low fuel pressure can cause hard starting, loss of power, rough idle, and poor fuel economy. It’s a foundational test for many drivability complaints.

- Capabilities: A kit allows for physical cleaning of the EBP tube. A separate pressure gauge (or using the scan tool to monitor EBP) can verify readings.

- Applications: Diagnosing high or low exhaust back pressure readings, which can lead to turbocharger control issues or a “limp mode” scenario.

- Why it’s essential: A clogged EBP tube will send false high-pressure signals to the PCM, leading to an over-actuated EBPV (Exhaust Back Pressure Valve) or incorrect fuel/air mixture adjustments, hurting performance and fuel economy.

- Capabilities: Includes a high-pressure oil gauge (2,000-4,000 PSI range) to directly measure HPOP output and an air test fitting to check for internal leaks within the HPOP system (e.g., stand pipes, dummy plugs, injector O-rings).

- Applications: Diagnosing hard starts, no-starts, rough idle, and misfires related to insufficient oil pressure for injector actuation.

- Why it’s essential: HPOP failures, leaks, or IPR valve issues are common culprits for 7.3 Powerstroke no-start or poor-running conditions. Direct measurement and leak testing are crucial.

- Check Fuel Pressure: Connect your fuel pressure gauge to the fuel bowl. Crank the engine and observe the pressure. It should be 60-70 PSI. If low, troubleshoot the fuel pump, filter, or regulator.

- Perform an Injector Buzz Test: Use your OBD-II scan tool to initiate a buzz test. Listen for a distinct “buzz” from each injector. If one doesn’t buzz, it could indicate a faulty injector, harness, or PCM driver.

- Monitor ICP and IPR Live Data: With the scan tool, crank the engine and watch the ICP (Injector Control Pressure) and IPR (Injector Pressure Regulator) readings. You need at least 500 PSI ICP for the engine to fire. If ICP is low, check IPR duty cycle. A high IPR duty cycle (above 60-70%) with low ICP indicates a high-pressure oil leak or a weak HPOP.

- Perform an HPOP System Air Test: If ICP is low, remove the IPR valve and install the air test fitting. Apply shop air (100-120 PSI) to the system. Listen for air leaks in the valve covers (injector O-rings, dummy plugs, stand pipes) or from the oil pan (HPOP gasket).

- Check CPS and PCM Power: Verify power to the PCM and signal from the CPS (Camshaft Position Sensor) using your multimeter or by monitoring RPMs during cranking with the scan tool.

- Monitor Boost Pressure: Use your scan tool to check actual boost pressure versus desired boost. Low boost suggests turbocharger issues, wastegate problems, or a boost leak in the intercooler pipes.

- Inspect MAF Sensor: Visually inspect the MAF sensor for dirt or contamination. Clean with specific MAF cleaner, if necessary. Monitor MAF readings with the scan tool; they should increase smoothly with RPM.

- Check EBP Sensor and Tube: Monitor EBP readings with your scan tool. If they are erratic or unusually high/low, try cleaning the EBP tube. If the issue persists, test or replace the EBP sensor.

- Perform Cylinder Contribution Test: Your scan tool may have a cylinder contribution test function. This identifies individual cylinders that are misfiring, helping narrow down injector or compression issues.

- Fuel System Check: Re-check fuel pressure under load (if possible) and ensure fuel filters are clean.

- Black Smoke:

- Check for air intake restrictions (dirty air filter).

- Monitor MAF readings for accuracy.

- Check boost levels; low boost can cause over-fueling.

- Run an injector buzz test and cylinder contribution test for faulty injectors.

- Blue Smoke:

- Indicates oil burning. Check turbocharger for shaft play or oil leaks.

- Consider a compression test to rule out worn rings.

- Inspect valve stem seals if excessive oil consumption is noted.

- White Smoke:

- Often unburnt fuel: Check fuel pressure, injector function (buzz test, contribution test).

- Check glow plug system: Ensure glow plugs are working and the GPR (Glow Plug Relay) is functional, especially during cold starts.

- Monitor coolant levels; a rapidly disappearing coolant could indicate a head gasket failure or cracked head.

- Regular Fuel Filter Replacement: Replace your fuel filter every 10,000-15,000 miles, or as per your owner’s manual. A clogged filter is a primary cause of low fuel pressure.

- Use Quality Fuel: Always use reputable diesel fuel to prevent contamination and injector wear.

- Fuel Additives: Consider a good quality diesel fuel additive, especially if you live in colder climates, to prevent gelling and keep injectors clean.

- Air Filter Checks: Regularly inspect and replace your air filter. A restricted air filter chokes the engine and reduces power.

- Clean MAF Sensor: Periodically clean your MAF sensor with specialized MAF cleaner to ensure accurate air measurements.

- Inspect Intercooler Pipes: Check intercooler (CAC) boots and pipes for cracks or loose clamps that could cause boost leaks.

- Battery and Charging System: Ensure your batteries are healthy and the alternator is charging correctly. Weak batteries can lead to hard starts and issues with electronics.

- Wiring Harness Inspection: Periodically check wiring harnesses for chafing, corrosion, or loose connections, especially around sensors (ICP, IPR, CPS, EBP).

- Glow Plug System: For cold weather starts, ensure all glow plugs are functioning and the Glow Plug Relay (GPR) is operating correctly. Test with a multimeter.

- Oil Changes: Use the correct specification engine oil and adhere to your oil change intervals. The HPOP and injectors rely on clean, high-quality oil.

- Check for Leaks: Regularly inspect the engine valley for oil leaks, which could indicate failing dummy plugs, stand pipes, or injector O-rings.

- Ensure any scan tool explicitly states compatibility with Ford 7.3L Powerstroke engines (1994.5-2003) and supports enhanced Ford PIDs (Parameter IDs). Generic OBD-II scanners will only read basic engine codes.

- This is paramount. A good scan tool should display real-time sensor readings for ICP, IPR duty cycle, EBP, MAF, FRP (Fuel Rail Pressure – though 7.3 doesn’t have a rail, some tools interpret fuel bowl pressure as this), oil temperature, engine RPM, vehicle speed, and more.

- Advanced scan tools offer bi-directional control, allowing you to perform active tests like injector buzz tests, cylinder contribution tests, or actuating the IPR valve. This capability significantly speeds up diagnosis.

- The ability to record live data during a drive cycle and then graph it visually is incredibly useful for identifying intermittent issues or trends in sensor performance.

- Choose tools from reputable brands known for quality. The interface should be intuitive, and the device robust enough to handle shop environments.

- While professional tools can be expensive, many excellent mid-range options provide nearly the same diagnostic power for a fraction of the cost. For example, a laptop with FORScan and a quality OBD-II adapter can rival dedicated scanners.

3. Fuel Pressure Gauge

The 7.3 Powerstroke relies on adequate fuel pressure for proper injection and combustion. This is a common failure point that’s often overlooked.

4. Exhaust Back Pressure (EBP) Tube Cleaning Kit / Pressure Gauge

The EBP sensor and its tube are prone to clogging with soot, leading to erroneous readings and performance issues.

5. High-Pressure Oil System (HPOP) Diagnostic Tools

The 7.3 Powerstroke is an HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, meaning high-pressure engine oil is used to fire the injectors.

Specific Tests and Procedures for Common 7.3 Powerstroke Symptoms

Now that you know the right tools, let’s look at how to use them to tackle common 7.3 Powerstroke issues that people mistakenly attribute to an EGR valve. The goal is to avoid the pitfalls of searching for 7.3 Powerstroke EGR valve testing equipment and instead focus on what truly affects your engine.

1. Diagnosing Hard Starts / No Starts

This is one of the most common and frustrating 7.3 Powerstroke problems.

2. Troubleshooting Loss of Power and Rough Running

When your 7.3 feels weak, it’s time to dig deeper than looking for 7.3 Powerstroke EGR valve testing equipment.

3. Diagnosing Excessive Smoke

The color of the smoke provides crucial clues.

Maintaining Your 7.3 Powerstroke’s Emission-Related Components (No EGR!)

While you won’t be using 7.3 Powerstroke EGR valve testing equipment, proper maintenance of other systems is crucial for your truck’s longevity, performance, and to minimize emissions (even without an EGR). Proactive maintenance can prevent many of the issues discussed above.

1. Fuel System Purity and Pressure

2. Air Intake System Health

3. Electrical System Integrity

4. High-Pressure Oil System Maintenance

Choosing the Right Diagnostic Equipment: What to Look For

When investing in tools for your 7.3 Powerstroke, moving beyond the idea of 7.3 Powerstroke EGR valve testing equipment means focusing on versatility, accuracy, and compatibility. Here’s what to consider:

1. Compatibility with 7.3 Powerstroke

2. Live Data Monitoring Capabilities

3. Bi-Directional Control

4. Data Logging and Graphing

5. Durability and User-Friendliness

6. Value for Money

By prioritizing these features, you’ll build a diagnostic arsenal that truly helps you keep your 7.3 Powerstroke running strong for years to come.

Here’s a quick reference table for common 7.3 Powerstroke symptoms and the most likely diagnostic tools needed:

| Common Symptom | Likely Cause(s) | Essential Diagnostic Tool(s) |

|---|---|---|

| Hard Start / No Start | Low HPOP pressure, faulty IPR/ICP, weak fuel pressure, bad CPS | OBD-II Scan Tool (Live Data: ICP, IPR, RPM), Fuel Pressure Gauge, HPOP Air Test Kit |

| Loss of Power / Sluggishness | Low boost, clogged fuel filter, faulty MAF/EBP sensor, injector issues | OBD-II Scan Tool (Live Data: Boost, MAF, EBP), Fuel Pressure Gauge |

| Rough Idle / Misfire | Faulty Injectors, ICP/IPR issues, bad CPS, fuel supply problems | OBD-II Scan Tool (Injector Buzz Test, Cylinder Contribution, Live Data: ICP, IPR), Multimeter (for wiring) |

| Excessive Black Smoke | Over-fueling, restricted air intake, low boost | OBD-II Scan Tool (Live Data: MAF, Boost), Air Filter Inspection, Fuel Pressure Gauge |

| Poor Fuel Economy | Sensor malfunctions (MAF, EBP, ICP), fuel leaks, restricted air/fuel flow | OBD-II Scan Tool (Live Data on all sensors), Fuel Pressure Gauge, Visual Inspection |

| Check Engine Light (Various Codes) | Sensor failures, circuit issues, component malfunctions | OBD-II Scan Tool (Read/Clear DTCs, Live Data), Multimeter (for circuit testing) |

Conclusion: Empowering Your 7.3 Powerstroke Diagnosis

While the initial search for 7.3 Powerstroke EGR valve testing equipment might have led you down the wrong path, we hope this guide has redirected your focus to the actual diagnostic needs of your legendary diesel truck. The 7.3 Powerstroke is a magnificent engine, but its unique architecture demands a specific approach to troubleshooting. Understanding that it lacks a factory EGR system is the first step towards accurate and effective repairs.

By equipping yourself with the right diagnostic tools – a capable OBD-II scan tool, a reliable multimeter, a fuel pressure gauge, and specific high-pressure oil system testers – you empower yourself to accurately identify and resolve the common issues that plague these engines. From hard starts and loss of power to rough idling and excessive smoke, the solutions lie in meticulous testing of the actual components that affect your 7.3’s performance. Don’t waste time and money chasing a non-existent EGR valve. Invest in the knowledge and tools that will truly keep your 7.3 Powerstroke roaring strong for many more years and miles to come.

Frequently Asked Questions

What exactly is 7.3 Powerstroke EGR valve testing equipment used for?

This specialized equipment is designed to accurately diagnose problems with the Exhaust Gas Recirculation (EGR) valve on 7.3L Powerstroke diesel engines. It allows mechanics and DIY enthusiasts to determine if the EGR valve is functioning correctly, stuck open, or stuck closed.

Why is it important to test the EGR valve on my 7.3 Powerstroke?

Testing your 7.3 Powerstroke’s EGR valve is crucial because a malfunctioning valve can lead to poor engine performance, increased emissions, and potential damage to other components. Early diagnosis using proper testing equipment can prevent more costly repairs down the line and maintain your truck’s efficiency.

What common symptoms suggest I need to use EGR valve testing equipment on my 7.3 Powerstroke?

Common symptoms indicating a potential EGR valve issue on your 7.3 Powerstroke include a “Check Engine” light, rough idling, reduced fuel economy, decreased engine power, or excessive black smoke from the exhaust. If you experience these signs, using specialized testing equipment can pinpoint whether the EGR valve is the culprit.

How does this 7.3 Powerstroke EGR valve testing equipment help diagnose issues?

The 7.3 Powerstroke EGR valve testing equipment typically works by simulating operating conditions or by directly testing electrical and mechanical functions of the valve. It can check for proper solenoid operation, valve movement, and confirm that the valve opens and closes at the correct times, revealing electrical faults or mechanical blockages.

Can a DIY mechanic effectively use this 7.3 Powerstroke EGR valve testing equipment?

Yes, many types of 7.3 Powerstroke EGR valve testing equipment are designed with user-friendliness in mind, making them accessible for DIY mechanics with basic diagnostic knowledge. While some advanced tools might require more expertise, fundamental testers often come with clear instructions to help you accurately diagnose EGR problems.

What types of malfunctions can be identified with 7.3 Powerstroke EGR valve testing equipment?

This testing equipment can identify various malfunctions such as a valve that is stuck open or closed, an intermittent electrical fault in the solenoid, or a complete failure of the valve’s internal components. It helps determine if the valve is failing to open or close properly, which is critical for emissions control and engine performance.