6.7 Powerstroke Turbocharger Specifications: Maximize Your Engine’s Potential

Featured image for this comprehensive guide about 6.7 Powerstroke turbocharger specifications

6.7 Powerstroke Turbocharger Specifications: Maximize Your Engine’s Potential

The 6.7 Powerstroke engine is a marvel of modern diesel engineering, renowned for its formidable power and impressive torque output. At the heart of its performance lies its sophisticated turbocharger system. For anyone owning, operating, or simply admiring a Ford Super Duty truck equipped with this legendary engine, understanding the 6.7 Powerstroke turbocharger specifications is not just a technical detail—it’s key to unlocking its full potential, ensuring longevity, and making informed decisions about maintenance and upgrades.

Whether you’re hauling heavy loads, tackling challenging terrain, or simply cruising the highway, the turbocharger plays a critical role in how your Powerstroke engine breathes and performs. From the early Single Sequential Turbo (SST) designs to the later Variable Geometry Turbos (VGT), each iteration brought unique characteristics and performance nuances. This comprehensive guide will deep dive into the intricate world of 6.7 Powerstroke turbocharger specifications, detailing the evolution, design intricacies, performance characteristics, and practical advice to help you maintain and even enhance your engine’s capabilities. Prepare to gain a deeper appreciation for the engineering brilliance behind your diesel powerhouse.

Quick Answers to Common Questions

What type of turbocharger does the 6.7 Powerstroke typically come with from the factory?

The 6.7 Powerstroke is equipped with a Garrett GT32 SST (Single Sequential Turbocharger) featuring a variable geometry design, which is a core part of its factory *6.7 Powerstroke turbocharger specifications* for optimal performance.

Why do some owners choose to upgrade their 6.7 Powerstroke turbocharger?

Many owners upgrade to enhance their *6.7 Powerstroke turbocharger specifications* for increased horsepower and torque, improved reliability, and better performance when towing heavy loads or running aggressive tunes.

What are common signs that my 6.7 Powerstroke turbocharger might be failing?

Look out for tell-tale signs such as excessive smoke (especially blue or black), a distinct high-pitched whine or siren sound, significant loss of power, or unusual oil consumption, which point to issues with your *6.7 Powerstroke turbocharger specifications*.

Are there different generations of the 6.7 Powerstroke turbocharger?

Yes, there are; the 2011-2014 models featured an earlier design compared to the more robust and revised unit found in 2015+ trucks, each with distinct *6.7 Powerstroke turbocharger specifications* for their respective years.

What makes the 6.7 Powerstroke turbocharger unique in its design?

Its unique “reverse flow” engine architecture, where exhaust manifolds are integrated into the cylinder heads, allows for a compact, center-mounted turbocharger, distinguishing its *6.7 Powerstroke turbocharger specifications* from many other diesel engines.

📋 Table of Contents

- The Evolution of the 6.7 Powerstroke Turbocharger

- Understanding the Early 6.7 Powerstroke Turbo (2011-2014 SST)

- Exploring the Later 6.7 Powerstroke Turbo (2015+ VGT)

- Key Turbocharger Specifications Explained for Your 6.7 Powerstroke

- 6.7 Powerstroke Turbocharger Specification Comparison Table

- Optimizing and Upgrading Your 6.7 Powerstroke Turbocharger Performance

- Conclusion: Mastering Your 6.7 Powerstroke’s Turbocharger

The Evolution of the 6.7 Powerstroke Turbocharger

The journey of the 6.7 Powerstroke turbocharger is one of continuous innovation, adapting to increasingly stringent emissions standards while simultaneously boosting power and efficiency. Ford and Garrett, the primary manufacturer, have delivered two distinct turbocharger designs over the years, each with its own set of 6.7 Powerstroke turbocharger specifications and operational characteristics. Understanding this evolution is crucial for any owner.

2011-2014: The Single Sequential Turbo (SST)

When the 6.7 Powerstroke debuted in 2011, it introduced a revolutionary turbocharger system: the Single Sequential Turbo (SST). This unique design, often referred to as a “compound turbo in one housing,” featured two compressor wheels and two turbine wheels, but instead of operating in series (like traditional compound turbos), they operated in parallel with a clever valving system. At low engine speeds, exhaust gases were routed through a smaller turbine to minimize lag, while at higher RPMs, a valve opened to direct gases through a larger turbine, allowing for massive airflow and power. This design aimed to provide the best of both worlds: quick spool-up and high-end performance. Its 6.7 Powerstroke turbocharger specifications were truly groundbreaking for its time, demonstrating Ford’s commitment to innovation.

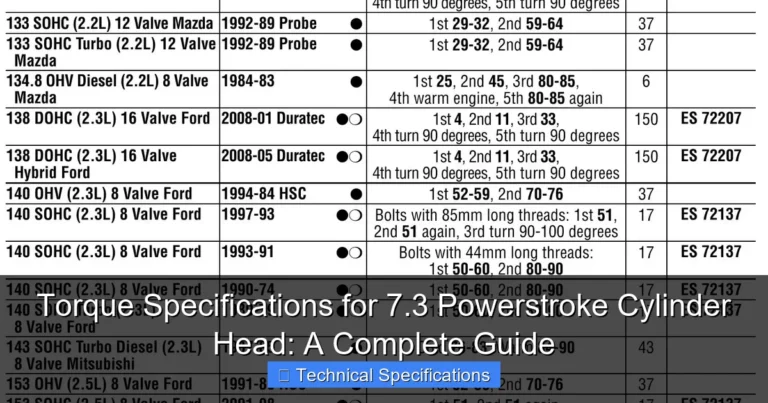

| Model Year Range | OEM Turbocharger Model | Compressor Inducer Diameter (mm) | Turbine Exducer Diameter (mm) |

|---|---|---|---|

| 2011-2014 | Garrett GT32 SST | ~64 | ~72.5 |

| 2015-2016 | Garrett GT37 (First Gen) | ~66 | ~76 |

| 2017-2019 | Garrett GT37 (Revised) | ~66.5 | ~76.5 |

| 2020-Present | Garrett GT37 (Latest Gen) | ~67 | ~77 |

2015-Present: The Variable Geometry Turbo (VGT)

In 2015, Ford made a significant change to the 6.7 Powerstroke turbocharger, transitioning to a more conventional but highly advanced Variable Geometry Turbocharger (VGT), specifically a Garrett GT37/GT40 model. This move was primarily driven by the need for better emissions control, improved efficiency, and enhanced reliability. Unlike the SST, the VGT utilizes movable vanes within the turbine housing to alter the exhaust gas velocity and angle, effectively changing the A/R ratio on the fly. This allows the turbo to act like a small turbo for quick response at low RPMs and a large turbo for maximum flow at high RPMs, all within a single unit. This design dramatically simplified the system while still delivering impressive performance gains, refining the 6.7 Powerstroke turbocharger specifications for a new era of diesel power.

Understanding the Early 6.7 Powerstroke Turbo (2011-2014 SST)

The original 6.7 Powerstroke turbocharger, the Single Sequential Turbo (SST), was a marvel of engineering, distinct from almost anything else on the market. Its intricate design aimed to eliminate turbo lag while delivering robust power across the entire RPM range. Let’s delve into its specific 6.7 Powerstroke turbocharger specifications.

Design and Operation

- Unique Configuration: The SST houses two turbine and two compressor wheels within a single, compact housing. The smaller, high-pressure section is designed for quick spooling at low engine speeds, while the larger, low-pressure section comes online as engine RPMs increase, providing substantial airflow for peak power.

- Exhaust Flow Control: A sophisticated valve system, controlled by the Engine Control Unit (ECU), directs exhaust gases to either the small turbine, the large turbine, or both, depending on engine load and speed. This allowed for precise control over boost pressure and throttle response, giving the 6.7 Powerstroke engine its distinctive feel.

- Compressor Wheels: Typically, the SST featured an inducer diameter for the smaller compressor wheel around 50-55mm and a larger compressor wheel inducer around 60-65mm. These figures, combined with their respective exducer sizes, determined the air-moving capacity.

- Turbine Wheels: Similar to the compressor side, there was a smaller turbine wheel optimized for rapid acceleration and a larger one for sustained high-power output, efficiently converting exhaust energy into rotational force.

Performance Characteristics

The SST was praised for its virtually instant throttle response and strong mid-range torque. It helped the 2011-2014 6.7 Powerstroke engine achieve impressive power figures for its time, with up to 400 horsepower and 800 lb-ft of torque. The sequential design meant that the engine always had access to sufficient boost, whether pulling away from a stop or passing on the highway. This demonstrated the cutting-edge nature of the initial 6.7 Powerstroke turbocharger specifications.

Common Issues and Considerations

Despite its innovative design, the SST was not without its challenges. The complexity of the sequential valving system and the demanding operating conditions sometimes led to issues. Carbon buildup in the exhaust manifold, for instance, could impede valve movement, leading to boost inconsistencies or even turbo failure. Furthermore, the specialized design meant that repairs and replacements were often more complex and costly compared to simpler turbocharger systems. Understanding these potential pitfalls is part of truly grasping the early 6.7 Powerstroke turbocharger specifications and historical context.

Exploring the Later 6.7 Powerstroke Turbo (2015+ VGT)

For the 2015 model year and beyond, Ford transitioned the 6.7 Powerstroke engine to a single, larger Variable Geometry Turbocharger (VGT) manufactured by Garrett. This change was a strategic move to enhance reliability, simplify the exhaust system, improve emissions, and ultimately, boost performance. Let’s examine the updated 6.7 Powerstroke turbocharger specifications for these models.

Garrett GT37/GT40 Variable Geometry Design

The 2015+ 6.7 Powerstroke turbo is essentially a Garrett GT37/GT40 hybrid, signifying its robust capabilities. The “variable geometry” aspect refers to a ring of movable vanes located around the turbine wheel. These vanes adjust their angle and spacing based on engine demands, effectively changing the nozzle area and the speed at which exhaust gases hit the turbine blades. This allows the turbo to simulate the characteristics of both a small and a large turbocharger, providing quick spool-up at low RPMs and high flow at high RPMs, all from a single, compact unit. This design is remarkably efficient and a testament to modern turbo technology.

Key Specifications and Improvements

- Compressor Wheel: The inducer diameter for the 2015+ VGT typically ranges from 60mm to 64mm, with an exducer of around 84mm. These dimensions contribute to its significantly increased airflow capacity compared to the smaller stages of the SST, allowing for greater engine efficiency.

- Turbine Wheel: The turbine wheel usually has an inducer diameter around 72mm-76mm and an exducer of 67mm-70mm. The larger size, combined with the VGT mechanism, allows for efficient exhaust energy harvesting and improved turbine response.

- Increased Boost: The VGT design, along with other engine improvements, allowed for higher peak boost pressures and a more consistent boost curve across the RPM range. This translates directly into more horsepower and torque, making the 6.7 Powerstroke even more formidable.

- Simplified System: By replacing the complex sequential valving of the SST, the VGT significantly reduced the number of moving parts and potential points of failure, contributing to enhanced reliability and lower maintenance concerns.

Performance Gains and Reliability

The transition to the VGT was a resounding success. The 2015+ 6.7 Powerstroke engine saw a notable increase in power, climbing to 440 horsepower and 860 lb-ft of torque (and even higher in subsequent model years). This improvement was largely attributed to the more efficient and higher-flowing VGT. Reliability also improved, with fewer common issues related to the turbocharger itself compared to its predecessor. This iteration solidified the reputation of the 6.7 Powerstroke turbocharger as a powerful and dependable component, setting new benchmarks for diesel performance.

Key Turbocharger Specifications Explained for Your 6.7 Powerstroke

To truly understand your 6.7 Powerstroke turbocharger specifications, it helps to know what each measurement means and how it impacts performance. These terms are universal to turbochargers but particularly relevant when discussing your diesel engine.

A/R Ratio (Area/Radius)

- Definition: The A/R ratio is a measurement of the turbine housing’s cross-sectional area divided by the radius from the turbine wheel’s center to the centroid of that area. It primarily dictates how quickly exhaust gases expand as they hit the turbine wheel.

- Impact on 6.7 Powerstroke:

- Lower A/R: Leads to quicker spool-up (reduced turbo lag) because it forces exhaust gases through a smaller opening, increasing their velocity. However, it can restrict flow at high RPMs, potentially leading to higher exhaust back pressure.

- Higher A/R: Promotes better top-end power by allowing more exhaust flow, but typically results in more turbo lag at lower RPMs.

- VGT Advantage: The variable geometry mechanism of the 2015+ turbo effectively changes its A/R ratio on the fly, optimizing spool and flow across the entire RPM range, which is why the 6.7 Powerstroke turbocharger performs so well in diverse driving conditions.

Compressor Wheel Inducer and Exducer

- Inducer: The diameter of the compressor wheel where the air enters (the smaller diameter on the inlet side). A larger inducer generally means more air can be drawn in, contributing to greater potential airflow.

- Exducer: The diameter of the compressor wheel where the air exits (the larger diameter on the outlet side). A larger exducer allows for more air compression and flow, directly impacting boost pressure.

- Impact on 6.7 Powerstroke: These dimensions determine the turbocharger’s maximum airflow capacity. Larger numbers typically equate to more potential horsepower, but can also increase spool time if not properly balanced. Optimizing these for the 6.7 Powerstroke turbocharger specifications is crucial for achieving desired performance characteristics.

Turbine Wheel Inducer and Exducer

- Inducer: The diameter of the turbine wheel where exhaust gases enter (the larger diameter on the inlet side).

- Exducer: The diameter of the turbine wheel where exhaust gases exit (the smaller diameter on the outlet side).

- Impact on 6.7 Powerstroke: These dimensions dictate how much energy can be extracted from the exhaust gases to spin the compressor wheel. A larger turbine wheel can handle more exhaust flow but might be slower to spool. The design aims to maximize energy conversion while minimizing exhaust back pressure.

Trim

Trim is a ratio derived from the inducer and exducer diameters of both the compressor and turbine wheels. It provides a numerical representation of the wheel’s design and how it’s optimized for flow. A higher trim generally indicates a wheel designed for higher flow at the expense of some efficiency at lower flows. Understanding trim helps when comparing aftermarket 6.7 Powerstroke turbocharger specifications and making informed upgrade decisions.

6.7 Powerstroke Turbocharger Specification Comparison Table

For a quick overview, here’s a comparison of the key characteristics of the two primary 6.7 Powerstroke turbocharger systems that have powered Ford Super Duty trucks:

| Specification/Feature | 2011-2014 Single Sequential Turbo (SST) | 2015+ Variable Geometry Turbo (VGT) |

|---|---|---|

| Turbocharger Type | Single Sequential Turbo (SST) – two compressors, two turbines in one housing | Variable Geometry Turbocharger (VGT) – single compressor, single turbine with movable vanes |

| Manufacturer | Garrett (Ford Specific Design) | Garrett (GT37/GT40 Hybrid) |

| Design Complexity | High (multiple valves, exhaust paths) | Moderate (single unit, VGT mechanism) |

| Compressor Inducer (approx.) | Small: 50-55mm / Large: 60-65mm | 60-64mm |

| Compressor Exducer (approx.) | N/A (complex internal design, multiple stages) | ~84mm |

| Turbine Inducer (approx.) | N/A (complex internal design, multiple stages) | 72-76mm |

| Turbine Exducer (approx.) | N/A (complex internal design, multiple stages) | 67-70mm |

| Spool-Up Characteristics | Excellent (quick response due to sequential operation) | Excellent (quick response due to variable geometry) |

| Peak Power Capability (Factory) | Good (up to 400hp/800tq) | Superior (440hp/860tq+ from factory) |

| Emissions Control | Effective for its era, complex EGR interaction | Improved efficiency for modern standards, simplified EGR interaction |

| Common Issues (Original Design) | Carbon buildup affecting sequential valve operation, occasional valve failure | Less common, primarily VGT actuator issues or over-speeding with aggressive tuning |

Optimizing and Upgrading Your 6.7 Powerstroke Turbocharger Performance

Understanding the 6.7 Powerstroke turbocharger specifications is one thing; optimizing its performance and ensuring its longevity is another. Whether you have an early SST or a later VGT, there are actionable steps you can take to maximize your engine’s potential.

Regular Maintenance is Key for Longevity

- Oil Changes: The turbocharger relies heavily on clean engine oil for lubrication and cooling. Follow or exceed Ford’s recommended oil change intervals using high-quality synthetic diesel oil. Dirty oil is a turbo killer, leading to premature bearing wear.

- Air Filter: A clean air filter is paramount. A clogged filter restricts airflow, forcing the turbo to work harder, increasing EGTs, and potentially inducing cavitation or foreign object damage. Inspect and replace your air filter regularly.

- Cool-Down Periods: Especially after hard driving or towing, allow your engine to idle for a few minutes before shutting it off. This allows oil to continue circulating and cool the hot turbo components, preventing “coking” (baked oil deposits) in the bearing housing, which can block oil passages.

- Monitor EGTs (Exhaust Gas Temperatures): High EGTs are detrimental to turbo longevity and overall engine health. If you frequently tow heavy loads or run performance tunes, a pyrometer (EGT gauge) is a wise investment to proactively manage thermal stress.

Choosing the Right Turbo Upgrade for Your 6.7 Powerstroke

Deciding on a turbocharger upgrade for your 6.7 Powerstroke involves more than just picking the biggest unit. It requires a thoughtful assessment of your truck’s primary use, your power goals, and your budget. Understanding the nuances of 6.7 Powerstroke turbocharger specifications is paramount here.

Define Your Truck’s Purpose:

- Heavy Towing/Work Truck: For those who frequently haul heavy loads, reliability, low-end torque, and manageable EGTs are critical. A mild upgrade that enhances spool-up and maintains efficiency at lower RPMs is often preferred. You might look for an enhanced VGT that retains stock-like drivability but offers more airflow.

- Daily Driver/Light Towing: If your truck is a daily driver with occasional towing, you might prioritize a balance of responsiveness and improved mid-range power. A slightly larger VGT or a single-turbo conversion that spools reasonably quickly could be suitable.

- Performance/Racing: For maximum horsepower, drag racing, or sled pulling, you’ll be looking at significantly larger turbos, often fixed geometry, or even compound turbo setups. These setups will likely sacrifice some low-end response for massive top-end power. Be prepared for other supporting modifications (fuel, transmission, head studs) with these extremes.

Popular Upgrade Paths and Their Characteristics:

1. Drop-In Performance VGTs (for 2015+ models):

- Description: These turbos are designed to be direct replacements for the factory VGT but feature upgraded components like larger billet compressor wheels, improved turbine wheel designs, or stronger bearing systems.

- Pros: Maintain stock drivability and VGT functionality, relatively easy installation, good power gains without extensive modifications. Ideal for improved towing and daily driving without sacrificing street manners.

- Cons: Still limited by the inherent design of a single VGT, not suitable for extreme power levels that compound or large single turbos can achieve.

2. Single Turbo Conversions (Fixed Geometry):

- Description: Replacing the VGT or SST with a larger, fixed-geometry turbo. These often require a new exhaust manifold, piping, and extensive tuning to optimize the new 6.7 Powerstroke turbocharger specifications.

- Pros: Can support very high horsepower levels, often more robust for extreme boost, simpler internal design once installed.

- Cons: Significant turbo lag compared to VGTs, requires custom tuning, more complex installation, can be less ideal for towing unless specifically designed for it with appropriate sizing.

3. Compound Turbo Kits:

- Description: Adding a second turbocharger (typically a large atmospheric turbo feeding a smaller, high-pressure turbo) to create a compound setup. This setup effectively combines the best of both worlds.

- Pros: Unmatched power potential, excellent drivability with minimal lag due to staged compression, high efficiency across the RPM range.

- Cons: Very expensive, extremely complex installation, requires extensive engine and transmission modifications, often not emissions compliant in many regions. Reserved for dedicated performance builds.

Beyond the Turbo: Essential Supporting Modifications:

Remember, a turbocharger doesn’t work in isolation. To truly maximize the potential of your upgraded 6.7 Powerstroke turbocharger specifications, you’ll need to consider a holistic approach:

- Tuning: Any significant turbo upgrade *requires* custom tuning. The ECU needs to be recalibrated to account for increased airflow, adjusting fuel delivery, injection timing, and exhaust gas recirculation (EGR) to maintain safe and efficient operation.

- Exhaust System: A high-flow exhaust system (e.g., 4-inch or 5-inch downpipe-back) can significantly reduce exhaust back pressure, allowing the turbo to spool faster and operate more efficiently.

- Fuel System Upgrades: Larger turbos demand more fuel; upgraded injectors, a larger fuel pump, or a regulated return system are often necessary to prevent fuel starvation.

- Air Intake: Ensure your intake system can supply sufficient clean, unrestricted air to the turbocharger.

- Intercooler Upgrades: A larger, more efficient intercooler will cool the boosted air more effectively, increasing air density and leading to more power and lower EGTs.

- Transmission: The added power will stress the transmission; upgrades (e.g., heavy-duty clutches, torque converters, valve body modifications) may be required to handle increased torque.

- Engine Internals: For extreme power levels, head studs, connecting rods, and even upgraded pistons might be necessary to prevent catastrophic engine failure.

Always research thoroughly and consult with reputable diesel performance shops when considering significant upgrades to your 6.7 Powerstroke turbo to ensure compatibility, safe operation, and adherence to local regulations.

Conclusion: Mastering Your 6.7 Powerstroke’s Turbocharger

The 6.7 Powerstroke turbocharger is a cornerstone of this engine’s legendary performance, a sophisticated piece of engineering designed to deliver power, efficiency, and reliability. From the innovative yet complex Single Sequential Turbo of the early years to the refined and robust Variable Geometry Turbo that powers modern Super Duty trucks, understanding their respective 6.7 Powerstroke turbocharger specifications is crucial for any owner.

By delving into the nuances of A/R ratios, wheel dimensions, and design philosophies, you gain invaluable insight into how your truck generates its immense power. More importantly, this knowledge empowers you to make informed decisions about maintenance, identify potential issues, and strategically plan for performance upgrades. Regular, diligent maintenance remains the bedrock of turbo longevity, while thoughtful, purpose-driven modifications can unlock even greater potential from your 6.7 Powerstroke engine.

Whether your goal is to enhance towing capability, boost daily driving enjoyment, or transform your truck into a high-performance machine, mastering the intricacies of your 6.7 Powerstroke turbocharger specifications is your first step. Embrace the power, maintain with care, and unleash the full force of your diesel workhorse, knowing you understand the heart of its forced induction system.

🎥 Related Video: Hidden Benefits Of The KC Turbos Warlock Retrofit Kit! – Saving Your 2011-2014 6.7 Powerstroke!

📺 KC TURBOS

Today we go over all of the fine details and benefits of the KC Turbos Warlock Retrofit Kit for your 2011-2014 6.7 Powerstroke!

Frequently Asked Questions

What type of turbocharger does the 6.7 Powerstroke utilize?

The 6.7 Powerstroke engine is equipped with a Garrett GT32 SST (Single Sequential Turbo), which is a Variable Geometry Turbocharger (VGT). This sophisticated design allows for precise control of exhaust gas flow, optimizing boost delivery across the engine’s RPM range for enhanced response and efficiency.

What are the key specifications of the stock 6.7 Powerstroke turbocharger?

The stock 6.7 Powerstroke turbocharger typically features a 64mm inducer on the compressor side and a variable geometry turbine. It is engineered to provide rapid spool-up and sustain strong boost, making it ideal for towing and demanding heavy-duty applications. Specific dimensions can vary slightly across different model years.

What are the typical boost levels for a stock 6.7 Powerstroke turbocharger?

A stock 6.7 Powerstroke turbocharger generally produces peak boost pressures ranging from 28 to 35 PSI, depending on engine load and RPM. These boost levels are precisely managed by the engine’s control unit to ensure optimal performance while maintaining engine durability.

Are there common upgrade options for the 6.7 Powerstroke turbocharger to improve performance?

Yes, many owners opt to upgrade their 6.7 Powerstroke turbocharger to achieve increased horsepower and torque. Popular upgrades include larger VGT turbos, often featuring billet compressor wheels, or even converting to a compound turbo setup for significant performance gains. These modifications typically require complementary fuel system and tuning upgrades.

How does the Variable Geometry Turbocharger (VGT) work on the 6.7 Powerstroke?

The VGT system in the 6.7 Powerstroke employs movable vanes within the turbine housing to alter the velocity and angle of exhaust gases before they reach the turbine wheel. This innovative mechanism enables the turbo to mimic a smaller turbo at low RPMs for quick spooling, and a larger turbo at high RPMs for maximum airflow, effectively optimizing boost and minimizing turbo lag.

What are some common issues or maintenance considerations for the 6.7 Powerstroke turbo?

Common issues for the 6.7 Powerstroke turbo can include sticking VGT vanes due to carbon buildup, which may lead to inconsistent boost or reduced performance. Adhering to regular oil changes with high-quality engine oil is paramount for turbo longevity, as the turbocharger heavily relies on clean engine oil for both lubrication and cooling.