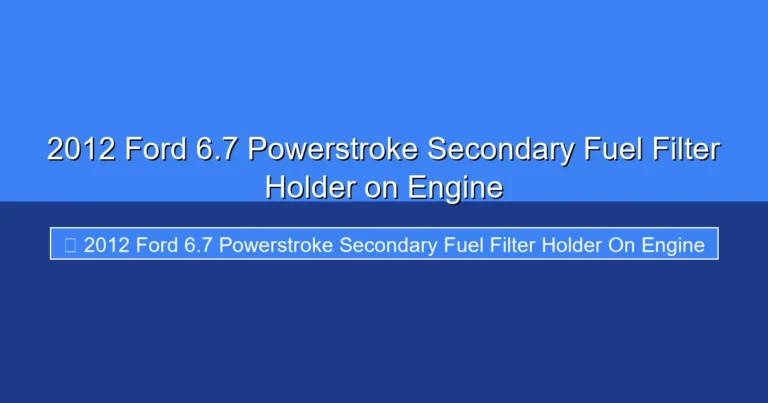

6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power Explained

Featured image for this comprehensive guide about 6.7 powerstroke low fuel pressure reduced engine power

Image source: mechanicsdiary.com

There’s nothing quite like the feeling of commanding a powerful truck, especially one equipped with a Ford 6.7 Powerstroke engine. Known for its incredible torque and reliability, it’s a workhorse that many depend on. However, when your trusty truck starts to act up, exhibiting signs like sluggish acceleration, rough idling, or even outright stalling, it can be frustrating, to say the least. One of the most common and critical issues behind these performance woes is low fuel pressure, which invariably leads to reduced engine power.

Imagine towing a heavy load, only to feel your truck lose its grunt on an incline, or experiencing a sudden lack of responsiveness when you press the accelerator. These are classic indicators that your 6.7 Powerstroke low fuel pressure reduced engine power concerns are becoming a reality. This isn’t just about inconvenience; compromised fuel pressure can lead to more severe, and expensive, engine damage if left unaddressed. Understanding the intricacies of your truck’s fuel system and knowing how to diagnose and rectify these issues is paramount for any Powerstroke owner.

This comprehensive guide will dive deep into the world of 6.7 Powerstroke low fuel pressure, exploring its causes, symptoms, and the precise diagnostic steps you need to take. More importantly, we’ll equip you with actionable solutions and preventative maintenance tips to keep your diesel beast running strong, ensuring that reduced engine power doesn’t become a permanent fixture in your driving experience.

Quick Answers to Common Questions

What does “reduced engine power” actually mean when my 6.7 Powerstroke acts up?

When your 6.7 Powerstroke displays “reduced engine power,” it means the engine’s computer is limiting output to protect components, often a direct result of low fuel pressure. You’ll notice less acceleration and a general lack of responsiveness from your truck.

Why is my 6.7 Powerstroke suddenly experiencing low fuel pressure?

Common culprits for low fuel pressure in a 6.7 Powerstroke include a failing fuel pump, clogged fuel filters, or issues with the fuel pressure regulator. It’s often a sign that a key component in your fuel system isn’t working optimally.

Can I keep driving my 6.7 Powerstroke if I’m seeing “low fuel pressure reduced engine power”?

We strongly advise against extended driving with “6.7 Powerstroke low fuel pressure reduced engine power.” Continuing to drive could potentially lead to further damage to your fuel system or engine components, so it’s best to address it promptly.

What’s the very first thing I should check if my 6.7 Powerstroke has low fuel pressure?

Start by checking your fuel filters! Clogged fuel filters are a very common and relatively easy fix for a 6.7 Powerstroke low fuel pressure issue, often directly contributing to reduced engine power.

Will addressing the low fuel pressure fix my 6.7 Powerstroke’s reduced engine power?

Absolutely! Since reduced engine power is often a symptom of your 6.7 Powerstroke’s low fuel pressure, diagnosing and repairing the underlying fuel system problem will typically restore your truck’s full power and performance.

📋 Table of Contents

- Understanding the 6.7 Powerstroke Fuel System: A Deep Dive

- Recognizing the Symptoms: Is Your 6.7 Powerstroke Struggling?

- The Root Causes: Why Your 6.7 Powerstroke Has Low Fuel Pressure

- Diagnosing Low Fuel Pressure: Pinpointing the Problem Accurately

- Effective Solutions and Preventive Maintenance

- Conclusion: Keeping Your 6.7 Powerstroke Strong

Understanding the 6.7 Powerstroke Fuel System: A Deep Dive

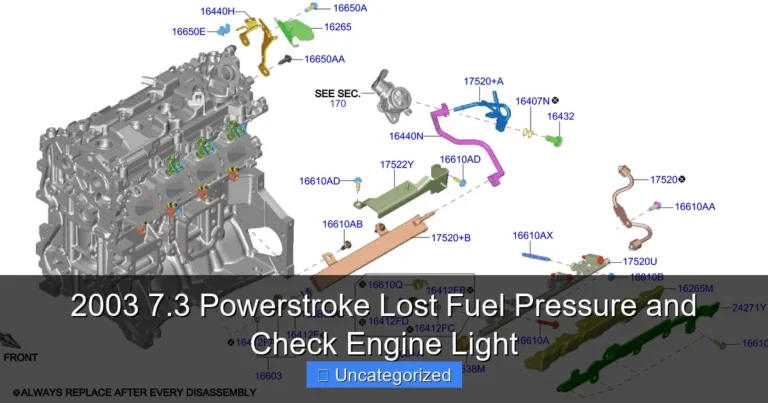

Before we can tackle the problem of low fuel pressure, it’s essential to grasp how the 6.7 Powerstroke fuel system is designed to operate. It’s a sophisticated, high-pressure common rail system that demands precision to deliver its renowned performance. Any deviation from its operating parameters can lead to significant issues, including reduced engine power.

Learn more about 6.7 powerstroke low fuel pressure reduced engine power – 6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power Explained

Image source: autocarneed.com

How the System Works: From Tank to Injector

The journey of fuel in your 6.7 Powerstroke begins in the fuel tank, where it is drawn by a low-pressure fuel pump, often referred to as the lift pump. This pump pushes the fuel through a series of filters – typically a primary fuel filter and a secondary fuel filter – which are crucial for removing contaminants that could damage sensitive components. After filtration, the fuel reaches the high-pressure fuel pump (HPFP), specifically the Bosch CP4 pump in the 6.7 Powerstroke. This pump is the heart of the high-pressure system, responsible for generating immense pressure, often exceeding 29,000 PSI (2,000 bar).

| Fuel System Status | Observed Low-Pressure Fuel (LPF) PSI | Engine Performance Symptoms | Potential Diagnostic Trouble Codes (DTCs) |

|---|---|---|---|

| **Normal Operation** | 65-75 PSI | Smooth acceleration, consistent power, quick starts. | None (or healthy fuel system codes) |

| **Mild Low Pressure** | 50-60 PSI | Slight hesitation under heavy load, minor power reduction, reduced fuel economy. | P0087 (Fuel Rail/System Pressure – Too Low, intermittent) |

| **Moderate Low Pressure** | 30-45 PSI | Noticeable power loss, longer crank times, rough idle, engine stalling. | P0087 (persistent), P0299 (Turbocharger/Supercharger “A” Underboost) |

| **Severe Low Pressure** | Less than 25 PSI | Significant power loss, limp mode activation, misfires, engine won’t start or stalls immediately. | P0087, P1291 (Injector High Side Open Bank 1), P0093 (Fuel System Leakage – Large Leak) |

From the HPFP, fuel is directed to the common rail, a reservoir that distributes the highly pressurized fuel to each injector. The fuel injectors, controlled by the Engine Control Module (ECM), precisely spray fuel into the combustion chambers at the optimal time and quantity, ensuring efficient combustion and maximum power output. A dedicated fuel pressure regulator (FPR) sensor monitors and helps maintain the desired pressure within this high-pressure circuit, sending crucial feedback to the ECM.

Why Fuel Pressure is Crucial for Performance

Imagine trying to spray a garden hose with low water pressure – it dribbles instead of spraying. The same principle applies to your diesel engine. Adequate fuel pressure is not merely important; it’s absolutely critical for several reasons:

- Optimal Atomization: High pressure ensures the fuel is finely atomized (sprayed into a mist) when injected into the cylinders. This fine mist mixes thoroughly with air, leading to more complete and efficient combustion, which translates directly to power and fuel economy.

- Precise Fuel Delivery: The ECM relies on consistent pressure to accurately control the amount of fuel delivered by the injectors. If pressure is low, the delivered fuel quantity will be less than expected, causing a lean condition and reduced engine power.

- Injector Health: While perhaps counterintuitive, operating injectors with insufficient pressure can put undue stress on them, potentially leading to premature wear and failure.

- Engine Protection: The ECM uses fuel pressure data to protect the engine. When pressure drops below acceptable limits, it can trigger diagnostic trouble codes (DTCs) and may even force the engine into “limp mode” to prevent damage, resulting in significant reduced engine power.

Recognizing the Symptoms: Is Your 6.7 Powerstroke Struggling?

When your 6.7 Powerstroke experiences low fuel pressure, it won’t keep it a secret. The symptoms can range from subtle annoyances to alarming performance drops. Learning to identify these signs early can save you from more severe damage and costly repairs.

Learn more about 6.7 powerstroke low fuel pressure reduced engine power – 6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power Explained

Image source: automotivian.com

Common Indicators of Low Fuel Pressure

The most noticeable symptom is often a feeling of a significant drop in power, especially under load. Here are the key indicators:

- Reduced Engine Power: This is the hallmark symptom. You’ll notice sluggish acceleration, difficulty maintaining speed on inclines, or a general lack of responsiveness from the engine. Your truck might feel like it’s “choking” or struggling to breathe.

- Rough Idling or Stalling: Inconsistent fuel delivery can cause the engine to idle roughly, shaking more than usual. In severe cases, the engine might stall, particularly after starting or at low speeds.

- Hesitation or Misfires: You might feel the engine hesitate or stumble during acceleration, or experience what feels like misfires as individual cylinders struggle to get enough fuel.

- Check Engine Light (CEL) Illumination: Your truck’s sophisticated monitoring system will likely detect the issue and illuminate the check engine light on your dashboard. This is a critical sign that something is amiss.

- Difficulty Starting: If there’s insufficient pressure in the fuel system, especially the high-pressure side, the engine may crank for an extended period before starting, or it might not start at all.

- Increased Fuel Consumption: While not always immediately obvious, a lean running condition due to low fuel pressure can sometimes lead to the ECM attempting to compensate, potentially resulting in poorer fuel economy.

Diagnostic Trouble Codes (DTCs) to Watch For

When the Check Engine Light comes on, it’s usually accompanied by one or more specific Diagnostic Trouble Codes (DTCs) stored in the ECM. These codes are invaluable for narrowing down the problem. For 6.7 Powerstroke low fuel pressure reduced engine power issues, look out for:

- P0087: Fuel Rail/System Pressure – Too Low. This is perhaps the most direct and common code indicating insufficient fuel pressure.

- P0088: Fuel Rail/System Pressure – Too High. While this guide focuses on low pressure, a faulty regulator could cause this, which might indirectly impact consistent delivery.

- P0191-P0194: Fuel Rail Pressure Sensor Circuit Range/Performance problems. These indicate issues with the sensor itself, which could give false readings about the actual pressure.

- P1093: Fuel Pressure Regulation Valve Implausible Signal / Pressure Control Valve (PCV) Performance. This code points to problems with the fuel pressure regulator or its control.

- P0200-P0209: Injector Circuit/Open. While not directly about pressure, sustained low pressure can sometimes lead to injector-related issues that trigger these codes.

Common DTCs Related to 6.7 Powerstroke Fuel Pressure

Understanding these codes is the first step towards an accurate diagnosis. Always use a reliable scan tool to retrieve them.

| DTC Code | Description | Potential Implication for Low Fuel Pressure |

|---|---|---|

| P0087 | Fuel Rail/System Pressure – Too Low | Direct indication of insufficient fuel pressure, often linked to HPFP, lift pump, or filter issues. |

| P0191 | Fuel Rail Pressure Sensor Range/Performance | Sensor may be faulty, providing incorrect pressure readings to the ECM. |

| P1093 | Fuel Pressure Regulation Valve Performance | Issue with the fuel pressure regulator, which controls pressure in the rail. |

| P0089 | Fuel Pressure Regulator 1 Performance | Similar to P1093, points to a problem with the fuel pressure regulator. |

| P0251-P0258 | Injector Pump Fuel Metering Control “A” (or “B”) Range/Performance | Suggests problems with the HPFP’s ability to regulate fuel flow or pressure. |

The Root Causes: Why Your 6.7 Powerstroke Has Low Fuel Pressure

Identifying that your 6.7 Powerstroke has low fuel pressure and reduced engine power is only half the battle. The next crucial step is pinpointing *why* it’s happening. The 6.7 Powerstroke fuel system is complex, and several components can fail, leading to this critical issue.

1. Failing Lift Pump (Fuel Pump Control Module – FPCM)

The lift pump, located in the fuel tank, is responsible for drawing fuel and sending it to the engine. If this pump weakens or fails, it won’t deliver enough fuel to the HPFP, leading to an immediate drop in pressure on the low-pressure side, and consequently, the high-pressure side. Often, problems with the lift pump are linked to its control module (FPCM), which regulates its operation.

- Symptoms: Hard starting, stalling, especially when fuel level is low, and general lack of power.

- Why it fails: Age, contamination, electrical issues.

2. Clogged Fuel Filters

The 6.7 Powerstroke relies on two fuel filters (primary and secondary) to protect its delicate fuel system components from contaminants. Neglecting regular fuel filter replacement is a common, yet easily avoidable, cause of low fuel pressure. Clogged filters restrict fuel flow, essentially starving the HPFP.

- Symptoms: Gradual loss of power, hesitation, reduced fuel economy, and eventual illumination of the CEL.

- Why it fails: Accumulation of dirt, debris, rust, and water from fuel.

3. High-Pressure Fuel Pump (HPFP – CP4) Failure: The Big One

The Bosch CP4 pump is notoriously sensitive to fuel quality and lubrication. When the CP4 pump fails, it often disintegrates internally, sending metal shavings throughout the entire high-pressure fuel system. This is a catastrophic failure that not only causes severe low fuel pressure but also contaminates the fuel rails, injectors, and other components, leading to an extremely expensive repair often referred to as a “CP4 disaster.”

- Symptoms: Sudden, severe loss of power, engine stalling, no-start condition, accompanied by loud ticking/knocking noises from the engine bay.

- Why it fails: Lack of lubrication from ultra-low sulfur diesel, water contamination, extended maintenance intervals, or inherent design flaws.

4. Leaky Fuel Injectors or Lines

Even small leaks in the high-pressure fuel lines or faulty injectors can cause significant pressure drops. A leaky injector might allow fuel to return to the tank prematurely or prevent it from reaching the combustion chamber effectively. Similarly, a breach in a fuel line can cause fuel to escape, reducing the pressure available to the other components.

- Symptoms: Rough idle, excessive smoke (black or white), fuel smell, decreased fuel economy, and visible fuel leaks (if external).

- Why it fails: Wear and tear, extreme pressure, heat cycles, physical damage, or poor installation.

5. Fuel Pressure Regulator (FPR) Sensor Malfunction

The FPR sensor (also sometimes referred to as the Fuel Rail Pressure – FRP sensor) is crucial for monitoring and maintaining the correct pressure in the common rail. If this sensor fails or sends inaccurate readings to the ECM, the computer might incorrectly command the HPFP to reduce pressure, or fail to increase it when needed, leading to actual low fuel pressure or perceived low fuel pressure issues.

- Symptoms: Intermittent power loss, erratic idle, trouble codes P0191-P0194, P1093.

- Why it fails: Electrical issues, sensor degradation, contamination.

6. Air Intrusion in the Fuel System

Air bubbles in the fuel system can disrupt the smooth flow of fuel and prevent the HPFP from building adequate pressure. This is particularly common after fuel filter changes if the system isn’t properly bled, or if there’s a loose connection allowing air to be drawn in.

- Symptoms: Hard starting, rough idle, stalling, air “gurgling” sounds in the fuel lines.

- Why it fails: Improper filter changes, loose fuel lines, cracked hoses.

Diagnosing Low Fuel Pressure: Pinpointing the Problem Accurately

Accurately diagnosing the source of low fuel pressure in your 6.7 Powerstroke is crucial to avoid throwing parts at the problem. It requires a systematic approach, often combining basic checks with advanced diagnostic tools.

1. Basic Checks and Visual Inspection

Start with the simplest things. You’d be surprised how often a fundamental issue is overlooked.

- Fuel Level: Is the tank nearly empty? While obvious, it’s worth checking.

- Fuel Filter History: When were the fuel filters last changed? If it’s been more than 15,000-20,000 miles, or you’ve recently filled up with suspect fuel, they’re prime suspects.

- Visual Inspection for Leaks: Look for any signs of fuel leaks around the fuel lines, injectors, or filter housings. A strong diesel smell is a giveaway.

- Check for Air Intrusion: Look for bubbles in transparent fuel lines (if accessible) or listen for unusual gurgling noises after starting.

2. Using a Scan Tool: Monitoring Fuel Pressure Data

A good quality scan tool (like FORScan, AutoEnginuity, or a professional diagnostic scanner) is your best friend here. It allows you to monitor live data from various sensors, including the Fuel Rail Pressure (FRP) sensor.

- Key PIDs to Monitor:

- FRP (Fuel Rail Pressure) Commanded: What the ECM *wants* the pressure to be.

- FRP Actual: What the sensor *reports* the actual pressure is.

- Fuel Pressure Control Valve (FPCV) Duty Cycle: How hard the ECM is working the pressure regulator.

- Low-Pressure Fuel Sensor (if available): Measures pressure pre-HPFP.

- Interpreting Readings: Compare commanded vs. actual. If actual is consistently lower than commanded, especially under load, you have a low fuel pressure issue. Note the pressure at idle, during acceleration, and under load.

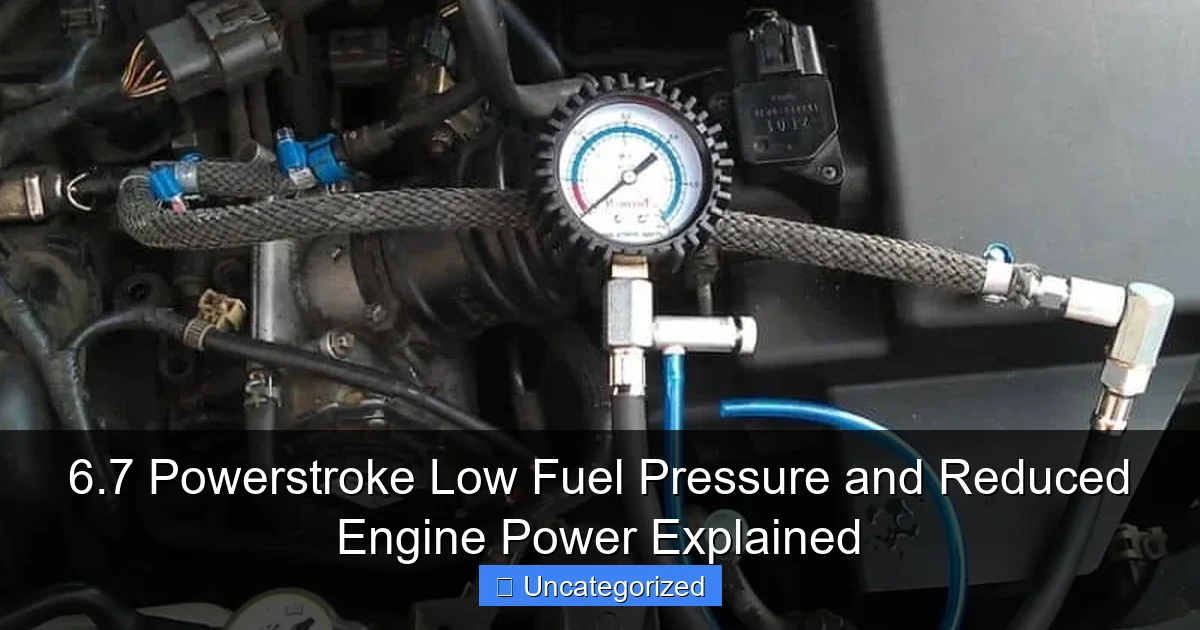

3. Manual Pressure Testing

Sometimes, relying solely on sensor data isn’t enough, especially if you suspect a faulty sensor. Manual pressure testing can confirm actual pressures.

- Low-Pressure Side Test: Install a fuel pressure gauge in the low-pressure fuel line (after the secondary filter, before the HPFP). You should typically see pressures in the range of 50-75 PSI. If it’s significantly lower, suspect the lift pump, clogged filters, or a restriction.

- High-Pressure Side Test: This is more complex and usually requires specialized tools and expertise, as the pressures are extremely high. It involves connecting a high-pressure gauge to the fuel rail. This test is often performed to verify HPFP function or to isolate issues with the FPR.

4. Performing a Volume Test

A volume test assesses the quantity of fuel delivered, not just the pressure. This is particularly useful for diagnosing a weak lift pump or a restricted fuel line/filter on the low-pressure side. It involves disconnecting a low-pressure fuel line (e.g., at the secondary filter housing or return line) and measuring the amount of fuel delivered into a container over a specific time (e.g., 30 seconds) while the key is on or the engine is cranking. Consult your service manual for exact specifications.

5. Other Diagnostic Steps

- Return Fuel Flow Test: For injectors, excessive fuel returning to the tank can indicate an internal leak, causing a pressure drop.

- Injector Buzz Test: Using a scan tool, you can activate each injector to listen for a distinct “buzz,” indicating electrical function. This doesn’t confirm fuel delivery but helps rule out electrical injector issues.

- Compression Test: While less direct, poor compression can sometimes mimic fuel pressure issues or exacerbate them.

Effective Solutions and Preventive Maintenance

Once you’ve accurately diagnosed the cause of your 6.7 Powerstroke low fuel pressure and reduced engine power, it’s time for the fix. Many solutions are straightforward, while others, like HPFP failure, can be quite extensive. Prevention, however, is always better than cure.

1. Immediate Fixes for Common Issues

- Fuel Filter Replacement: This is often the first and easiest step. Replace both the primary (frame-mounted) and secondary (engine-mounted) fuel filters with quality OEM or equivalent filters. Ensure proper bleeding of the system afterward to prevent air intrusion.

- Fuel Pump Control Module (FPCM) / Lift Pump Replacement: If diagnostics point to a failing lift pump or its FPCM, replacement is necessary. This restores proper low-pressure fuel supply.

- Clear Air from Fuel System: If air intrusion is suspected, ensure all fuel line connections are tight. After filter changes, cycle the key multiple times (without starting) to activate the lift pump and prime the system, allowing air to be purged.

2. Addressing High-Pressure Fuel Pump (HPFP – CP4) Failure

This is the most severe and costly repair. If your 6.7 Powerstroke CP4 pump has failed and sent metal shavings through the system, a full system flush and replacement of contaminated components is necessary.

- Full Fuel System Replacement: This typically includes:

- New HPFP (CP4)

- New fuel injectors

- New fuel rails

- New high-pressure fuel lines

- Thorough cleaning/flushing of the fuel tank and low-pressure lines

- Replacement of all fuel filters.

- Disaster Prevention Kits: Many owners opt for aftermarket “disaster prevention” kits or CP4 bypass kits. These reroute the return fuel from the CP4 pump directly back to the tank, preventing contamination of the rest of the high-pressure system if the CP4 fails. While not preventing the CP4 from failing, they drastically reduce the cost of repair by saving the injectors and fuel rails.

- CP3 Conversion: Some owners choose to replace the problematic CP4 pump with a more robust CP3 pump (used in older Duramax engines), requiring an adapter kit and recalibration. This is a significant modification but offers enhanced reliability.

3. Injector Replacement and Fuel Pressure Regulator

- Injector Replacement: If individual injectors are found to be leaking or faulty, they must be replaced. It’s often recommended to replace them in sets or all at once, especially on high-mileage engines.

- Fuel Pressure Regulator (FPR) Sensor: If the sensor or the regulating valve itself is faulty, replacement will restore accurate pressure control.

4. Regular Maintenance Schedule: Your Best Defense

Prevention is key to avoiding 6.7 Powerstroke low fuel pressure reduced engine power issues.

- Timely Fuel Filter Changes: Adhere strictly to Ford’s recommended fuel filter change intervals, or even shorten them if you use lower quality fuel or operate in dusty conditions (e.g., every 10,000-15,000 miles).

- Use Quality Fuel: Always use reputable fuel stations. Contaminated or poor-quality diesel is a primary enemy of the 6.7 Powerstroke fuel system, especially the CP4 pump.

- Drain Water Separator: Regularly drain the water separator located on the primary fuel filter housing. Water in the fuel system is highly damaging.

- Fuel Additives: Consider using a quality diesel fuel additive, especially one designed to enhance lubricity and clean injectors. This can help compensate for the dryness of modern ultra-low sulfur diesel and keep your system healthy.

Conclusion: Keeping Your 6.7 Powerstroke Strong

Experiencing 6.7 Powerstroke low fuel pressure reduced engine power can be a distressing ordeal for any truck owner. However, by understanding the intricate workings of your fuel system, recognizing the tell-tale symptoms, and knowing how to diagnose the underlying causes, you’re well-equipped to tackle the problem head-on. From clogged filters and failing lift pumps to the dreaded CP4 disaster, each issue requires a specific approach.

The key takeaway is clear: proactive maintenance and swift action at the first sign of trouble are your best allies. Regular fuel filter replacements, using high-quality diesel, and prompt diagnosis with a reliable scan tool can prevent minor issues from escalating into major, wallet-draining repairs. Don’t let reduced engine power diminish your driving experience or the lifespan of your robust 6.7 Powerstroke. Stay vigilant, maintain your truck diligently, and you’ll ensure your diesel workhorse continues to perform at its peak for years to come.

Frequently Asked Questions

What causes 6.7 Powerstroke low fuel pressure and reduced engine power?

Low fuel pressure in a 6.7 Powerstroke is often caused by clogged fuel filters, a failing lift pump, or a faulty High-Pressure Fuel Pump (HPFP). Other potential culprits include air in the fuel system, a restricted fuel tank pick-up, or leaks in the fuel lines.

What are the common symptoms of low fuel pressure in a 6.7 Powerstroke?

You will typically experience noticeable reduced engine power, rough idling, hesitation during acceleration, and difficulty starting. A “Check Engine” light often illuminates, and the vehicle may enter a “limp mode” to protect the engine.

Is it safe to drive my 6.7 Powerstroke with low fuel pressure and reduced engine power?

It is not recommended to drive your 6.7 Powerstroke with persistent low fuel pressure. Continuing to operate the vehicle can cause severe, irreversible damage to expensive components like the High-Pressure Fuel Pump (HPFP) and fuel injectors, leading to much costlier repairs.

How is low fuel pressure diagnosed on a 6.7 Powerstroke?

Diagnosis involves checking for Diagnostic Trouble Codes (DTCs) with a scan tool and monitoring live fuel pressure readings for both low-pressure and high-pressure circuits. Technicians will also inspect fuel filters, test pump functionality, and check for any visible leaks or restrictions in the fuel system.

What are the most common repairs for a 6.7 Powerstroke experiencing low fuel pressure?

The most common repairs include replacing clogged fuel filters, diagnosing and replacing a failing fuel lift pump or High-Pressure Fuel Pump (HPFP), or bleeding air from the fuel system. Sometimes, a faulty fuel pressure sensor or regulator might be the underlying issue requiring replacement.

How can I prevent low fuel pressure issues in my 6.7 Powerstroke?

Regular and timely replacement of both fuel filters according to Ford’s recommended service intervals is the most critical preventative measure. Using high-quality diesel fuel and avoiding consistently running your fuel tank very low can also help maintain the overall health and longevity of your 6.7 Powerstroke fuel system.