6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power

Featured image for this comprehensive guide about 6.7 powerstroke low fuel pressure/reduced engine power

Image source: freeimageslive.co.uk

6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power: Diagnosing and Fixing Your Truck’s Woes

There’s nothing quite like the raw power and reliability of a Ford 6.7 Powerstroke diesel engine. Whether you’re hauling heavy loads, tackling tough job sites, or simply enjoying the open road, your Super Duty is built to perform. However, when your trusty truck starts exhibiting signs of low fuel pressure, it can quickly lead to frustrating symptoms like sluggish acceleration, rough idling, and, most critically, reduced engine power. This isn’t just an inconvenience; it can indicate a significant issue within your sophisticated 6.7 Powerstroke fuel system that demands immediate attention.

Experiencing a drop in performance from your Powerstroke can be unnerving. You might notice your truck struggling on inclines, or the dreaded “wrench light” illuminating on your dashboard, signaling a deeper problem. Understanding the causes and symptoms of low fuel pressure is the first step toward getting your Powerstroke back to its peak performance. In this comprehensive guide, we’ll dive deep into the world of 6.7 Powerstroke fuel pressure issues, offering a detailed look at diagnosis, solutions, and preventative measures to keep your diesel beast roaring.

We know how much you rely on your truck, and dealing with Ford 6.7 Powerstroke problems can be a real headache. Our goal is to equip you with the knowledge and actionable tips to confidently address these issues, whether you’re a seasoned DIY mechanic or seeking to understand what your trusted technician is doing. Let’s get to the bottom of your Powerstroke’s performance concerns and restore that legendary power you’ve come to expect.

Quick Answers to Common Questions

What does “reduced engine power” actually feel like in my 6.7 Powerstroke?

When your 6.7 Powerstroke experiences reduced engine power, you’ll likely notice a significant drop in acceleration, responsiveness, and overall performance, often accompanied by a “limp mode” where the truck limits speed to protect itself. This is often a direct symptom of underlying issues like low fuel pressure.

Why is my 6.7 Powerstroke suddenly showing low fuel pressure?

Common culprits for low fuel pressure in your 6.7 Powerstroke include a failing fuel pump, clogged fuel filters, a leaking fuel line, or issues with the fuel pressure regulator. It’s often one of these core components acting up.

Is it safe to drive my truck if I have 6.7 Powerstroke low fuel pressure and reduced engine power?

While your truck might still move, it’s generally not recommended to drive extensively with 6.7 Powerstroke low fuel pressure and reduced engine power. Continuing to drive could lead to further damage to the fuel system or even the engine itself.

What’s the very first thing I should check if my 6.7 Powerstroke indicates low fuel pressure?

Start by checking your fuel filters! Clogged fuel filters are a super common and relatively easy fix for 6.7 Powerstroke low fuel pressure, often restoring full engine power.

How serious is 6.7 Powerstroke low fuel pressure? Is it an emergency?

While not always an immediate roadside emergency, 6.7 Powerstroke low fuel pressure is a serious issue that needs prompt attention. Ignoring it can lead to costly damage to injectors, the high-pressure fuel pump, and further reduced engine power.

📋 Table of Contents

- The Critical Role of Fuel Pressure in Your 6.7 Powerstroke

- Top Culprits Behind Low Fuel Pressure in 6.7 Powerstrokes

- Diagnosing Low Fuel Pressure: A Step-by-Step Approach

- Effective Solutions for Restoring Fuel Pressure and Power

- Preventing Future Low Fuel Pressure Issues: Proactive Maintenance

- Understanding Fuel Pressure Specifications & Potential Costs

- Conclusion: Keep Your 6.7 Powerstroke Running Strong

The Critical Role of Fuel Pressure in Your 6.7 Powerstroke

At the heart of your 6.7 Powerstroke‘s performance lies its intricate fuel system, a marvel of modern diesel engineering. This system relies on precise and consistent fuel pressure to deliver fuel efficiently to the injectors, ensuring optimal combustion. When fuel pressure drops below specified levels, it starves the engine, leading directly to reduced engine power and a host of other undesirable symptoms. It’s a foundational element; without adequate pressure, your Powerstroke simply cannot operate as intended.

Learn more about 6.7 powerstroke low fuel pressure/reduced engine power – 6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power

Image source: lalizas.com

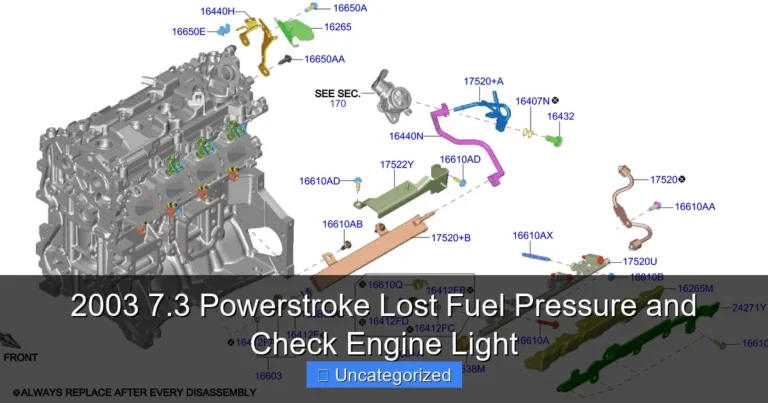

Understanding the 6.7 Powerstroke Fuel System

The 6.7 Powerstroke fuel system is a two-stage design, common in modern common rail diesel engines. It starts with a low-pressure lift pump (often located in the fuel tank or frame-mounted) that draws fuel from the tank and sends it through a series of filters to the high-pressure fuel pump (HPFP), specifically the Bosch CP4.2 pump. The HPFP then pressurizes the fuel to extremely high levels (up to 30,000 psi or more) before delivering it to the fuel rails and ultimately to the sophisticated piezoelectric injectors. This precise sequence requires robust components and accurate pressure regulation to function flawlessly. Any disruption at any stage can manifest as 6.7 Powerstroke low fuel pressure.

| Common Cause / Issue | Typical Symptom / Impact | Observed Fuel Pressure (PSI) |

|---|---|---|

| **Optimal System Performance** | Full engine power, smooth acceleration, no DTCs | 60-70 PSI (Under Load) |

| **Clogged Fuel Filter(s)** | Reduced engine power, hesitation, P0087 DTC (Fuel Rail Pressure Low) | Drops to 40-50 PSI, lower under heavy load |

| **Failing Fuel Lift Pump** | Hard starting, extended cranking, significant power loss, engine stalling | Consistently < 40 PSI, can be erratic |

| **Air Intrusion / Leaky Fuel Line** | Rough idle, surging, intermittent power loss, air bubbles in fuel lines | Fluctuating pressure, often drops to 30-50 PSI |

| **Failing Fuel Pressure Sensor** | Inaccurate pressure readings, false P0087 DTCs, engine limp mode | Reads low (e.g., 20-30 PSI) despite actual pressure being adequate |

Common Symptoms of Low Fuel Pressure

Identifying the symptoms of low fuel pressure in your 6.7 Powerstroke is crucial for early intervention. These signs often escalate in severity, so paying attention to even subtle changes in your truck’s behavior can save you from more extensive repairs down the line. If you’re experiencing any of the following, it’s time to investigate:

- Reduced Engine Power: This is often the most noticeable symptom. Your truck might feel sluggish, struggle to accelerate, or lose speed on inclines, especially when towing or under load. It’s the engine’s way of telling you it’s not getting enough fuel to generate its full output.

- Rough Idle or Stalling: An inconsistent supply of fuel can cause the engine to idle roughly, shaking more than usual, or even stall, particularly when cold or at low RPMs.

- Misfires or Hesitation: The engine might stumble or hesitate under acceleration, feeling like it’s momentarily losing power before catching up. This can be directly linked to individual cylinders not receiving adequate fuel.

- Check Engine Light (CEL) or Wrench Light: Your dashboard warning lights are your first line of defense. The CEL might illuminate with specific diagnostic trouble codes (DTCs) related to fuel pressure or fuel system performance. The “wrench light” often indicates a powertrain fault, frequently tied to fuel delivery issues.

- Poor Fuel Economy: While not always immediately obvious, an engine struggling with low fuel pressure might try to compensate, leading to inefficient combustion and a noticeable drop in miles per gallon.

- Difficulty Starting: If the fuel system struggles to build adequate pressure during cranking, your truck might take longer to start or require multiple attempts.

- Visible Smoke from Exhaust: Unburnt fuel due to poor atomization (a consequence of low pressure) can sometimes lead to black or white smoke from the exhaust.

Top Culprits Behind Low Fuel Pressure in 6.7 Powerstrokes

Pinpointing the exact cause of 6.7 Powerstroke low fuel pressure can sometimes feel like a detective mission. The complexity of the fuel system means several components could be at fault. Understanding the most common culprits will significantly narrow down your diagnostic efforts.

Learn more about 6.7 powerstroke low fuel pressure/reduced engine power – 6.7 Powerstroke Low Fuel Pressure and Reduced Engine Power

Image source: png.pngtree.com

Clogged Fuel Filters: The Most Common Offender

This is by far the most frequent cause of low fuel pressure issues in a 6.7 Powerstroke. Ford’s 6.7L engine utilizes two fuel filters: a primary frame-mounted filter (which often includes a water separator) and a secondary engine-mounted filter. These filters are designed to protect the sensitive high-pressure components from contaminants like dirt, rust, and water. When these filters become clogged, they restrict fuel flow, causing the fuel pumps to work harder and ultimately leading to a significant drop in pressure reaching the HPFP and injectors. Skipping routine fuel filter replacements is a guaranteed path to performance degradation and potential damage to more expensive components.

Failing Fuel Pumps (Lift Pump & HPFP)

Your Powerstroke relies on two main fuel pumps, and a failure in either can cause severe low fuel pressure:

- Lift Pump: This low-pressure pump (often integrated into the fuel tank sending unit) is responsible for drawing fuel from the tank and delivering it to the HPFP. If the lift pump is weak or failing, it won’t supply enough fuel to the HPFP, resulting in low pressure across the entire system.

- High-Pressure Fuel Pump (HPFP – Bosch CP4.2): This is the heart of the high-pressure system. Unfortunately, the CP4.2 pump used in early 6.7L Powerstrokes (2011-2019, though issues are more prevalent in earlier models) has a known reputation for premature failure. When the HPFP begins to fail, it can’t generate or maintain the incredibly high pressures required, leading to critical reduced engine power and potentially catastrophic metal debris contamination throughout the entire fuel system. This is one of the most feared 6.7 Powerstroke fuel system problems due to the high repair costs involved.

Fuel Pressure Regulator Issues

The fuel pressure regulator (also known as the fuel volume control valve or fuel rail pressure sensor/actuator) is responsible for maintaining consistent fuel pressure within the common rail. If this component malfunctions or gets stuck, it can lead to either excessively high or, more commonly, low fuel pressure, disrupting the precise fuel delivery to the injectors. These failures can be intermittent, making diagnosis tricky.

Leaks and Air Intrusion

Any breach in the fuel lines, O-rings, or connections can lead to fuel leaks or, worse, air entering the fuel system. Air in the fuel lines can cause cavitation, reduce fuel volume, and create an erratic fuel supply, all contributing to low fuel pressure and potentially damaging the fuel pumps. Inspecting for visible leaks or signs of air bubbles in clear fuel lines is a critical diagnostic step.

Fuel Pressure Sensor Malfunctions

Your Powerstroke’s engine control module (ECM) relies on accurate readings from fuel pressure sensors (both low and high pressure) to manage the fuel system. If a sensor is faulty, it might send incorrect data to the ECM, causing it to misinterpret actual fuel pressure. This can lead to the ECM commanding incorrect fuel pump operation or triggering false diagnostic trouble codes, even if actual pressure isn’t the primary issue. While not a direct cause of low fuel pressure, a bad sensor can certainly mislead you during diagnosis.

Injector Problems

While often a symptom rather than a primary cause, faulty fuel injectors can sometimes contribute to low fuel pressure issues. Leaking injectors can allow fuel to bypass the combustion chamber, effectively “bleeding off” pressure from the fuel rail. While less common than filter or pump issues, problematic injectors can exacerbate or mimic fuel pressure issues 6.7 Powerstroke owners experience.

Diagnosing Low Fuel Pressure: A Step-by-Step Approach

Effective diagnosis is key to efficiently resolving low fuel pressure issues in your 6.7 Powerstroke. Don’t just guess; follow a methodical approach to pinpoint the root cause. This section will guide you through the essential steps and tools for accurate troubleshooting.

Essential Diagnostic Tools

To accurately diagnose fuel pressure problems, you’ll need a few specialized tools:

- Diagnostic Scan Tool: A high-quality scan tool capable of reading Ford-specific codes and live data is indispensable. This allows you to monitor actual and desired fuel pressure values (both low-pressure and high-pressure side), fuel pump command, and injector pulse width.

- Fuel Pressure Gauge: A physical fuel pressure gauge with the correct adapters for your 6.7 Powerstroke’s low-pressure side can provide a direct reading, confirming what your scan tool indicates.

- Visual Inspection Tools: A good flashlight, inspection mirror, and perhaps some clear tubing to check for air in fuel lines.

- Multimeter: For checking electrical signals to sensors and pumps.

Performing a Fuel Pressure Test

A crucial step is to directly measure fuel pressure. With your scan tool, monitor the “Desired Fuel Pressure” and “Actual Fuel Pressure” readings for both the low-pressure (lift pump) and high-pressure (rail pressure) circuits. Compare these values with manufacturer specifications. If there’s a significant discrepancy, especially with the actual pressure consistently lower than desired, you’ve confirmed a low fuel pressure problem. A physical gauge can also be hooked up to the low-pressure side to confirm the lift pump’s output.

Typically, you’d look for low-pressure side readings around 60-75 PSI at idle and under load. High-pressure side readings will vary wildly based on engine demand, ranging from a few thousand PSI at idle to over 25,000 PSI under heavy acceleration. Consistently low readings on either side, especially the high-pressure side under load, are a clear indicator of a fault.

Interpreting Diagnostic Trouble Codes (DTCs)

When the Check Engine Light or Wrench Light illuminates, your truck’s ECM has stored a DTC. Common codes related to 6.7 Powerstroke fuel pressure include:

- P0087: Fuel Rail/System Pressure – Too Low

- P0088: Fuel Rail/System Pressure – Too High (less common with low pressure, but indicates a regulator issue)

- P008A: Low Pressure Fuel System Pressure – Too Low

- P008B: Low Pressure Fuel System Pressure – Too High

- P0191-P0194: Fuel Rail Pressure Sensor Circuit Malfunction

- P0200-P0208: Injector Circuit Malfunction (can sometimes be a symptom of fuel starvation)

These codes provide an excellent starting point, but always remember that a code only points to a symptom, not always the direct cause. For instance, P0087 could be a clogged filter, a weak pump, or a faulty sensor.

Visual Inspections

Don’t underestimate the power of a thorough visual inspection:

- Fuel Filters: Check the date of last replacement. If they’re overdue, this is a prime suspect.

- Fuel Lines and Connections: Look for any signs of leaks, corrosion, or kinks. Pay close attention to the lines around the frame and engine.

- Fuel Tank: Check for damage or unusual sounds from the in-tank lift pump.

- Wiring: Inspect wiring harnesses to the fuel pumps, sensors, and injectors for signs of damage, chafing, or loose connections.

Effective Solutions for Restoring Fuel Pressure and Power

Once you’ve accurately diagnosed the cause of your 6.7 Powerstroke’s low fuel pressure, it’s time to implement the solution. Addressing these issues promptly is crucial to prevent further damage and restore your truck’s performance.

Fuel Filter Replacement

If clogged fuel filters are the culprit, this is the easiest and most affordable fix. Replace both the frame-mounted and engine-mounted fuel filters. Always use high-quality, OEM-spec filters to ensure proper filtration and fitment. This simple maintenance step often resolves cases of reduced engine power caused by fuel starvation and is an essential part of routine 6.7 Powerstroke maintenance.

Fuel Pump Repair or Replacement

If your diagnostic tests point to a failing fuel pump:

- Lift Pump: A weak lift pump usually requires replacement. In many 6.7 Powerstrokes, this is integrated into the fuel tank sending unit, making it a more involved job, but still manageable for an experienced DIYer or technician.

- High-Pressure Fuel Pump (HPFP): If the CP4.2 pump is failing, replacement is typically the only option. Due to the high risk of metal contamination, if a HPFP fails catastrophically, it’s critical to thoroughly flush the entire fuel system and replace all affected components (injectors, fuel rails, lines, return lines, and often the fuel tank) to prevent immediate re-contamination and subsequent failure. This is often the most expensive 6.7 Powerstroke fuel system problem to fix.

Addressing Fuel Leaks and Air Intrusion

Locate and repair any fuel leaks immediately. This might involve replacing a cracked fuel line, tightening a loose connection, or replacing worn O-rings on components like the fuel pressure regulator or injectors. If air intrusion is suspected, the affected lines or connections must be sealed. Sometimes, a simple clamp adjustment can resolve the issue, while other times, a full line replacement is needed.

Sensor and Regulator Replacement

If a faulty fuel pressure sensor or regulator is sending incorrect signals or failing to maintain pressure, replacement is necessary. These components are usually accessible on the fuel rail or HPFP. Ensure you use OEM or equivalent quality parts for proper function and longevity. Once replaced, clear any stored DTCs and verify correct pressure readings with your scan tool.

Injector Maintenance or Replacement

While often a secondary issue, if diagnostics confirm leaking or failing injectors are contributing to low fuel pressure, they will need attention. In some cases, specialized cleaning can help, but often, replacement is required for consistently performing injectors. This work typically requires specialized tools and expertise, making it a job best left to professional diesel mechanics.

Preventing Future Low Fuel Pressure Issues: Proactive Maintenance

An ounce of prevention is worth a pound of cure, especially with the complex and expensive 6.7 Powerstroke fuel system. Proactive maintenance is your best defense against low fuel pressure and reduced engine power, ensuring your truck remains reliable and powerful for years to come.

Adhering to Manufacturer’s Service Intervals

The single most important preventative measure is to follow Ford’s recommended maintenance schedule religiously. This includes:

- Regular Fuel Filter Replacement: Ford typically recommends replacing both fuel filters every 22,500 miles or 36,000 km, or every 30,000 miles for specific models/years. However, if you use lower quality fuel or operate in dusty/dirty environments, consider more frequent changes, possibly every 10,000-15,000 miles. This is the simplest way to prevent common 6.7 Powerstroke fuel system problems.

- Oil Changes: While not directly related to fuel pressure, regular oil changes are crucial for overall engine health, which indirectly affects fuel system longevity.

- Fluid Checks and General Inspections: Regularly inspect your fuel lines for wear, cracks, or leaks during other maintenance tasks.

Importance of Quality Fuel

The type and quality of diesel fuel you put into your Powerstroke have a direct impact on the longevity of your fuel system components. Always use high-quality, clean diesel fuel from reputable stations. Avoid “bargain” fuel that may contain excessive water or contaminants, as these can quickly clog filters and damage sensitive components like the HPFP and injectors. Water in fuel is a major enemy of diesel systems, leading to corrosion and component failure.

Regular Fuel System Additives

Consider using a reputable diesel fuel additive, especially one designed for your Powerstroke. These additives can offer several benefits:

- Lubricity Enhancers: Diesel fuel has reduced lubricity compared to older formulations, which can impact the lifespan of the HPFP. Additives can restore crucial lubrication.

- Cetane Boosters: Improve combustion efficiency and cold starting.

- Water Demulsifiers: Help separate water from the fuel, allowing the water separator to work more effectively.

- Cleaning Agents: Keep injectors and fuel lines free from deposits, ensuring optimal fuel atomization and flow.

Always choose additives that are specifically safe for your 6.7 Powerstroke and its exhaust aftertreatment system (DEF and DPF).

Monitoring Fuel System Health

If you have access to a good diagnostic scan tool, periodically monitor your actual versus desired fuel pressure readings, even when your truck isn’t showing symptoms. This can help you identify a subtle drop in pressure before it becomes a critical issue, allowing for proactive intervention. Pay attention to any new or unusual engine noises, changes in performance, or warning lights.

Understanding Fuel Pressure Specifications & Potential Costs

Knowing what constitutes normal fuel pressure and having an idea of potential repair costs can help you make informed decisions when your 6.7 Powerstroke experiences issues. This section provides a general overview.

| Component/Parameter | Normal Operating Range (Approx.) | Typical Repair Cost (Estimates, parts + labor) |

|---|---|---|

| Low-Pressure (Lift Pump) Output | 60-75 PSI at idle & load | $300 – $800 (for in-tank pump) |

| High-Pressure (Rail) Pressure (Idle) | 5,000 – 8,000 PSI | (Dependent on cause) |

| High-Pressure (Rail) Pressure (WOT) | 25,000 – 30,000+ PSI | (Dependent on cause) |

| Fuel Filter Replacement (Both) | N/A (Maintenance item) | $100 – $300 |

| HPFP (CP4.2) Replacement | N/A (Component) | $3,000 – $8,000+ (if full system flush/injector replacement needed) |

| Fuel Pressure Regulator/Sensor | N/A (Component) | $400 – $1,200 |

| Fuel Injector (Single) | N/A (Component) | $400 – $800 (per injector) |

Note: These costs are approximate and can vary significantly based on location, labor rates, parts availability (OEM vs. aftermarket), and the extent of damage. A catastrophic HPFP failure requiring a full fuel system replacement can easily push into the $8,000 – $15,000 range.

Conclusion: Keep Your 6.7 Powerstroke Running Strong

Dealing with low fuel pressure and reduced engine power in your 6.7 Powerstroke can be a source of major concern, but with the right knowledge and a systematic approach, these issues are entirely diagnosable and fixable. From the simple act of replacing a clogged fuel filter to the more complex task of addressing a failing HPFP, understanding the intricacies of your 6.7 Powerstroke fuel system is your best defense.

Remember, your Ford Powerstroke is a precision machine, and its performance hinges on a healthy fuel delivery system. Prioritizing routine maintenance, especially the timely replacement of fuel filters and using high-quality fuel, can prevent many of the common 6.7 Powerstroke problems that lead to low fuel pressure. Pay attention to the subtle cues your truck gives you – a rough idle, a slight hesitation, or the dreaded illuminated dashboard light – and act quickly.

Don’t let fuel pressure issues sideline your powerful truck. By being proactive, performing diligent diagnostics, and choosing quality repairs, you can ensure your 6.7 Powerstroke continues to deliver the reliable performance and robust power you depend on for every mile of your journey. Keep that Powerstroke roaring!

Frequently Asked Questions

What are the common symptoms of low fuel pressure in a 6.7 Powerstroke?

You’ll often notice a significant reduction in engine power, poor acceleration, and rough idling. The “Check Engine” light or a “Reduced Engine Power” message might also appear on your dashboard, indicating a problem with the fuel delivery system.

What are the common causes of low fuel pressure and reduced engine power in a 6.7 Powerstroke?

Common culprits include a clogged fuel filter, a failing fuel pump (like the High-Pressure Fuel Pump or HPFP), or issues with the fuel pressure regulator. Leaking fuel lines, faulty fuel injectors, or a restricted fuel tank sending unit can also contribute to this problem.

How is low fuel pressure diagnosed on a 6.7 Powerstroke?

A technician will typically connect a diagnostic scan tool to read error codes and monitor live fuel pressure data during operation. They’ll also inspect fuel filters, perform specific fuel pressure tests at various points in the system, and check for any visible leaks or restrictions in the fuel lines.

Is it safe to drive my 6.7 Powerstroke when experiencing low fuel pressure or reduced engine power?

It is generally not recommended to drive with low fuel pressure, as it can lead to further, more severe damage to critical fuel system components like the injectors and HPFP. The reduced engine power also presents a significant safety hazard, especially when attempting to accelerate or maintain speed in traffic.

What maintenance steps can help prevent low fuel pressure issues in my 6.7 Powerstroke?

Regular and timely replacement of your fuel filters is crucial, typically every 15,000 to 20,000 miles or as per your owner’s manual. Using high-quality diesel fuel, avoiding running the tank extremely low, and considering a reputable fuel additive can also help maintain system health and prevent fuel pressure problems.

What are the typical repairs for low fuel pressure in a 6.7 Powerstroke, and how much do they cost?

Repairs can range from simple fuel filter replacement to more extensive work like replacing the fuel pump, fuel pressure regulator, or even contaminated injectors. Costs vary widely depending on the diagnosed component, from a few hundred dollars for filters to several thousands for major fuel pump or injector system overhauls.