6.0 Powerstroke Oil Cooler Specifications: Ensuring Your Engine Stays Cool

Featured image for this comprehensive guide about 6.0 Powerstroke oil cooler specifications

The Ford 6.0 Powerstroke diesel engine, a powerhouse known for its impressive torque and towing capabilities, has a reputation that precedes it. While often revered for its raw strength, it also comes with a unique set of challenges, particularly concerning its cooling system. At the heart of many common 6.0 Powerstroke woes lies a component that often gets overlooked until it’s too late: the 6.0 Powerstroke oil cooler. This vital part is not just an accessory; it’s the lifeblood of your engine’s temperature regulation, directly impacting everything from engine longevity to the performance of other critical systems like the EGR cooler.

Understanding the intricacies of your 6.0 Powerstroke oil cooler specifications is not merely an exercise in technical knowledge; it’s a critical step toward proactive maintenance and preventing catastrophic engine failure. Many owners have faced the dreaded “delta T” issue – a significant difference between engine oil temperature (EOT) and engine coolant temperature (ECT) – which is a tell-tale sign of a compromised oil cooler. Ignoring these warnings can lead to a cascade of expensive repairs, including EGR cooler failure, head gasket issues, and even turbocharger damage. This comprehensive guide will delve deep into the world of the 6.0 Powerstroke oil cooler, equipping you with the knowledge to diagnose, maintain, and even upgrade this essential component, ensuring your robust diesel engine continues to perform optimally for years to come.

Whether you’re a seasoned Powerstroke owner, a new enthusiast, or a professional mechanic, this post will provide valuable insights into the design, function, common failure points, and crucial maintenance strategies surrounding the 6.0 Powerstroke oil cooler. We’ll explore the original equipment manufacturer (OEM) specifications, discuss why these coolers tend to fail, and offer actionable advice on how to keep your engine running cool and strong. Get ready to dive into the technical details that can save you thousands of dollars and countless headaches.

Quick Answers to Common Questions

What’s the primary issue with the 6.0 Powerstroke oil cooler specifications?

The factory 6.0 Powerstroke oil cooler specifications are prone to clogging, often due to casting sand or debris in the cooling system, which restricts coolant flow and leads to dangerously high oil temperatures.

How can I tell if my 6.0 Powerstroke oil cooler specifications are failing?

A key indicator is a significant and consistent difference between your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT); if your EOT is regularly 15-20 degrees Fahrenheit or more hotter than your ECT, your 6.0 Powerstroke oil cooler specifications are likely compromised.

Are there upgraded 6.0 Powerstroke oil cooler specifications available for better performance?

Yes, absolutely! Many aftermarket solutions offer improved 6.0 Powerstroke oil cooler specifications, including remote oil cooler setups or enhanced factory-style designs that provide better flow and more efficient heat exchange.

Does coolant quality directly impact my 6.0 Powerstroke oil cooler specifications?

It absolutely does! Using proper, high-quality coolant and performing regular coolant flushes are crucial for preventing sediment buildup and preserving the longevity of your 6.0 Powerstroke oil cooler specifications.

What’s the recommended maintenance to protect my 6.0 Powerstroke oil cooler specifications?

Regularly flushing your cooling system, using a high-quality coolant filter, and consistently monitoring your EOT and ECT temperatures are vital steps to ensure your 6.0 Powerstroke oil cooler specifications continue to perform optimally.

📋 Table of Contents

- The Critical Role of the 6.0 Powerstroke Oil Cooler

- Understanding the OEM 6.0 Powerstroke Oil Cooler Specifications

- Common Failure Modes and Symptoms of a Failing 6.0 Powerstroke Oil Cooler

- Diagnosing 6.0 Powerstroke Oil Cooler Issues: What to Look For

- Upgrading Your 6.0 Powerstroke Oil Cooler: Performance and Longevity Solutions

- Essential Maintenance Tips for Your 6.0 Powerstroke Oil Cooler

- Conclusion: Keeping Your 6.0 Powerstroke Cool and Reliable

The Critical Role of the 6.0 Powerstroke Oil Cooler

Before we dive into the specific details of the 6.0 Powerstroke oil cooler specifications, it’s essential to grasp exactly what this component does and why it’s so critical to your engine’s health. The oil cooler in your 6.0 Powerstroke is not just about keeping the oil cool; it’s a heat exchanger that plays a central role in maintaining optimal operating temperatures for both your engine oil and your coolant.

The 6.0 Powerstroke engine is a “wet sump” design, meaning engine oil is stored in the oil pan and circulated under pressure to lubricate various moving parts. As the engine operates, friction and combustion generate immense heat. This heat is absorbed by the engine oil as it lubricates components. If left unchecked, this oil would quickly overheat, losing its viscosity and lubricating properties, leading to excessive wear and potential engine seizure. This is where the 6.0 Powerstroke oil cooler steps in.

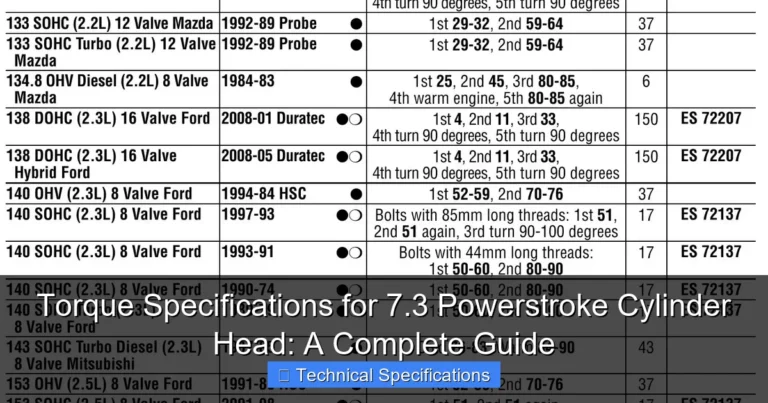

| Specification | OEM (Stock) Oil Cooler | Common Upgraded Oil Cooler | Significance / Impact |

|---|---|---|---|

| Design Type | Plate-style heat exchanger (liquid-to-liquid) | Improved plate-style, larger capacity, or remote air-to-oil kits | Transfers heat from engine oil to engine coolant. Efficiency is critical. |

| Core Material | Brazed Aluminum | Brazed Aluminum (often thicker/more robust), or Copper/Brass | Affects heat transfer rate and long-term durability against corrosion/erosion. |

| Primary Failure Mode | Internal clogging from coolant debris (casting sand, silicate drop-out). | Generally more resistant to clogging (larger passages), but still reliant on clean coolant. | Clogging reduces oil cooling efficiency, leading to higher oil temperatures and potential engine damage. |

| Max EOT-ECT Delta (Diagnostic) | < 15°F (at 65mph cruise, level road, 200°F+ ECT) | Often < 10-12°F (due to improved efficiency and flow) | Crucial indicator of oil cooler health. A higher delta suggests restriction or failure. |

| Recommended Service Life | 100,000 – 150,000 miles (highly dependent on coolant quality & maintenance) | Can exceed OEM lifespan with proper coolant filtration and maintenance. | Preventative replacement is highly recommended to avoid catastrophic engine issues. |

The cooler is essentially a plate-style heat exchanger nestled within the engine’s “valley,” beneath the oil filter housing and directly above the high-pressure oil pump (HPOP). Hot engine oil flows through one set of passages, while engine coolant flows through another, parallel set of passages. The heat from the oil is transferred to the cooler, which then transfers it to the coolant. The coolant, now warmer, then flows to the main radiator to dissipate this heat into the ambient air. This intricate dance ensures that your engine oil stays within its optimal operating temperature range, maintaining its protective properties.

Beyond just cooling the engine oil, the 6.0 Powerstroke oil cooler has an equally crucial secondary function: it supplies cooled coolant to the EGR (Exhaust Gas Recirculation) cooler. The EGR cooler is designed to cool hot exhaust gases before they are recirculated back into the intake manifold, reducing NOx emissions. If the oil cooler is clogged or operating inefficiently, the coolant flowing to the EGR cooler will be excessively hot, causing the EGR cooler to work harder or fail prematurely due to thermal stress. This direct link makes the health of your 6.0 Powerstroke oil cooler paramount for the longevity of your entire cooling and emissions system.

Understanding the OEM 6.0 Powerstroke Oil Cooler Specifications

The original equipment manufacturer (OEM) 6.0 Powerstroke oil cooler specifications provide the baseline for its design and expected performance. While subsequent revisions have aimed to improve its reliability, the fundamental design remains a plate-style heat exchanger. Let’s break down some of the key aspects of the OEM cooler.

Design and Construction

The OEM 6.0 Powerstroke oil cooler is a compact, stacked plate design. It typically consists of a series of alternating plates for oil and coolant, separated by thin fins. These fins increase the surface area for heat exchange. The cooler unit itself is housed within a cast aluminum assembly, which also incorporates the oil filter housing and the passage for coolant to the EGR cooler. The dimensions are designed to fit precisely within the engine valley, a space-constrained area.

- Type: Oil-to-Coolant heat exchanger

- Location: Mounted in the engine valley, beneath the oil filter housing.

- Material: Internal plates are typically stainless steel or aluminum, enclosed in a cast aluminum housing.

- Flow Path: Engine oil flows from the HPOP cover into the cooler, then out to the engine. Coolant flows from the oil cooler housing into the cooler, and then out to the EGR cooler and then back to the degas bottle.

Heat Exchange Capacity

The factory 6.0 Powerstroke oil cooler is designed to manage the heat generated by a stock engine under normal operating conditions. Its heat transfer capacity is dictated by the surface area of the internal plates, the materials used, and the flow rates of both oil and coolant through it. In a healthy system, the cooler should be able to maintain a relatively small temperature differential between engine oil temperature (EOT) and engine coolant temperature (ECT).

Temperature Differential (Delta T)

One of the most crucial performance specifications for any 6.0 Powerstroke oil cooler is its ability to maintain a small delta T. This is the difference between your Engine Oil Temperature (EOT) and your Engine Coolant Temperature (ECT). Under normal, fully warmed-up operating conditions (e.g., cruising at highway speeds), the ideal delta T should be:

- Maximum Acceptable Delta T: 15 degrees Fahrenheit (approx. 8.3 degrees Celsius)

- Ideal Delta T: 5-10 degrees Fahrenheit (approx. 2.8-5.6 degrees Celsius)

A delta T consistently exceeding 15 degrees Fahrenheit is a strong indicator of a compromised or clogged 6.0 Powerstroke oil cooler. This specification is not just a guideline; it’s a diagnostic benchmark that every 6.0 Powerstroke owner should be aware of and regularly monitor.

Flow Characteristics

The internal design of the cooler, particularly the density of its fin pack, is a critical specification. The OEM coolers, especially earlier revisions, had a relatively fine fin pack. While this increased surface area for heat exchange, it also made them susceptible to clogging from solid contaminants in the coolant. Over time, casting sand from the engine block, silicate dropout from conventional coolants, and general corrosion can build up within these narrow passages, restricting coolant flow and reducing the cooler’s efficiency. This restriction is often the root cause of the infamous “delta T” issue, as the oil can no longer shed heat effectively into the poorly flowing coolant.

Common Failure Modes and Symptoms of a Failing 6.0 Powerstroke Oil Cooler

Despite robust initial 6.0 Powerstroke oil cooler specifications, the factory design unfortunately proved susceptible to specific failure modes. Understanding these is key to early detection and preventing more severe engine damage.

Primary Failure Mode: Clogging and Restriction

The most prevalent failure mode for the 6.0 Powerstroke oil cooler is internal clogging. This isn’t due to a fault in the cooler’s material itself but rather a systemic issue with the cooling system and the cooler’s design tolerances. The primary culprits for clogging are:

- Casting Sand: Residual casting sand from the engine block, which was not adequately flushed during manufacturing, can circulate in the coolant system and settle in the fine passages of the cooler.

- Silicate Dropout: Use of conventional coolants (such as green “universal” coolant) or extended-life coolants that are incompatible with the 6.0 Powerstroke (which requires an ELC – Extended Life Coolant like Ford Gold or equivalent) can lead to silicate precipitation. These solid particles accumulate in the cooler.

- Corrosion and Scale: Neglecting coolant maintenance, using tap water instead of distilled water, or allowing air pockets in the system can lead to internal corrosion and scale buildup, further restricting flow.

Secondary Failure: EGR Cooler Failure

As discussed, the 6.0 Powerstroke oil cooler supplies coolant to the EGR cooler. When the oil cooler becomes restricted, the coolant flowing through it gets excessively hot because it’s not effectively shedding heat from the oil. This superheated coolant is then sent directly to the EGR cooler. The EGR cooler, designed to handle hot exhaust gases, cannot withstand the additional thermal stress of superheated coolant. This leads to premature failure of the EGR cooler, which can manifest as:

- Cracks in the EGR cooler core, allowing coolant to enter the exhaust stream.

- White smoke from the exhaust (coolant burning).

- Loss of coolant without external leaks.

- Hydro-locking (in severe cases) if enough coolant gets into the intake.

Other Related Symptoms of a Failing Oil Cooler

- High Engine Oil Temperature (EOT): Your engine oil will consistently run hotter than normal, especially under load. This is the direct result of the cooler not being able to dissipate heat.

- Significant EOT/ECT Delta: This is the most reliable diagnostic indicator. A delta T consistently above 15°F is a clear sign.

- Overheating: While less common for just an oil cooler issue, a severely restricted oil cooler can contribute to overall engine overheating, especially if other cooling components are also compromised.

- Degas Bottle Puking: While more commonly associated with head gasket issues, a struggling oil cooler can contribute to excessive heat in the cooling system, leading to coolant expansion and overflow from the degas bottle.

- Reduced Engine Performance: High oil temperatures can lead to fuel economy degradation and even a reduction in engine power as the PCM (Powertrain Control Module) may derate the engine to prevent damage.

Diagnosing 6.0 Powerstroke Oil Cooler Issues: What to Look For

Diagnosing a failing 6.0 Powerstroke oil cooler doesn’t require tearing the engine apart immediately. With the right tools and knowledge, you can often pinpoint the problem before it escalates. The key lies in monitoring your engine’s vitals, particularly temperatures.

Temperature Monitoring: The Delta T Test

This is the cornerstone of 6.0 Powerstroke oil cooler diagnostics. You’ll need a way to read your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT simultaneously. This usually requires a diagnostic scan tool (like an SCT tuner, Forscan with an OBD2 adapter, or similar devices). Many aftermarket gauges can also display these values.

- Warm Up the Engine: Drive your truck until both EOT and ECT are fully warmed up and stable. This usually means cruising at highway speeds (e.g., 60-70 mph) for at least 20-30 minutes.

- Observe Temperatures: Monitor EOT and ECT.

- Calculate Delta T: Subtract ECT from EOT (EOT – ECT = Delta T).

What to Look For:

- Delta T < 15°F (8.3°C): Your oil cooler is likely healthy and functioning as per 6.0 Powerstroke oil cooler specifications.

- Delta T 15-20°F (8.3-11.1°C): The cooler is showing signs of restriction. Proactive maintenance is highly recommended.

- Delta T > 20°F (11.1°C): The cooler is severely restricted and needs immediate attention. Further driving risks EGR cooler failure and other costly damage.

Remember, this test should be performed under consistent driving conditions, not while idling or during rapid acceleration, as temperatures will fluctuate. Also, be aware that ambient temperature can affect these numbers slightly, but the delta should remain consistent.

Visual Inspection and Coolant Condition

While the oil cooler itself is internal, you can get clues about its health by examining your coolant system.

- Coolant Color and Clarity: Open your degas bottle (when the engine is cool!) and inspect the coolant. Is it clear, or is it murky, discolored, or does it have solid particles floating in it? Brown, sludgy coolant is a strong indicator of casting sand or silicate dropout, which are direct causes of oil cooler clogging.

- Coolant Contamination: Look for any signs of oil in the coolant or fuel in the coolant. While not direct oil cooler issues, they can be signs of other underlying problems that might exacerbate oil cooler stress.

- Coolant Filter: If you have an aftermarket coolant filter, check its condition. A clogged filter indicates contaminants in the system that could also be affecting the oil cooler.

Data Logging for Advanced Diagnostics

For more in-depth diagnosis, especially if you have intermittent issues, data logging with a capable scan tool can provide valuable insights. Log EOT, ECT, IPR (Injector Pressure Regulator) duty cycle, FICM (Fuel Injection Control Module) voltage, and other relevant parameters over a drive cycle. This can help identify patterns or specific conditions under which the oil cooler’s performance degrades.

Upgrading Your 6.0 Powerstroke Oil Cooler: Performance and Longevity Solutions

Given the known vulnerabilities of the OEM 6.0 Powerstroke oil cooler, many owners choose to upgrade or replace it with an improved design or a completely different system. These upgrades aim to enhance durability, improve heat exchange, and prevent future clogging issues.

Improved OEM-Style Replacements

Many aftermarket manufacturers offer “improved” or “heavy-duty” versions of the OEM-style 6.0 Powerstroke oil cooler. These typically retain the original form factor but feature design enhancements:

- Higher Flow Fin Packs: Some designs incorporate wider passages or a less dense fin pack on the coolant side to reduce the likelihood of clogging from solid contaminants while still maintaining adequate heat transfer.

- Better Materials: Use of more robust materials or improved welding/brazing techniques can enhance durability.

- OEM Revisions: Ford itself has released revised oil coolers over the years (e.g., the 2007 update). While these offered some improvements, they didn’t fully resolve the fundamental clogging issue for neglected coolant systems.

These improved OEM-style coolers are a good choice for those who want a direct replacement that offers better reliability than the original, often at a competitive price. However, they are still susceptible to clogging if proper coolant maintenance is not strictly followed.

Remote Oil Cooler Kits

Perhaps the most significant upgrade option for the 6.0 Powerstroke oil cooler is a remote oil cooler system. These kits completely relocate the oil cooler from the engine valley to a more accessible location, often in front of the radiator, similar to a traditional oil cooler found on many performance vehicles. This involves:

- Eliminating the OEM Cooler: The factory cooler is bypassed or removed entirely.

- External Heat Exchanger: A larger, more efficient air-to-oil heat exchanger is mounted where it can receive direct airflow.

- Coolant Block-Off: The coolant passages to the factory cooler location are blocked off or rerouted.

- Adapter Plates and Lines: Custom adapter plates are used at the oil filter housing, and braided stainless steel lines route the oil to and from the remote cooler.

Advantages of Remote Kits:

- Superior Cooling: Air-to-oil coolers generally offer more efficient heat dissipation than the original oil-to-coolant design, potentially leading to lower EOTs.

- Eliminates Clogging Risk: Since the new cooler doesn’t use engine coolant, it’s immune to the issues of casting sand and silicate dropout.

- Easier Maintenance: The remote location makes the cooler much easier to access for cleaning or replacement if needed.

- Unloads EGR Cooler: The EGR cooler now receives truly “cool” coolant directly from the radiator, reducing its thermal stress and extending its life.

Disadvantages of Remote Kits:

- Higher Cost: These kits are significantly more expensive than OEM-style replacements.

- Complex Installation: Installation is more involved and typically requires advanced mechanical skills.

- Longer Warm-Up Times: In colder climates, engine oil may take longer to reach optimal operating temperature due to the increased cooling capacity.

Other Considerations for Performance

Beyond the cooler itself, other components can impact its performance:

- Coolant Filter System: An aftermarket coolant filter is an excellent preventative measure, catching contaminants before they reach the oil cooler’s delicate passages.

- High-Quality Coolant: Always use the correct extended-life coolant (ELC) that meets Ford’s specifications, and ensure it’s mixed with distilled water.

- Thermostat: A faulty thermostat can prevent the engine from reaching or maintaining proper operating temperature, indirectly affecting the oil cooler’s efficiency.

Essential Maintenance Tips for Your 6.0 Powerstroke Oil Cooler

Prevention is always better than cure, especially with a component as critical and labor-intensive to replace as the 6.0 Powerstroke oil cooler. Adhering to strict maintenance practices for your cooling system is paramount to extending the life of your oil cooler and your entire engine.

1. Use the Correct Coolant – Absolutely Critical!

This cannot be stressed enough. The 6.0 Powerstroke requires a specific type of coolant to prevent silicate dropout and corrosion that lead to oil cooler clogging.

Always use an Extended Life Coolant (ELC) that is Nitrite-Free and meets Ford’s WSS-M97B44-D specification (Ford Gold or an equivalent CAT EC-1 rated coolant). Never use conventional green silicate-based coolants or universal “all makes, all models” coolants unless they specifically state compliance with Ford’s ELC specifications. Mixing coolants can also lead to issues.

2. Use Distilled Water – Not Tap Water

When mixing concentrated coolant or topping off your system, always use distilled water. Tap water contains minerals that can precipitate out over time, contributing to scale and sludge buildup in your cooling system, including the 6.0 Powerstroke oil cooler.

3. Regular Coolant Flushes and Changes

Follow Ford’s recommended coolant change intervals, or ideally, perform them more frequently if you’re concerned about longevity or if you’ve had previous contamination issues. A thorough flush helps remove accumulated debris from the system. Many experts recommend a complete flush every 3-5 years or 50,000-75,000 miles, depending on driving conditions and coolant quality.

4. Install a Coolant Filter

An aftermarket coolant filter is one of the best investments you can make for your 6.0 Powerstroke. It acts as a bypass filter, continuously cleaning the coolant as it circulates, capturing solid contaminants like casting sand and silicate particles before they can reach the fine passages of the 6.0 Powerstroke oil cooler and EGR cooler.

Coolant Filter Maintenance Schedule:

- Initial Filter Change: After installing a new filter, change it within 1,000-2,000 miles to capture any loose debris agitated during installation.

- Subsequent Changes: Every 15,000 miles or annually, along with a visual inspection of the filter element.

5. Monitor EOT/ECT Delta Regularly

As discussed, regularly monitoring your EOT/ECT delta T is your best diagnostic tool. Make it a habit to check these temperatures, especially during long drives or towing. Early detection of a rising delta T can prevent more serious damage.

6. Ensure Proper System Bleeding

Air pockets in the cooling system can cause localized hot spots and reduce the efficiency of heat transfer. After any work on the cooling system, ensure it is thoroughly bled according to Ford’s procedures, often involving filling the degas bottle and running the engine with the heater on to circulate coolant and purge air.

7. Inspect Hoses and Connections

Periodically inspect all cooling system hoses for cracks, swelling, or leaks. Ensure all clamps are secure. A small leak can lead to coolant loss and air entering the system, compromising overall cooling efficiency.

Conclusion: Keeping Your 6.0 Powerstroke Cool and Reliable

The 6.0 Powerstroke oil cooler specifications, while initially designed to meet the engine’s rigorous demands, present unique challenges that demand vigilance from owners. This often-underestimated component is directly responsible for maintaining optimal oil temperatures and, critically, for delivering appropriately cooled coolant to the EGR cooler. Understanding its function, common failure modes, and the importance of monitoring the EOT/ECT delta T is fundamental to preventing costly repairs and ensuring the longevity of your diesel truck.

By adhering to a proactive maintenance schedule, utilizing the correct extended-life coolant, incorporating distilled water, and strongly considering the installation of a coolant filter, you can significantly mitigate the risk of a clogged or failing 6.0 Powerstroke oil cooler. For those seeking maximum reliability and enhanced cooling performance, exploring aftermarket “improved” coolers or a comprehensive remote oil cooler kit offers compelling solutions to permanently address the inherent weaknesses of the original design.

Don’t wait for the signs of overheating or a “puking” degas bottle to take action. Invest in a reliable diagnostic tool, make regular temperature monitoring a part of your routine, and commit to meticulous coolant system care. Your 6.0 Powerstroke is a formidable engine, and with proper attention to its cooling system and specifically its 6.0 Powerstroke oil cooler, it can provide you with many more miles of powerful and reliable service. Drive smart, maintain diligently, and keep your Powerstroke running cool.

Frequently Asked Questions

What are the critical 6.0 Powerstroke oil cooler specifications I should be aware of?

The 6.0 Powerstroke oil cooler is a plate-style heat exchanger designed to transfer heat from the engine oil to the engine coolant, maintaining optimal oil temperatures. Its internal passages are crucial for efficient heat exchange, and the design dictates how well it can manage the temperature delta between oil and coolant. Understanding these specifications helps in diagnosing cooling system issues.

How can I tell if my 6.0 Powerstroke oil cooler is failing or needs replacement?

Common symptoms of a failing 6.0 Powerstroke oil cooler include a significant temperature difference (delta) between the Engine Coolant Temperature (ECT) and Engine Oil Temperature (EOT), often exceeding 15 degrees Fahrenheit after the engine is fully warmed up. Other signs can be persistent cooling system contamination, frequent EGR cooler failures, or an engine that runs hotter than normal. Monitoring your EOT and ECT with a diagnostic scanner is the most accurate way to detect a problem with your 6.0 Powerstroke oil cooler specifications.

When should I consider replacing my 6.0 Powerstroke oil cooler, even if it’s not completely failed?

It’s often recommended to consider preventative replacement of your 6.0 Powerstroke oil cooler during other major engine services, such as when replacing the EGR cooler, head gaskets, or performing other extensive work that requires significant disassembly. Given its critical role and common failure points, proactive replacement can prevent future, more severe engine damage. Even if not completely failed, a partially clogged 6.0 Powerstroke oil cooler can contribute to other system stresses.

Are there differences in 6.0 Powerstroke oil cooler specifications between OEM and aftermarket units?

While OEM 6.0 Powerstroke oil cooler specifications adhere strictly to original factory design, many aftermarket units aim to improve upon this design. Some aftermarket coolers feature larger internal passages, different construction materials, or enhanced flow designs to reduce the likelihood of clogging and improve heat transfer efficiency. When selecting an aftermarket unit, it’s vital to research reputable brands that offer genuine improvements and not just cheaper alternatives.

What is the ideal oil-to-coolant temperature delta for the 6.0 Powerstroke oil cooler?

For a properly functioning 6.0 Powerstroke oil cooler, the general rule of thumb is that the Engine Oil Temperature (EOT) should be within 15 degrees Fahrenheit of the Engine Coolant Temperature (ECT) once the engine is fully warmed up and under normal driving conditions. A consistent difference greater than 15 degrees Fahrenheit indicates a restriction or inefficiency within the 6.0 Powerstroke oil cooler’s internal passages. Maintaining this delta is crucial for engine longevity.

Are there any upgraded 6.0 Powerstroke oil cooler specifications or heavy-duty options available?

Yes, several aftermarket companies offer upgraded 6.0 Powerstroke oil cooler specifications, often referred to as “improved” or “heavy-duty” versions. These typically feature revised internal designs with larger passage ways, which are less prone to clogging from coolant silicate drop-out, and can offer better overall heat exchange. Investing in such upgrades can enhance the reliability and longevity of your cooling system, especially for trucks used for heavy towing or performance applications.