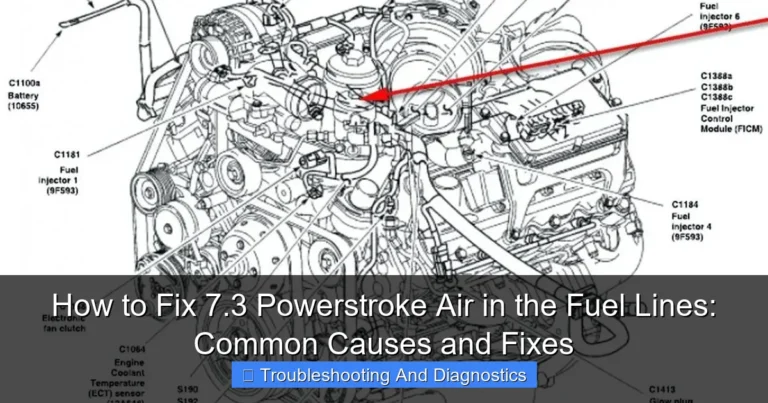

6.0 Powerstroke Injector Leak Troubleshooting: Diagnose and Fix the Issue

Featured image for this comprehensive guide about 6.0 Powerstroke injector leak troubleshooting

Image source: i.pinimg.com

6.0 Powerstroke Injector Leak Troubleshooting: Diagnose and Fix the Issue

The Ford 6.0 Powerstroke diesel engine, while known for its impressive power, can also be notorious for a few common issues. Among the most frustrating for owners is dealing with 6.0 Powerstroke injector leaks. These leaks, whether oil or fuel, can lead to a cascade of problems, from performance degradation and rough idling to potential engine damage if left unaddressed. It’s a challenge many 6.0 Powerstroke enthusiasts and professionals alike have faced, turning a powerful workhorse into a temperamental beast.

If you’ve noticed a strange smell, visible fluid, or your engine just isn’t running as smoothly as it should, you might be dealing with a leaking 6.0 Powerstroke injector. The good news is that with the right knowledge and a systematic approach to 6.0 Powerstroke injector leak troubleshooting, you can diagnose the issue and get your truck back on track. This comprehensive guide will walk you through everything you need to know, from understanding the HEUI system to advanced diagnostic techniques and effective repair strategies.

Ignoring these leaks isn’t an option. Early detection and proactive repair can save you significant time, money, and headaches down the road. Let’s dive deep into the world of 6.0 Powerstroke injector leaks and empower you with the expertise to tackle them head-on.

Quick Answers to Common Questions

What are the common signs of a 6.0 Powerstroke injector leak?

You might notice a strong diesel smell inside or outside the cabin, a rough idle, excessive white or blue smoke from the exhaust, or even oil present in your fuel filter housing. Recognizing these symptoms early is key to successful 6.0 Powerstroke injector leak troubleshooting.

Where do 6.0 Powerstroke injector leaks typically occur?

Most leaks happen at the O-rings that seal the injector to the cylinder head, allowing fuel to mix with oil or exhaust gas. Sometimes, it can also be a leak from the standpipes or dummy plugs within the oil rail, which is also part of 6.0 Powerstroke injector leak troubleshooting.

Is a 6.0 Powerstroke injector leak serious, or can I keep driving?

Don’t ignore it! An injector leak can lead to serious issues like fuel dilution in your engine oil, increased wear, or even hydro-locking in severe cases. Prompt 6.0 Powerstroke injector leak troubleshooting is essential to prevent costly engine damage.

What’s the first step for diagnosing a suspected 6.0 Powerstroke injector leak?

Start by carefully checking your fuel filter housing for any signs of oil contamination and inspect around the injectors themselves for wetness or a diesel residue. These visual checks are often the initial step in 6.0 Powerstroke injector leak troubleshooting.

Is 6.0 Powerstroke injector leak troubleshooting a DIY job, or should I take it to a mechanic?

While basic visual checks can be done at home, replacing injectors or their seals requires specific tools, experience, and careful attention to detail. For most owners, professional assistance is recommended for proper 6.0 Powerstroke injector leak troubleshooting and repair to avoid further complications.

📋 Table of Contents

- Understanding 6.0 Powerstroke Injectors and Common Leak Points

- Symptoms of 6.0 Powerstroke Injector Leaks

- Initial Diagnosis: Visual Inspection and Basic Tests

- Advanced Troubleshooting Techniques for 6.0 Injector Leaks

- Fixing 6.0 Powerstroke Injector Leaks: Repair vs. Replacement

- Preventative Maintenance to Avoid Future Injector Leaks

- 6.0 Powerstroke Injector Leak Diagnosis & Repair Cost Table

- Conclusion: Empowering Your 6.0 Powerstroke Journey

Understanding 6.0 Powerstroke Injectors and Common Leak Points

Before you can effectively troubleshoot a 6.0 Powerstroke injector leak, it’s essential to understand how the 6.0 Powerstroke’s High-Pressure Oil (HEUI) injection system works and where leaks commonly originate. Unlike many modern common-rail systems, the 6.0 uses engine oil pressurized to extremely high levels (up to 3,600 PSI) to fire its fuel injectors. This complex system, while robust when maintained, presents unique challenges when leaks occur.

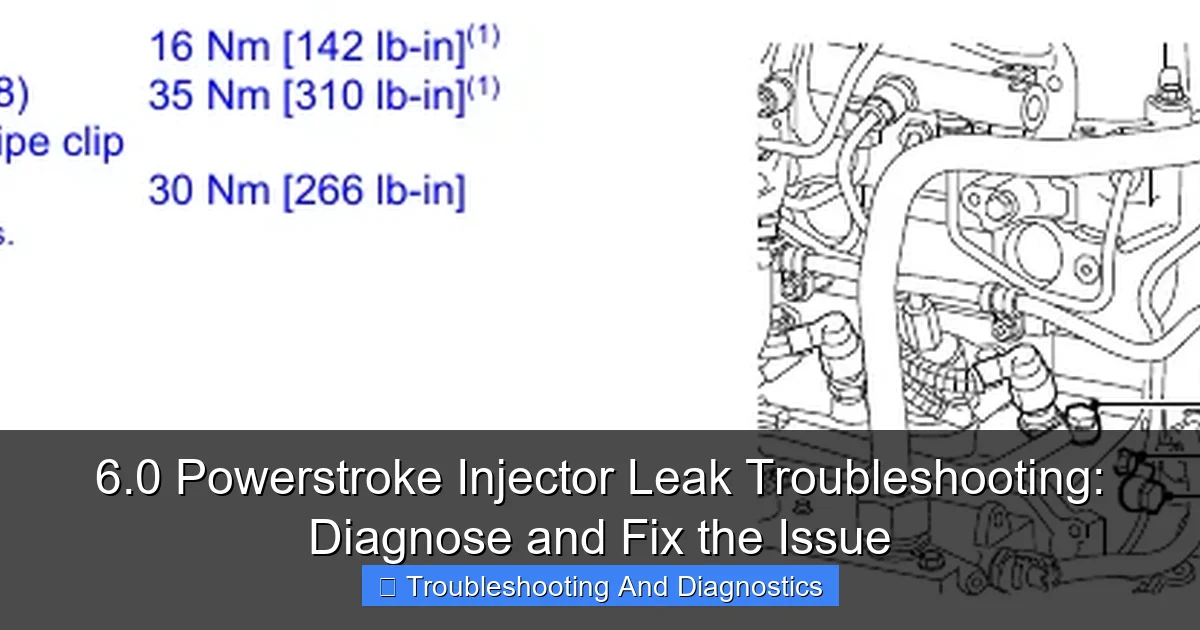

Learn more about 6.0 Powerstroke injector leak troubleshooting – 6.0 Powerstroke Injector Leak Troubleshooting: Diagnose and Fix the Issue

Image source: dieselmotors.info

The HEUI System: A Dual-Fluid Operation

The HEUI system relies on two fluids: low-pressure fuel (around 45-70 PSI) delivered to the injectors, and high-pressure engine oil supplied by the High-Pressure Oil Pump (HPOP). The HPOP sends oil through the Stand Pipes and Dummy Plugs into the oil rails, which then feed the injectors. This high-pressure oil acts on an intensifier piston within the injector, which in turn pressurizes the fuel, injecting it into the combustion chamber. This intricate dance of oil and fuel means a leak can involve either fluid, or both.

| Observed Symptom / Condition | Likely Injector Leak Cause | Diagnostic Action / Confirmation |

|---|---|---|

| Hard Start / No Start (Hot Engine) | Worn injector spool valve; degraded internal O-rings (high-pressure oil side) leading to ICP bleed-off. | Monitor ICP (Injection Control Pressure) and IPR (Injection Pressure Regulator) duty cycle during crank. Perform HPOP air test. |

| Rough Idle / Misfire / Stalling | Injector tip leak (drips fuel into cylinder); inconsistent fuel delivery due to internal wear. | Perform cylinder contribution test (scan tool). Listen for ‘stiction’ on injectors with a stethoscope. |

| Excessive White Smoke (especially on startup or cold) | Injector nozzle stuck open or severely leaking, dumping raw fuel into cylinder. | Check exhaust for raw diesel smell. Compare cylinder contribution. Check fuel pressure at the secondary filter. |

| Fuel in Oil (Rising Oil Level, Diesel Smell) | Failed injector body O-rings (external); cracked injector body or severe internal leak allowing fuel into crankcase. | Perform oil analysis (confirms fuel dilution). Smell dipstick for strong diesel odor. Immediate attention required. |

| Low Power / Poor Fuel Economy | Inefficient fuel atomization or incorrect spray pattern due to internal injector wear/leak. | Monitor FICM voltage, ICP, and IPR values. Review cylinder contribution data for inconsistencies. Compare actual MPG to OEM specs. |

Primary Leak Sources in 6.0 Powerstroke Injectors

When we talk about 6.0 Powerstroke injector leaks, we’re typically referring to several key areas. Understanding these will help narrow down your diagnosis:

- Oil Leaks: These are often from the high-pressure oil side of the injector system.

- Injector O-rings: Each injector has several O-rings (top, middle, and bottom) that seal the injector within the cylinder head and separate the fuel and oil passages. Over time, these O-rings can harden, shrink, or become damaged, leading to oil leaks into the fuel or combustion chamber, or even externally.

- Stand Pipes and Dummy Plugs: These components seal the high-pressure oil rails to the cylinder heads and can develop leaks, allowing high-pressure oil to escape, often returning to the crankcase or leaking externally.

- HPOP Cover Gasket: While not directly an injector component, a faulty HPOP cover gasket can allow oil to escape, mimicking injector-related oil leaks.

- Fuel Leaks: These usually involve the low-pressure fuel side.

- Injector Body Leaks: Cracks in the injector body or issues with internal seals can lead to fuel leaking externally or internally (into the oil).

- Fuel Supply/Return Line Connections: Loose or damaged fuel lines leading to and from the injectors can result in visible fuel leaks.

- Upper Fuel Filter Housing: Leaks around the primary fuel filter can be mistaken for injector leaks, especially when fuel drips down the engine.

Pinpointing the exact source is crucial for effective 6.0 Powerstroke injector leak troubleshooting.

Symptoms of 6.0 Powerstroke Injector Leaks

Recognizing the symptoms of a 6.0 Powerstroke injector leak is the first step in diagnosis. These leaks can manifest in various ways, affecting engine performance, fuel economy, and even leading to visible signs. Pay close attention to any changes in your truck’s behavior, as early detection can prevent more severe damage.

Learn more about 6.0 Powerstroke injector leak troubleshooting – 6.0 Powerstroke Injector Leak Troubleshooting: Diagnose and Fix the Issue

Image source: printables.space

Performance-Related Symptoms

- Hard Starts (Especially When Hot): This is one of the most common indicators of an internal high-pressure oil leak, often from injector O-rings or stand pipes. When the engine is hot, the oil is thinner and can leak out faster, causing the HPOP to struggle to build sufficient pressure to fire the injectors.

- Rough Idle or Misfires: A leaking injector can lead to inconsistent fuel delivery or improper combustion, resulting in a noticeable rough idle, stuttering, or misfires, particularly when the engine is warm. You might feel a distinct “lope” in the engine sound.

- Loss of Power/Reduced Acceleration: If injectors aren’t firing correctly due to insufficient oil pressure or improper fuel delivery, your truck will feel sluggish and lack its usual power.

- Excessive Smoke from Exhaust:

- White Smoke: Often indicates unburnt fuel or coolant. If it’s a cold start and disappears, it might be normal condensation. Persistent white smoke can point to a fuel leak into the combustion chamber.

- Blue Smoke: Typically signifies burning oil. An internal oil leak from an injector (e.g., failed O-ring) can allow oil to enter the combustion chamber and burn off.

- Increased Fuel Consumption: Leaking fuel injectors can cause more fuel to be consumed than necessary, either by leaking externally or by failing to atomize fuel correctly for efficient combustion.

Visible and Olfactory Symptoms

- Fuel Smell in Cabin or Around Truck: An external fuel leak from an injector or fuel line will often produce a strong diesel smell. This is a clear indicator that you need to investigate immediately.

- Visible Fuel Leaks: Inspect the top of the engine, particularly around the valve covers and fuel lines. Any puddles or damp spots indicating fuel are a definite sign of a fuel injector leak 6.0 Powerstroke.

- Oil in Fuel or Fuel in Oil: This is a critical symptom.

- Oil in Fuel: If your fuel filter housing or fuel tank shows signs of oil contamination, it often points to a high-pressure oil leak into the low-pressure fuel system, typically from a failing injector O-ring or stand pipe.

- Fuel in Oil: This can be harder to detect without a lab analysis, but a rising oil level or a diluted oil smell can indicate fuel entering the crankcase through a leaking injector body. This dilutes the oil, reducing its lubricating properties and potentially causing severe engine damage.

- Oil Leaks on Top of Engine/Under Valve Covers: While a general oil leak can come from many sources, oil pooling specifically around the injectors under the valve covers, or dripping down the side of the engine, can point to 6.0 Powerstroke injector oil leaks, often from the top O-rings or high-pressure oil rail seals.

Any of these symptoms warrant immediate investigation using systematic 6.0 Powerstroke injector leak troubleshooting methods.

Initial Diagnosis: Visual Inspection and Basic Tests

Once you suspect a 6.0 Powerstroke injector leak, the first step is to perform a thorough visual inspection and some basic, non-invasive tests. These initial steps can often pinpoint obvious leaks or guide you toward more advanced diagnostics.

Safety First!

Before you begin, ensure the engine is off and cool. Disconnect the battery’s negative terminal to prevent accidental starting or electrical shorts. Always wear appropriate personal protective equipment (PPE), including gloves and eye protection.

Step-by-Step Visual Inspection

- Check for External Leaks:

- Around Valve Covers: Remove the engine cover to get a good view. Look for any signs of wetness, oil, or fuel pooling on top of the engine, especially around the valve covers. Leaks from the top of the injectors or oil rail can often be seen here.

- Fuel Filter Housing: Inspect the primary (upper) fuel filter housing for any signs of fuel leaks. Sometimes, a leaking filter cap O-ring or housing crack can mimic an injector leak.

- Fuel Lines and Connections: Trace the fuel lines leading to and from the cylinder heads. Look for cracks, chafing, or loose connections where fuel could be seeping out.

- Exhaust Manifolds: Check the exhaust manifolds for signs of wetness or soot. A leaking injector could cause unburnt fuel or oil to escape into the exhaust.

- Inspect the Degas Bottle (Coolant Reservoir): While not directly related to injector leaks, a compromised head gasket (another common 6.0 issue) can push exhaust gases into the cooling system, causing coolant to overflow. It’s good practice to check this.

- Check Oil and Fuel Condition:

- Oil Dipstick: Pull the oil dipstick. Look for an abnormally high oil level, which could indicate fuel dilution. Also, smell the oil – a strong diesel odor is a red flag for fuel in oil 6.0 Powerstroke.

- Fuel Samples: If you suspect oil in fuel, drain a small amount of fuel from the secondary (lower) fuel filter housing or the fuel bowl. Let it sit in a clear container. Oil will typically separate and float on top of the diesel fuel. This is a strong indicator of a high-pressure oil leak into the fuel system.

Basic Functional Checks

- Wiggle Test (Engine Off): Gently try to wiggle the electrical connectors on each injector. A loose connection can sometimes cause intermittent misfires, though it’s less common for actual fluid leaks.

- Listen for Stethoscope Test (Engine On, Caution!): With the engine running (if it starts), carefully use a mechanic’s stethoscope (or a long screwdriver to your ear) to listen to each injector. Listen for consistent firing patterns. Any irregular clicking or thumping could indicate an injector issue. Exercise extreme caution around moving engine parts.

- Cranking Pressure Test (for Hard Starts): If you have a hard hot start, this is a strong indicator of low ICP (Injector Control Pressure). While not a direct leak detection, it points to a high-pressure oil system issue. You’ll need a diagnostic scanner for this.

These initial steps in 6.0 Powerstroke injector leak troubleshooting can often guide you towards the type of leak you’re dealing with (oil vs. fuel, external vs. internal) and help you decide if further, more involved testing is necessary.

Advanced Troubleshooting Techniques for 6.0 Injector Leaks

If your initial visual inspection and basic tests don’t definitively pinpoint the source of your 6.0 Powerstroke injector leak, it’s time to employ some more advanced diagnostic techniques. These methods require specialized tools and a deeper understanding of the HEUI system but are often necessary to accurately diagnose internal leaks or elusive external ones.

1. High-Pressure Oil System Diagnostics

This is crucial for diagnosing 6.0 Powerstroke oil leak injector issues, especially hard hot starts.

- ICP (Injector Control Pressure) Sensor Monitoring: Use a diagnostic scanner (Forscan, AutoEnginuity, Snap-on, etc.) to monitor ICP and IPR (Injector Pressure Regulator) duty cycle during cranking and running.

- Low ICP During Cranking (Below 500 PSI): Indicates a significant leak in the high-pressure oil system. The engine won’t start if ICP doesn’t reach roughly 500 PSI.

- High IPR Duty Cycle (Above 70-85%) with Low ICP: The IPR is working overtime to try and build pressure, but a large leak is preventing it.

- Air Test the High-Pressure Oil System: This is a definitive test for high-pressure oil leaks.

- Remove the ICP sensor and install an air fitting.

- Apply shop air (100-120 PSI) into the high-pressure oil system.

- Listen for air leaks.

- Under Valve Covers: Listen for hissing. Air leaks here typically indicate failed injector top O-rings, stand pipes, or dummy plugs.

- Oil Fill Tube: Air escaping from the oil fill tube suggests a leak in the HPOP housing or a serious internal leak returning to the crankcase.

- Fuel Tank/Fuel Filter Housing: If you hear air in the fuel tank or see bubbles in the fuel filter housing, it confirms an oil-to-fuel leak, usually from injector O-rings or a stand pipe.

- Exhaust: Air from the exhaust indicates a blown injector tip or a very severe O-ring leak allowing air into the combustion chamber.

- Alternatively, use a smoke machine with the air test. Smoke will visibly exit the leak point.

- HPOP Air Test with Valve Covers Off: To isolate which side (left or right bank) has the leak, you can block off one oil rail feed line (using a specialized tool or even a golf tee if you’re careful) and test each side individually.

2. Low-Pressure Fuel System Diagnostics

For investigating 6.0 Powerstroke fuel injector leak symptoms.

- Fuel Pressure Test: Use a fuel pressure gauge connected to the secondary fuel filter housing. The 6.0 Powerstroke should maintain 45-70 PSI at idle and under load. Low fuel pressure can strain injectors and exacerbate existing leaks.

- Return Fuel Volume Test: This test measures the amount of fuel returning to the tank. While less common for simple leaks, excessive return fuel can indicate internal injector issues.

- Injector Buzz Test (Scanner Function): Your diagnostic scanner can perform a “buzz test” which cycles each injector electrically. Listen for clear, consistent buzzing from each injector. A missing or faint buzz could indicate an electrical problem with the injector, which might be related to its overall health and propensity to leak.

3. Relative Compression Test / Cylinder Contribution Test

- Relative Compression Test: Many advanced scanners can perform a relative compression test, which compares the cranking speed of each cylinder. A cylinder that spins faster than the others indicates lower compression, which could be due to a faulty injector sealing in the head or a worn injector tip allowing combustion gases to escape.

- Cylinder Contribution Test: This test identifies cylinders that are not contributing their share of power. While it doesn’t directly diagnose a leak, a non-contributing cylinder with associated leak symptoms strongly points to that injector as the culprit for your Powerstroke injector leak diagnosis.

These advanced techniques provide crucial data for precise diagnosis, helping you to avoid unnecessary part replacements and costly mistakes in 6.0 Powerstroke injector leak troubleshooting.

Fixing 6.0 Powerstroke Injector Leaks: Repair vs. Replacement

Once you’ve accurately diagnosed the source of your 6.0 Powerstroke injector leak, the next step is to decide on the best course of action: repair or replacement. This often depends on the specific component leaking and the overall condition of the injector itself. It’s a critical decision that balances cost, effort, and long-term reliability.

Common Repair Scenarios and Solutions

- Injector O-Ring Leaks:

- Diagnosis: Hard hot starts, oil in fuel, external oil leaks under valve covers, air test revealing leaks under valve covers or into fuel system.

- Solution: Replace all injector O-rings. This is a common and relatively affordable repair. You’ll need to remove the valve covers, oil rails, and then the injectors. It’s highly recommended to replace all O-rings on all injectors while you’re in there, even if only one is confirmed to be leaking, as others are likely to fail soon. Ensure you use quality O-ring kits (e.g., from Ford, Alliant Power, or reputable aftermarket brands).

- Stand Pipe and Dummy Plug Leaks:

- Diagnosis: Primarily hard hot starts, low ICP during cranking, air test revealing leaks under valve covers.

- Solution: Replace the stand pipes and dummy plugs. These components are located under the valve covers and seal the high-pressure oil rail. They are often sold as a kit and are crucial for maintaining oil pressure. Like O-rings, it’s best practice to replace all of them on both banks once you’re in for service.

- HPOP Cover Gasket Leaks:

- Diagnosis: External oil leaks near the HPOP, typically at the rear of the engine. Can sometimes mimic injector leaks but is more general oil seepage.

- Solution: Replace the HPOP cover gasket. This involves removing the turbocharger and often other components to access the HPOP cover.

- Fuel Line Leaks:

- Diagnosis: Visible fuel drips, strong diesel smell, usually originating from fuel line connections or a cracked line.

- Solution: Replace the affected fuel line or tighten the connection. Ensure all fuel lines are properly torqued and free from damage.

When to Replace the Injector Itself

While O-rings and seals are replaceable, sometimes the injector itself is compromised and requires full replacement. This is typically the case for more severe issues:

- Internal Fuel Leaks (Fuel in Oil): If an injector’s internal seals or body are cracked, allowing fuel to leak into the engine oil, the entire injector needs replacement. Continuing to run with fuel-diluted oil can lead to catastrophic engine failure.

- Cracked Injector Body: A visibly cracked injector body (rare, but possible) requires immediate replacement.

- Injector Tip Damage/Failure: If diagnostics (like a contribution test or relative compression test) point to a specific injector failing to atomize fuel correctly or having a physically damaged tip, it needs replacement. This can manifest as excessive smoke, rough running, or lack of power.

- Repeated O-Ring Failure on the Same Injector: If you’ve replaced O-rings on a specific injector multiple times and it keeps leaking, there might be a defect in the injector bore or the injector itself.

Recommendation: When replacing a single injector, it’s often advisable to consider replacing them in sets (e.g., all four on one bank, or all eight). This ensures consistent performance across all cylinders, as injectors often wear similarly. Always use new hold-down bolts for injectors and torque them to specification to prevent future issues.

Choosing between repairing seals and replacing the entire injector is a key part of effective 6.0 Powerstroke injector leak troubleshooting. Prioritize fixing the root cause with quality parts to ensure long-term reliability.

Preventative Maintenance to Avoid Future Injector Leaks

Preventing 6.0 Powerstroke injector leaks is far more desirable than troubleshooting and fixing them. Adopting a rigorous preventative maintenance schedule can significantly extend the life of your injectors and the entire HEUI system, saving you from costly repairs and downtime. Here are actionable tips to keep your 6.0 Powerstroke running strong.

1. Maintain Impeccable Oil Quality and Level

The 6.0 Powerstroke’s injectors rely heavily on engine oil for their operation. High-pressure oil is what fires the injectors, so the quality and cleanliness of this oil are paramount.

- Regular Oil Changes: Follow Ford’s recommended oil change intervals (typically every 5,000 to 7,500 miles or 6 months, whichever comes first) using API CJ-4 or newer diesel-rated oil. Dirty or degraded oil can accelerate wear on HPOP components and injector O-rings.

- Use the Correct Oil Viscosity: Stick to the recommended 15W-40 for most climates, or 10W-30 for colder weather. Incorrect viscosity can affect oil flow and pressure, putting stress on the system.

- Monitor Oil Level: Regularly check your oil level. Low oil can starve the HPOP, and an abnormally high oil level could indicate fuel dilution, which is harmful to the oil’s lubricating properties.

2. Ensure Pristine Fuel Quality and Pressure

Just as important as oil, clean fuel at the correct pressure is vital for injector health.

- Frequent Fuel Filter Replacement: The 6.0 Powerstroke has two fuel filters (primary and secondary). Replace both filters religiously at recommended intervals (e.g., every 10,000 to 15,000 miles or annually). Clogged filters can starve injectors of fuel or allow contaminants to pass, causing damage and potential leaks.

- Use High-Quality Fuel: Always use reputable diesel fuel. Avoid “mystery” fuel sources that may contain water or excessive contaminants. Water in fuel is a destroyer of injectors.

- Maintain Proper Fuel Pressure: A common modification for 6.0 Powerstroke owners is to install a fuel pressure gauge. Ensure your fuel pressure consistently stays within the 45-70 PSI range at all times (idle and under load). Low fuel pressure puts added strain on the injectors, causing them to work harder and potentially lead to premature failure or internal leaks. Upgrading to a regulated return fuel system or an aftermarket fuel pump can help maintain consistent pressure.

3. Address Related Components Proactively

Some components work in conjunction with injectors and can contribute to leaks or mimic their symptoms.

- Check Stand Pipes and Dummy Plugs: Consider replacing these seals (or the entire components) during major services where the valve covers are off, especially if your truck has high mileage. They are a common failure point for high-pressure oil leaks.

- Injector Hold-Down Bolts: Always use new hold-down bolts when removing and reinstalling injectors, and torque them to specification. Reusing old, stretched bolts can lead to improper seating and potential O-ring leaks.

- EGR Cooler and Valve Health: While not directly causing injector leaks, a failing EGR system can contribute to excessive carbon buildup, which can indirectly impact injector performance and lifespan.

4. Regular Diagnostic Monitoring

Utilize a diagnostic scanner (such as Forscan with an OBD-II adapter) to regularly monitor key parameters:

- ICP and IPR Duty Cycle: Watch these values. If IPR duty cycle is consistently high (e.g., above 50% at idle, or spikes too high under load) while ICP is lower than desired, it could indicate an developing high-pressure oil leak before it becomes a major problem.

- Cylinder Contribution: Periodically run a cylinder contribution test to catch any underperforming injectors early.

By adhering to these preventative maintenance practices, you can significantly reduce your chances of encountering severe 6.0 Powerstroke injector leaks and ensure your truck remains a reliable and powerful machine for years to come.

6.0 Powerstroke Injector Leak Diagnosis & Repair Cost Table

Understanding the potential costs associated with 6.0 Powerstroke injector leak troubleshooting and repair can help you budget and make informed decisions. Please note that these are estimated costs and can vary significantly based on labor rates, parts quality (OEM vs. aftermarket), your location, and whether you perform the work yourself (DIY) or hire a professional.

| Leak Source/Symptom | Likely Cause | DIY Parts Cost (Est.) | Professional Repair Cost (Est.) |

|---|---|---|---|

| Hard Hot Start, Low ICP, Oil in Fuel | Injector O-rings (top/mid), Stand Pipes, Dummy Plugs | $50 – $200 (O-rings/Seals) $100 – $250 (Stand Pipes/Dummy Plugs) |

$800 – $2,000 (Labor intensive due to removal of valve covers, oil rails) |

| Visible External Oil Leak (under valve cover) | Injector Top O-rings, HPOP Cover Gasket, Stand Pipe Seals | $50 – $250 (O-rings, HPOP gasket) | $600 – $1,800 (Accessing HPOP can require turbo removal) |

| Visible External Fuel Leak, Fuel Smell | Fuel Lines, Fuel Filter Housing Seals, External Injector Body Leak | $20 – $150 (Seals, lines) | $200 – $800 (Depends on access and specific component) |

| Fuel in Oil, Rough Idle, Smoke, Loss of Power | Internal Injector Body Leak, Injector Tip Damage | $200 – $400 (Single Reman Injector) $1,200 – $2,500+ (Set of 8 Reman Injectors) |

$500 – $1,000 (Single Injector Replacement) $2,500 – $5,000+ (All 8 Injectors) |

| Low Fuel Pressure, Engine Stumbling | Clogged Fuel Filters, Weak Fuel Pump, Pressure Regulator Issue | $50 – $150 (Filters) $200 – $500 (Pump/Regulator) |

$150 – $300 (Filter replacement) $400 – $1,200 (Pump/Regulator replacement) |

Note on Professional vs. DIY: While DIY can save significantly on labor costs, performing these repairs (especially internal ones) requires specialized tools, mechanical aptitude, and a thorough understanding of the 6.0 Powerstroke. Incorrect installation can lead to more severe and costly damage. For complex issues or if you’re unsure, consulting a qualified diesel mechanic is always recommended.

Conclusion: Empowering Your 6.0 Powerstroke Journey

Dealing with 6.0 Powerstroke injector leaks can feel like a daunting challenge, but with the comprehensive knowledge and actionable steps outlined in this guide, you are now equipped to tackle the issue head-on. From understanding the intricate HEUI system to performing meticulous visual inspections, advanced diagnostic tests, and finally, executing precise repairs, you have a roadmap to restoring your truck’s performance and reliability.

Remember, prompt and accurate 6.0 Powerstroke injector leak troubleshooting is key. Ignoring symptoms can lead to exacerbated problems, including significant engine damage and even more expensive repairs down the line. By paying attention to the subtle cues your truck provides, maintaining a disciplined preventative maintenance schedule, and leveraging the right diagnostic tools, you can minimize the chances of recurring issues.

Whether you’re a seasoned DIY mechanic or seeking to understand the problem before visiting a professional, this guide on diagnosing 6.0 Powerstroke fuel injector leaks and oil leaks provides the essential insights. Your 6.0 Powerstroke is a powerful machine, and with proper care and attention, it can continue to serve you reliably for many miles to come. Stay proactive, stay informed, and enjoy the power of your diesel!

🎥 Related Video: 6.0 Ford Power Stroke Injector Diagnostic Trick

📺 Dave’s Auto Center

Frequently Asked Questions

What are the common symptoms of a 6.0 Powerstroke injector leak?

Fuel or oil smells, visible fluid around the valve covers, a rough running engine, or excessive white smoke from the exhaust can all indicate a 6.0 Powerstroke injector leak. You might also experience misfires, decreased fuel economy, or difficulty starting the engine.

How can I diagnose an injector leak on my 6.0 Powerstroke?

Start by visually inspecting the valve covers for pooling fuel or oil. A “bubble test” using compressed air into the fuel rail while observing the fuel return lines can help pinpoint which injector is leaking. A professional might use a clear hose return line test for more precise diagnosis.

What causes 6.0 Powerstroke injector seals to fail and leak?

Injector leaks often result from worn or damaged o-rings and copper crush washers, which seal the injector and prevent fuel or oil bypass. High mileage, age, and improper installation are common factors contributing to the degradation of these critical seals.

What is the repair process for fixing a leaking 6.0 Powerstroke injector?

Repairing a leaking 6.0 Powerstroke injector typically involves removing the valve cover and the affected injector(s) to replace the o-rings and copper washers. In some cases, the injector body itself might be cracked or faulty, necessitating a full injector replacement.

Is it safe to drive my 6.0 Powerstroke if I suspect an injector leak?

It is not recommended to drive for extended periods with a significant injector leak on your 6.0 Powerstroke. Leaking fuel or oil can dilute your engine oil, leading to premature engine wear, and poses a potential fire hazard if fuel drips onto hot exhaust components.

How can I prevent future injector leaks on my 6.0 Powerstroke?

Regular maintenance, including timely oil changes with the correct specification oil, can help extend seal life. When injectors are serviced or replaced, ensuring high-quality o-rings and crush washers are used, and they are installed correctly with proper torque, is crucial for preventing future leaks.