6.0 Powerstroke EGR Valve Specifications: Key Information You Should Know

Featured image for this comprehensive guide about 6.0 Powerstroke EGR valve specifications

Image source: i.pinimg.com

6.0 Powerstroke EGR Valve Specifications: Key Information You Should Know

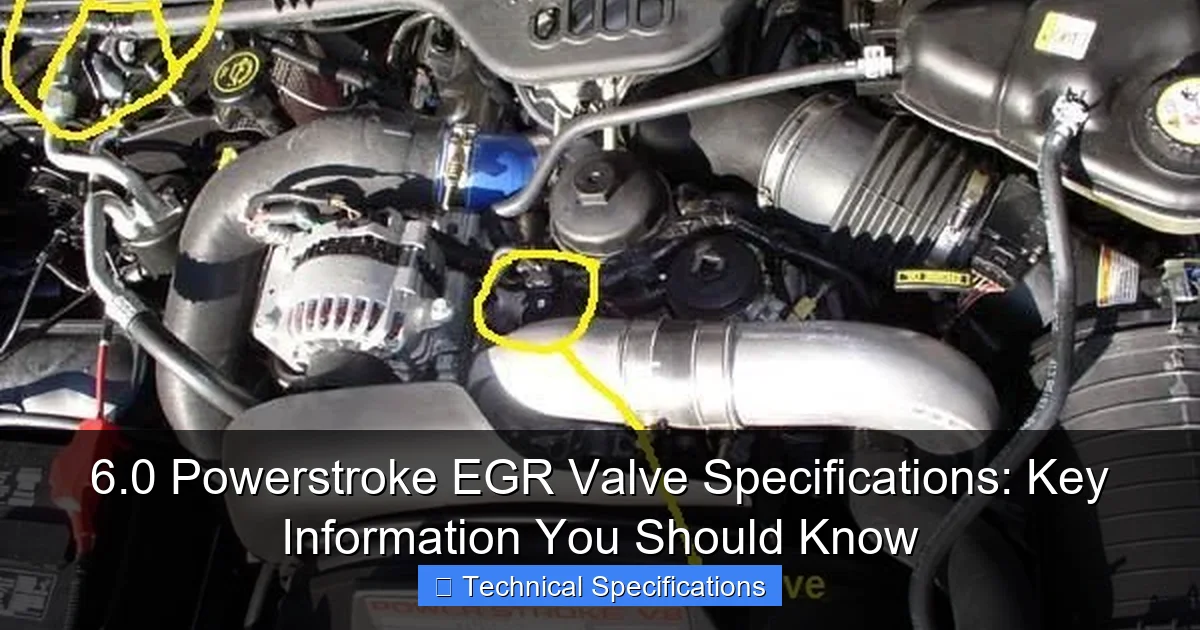

The legendary 6.0 Powerstroke engine, a powerhouse found in countless Ford Super Duty trucks and E-Series vans from 2003-2007, is known for its formidable torque and workhorse capabilities. However, like any complex piece of engineering, it has its quirks. Among the components that often require attention, the 6.0 Powerstroke EGR valve stands out as a critical, yet frequently misunderstood, part of the emissions system. Its proper functioning is vital not only for meeting environmental standards but also for maintaining your truck’s performance and fuel efficiency.

Understanding the intricate details of your 6.0 Powerstroke EGR valve specifications is not just for mechanics; it’s essential for any owner looking to proactively manage their vehicle’s health. From diagnosing peculiar engine symptoms to making informed decisions about maintenance and replacement, a deep dive into these specifications can save you time, money, and headaches. This comprehensive guide will equip you with the knowledge needed to demystify the 6.0 Powerstroke’s EGR system, ensuring your diesel beast continues to run strong for years to come.

Quick Answers to Common Questions

What exactly does the 6.0 Powerstroke EGR valve do?

The 6.0 Powerstroke EGR valve recirculates a small portion of exhaust gases back into the engine’s combustion chambers. This process helps lower combustion temperatures, which in turn reduces harmful nitrogen oxide (NOx) emissions, making your truck run cleaner according to its original 6.0 Powerstroke EGR valve specifications.

How do I know if my 6.0 Powerstroke EGR valve is failing?

Common signs of a failing 6.0 Powerstroke EGR valve include a “Check Engine” light, rough idle, poor acceleration, black smoke from the exhaust, and even increased fuel consumption. These symptoms often indicate the valve is not meeting its intended 6.0 Powerstroke EGR valve specifications.

Are there specific specifications I need to consider when buying a replacement 6.0 Powerstroke EGR valve?

Absolutely! Ensure you get an EGR valve specifically designed for the 6.0 Powerstroke engine, as there are different part numbers and designs depending on the exact year of your truck. Always cross-reference the part number with your vehicle’s VIN to guarantee the correct 6.0 Powerstroke EGR valve specifications for your model year.

Is replacing the 6.0 Powerstroke EGR valve a DIY job or should I take it to a mechanic?

While some mechanically inclined individuals might tackle it, replacing the 6.0 Powerstroke EGR valve can be complex due to its location and necessary cooling system work. It often involves draining coolant and accessing tight spaces, so for many, a professional mechanic is the safer bet to ensure proper installation and function according to specific 6.0 Powerstroke EGR valve specifications.

Can a faulty 6.0 Powerstroke EGR valve cause more serious engine problems?

Yes, definitely. A sticking or failed 6.0 Powerstroke EGR valve can lead to excessive carbon buildup, reduced engine performance, and even overheating if it’s constantly open, potentially causing damage to other engine components over time if not addressed in line with proper 6.0 Powerstroke EGR valve specifications.

📋 Table of Contents

- Understanding the 6.0 Powerstroke EGR System and Its Valve

- Detailed 6.0 Powerstroke EGR Valve Specifications

- Common 6.0 Powerstroke EGR Valve Failures, Symptoms, and Diagnostics

- Maintenance, Cleaning, and Replacement of the 6.0 Powerstroke EGR Valve

- Data Table: Quick Reference 6.0 Powerstroke EGR Valve Specs & DTCs

- Conclusion: Mastering Your 6.0 Powerstroke EGR Valve

Understanding the 6.0 Powerstroke EGR System and Its Valve

Before diving into the precise 6.0 Powerstroke EGR valve specifications, it’s crucial to grasp the overarching purpose and design of the Exhaust Gas Recirculation (EGR) system in your 6.0 Powerstroke. This system is a cornerstone of modern diesel engine emissions control, working diligently behind the scenes to keep the air cleaner and your engine running optimally under specific conditions.

Learn more about 6.0 Powerstroke EGR valve specifications – 6.0 Powerstroke EGR Valve Specifications: Key Information You Should Know

Image source: i.ytimg.com

What is Exhaust Gas Recirculation (EGR)?

Exhaust Gas Recirculation (EGR) is an emissions control technology designed to reduce nitrogen oxides (NOx) emissions produced during the combustion process. NOx gases are major contributors to smog and acid rain. In a diesel engine, high combustion temperatures create a perfect environment for NOx formation. The EGR system mitigates this by recirculating a small portion of the engine’s exhaust gas back into the intake manifold.

| Specification/Aspect | Detail/Value | Typical Condition/Measurement | Notes/Implication |

|---|---|---|---|

| Valve Type | Electronic, Stepper Motor Actuated | Normally closed (energized to open) | Precision control by PCM based on engine parameters. |

| Operating Principle | Recirculates exhaust gas into intake manifold | Varies with RPM, load, and temperature (e.g., closed at idle/WOT) | Reduces Nitrogen Oxide (NOx) emissions by lowering combustion temperatures. |

| Common Failure Mode | Sticking (Open or Closed) | Carbon buildup, electrical failure, coolant intrusion | Sticking open: low boost, rough idle. Sticking closed: increased EGTs, NOx. |

| Diagnostic Trouble Codes (DTCs) | P0401 (Insufficient Flow), P0404 (Circuit Range/Performance) | Check Engine Light (CEL) illuminated, reduced engine performance. | Requires diagnosis with a scan tool to monitor valve position and commanded state. |

| Replacement Recommendation | No fixed interval, service as needed | Often needed between 80,000 – 150,000 miles due to carbon buildup or failure. | Symptoms like poor fuel economy, smoke, or CEL often trigger replacement. |

| Location | Top of the engine, behind the oil filter housing | Bolted to the intake manifold, connected to the EGR cooler. | Relatively accessible for servicing; removal involves unbolting and electrical disconnection. |

- How it works: Introducing inert exhaust gas into the combustion chamber displaces some of the oxygen, effectively lowering the peak combustion temperatures. Cooler combustion means less NOx formation.

- When it operates: The EGR system is typically active during specific engine operating conditions, such as cruising speeds or light loads, when NOx emissions are naturally higher. It’s usually inactive during cold starts, heavy acceleration, or idle.

The 6.0 Powerstroke EGR Valve’s Role

The 6.0 Powerstroke EGR valve is the gateway for these recirculated exhaust gases. It’s a precisely controlled, electronically actuated valve that opens and closes to allow a metered amount of exhaust gas to enter the intake manifold. Without a properly functioning EGR valve, the entire system cannot perform its critical function, leading to potential emissions violations and engine performance issues.

The valve’s operation is dictated by the Powertrain Control Module (PCM), which monitors various engine parameters like engine load, RPM, coolant temperature, and intake air temperature. Based on these inputs, the PCM sends a signal to the EGR valve, commanding it to open or close to the appropriate degree. This precise control is essential for balancing emissions reduction with engine performance.

Key Components of the 6.0 EGR System

While the EGR valve is the star of our show, it’s part of a larger ecosystem:

- EGR Valve: The electromechanical device that meters exhaust flow. This is where understanding 6.0 Powerstroke EGR valve specifications becomes critical.

- EGR Cooler: Before exhaust gases reach the valve, they pass through the EGR cooler. This heat exchanger uses engine coolant to lower the temperature of the exhaust gases, making them less prone to causing damage or pre-ignition when introduced into the intake.

- PCM (Powertrain Control Module): The “brain” that monitors sensors and actuates the EGR valve based on its programming.

- EGR Sensor (Position Sensor): Often integrated into the valve itself, this sensor provides feedback to the PCM, indicating the actual position of the EGR valve pintle.

- Intake Manifold: Where the cooled exhaust gases mix with fresh air before entering the cylinders.

Detailed 6.0 Powerstroke EGR Valve Specifications

Understanding the nitty-gritty of 6.0 Powerstroke EGR valve specifications provides invaluable insight into how this component functions and, more importantly, how to diagnose problems when they arise. The 6.0 Powerstroke utilizes a specific type of EGR valve designed for precision and durability within the harsh environment of a diesel engine.

Valve Type and Design

The 6.0 Powerstroke EGR valve is an electronic, DC motor-driven pintle valve. This design allows for fine control over the exhaust gas flow. The “pintle” is the moving part of the valve that seats against an opening, regulating the flow. When the PCM commands the valve to open, an electric motor inside the valve mechanism moves the pintle, allowing exhaust gases to pass. When it commands it to close, the pintle seats, blocking the flow.

- Actuation: Electronically controlled DC motor.

- Position Feedback: Internal position sensor provides feedback to the PCM.

- Construction: Designed to withstand high temperatures and corrosive exhaust gases, typically using robust metals and seals.

Operating Voltage and Resistance

For diagnostic purposes, knowing the typical electrical specifications is crucial. While these can vary slightly between manufacturers (OEM vs. aftermarket), general ranges are consistent:

- Operating Voltage: The PCM typically supplies a 12-volt signal (battery voltage) to operate the motor within the EGR valve. The control signal itself might be a Pulse Width Modulated (PWM) signal, varying the duty cycle to precisely control the valve’s opening.

- Position Sensor Voltage: The integrated position sensor usually operates on a 5-volt reference signal from the PCM, returning a variable voltage (e.g., 0.5V to 4.5V) to indicate the valve’s actual position.

- Motor Resistance: The resistance of the internal DC motor can be a key diagnostic indicator. A typical range for the coil resistance might be around 8-15 ohms. A reading outside this range (e.g., open circuit or very low resistance) often indicates an internal electrical failure of the motor windings. Always consult a factory service manual or reputable aftermarket guide for precise values for your specific year/model.

Flow Rate and Control Mechanism

The flow rate of exhaust gas through the EGR valve is not a fixed number but is dynamically controlled by the PCM based on engine demands. The PCM’s programming, along with inputs from numerous sensors (MAP, MAF, EOT, EBP, etc.), determines the optimal percentage of EGR flow required at any given moment. The pintle’s precise movement allows for this variable flow, ensuring the correct balance between emissions reduction and performance.

The control mechanism involves a closed-loop system: the PCM commands a valve position, the position sensor reports the actual position, and the PCM adjusts its command until the desired position is achieved. This constant feedback loop is vital for accurate EGR operation.

Materials and Durability Considerations

Given the harsh environment—extreme heat, soot, and corrosive exhaust gases—the materials used in the 6.0 Powerstroke EGR valve are designed for resilience. Typically, they feature stainless steel components, high-temperature resistant plastics, and durable seals. However, even with robust construction, chronic issues like carbon buildup and heat cycling can lead to failures over time, which we’ll explore in the next section.

PCM Control Parameters

The PCM’s logic for controlling the 6.0 Powerstroke EGR valve is complex, integrating data from a multitude of sensors:

- Engine Coolant Temperature (ECT) / Engine Oil Temperature (EOT): EGR is typically disabled until the engine reaches operating temperature.

- Engine RPM and Load: EGR flow increases at higher RPMs and lighter loads where NOx formation is more prevalent.

- Manifold Absolute Pressure (MAP) & Mass Air Flow (MAF): Used to calculate engine air intake and determine appropriate EGR percentage.

- Exhaust Back Pressure (EBP): Can influence the pressure differential across the EGR valve.

- Throttle Position (TPS): Although a diesel doesn’t have a traditional throttle, the accelerator pedal position sensor plays a role in load calculation.

Common 6.0 Powerstroke EGR Valve Failures, Symptoms, and Diagnostics

The 6.0 Powerstroke EGR valve is unfortunately a common point of failure for many owners, often leading to frustrating driveability issues and illuminated check engine lights. Understanding the typical failure modes and their associated symptoms is the first step in effective diagnosis and repair.

Typical Failure Modes

The primary culprits behind 6.0 Powerstroke EGR valve failures are usually related to the harsh operating environment:

- Sticking Open (Carbon Buildup): This is perhaps the most common failure. Over time, soot and carbon from the exhaust gases accumulate on the pintle and in the valve passages. This buildup prevents the valve from fully closing. When stuck open, exhaust gases are continuously recirculated, even when not desired, leading to rough idle, poor performance, and potentially excessive smoke.

- Sticking Closed (Carbon Buildup or Electrical Failure): Conversely, excessive carbon can also prevent the valve from opening at all, or from opening sufficiently. This will typically result in elevated NOx emissions, potentially triggering a P040X code, and less noticeable driveability issues but still impacting emissions control. An electrical failure in the motor or solenoid can also cause it to remain closed.

- Electrical Failure: The internal DC motor or position sensor can fail. This could be due to worn brushes in the motor, a broken winding, or a fault in the sensor circuit. This usually results in a complete loss of EGR function and triggers specific electrical DTCs.

- Coolant Leak (Rare but Serious): While more commonly associated with the EGR cooler, in some cases, internal seals in the EGR valve can fail, allowing coolant to leak into the exhaust or intake. This is a severe issue that can lead to engine damage.

Recognizing EGR Valve Symptoms

A failing 6.0 Powerstroke EGR valve can manifest in a variety of ways. Keep an eye (and ear) out for these common indicators:

- Reduced Power & Acceleration: If the valve is stuck open, excessive exhaust gas can dilute the fresh air charge, leading to a noticeable drop in power.

- Rough Idle or Stalling: A continuously open EGR valve can cause a very rough idle, especially when the engine is warm, or even lead to stalling.

- Increased Black Smoke: In some cases, poor combustion due to uncontrolled EGR flow can lead to unburnt fuel and increased black smoke from the exhaust.

- Poor Fuel Economy: An improperly functioning EGR system can negatively impact combustion efficiency, leading to a decrease in miles per gallon.

- Check Engine Light (MIL): This is the most obvious sign. The PCM will detect out-of-range performance or electrical faults and illuminate the MIL.

- Engine Hesitation or Surging: Intermittent sticking of the valve can cause inconsistent engine behavior.

Diagnostic Trouble Codes (DTCs)

When the Check Engine Light comes on, reading the DTCs with a scan tool is your first step. For 6.0 Powerstroke EGR valve issues, you’ll commonly encounter codes in the P040X range:

- P0401: Exhaust Gas Recirculation Flow Insufficient Detected (Valve stuck closed or restricted flow).

- P0402: Exhaust Gas Recirculation Flow Excessive Detected (Valve stuck open).

- P0403: Exhaust Gas Recirculation Control Circuit Malfunction (Electrical fault in the valve circuit).

- P0404: Exhaust Gas Recirculation Control Circuit Range/Performance (Valve not achieving commanded position).

- P0405: Exhaust Gas Recirculation Sensor “A” Circuit Low (Electrical fault in the position sensor).

These codes provide strong clues but often require further testing to pinpoint the exact cause.

Testing the EGR Valve

To confirm an EGR valve issue, a few diagnostic steps can be taken:

- Visual Inspection: Remove the valve and inspect it for heavy carbon buildup around the pintle and seat. Also, check for any physical damage.

- Electrical Tests:

- Resistance Check: Measure the resistance across the motor terminals using a multimeter. Compare with factory 6.0 Powerstroke EGR valve specifications (e.g., 8-15 ohms).

- Voltage Check: With the ignition on (engine off), check for 5V reference voltage at the position sensor connector and 12V power at the motor connector.

- Scan Tool Actuation: A professional scan tool can command the EGR valve to open and close while monitoring the position sensor feedback. If the commanded position doesn’t match the actual position, or if there’s no movement, the valve is likely faulty.

- Smoke Test (for leaks): While less common for the valve itself, an EGR system can be smoke tested to find leaks in the associated plumbing.

Maintenance, Cleaning, and Replacement of the 6.0 Powerstroke EGR Valve

Proactive maintenance and understanding when to intervene can significantly extend the life of your 6.0 Powerstroke EGR valve and the overall health of your engine. When issues do arise, knowing your options for cleaning or replacement, along with selecting the right parts, is paramount.

Preventative Maintenance Tips

While the 6.0 Powerstroke EGR valve is prone to carbon buildup, certain practices can help mitigate the issue:

- Regular Oil Changes: Fresh oil reduces soot formation and helps maintain engine cleanliness. Follow manufacturer recommendations meticulously for oil type and change intervals.

- Quality Fuel: Using high-quality diesel fuel and a reputable fuel additive designed for diesel engines can help reduce carbon deposits and improve combustion efficiency.

- Proper Driving Habits: While not always possible, avoiding excessive idling and ensuring the engine reaches full operating temperature regularly can help burn off some deposits. Occasional “Italian tune-ups” (a good hard run on the highway) can also help.

- Coolant System Health: A healthy EGR cooler relies on a healthy cooling system. Ensure your coolant is clean, at the correct level, and free of contamination.

EGR Valve Cleaning Process

If your 6.0 Powerstroke EGR valve is showing symptoms of being stuck due to carbon buildup (e.g., P0401/P0402 without electrical faults), a thorough cleaning might be a viable solution before considering replacement. This is a common maintenance item for the 6.0 Powerstroke.

Steps for Cleaning:

- Disconnection: Disconnect the battery and allow the engine to cool.

- Removal: Carefully remove the EGR valve, often involving the removal of a few bolts and electrical connectors. Be prepared for potentially stubborn fasteners.

- Inspection: Visually inspect the valve for the amount and type of carbon buildup. Look for any physical damage to the pintle or housing.

- Cleaning: Use a specialized EGR valve cleaner or a strong carbon solvent (e.g., carburetor cleaner) along with a wire brush (avoid abrasive materials that could scratch delicate surfaces). Focus on the pintle, its seat, and the passages. Ensure all carbon is removed and the pintle can move freely.

- Reassembly: Install the cleaned valve with new gaskets. Torque bolts to factory specifications. Reconnect electrical connectors and the battery.

- Test Drive: After cleaning, perform a test drive to ensure the symptoms are resolved and clear any stored DTCs.

Always wear appropriate personal protective equipment (gloves, eye protection) when handling chemicals.

When to Replace Your EGR Valve

While cleaning can resolve many issues, there are times when replacement is the only viable option:

- Electrical Failure: If diagnostic tests reveal an open circuit, short, or out-of-spec resistance in the motor or position sensor, cleaning will not help.

- Physical Damage: Bent pintle, cracked housing, or damaged electrical connectors.

- Persistent Issues: If cleaning provides only a temporary fix, or the issue returns quickly, it indicates the valve is beyond effective repair.

- Coolant Leak: Any signs of coolant leaking from the valve warrant immediate replacement.

Choosing a Replacement EGR Valve

When selecting a new 6.0 Powerstroke EGR valve, consider these factors:

- OEM (Original Equipment Manufacturer): Ford/Motorcraft parts are generally the most reliable and designed to meet precise 6.0 Powerstroke EGR valve specifications. They come with a higher price tag but often offer peace of mind and better longevity.

- Aftermarket: Many reputable aftermarket manufacturers (e.g., BorgWarner, Standard Motor Products, Dorman) offer EGR valves. Quality can vary significantly. Research reviews and ensure the part meets or exceeds OEM specifications. Be wary of extremely cheap options, as they might not last.

- Warranty: Check the warranty offered by the manufacturer or seller.

Installation Considerations

Proper installation is crucial for the longevity of your new valve:

- New Gaskets: Always use new gaskets to ensure a proper seal and prevent exhaust leaks.

- Torque Specifications: Follow the factory torque specifications for the mounting bolts. Overtightening can warp components, while undertightening can lead to leaks.

- Clear Codes: After installation, clear any stored DTCs using a scan tool.

- PCM Relearn (if applicable): While less common for just an EGR valve, some component replacements benefit from a PCM relearn procedure. Consult your service manual.

Data Table: Quick Reference 6.0 Powerstroke EGR Valve Specs & DTCs

For quick reference, here are some critical 6.0 Powerstroke EGR valve specifications and common Diagnostic Trouble Codes you might encounter. Always cross-reference with your specific vehicle’s service manual for the most accurate data.

| Specification/Code | Description/Typical Value |

|---|---|

| EGR Valve Type | Electronic, DC Motor-Driven Pintle Valve |

| Motor Operating Voltage | 12 Volts (Battery Voltage) |

| Position Sensor Reference Voltage | 5 Volts DC (from PCM) |

| Motor Coil Resistance | 8 – 15 Ohms (approximate, consult manual) |

| P0401 | EGR Flow Insufficient Detected (often stuck closed/restricted) |

| P0402 | EGR Flow Excessive Detected (often stuck open) |

| P0403 | EGR Control Circuit Malfunction (electrical fault) |

| P0404 | EGR Control Circuit Range/Performance (valve not responding correctly) |

| P0405 | EGR Sensor “A” Circuit Low (position sensor fault) |

Note: All values are typical and may vary slightly based on specific manufacturing revisions or aftermarket parts. Always refer to your vehicle’s official service manual for definitive specifications.

Conclusion: Mastering Your 6.0 Powerstroke EGR Valve

The 6.0 Powerstroke EGR valve, while a small component, plays an outsized role in the performance, emissions compliance, and overall health of your engine. By delving into the intricate 6.0 Powerstroke EGR valve specifications, understanding its function, common failure modes, and the ins and outs of maintenance, you empower yourself to be a more informed and proactive truck owner. Whether you’re chasing down a mysterious check engine light or simply looking to keep your diesel running strong, this knowledge is invaluable.

Remember, a healthy EGR valve translates directly to a healthier engine, reduced emissions, and sustained performance. Don’t let common issues derail your experience with the powerful 6.0 Powerstroke. With the insights provided in this guide, you’re well-equipped to diagnose, maintain, and replace your EGR valve with confidence, ensuring your Ford Super Duty continues to tackle any challenge thrown its way.

🎥 Related Video: SYMPTOMS OF A BAD EGR VALVE

📺 EasyAutoFix

In this video, you will learn 5 symptoms of a bad EGR valve (exhaust gas recirculation). Watching this video will help you diagnose …

Frequently Asked Questions

What is the primary function of the 6.0 Powerstroke EGR valve?

The Exhaust Gas Recirculation (EGR) valve on your 6.0 Powerstroke is crucial for reducing nitrogen oxide (NOx) emissions. It recirculates a small portion of exhaust gases back into the engine’s combustion chambers, lowering combustion temperatures and thus reducing harmful pollutants.

What are the common specifications or characteristics of a 6.0 Powerstroke EGR valve?

A typical 6.0 Powerstroke EGR valve is an electronic, solenoid-operated valve that precisely controls exhaust flow into the intake manifold. Key specifications include its robust construction, often using stainless steel for durability, specific flow rate, and electronic actuation system, designed to withstand high temperatures and corrosive exhaust gases.

How do I know if my 6.0 Powerstroke EGR valve is failing? What are the symptoms?

Common symptoms of a failing 6.0 Powerstroke EGR valve include a “Check Engine” light (often with codes like P0401, P0402), rough idle, decreased engine performance, and increased exhaust smoke. You might also experience reduced fuel economy or a noticeable sulfur smell from the exhaust.

Are there different versions of the 6.0 Powerstroke EGR valve, and how do their specifications compare?

Yes, there are early (2003-2004) and late model (2004.5-2007) 6.0 Powerstroke EGR valves. While both are electronically actuated, later models often feature design revisions for improved reliability, though their fundamental operating specifications remain similar in purpose. Always confirm the exact part number for your vehicle’s build date.

What are the main causes of failure for a 6.0 Powerstroke EGR valve?

The most common causes of failure for a 6.0 Powerstroke EGR valve are carbon buildup, which can cause it to stick open or closed, and coolant leaks from the EGR cooler that contaminate the valve. These issues can impede its proper operation, leading to performance problems and emission failures.

When purchasing a replacement, what 6.0 Powerstroke EGR valve specifications should I look for?

When buying a replacement 6.0 Powerstroke EGR valve, ensure it’s specifically designed for your truck’s year and engine code to guarantee proper fitment and function. Look for OEM quality or reputable aftermarket brands that meet original equipment specifications regarding material, durability, and electronic compatibility for reliable performance.