2003 7.3 Powerstroke Lost Fuel Pressure and Check Engine Light

Featured image for this comprehensive guide about 2003 7.3 powerstroke lost fuel pressure and check engine light

Image source: images.simplepart.com

2003 7.3 Powerstroke Lost Fuel Pressure and Check Engine Light

Ah, the legendary 7.3L Powerstroke. If you own one, you know it’s more than just an engine; it’s a workhorse, a symbol of durability, and for many, a way of life. Revered for its longevity and a distinct exhaust note that turns heads, the 2003 7.3 Powerstroke represents the pinnacle of its production run. However, even legends have their quirks, and one particularly frustrating issue that can plague these robust diesels is a sudden lost fuel pressure and check engine light. When your trusty 7.3 starts sputtering, losing power, or refusing to start altogether, accompanied by that ominous amber glow on your dash, it’s a clear sign that something in its meticulously engineered fuel delivery system needs attention.

This isn’t just a minor inconvenience; a significant drop in fuel pressure can lead to a cascade of problems, from decreased performance and fuel economy to potential long-term damage to critical components like your injectors. The Check Engine Light (CEL) serves as your truck’s early warning system, but without understanding what specific issues might trigger it in conjunction with low fuel pressure, you might find yourself lost in a sea of possible culprits. From simple fixes like a clogged filter to more complex system failures, diagnosing the root cause requires a systematic approach and a solid understanding of your 2003 7.3 Powerstroke lost fuel pressure and check engine light symptoms.

Fear not, fellow Powerstroke enthusiast! This comprehensive guide is designed to arm you with the knowledge and actionable steps needed to diagnose, troubleshoot, and ultimately resolve the issues behind your 7.3 Powerstroke lost fuel pressure. We’ll delve deep into the common causes, equip you with diagnostic techniques, and offer practical solutions to get your 7.3 roaring back to life with the reliability it’s famous for. Let’s get your beloved truck back on the road, performing as it should be.

Quick Answers to Common Questions

My 2003 7.3 Powerstroke just experienced lost fuel pressure and the check engine light came on – what’s the very first thing I should look at?

Start by checking your fuel filter! A clogged fuel filter is a super common culprit for lost fuel pressure and can easily trigger that check engine light on your 2003 7.3 Powerstroke.

Okay, if the filter isn’t it, what are some other common reasons a 2003 7.3 Powerstroke loses fuel pressure and throws a CEL?

Beyond a clogged filter, you might be looking at issues with the fuel pressure regulator (FPR), a failing electric fuel pump (if applicable), or even air getting into the fuel lines. Any of these can lead to your 2003 7.3 Powerstroke lost fuel pressure and check engine light.

Is it safe to drive my 2003 7.3 Powerstroke if I’ve lost fuel pressure and the check engine light is on?

Absolutely not! Driving with lost fuel pressure can starve your injectors, causing expensive damage. It’s best to stop driving your 2003 7.3 Powerstroke immediately and diagnose the issue.

How can I quickly test the fuel pressure on my 2003 7.3 Powerstroke without taking it to a shop right away?

You can often get a quick reading by installing a simple fuel pressure gauge directly onto the Schrader valve on top of your fuel filter housing. This will confirm if your 2003 7.3 Powerstroke truly has lost fuel pressure.

What does the check engine light specifically tell me when my 2003 7.3 Powerstroke has lost fuel pressure?

The check engine light means your PCM has detected a fault, often directly related to the low fuel pressure itself or a sensor acting up. Getting the codes read will give you a clearer direction for your 2003 7.3 Powerstroke’s issue.

📋 Table of Contents

- Understanding Your 7.3’s Fuel System – The Basics

- Common Symptoms and Diagnostic Codes for Lost Fuel Pressure

- Top Culprits Behind Lost Fuel Pressure

- Step-by-Step Diagnostics: Pinpointing the Problem

- Solutions and Preventative Maintenance

- Data Table: Common 7.3L Powerstroke Fuel System Specifications & DTCs

- Conclusion: Keeping Your 7.3L Powerstroke a Legend

Understanding Your 7.3’s Fuel System – The Basics

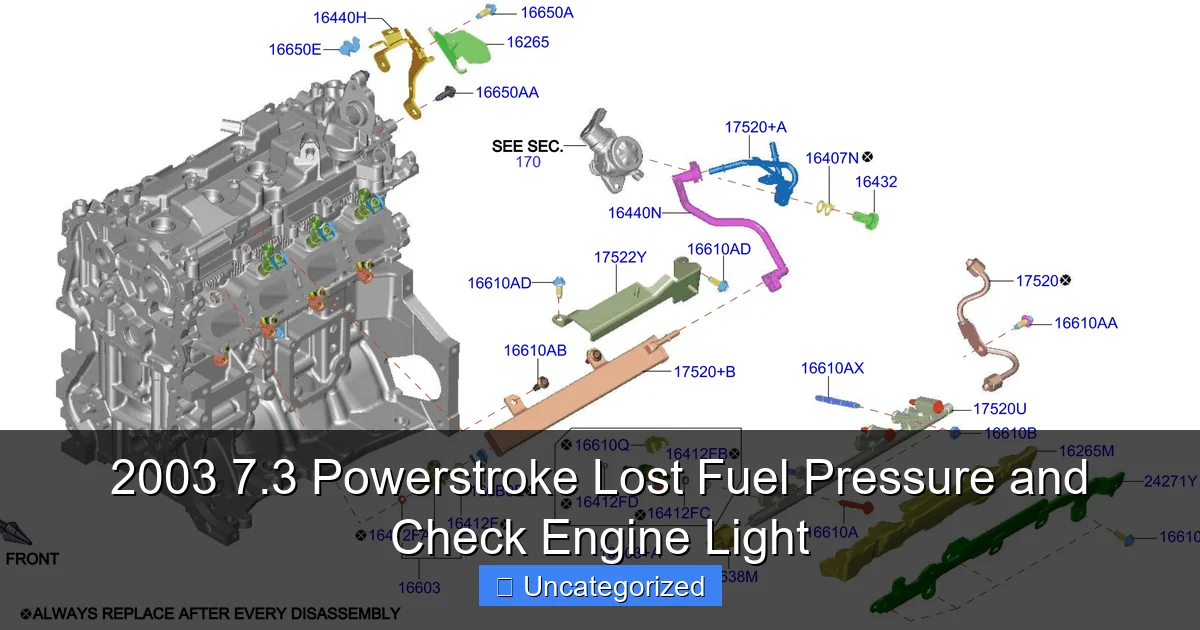

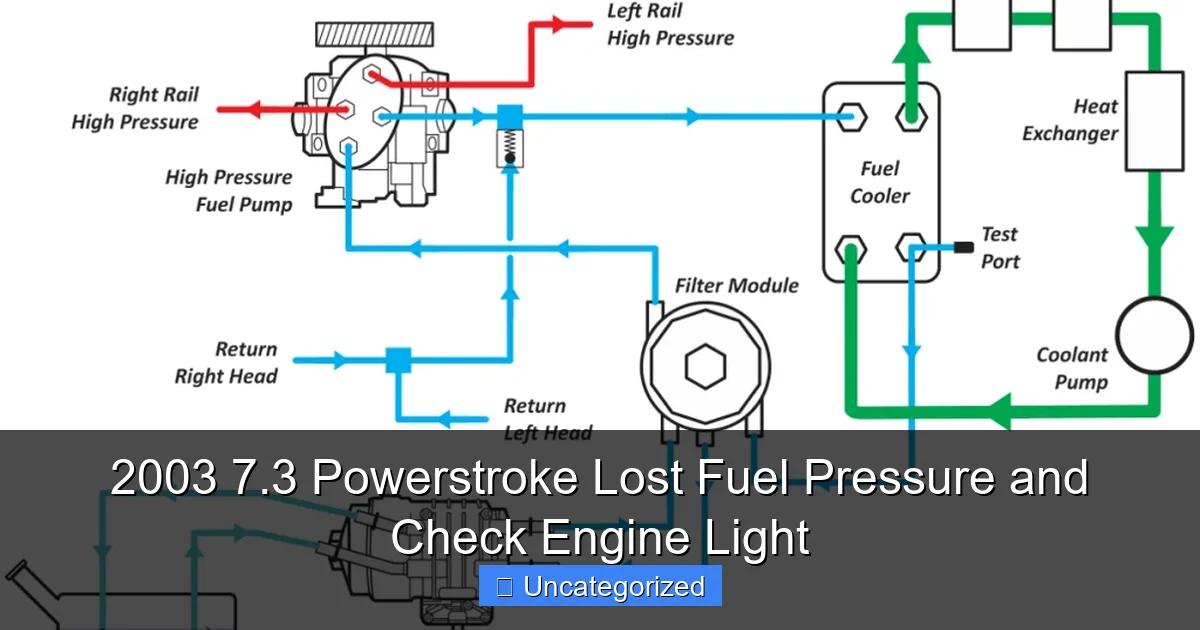

Before we dive into troubleshooting, it’s essential to grasp the fundamentals of how your 2003 7.3 Powerstroke fuel system operates. Unlike gasoline engines, diesels rely on extremely high fuel pressure and precise injection timing to achieve combustion. The 7.3L is an indirect injection system, meaning fuel is injected into a pre-combustion chamber before entering the main cylinder, but the principles of fuel delivery remain critical.

Learn more about 2003 7.3 powerstroke lost fuel pressure and check engine light – 2003 7.3 Powerstroke Lost Fuel Pressure and Check Engine Light

Image source: s3.amazonaws.com

How the 7.3L Fuel System Works

Fuel delivery in your 7.3 begins in the tank, where a lift pump (often integrated into the fuel tank module or frame-mounted) pulls fuel through a pre-filter screen. This low-pressure fuel then travels through fuel lines to the engine bay, where it passes through a primary fuel filter (usually located on top of the engine, in the fuel filter housing). After filtration, the fuel goes to the fuel pressure regulator (FPR), which maintains a steady pressure for the injectors. The excess fuel is then returned to the tank. This continuous flow is vital for cooling and lubricating the injectors. Inside the injectors, the High-Pressure Oil Pump (HPOP) system provides the pressure needed to atomize the fuel for injection, effectively using high-pressure oil to intensify fuel pressure within each injector. When any part of this intricate system falters, you could experience 7.3 Powerstroke low fuel pressure and a lit Check Engine Light.

| Potential Cause | Key Symptoms & Common DTCs | Typical Fuel Pressure Impact (Nominal: 45-65 PSI) | Recommended Diagnostic/Repair |

|---|---|---|---|

| Electric Fuel Pump Failure | Engine cranks but won’t start, stalling, significant power loss. Occasional P0230 (Fuel Pump Primary Circuit) but often no direct pump code. | Drops to 0-10 PSI, or highly inconsistent. | Check for pump hum, verify voltage at pump, replace fuel pump. |

| Clogged Fuel Filter (Fuel Bowl) | Loss of power under load, hesitation, rough running. No direct DTC, but can lead to misfire (P030x) or lean codes. | Normal at idle (45-65 PSI), drops to 20-40 PSI under load. | Replace fuel filter, inspect fuel bowl for debris. |

| Fuel Pressure Regulator (FPR) Malfunction / Fuel Bowl Leaks | Visible fuel leaks (especially around fuel bowl), hard starts (warm), fluctuating idle. No specific DTC for FPR. | Inconsistent pressure, often below 40 PSI, or drops quickly after engine shutdown. | Inspect fuel bowl for leaks, test FPR function, rebuild or replace fuel bowl/FPR. |

| Clogged Fuel Tank Pickup Screen (In-Tank) | Engine stalls or loses power when fuel tank is 1/4 full or less. No specific DTC, but fuel starvation symptoms. | Drops significantly when fuel level is low or under heavy acceleration. | Drop fuel tank, inspect/clean/replace pickup screen, consider “Harpoon Mod” to improve fuel draw. |

The Importance of Fuel Pressure

Maintaining adequate fuel pressure is paramount for the optimal performance and longevity of your 7.3L Powerstroke. The ideal fuel pressure for a 7.3L Powerstroke typically ranges from 45-60 PSI (pounds per square inch) at idle, with some slight variations depending on load. If the pressure drops below this critical range, the injectors won’t receive enough fuel to atomize correctly, leading to incomplete combustion, misfires, loss of power, and, inevitably, a check engine light. Prolonged operation with insufficient fuel pressure can also lead to premature wear of the injectors, which are expensive components to replace.

Common Symptoms and Diagnostic Codes for Lost Fuel Pressure

When your 2003 7.3 Powerstroke lost fuel pressure and check engine light comes on, it’s often accompanied by other tell-tale signs. Recognizing these symptoms can help you narrow down the potential causes even before you hook up a diagnostic scanner. The CEL itself is a broad indicator, but specific Diagnostic Trouble Codes (DTCs) will provide much more precise information about what’s going wrong in the fuel system.

Learn more about 2003 7.3 powerstroke lost fuel pressure and check engine light – 2003 7.3 Powerstroke Lost Fuel Pressure and Check Engine Light

Image source: diagraminfo.com

Beyond the Check Engine Light: What to Look For

A host of symptoms can point towards a 7.3 Powerstroke lost fuel pressure issue:

- Loss of Power: The most common symptom. Your truck feels sluggish, struggles to accelerate, or can’t maintain speed, especially under load (towing, uphill).

- Rough Idle/Stalling: The engine may run erratically, shake, or even stall, particularly when coming to a stop or after prolonged idling.

- Hard Starting or No Start: If fuel pressure is severely low, the engine might crank but not fire, or take an unusually long time to start.

- Hesitation or Surging: The engine might “buck” or surge intermittently as it struggles to maintain consistent fuel delivery.

- Increased Smoke from Exhaust: Unburnt fuel due to poor atomization can lead to excessive black or white smoke.

- Poor Fuel Economy: The engine’s computer (PCM) may try to compensate for low pressure, leading to inefficient fuel consumption.

Key Diagnostic Trouble Codes (DTCs) for Fuel Pressure Issues

The Check Engine Light illuminates when the Powertrain Control Module (PCM) detects a fault. Retrieving the DTCs using an OBD-II scanner is your next crucial step. While there isn’t one specific code exclusively for “low fuel pressure” on a 7.3, several codes are highly indicative of fuel system problems:

- P1211: Injector Control Pressure (ICP) Sensor out of range – high/low during cranking or running. While an oil-related code, P1211 often manifests as poor fuel delivery symptoms because the injectors rely on ICP. If the HPOP isn’t building enough pressure, the injectors won’t fire correctly, leading to issues that mimic or directly cause a 7.3 Powerstroke low fuel pressure condition in terms of performance.

- P0087: Fuel Rail/System Pressure – Too Low. This code, though more common on later common-rail diesels, can sometimes appear on older systems if an aftermarket sensor or monitoring system is in place, or if the PCM detects unusually low fuel system activity.

- P0093: Fuel System Leak Detected – Large Leak. This code often points to a significant leak or pressure drop within the fuel system, which directly leads to lost fuel pressure.

- P02xx Series Codes (e.g., P0261, P0264, etc.): Injector Circuit Low/High. These codes indicate issues with individual injectors, which can be a consequence of sustained low fuel pressure or contribute to overall poor fuel delivery.

- P03xx Series Codes (e.g., P030x): Cylinder Misfire Detected. A general misfire code that can be triggered by insufficient fuel delivery to one or more cylinders.

Always note down all present codes, as they provide valuable clues to accurately diagnose your 2003 7.3 Powerstroke lost fuel pressure and check engine light.

Top Culprits Behind Lost Fuel Pressure

Pinpointing the exact cause of 7.3 Powerstroke lost fuel pressure can be challenging, as several components contribute to the fuel delivery system. Here are the most common culprits, ranging from simple fixes to more involved repairs:

Failing Fuel Pump (Electric/Lift Pump)

The fuel pump, or lift pump, is responsible for drawing fuel from the tank and pushing it towards the engine. Over time, the electric motor can wear out, internal seals can fail, or debris can obstruct its operation. A failing fuel pump is a primary suspect when you have lost fuel pressure, leading to symptoms like hard starting, stalling, and a noticeable drop in power. You might hear a whining noise from the tank area if the pump is struggling, or it might become completely silent upon key-on if it has failed entirely.

Clogged Fuel Filter or Restricted Lines

A dirty or clogged fuel filter is one of the most common and easiest-to-fix reasons for a 7.3 Powerstroke low fuel pressure. Over time, sediment and contaminants from the fuel can accumulate in the filter, restricting fuel flow. If the filter is severely clogged, the engine will starve for fuel, leading to power loss, hesitation, and eventually, a Check Engine Light. Similarly, kinked, collapsed, or internally corroded fuel lines can restrict flow, causing similar symptoms. Always check your fuel filter’s last replacement date.

Injector O-Rings and Injector Issues

The 7.3L Powerstroke’s injectors use O-rings to seal the fuel and oil passages. Over time, these O-rings can harden, crack, or become brittle due to heat and fuel exposure, leading to internal or external leaks. If the fuel O-rings leak, fuel pressure can drop significantly because fuel is escaping the system or mixing with oil. Leaking O-rings can also cause air intrusion into the fuel system. While not a direct cause of low pressure *from the pump*, leaking injector O-rings cause a functional loss of pressure to the combustion chamber and can certainly trigger performance issues and a CEL related to injection quality. Faulty injectors themselves (e.g., sticking, weak solenoids) can also contribute to poor fuel atomization and system inefficiency.

Air Intrusion and Leaks in the Fuel System

Any leak in the fuel lines, fittings, or seals between the fuel tank and the injectors can allow air to enter the fuel system. Air in the fuel lines (known as “air in fuel”) is a common cause of hard starts, rough idle, and misfires, as air is incompressible and prevents proper fuel delivery and atomization. Common leak points include the fuel filter housing, cracked fuel lines, loose fittings, or even a faulty fuel tank sending unit. A strong smell of diesel fuel around the engine or under the truck is a clear sign of a leak, directly contributing to lost fuel pressure.

Fuel Pressure Regulator (FPR) Problems

The Fuel Pressure Regulator (FPR) is a critical component that maintains consistent fuel pressure to the injectors. It’s usually located on the fuel filter housing. If the FPR fails (e.g., a ruptured diaphragm, sticking valve), it can either allow too much fuel to return to the tank, leading to chronically low pressure, or it can stick closed, causing excessively high pressure (though low pressure is far more common for these symptoms). A faulty FPR can directly cause 7.3 Powerstroke low fuel pressure, resulting in performance issues and a Check Engine Light.

High-Pressure Oil Pump (HPOP) and IPR/ICP Issues

While the HPOP is part of the high-pressure oil system (not the low-pressure fuel system), it’s worth mentioning because the 7.3L injectors are “oil-fired.” The HPOP provides the extreme oil pressure that drives the fuel injection process within each injector. If the HPOP is weak, the Injector Pressure Regulator (IPR) valve is faulty, or the Injector Control Pressure (ICP) sensor is reading incorrectly, the engine might not be able to build or maintain the necessary oil pressure for proper fuel injection. This often leads to codes like P1211 and symptoms identical to lost fuel pressure, even if the low-pressure fuel system is technically functioning correctly. It’s an important distinction to make during diagnostics.

Step-by-Step Diagnostics: Pinpointing the Problem

When facing a 2003 7.3 Powerstroke lost fuel pressure and check engine light, a systematic diagnostic approach is key. Don’t just start replacing parts; that can get expensive quickly. Here’s a methodical way to diagnose the issue:

Initial Checks: Fuel Level, Visual Inspection

Start with the simplest things:

- Check Fuel Level: Sounds obvious, but sometimes the gauge can be faulty. Ensure you have plenty of diesel fuel.

- Visual Inspection:

- Look for obvious fuel leaks around the fuel filter housing, lines, and injectors. Any wet spots or strong diesel smells?

- Check for kinked or damaged fuel lines, especially near the frame rails or under the engine.

- Inspect electrical connections to the fuel pump, IPR, and ICP sensors for corrosion or looseness.

- Ensure the fuel cap is properly sealed.

Measuring Fuel Pressure: Tools and Techniques

This is arguably the most critical step. You’ll need a fuel pressure gauge designed for diesel (0-100 PSI range is good). There’s usually a Schrader valve or a test port on the fuel filter housing where you can connect the gauge.

- Connect the Gauge: Attach the fuel pressure gauge to the test port.

- Key On, Engine Off (KOEO): Turn the key to the “on” position without starting the engine. The fuel pump should prime for a few seconds. Note the pressure. It should build and hold.

- Idle Pressure: Start the engine and let it idle. Observe the fuel pressure. It should ideally be between 45-60 PSI.

- Under Load Test: If safe to do so (e.g., on a dyno or with a passenger observing the gauge), drive the truck and observe the pressure under acceleration and load. Pressure should remain stable or drop only slightly. A significant drop indicates a supply issue.

- Wiggle Test: With the engine running and the gauge connected, gently wiggle fuel lines, connectors, and the fuel pump wiring. Watch for any fluctuations in pressure that might indicate a loose connection or intermittent fault.

Scanning for DTCs: Interpreting the Codes

An OBD-II scanner is indispensable. Connect it to your truck’s diagnostic port and retrieve all stored and pending codes. As discussed, pay close attention to P1211, P0087, P0093, and any misfire codes. Don’t just read the code; research its specific meaning for the 7.3 Powerstroke and look for related factory service manual diagnostic trees.

Advanced Testing: Buzz Tests, Contribution Tests, and ICP/IPR Data

For more complex issues, especially if P1211 is present, you’ll need a more advanced scanner or diagnostic software (like Ford’s IDS or Forscan). These tools allow you to:

- Perform an Injector Buzz Test: This cycles the injector solenoids, allowing you to hear if any are not buzzing, indicating a potential electrical issue or failure.

- Run a Cylinder Contribution Test: This helps identify specific cylinders that are misfiring or underperforming, guiding you towards a particular injector issue.

- Monitor ICP and IPR Values: While cranking and running, observe the Injector Control Pressure (ICP) sensor readings and the Injector Pressure Regulator (IPR) duty cycle. Low ICP values or high IPR duty cycles (above 60-70%) indicate a problem with the high-pressure oil system (HPOP, IPR, or oil leaks) that can mimic or cause fuel delivery issues.

Solutions and Preventative Maintenance

Once you’ve diagnosed the specific issue causing your 2003 7.3 Powerstroke lost fuel pressure and check engine light, it’s time for the fix. Remember, using quality parts is always recommended for longevity and reliability, especially with the 7.3L.

Repairing Common Issues: From Filters to Pumps

- Clogged Fuel Filter: Replace the fuel filter. This is usually a simple DIY job, located on top of the engine. Ensure you bleed any air from the system after replacement. This is the first and cheapest step.

- Failing Fuel Pump: Replace the fuel pump. If it’s a frame-mounted pump, it’s fairly accessible. If it’s in-tank, you’ll likely need to drop the fuel tank, which is a more involved process. Consider upgrading to a higher-flow aftermarket pump for better future performance and reliability, but always ensure it’s compatible with your 7.3 Powerstroke.

- Leaking Fuel Lines/Fittings: Identify the source of the leak and repair or replace the affected section. Use appropriate fuel-rated hose and clamps, or factory replacement hard lines if necessary.

- Faulty Fuel Pressure Regulator (FPR): Replace the FPR, which is typically part of the fuel filter housing assembly.

- Injector O-Rings: This is a more involved repair, requiring removal of the valve covers and potentially the injectors. If O-rings are leaking, it’s often wise to replace all of them and inspect the injectors for wear.

- HPOP/IPR/ICP Issues: These are critical and often more expensive repairs. Replacing the HPOP or IPR valve can resolve low ICP issues. If the ICP sensor is faulty, a new sensor is needed. These repairs often require specialized tools and expertise.

Upgrades for Enhanced Reliability

Many 7.3 Powerstroke owners opt for upgrades to prevent future fuel pressure issues:

- External Fuel Pump Systems: Replacing the stock in-tank or frame-mounted pump with an external, higher-volume, and more robust aftermarket fuel pump system (e.g., from AirDog or FASS) can significantly improve fuel flow, filtration, and pressure stability. These systems often include better water separation and air removal.

- Fuel Pressure Regulators: Upgrading to an adjustable fuel pressure regulator can allow fine-tuning of your fuel pressure for optimal performance and can be more reliable than the stock unit.

- Fuel Bowl Delete: Some owners delete the factory fuel bowl (which contains the filter and FPR) in favor of an aftermarket filter system and regulator for improved flow and easier maintenance. This should only be done with a robust aftermarket fuel system in place.

Essential Preventative Maintenance Tips

Prevention is always better than cure. To keep your 7.3 Powerstroke running strong and avoid a future lost fuel pressure and check engine light:

- Regular Fuel Filter Replacement: Follow manufacturer recommendations or replace more frequently if you use questionable fuel or drive in dusty conditions. Typically every 10,000-15,000 miles.

- Use Quality Fuel: Always use clean, reputable diesel fuel. Water and contaminants are the enemies of your fuel system.

- Keep Your Tank Full: Especially in colder climates, keeping your fuel tank above half full helps prevent condensation and reduces the risk of fuel gelling.

- Inspect Fuel Lines Regularly: During oil changes or other maintenance, visually inspect fuel lines for cracks, leaks, or wear.

- Listen to Your Truck: Pay attention to any changes in engine noise, performance, or starting characteristics. Early detection can prevent major failures.

Data Table: Common 7.3L Powerstroke Fuel System Specifications & DTCs

To help you in your diagnostic journey, here’s a quick reference table for typical fuel pressure specifications and common Diagnostic Trouble Codes associated with fuel system issues on your 2003 7.3 Powerstroke.

| Component/Parameter | Typical Specification/Range | Notes |

|---|---|---|

| Fuel Pressure (Idle) | 45-60 PSI | Measure at the fuel filter housing test port. Below 40 PSI is a concern. |

| Fuel Pressure (WOT/Load) | Typically maintains >40 PSI | Should not drop excessively under heavy load. A significant drop indicates a supply issue. |

| ICP Sensor Voltage (KOEO) | 0.15 – 0.25 V (Key On, Engine Off) | Monitored via scanner. Indicates atmospheric pressure. |

| ICP Sensor Voltage (Idle) | 0.8 – 1.0 V | Corresponds to ~500 PSI ICP pressure. |

| IPR Duty Cycle (Idle) | 8-15% | Monitored via scanner. Higher % indicates the IPR is working harder to maintain pressure. |

| Diagnostic Trouble Code (DTC) | Description / Common Implication | Potential Related Fuel System Cause |

| P1211 | ICP Sensor out of range – high/low during cranking/running | Weak HPOP, IPR valve failure, oil leak in high-pressure oil system. (Indirectly impacts fuel injection) |

| P0087 | Fuel Rail/System Pressure – Too Low | Weak fuel pump, clogged filter, significant fuel leak. |

| P0093 | Fuel System Leak Detected – Large Leak | Fuel line rupture, leaking injector O-rings, faulty fuel pressure regulator. |

| P0261 – P0284 | Cylinder Contribution/Balance Codes | Failing injector, low fuel pressure causing poor atomization, air in fuel. |

Conclusion: Keeping Your 7.3L Powerstroke a Legend

Dealing with a 2003 7.3 Powerstroke lost fuel pressure and check engine light can be a daunting experience, but with a methodical approach and the right knowledge, it’s a problem you can conquer. From a simple clogged fuel filter to a more complex high-pressure oil system issue, understanding the common culprits and knowing how to test for them will save you time, money, and frustration. Remember, the 7.3L Powerstroke is an incredibly durable engine, and most issues are fixable with careful diagnosis and quality parts.

By regularly performing preventative maintenance, such as timely fuel filter replacements and visual inspections, you can significantly reduce the likelihood of encountering these issues. When the dreaded CEL does illuminate and your truck loses its characteristic grunt, use the information provided here as your guide. Arm yourself with a fuel pressure gauge and an OBD-II scanner, and methodically work through the diagnostic steps. With a little patience and persistence, you’ll have your 7.3 Powerstroke roaring back to life, proving once again why it’s considered one of the best diesel engines ever made.

Don’t let a temporary setback overshadow the legendary status of your 7.3. Keep it well-maintained, diagnose issues promptly, and it will continue to serve you faithfully for hundreds of thousands of miles to come. Happy wrenching!

Frequently Asked Questions

What are the most common reasons a 2003 7.3 Powerstroke loses fuel pressure and triggers a check engine light?

This issue often points to a failing fuel pump, a clogged fuel filter, or issues with the fuel pressure regulator. It could also be related to a leaking fuel line or a faulty Injector Pressure Regulator (IPR) or Injector Control Pressure (ICP) sensor, which can indirectly affect fuel delivery.

How can I diagnose lost fuel pressure on my 2003 7.3 Powerstroke at home?

Start by checking your fuel filter for clogs and ensuring the fuel bowl is full. You’ll need a fuel pressure gauge to directly measure pressure at the filter housing, which should be around 45-65 psi at idle. Also, scan for diagnostic trouble codes (DTCs) as these can point to specific sensor failures.

What specific Check Engine Light codes might indicate a fuel pressure problem on a 7.3 Powerstroke?

While there isn’t one direct “low fuel pressure” code, you might see codes like P1211 (ICP Actual vs. Desired Difference) or P0093 (Fuel System Leak Detected – Large Leak), which often indicate a lack of proper fuel delivery or pressure. Other codes related to the Injector Pressure Regulator (IPR) or Injector Control Pressure (ICP) sensor can also be triggered.

Is it safe to drive my 2003 7.3 Powerstroke if it has lost fuel pressure and the check engine light is on?

It is generally not recommended to drive your 2003 7.3 Powerstroke with lost fuel pressure. This can lead to further damage to the fuel pump, injectors, or other engine components due to lack of lubrication and cooling from the fuel. It’s best to diagnose and repair the issue promptly to prevent more extensive and costly damage.

How can I prevent my 2003 7.3 Powerstroke from losing fuel pressure in the future?

Regular maintenance is key, especially replacing your fuel filter every 10,000-15,000 miles or as recommended by the manufacturer. Using quality fuel and additives can also help keep the fuel system clean. Periodically inspecting fuel lines for leaks and ensuring your fuel pump is in good working order will contribute to reliable fuel pressure.

What’s the typical cost to repair lost fuel pressure on a 2003 7.3 Powerstroke?

The repair cost for lost fuel pressure on your 7.3 Powerstroke can vary significantly depending on the cause. A simple fuel filter replacement might be under $100, while a new fuel pump could range from $300-$800 for parts and labor. Issues with injectors, ICP/IPR sensors, or extensive fuel line repairs would be on the higher end, potentially exceeding $1000.