12V Cummins Throttle Linkage : Boost Performance

The 12V Cummins throttle linkage is a solid rod with a dogleg in the middle, featuring sockets on each end, and can be easily adjusted for idle control. This simple and cost-effective solution replaces the stock, complex throttle kit, making it perfect for engine swaps.

If you’re looking for an efficient and straightforward solution to control the idle of your 12V Cummins engine, the throttle linkage is the answer. This solid rod with a dogleg in the middle and sockets on each end provides a reliable and adjustable connection between the accelerator pedal and the engine throttle.

By eliminating the need for expensive and complex throttle kits, this simple setup is a popular choice for engine swaps. We will explore the 12V Cummins throttle linkage in detail and discover its benefits for optimal engine performance. So let’s dive in and understand how this essential component works and why it’s a preferred choice among Cummins enthusiasts.

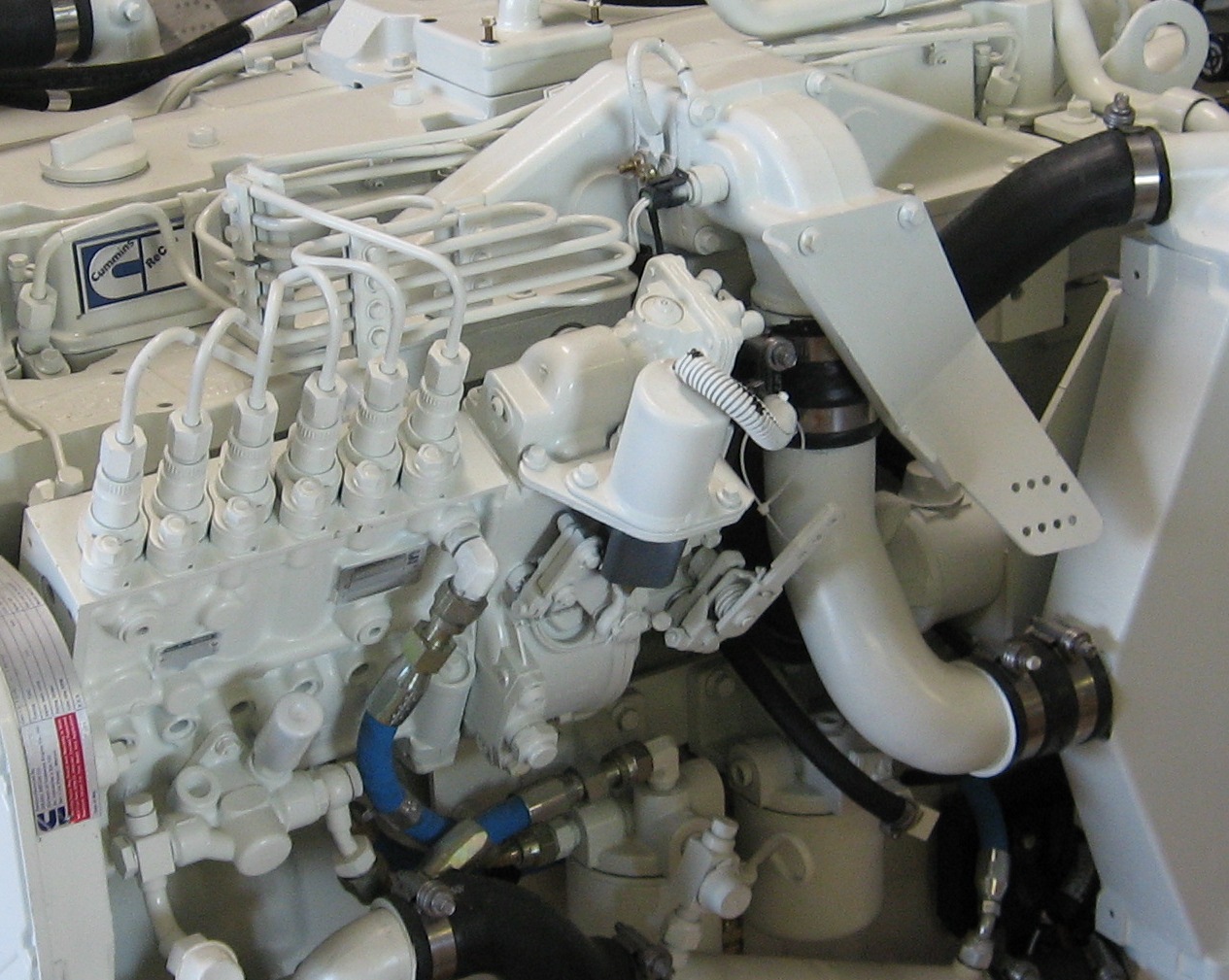

Credit: cppdiesel.com

Exploring Throttle Linkage Options

When it comes to optimizing the performance of your 12V Cummins engine, exploring throttle linkage options is a crucial step. The throttle linkage is responsible for controlling the flow of air and fuel into the engine, determining its power and responsiveness. In this article, we will explore two key options for upgrading your throttle linkage: aftermarket components and DIY modifications.

Aftermarket Components

If you’re looking for a quick and efficient way to upgrade your 12V Cummins throttle linkage, aftermarket components are a great option. These components are specifically designed to enhance the throttle response of your engine, providing a smoother acceleration and improved overall performance.

There are several reputable brands that offer a wide range of aftermarket throttle linkage kits. Pure Diesel Power, for instance, offers a Throttle Linkage Kit Adjustment on their website for just $29.99. This kit is designed for easy installation and comes with a 30-day return policy, giving you peace of mind in your purchase.

Crazy Carls Turbos is another trusted name in the industry, offering a Complete Throttle Linkage made of Unobtanium. While slightly more expensive at $88.49, this kit is known for its durable construction and enhanced throttle response.

Diy Modifications

If you prefer a more hands-on approach or are working within a budget, DIY modifications can be a viable option for upgrading your 12V Cummins throttle linkage. With some basic tools and a bit of patience, you can make custom adjustments to optimize the throttle response of your engine.

One popular DIY modification involves adjusting the length of the throttle linkage rod. By shortening or lengthening the rod, you can fine-tune the throttle response to your desired level. This allows for a more personalized driving experience and improved engine performance.

It’s important to note that DIY modifications require some mechanical knowledge and expertise. It’s always a good idea to consult with experts or refer to online forums and communities dedicated to Cummins diesel engines, such as the Cummins Diesel Forum or Turbo Diesel Register. These platforms can provide valuable insights and guidance to ensure a successful modification process.

In conclusion, exploring throttle linkage options for your 12V Cummins engine is crucial for optimizing its performance. Whether you choose to invest in aftermarket components or embark on a DIY modification journey, upgrading your throttle linkage will undoubtedly enhance the overall driving experience of your vehicle.

Credit: www.amazon.com

Common Throttle Linkage Issues

When it comes to the 12V Cummins throttle linkage, there are a few common issues that can arise. These issues can impact the performance and efficiency of your engine, so it’s important to address them promptly. In this section, we will discuss two of the most common throttle linkage issues: Wear and Tear and Inefficient Performance.

Wear And Tear

Over time, the throttle linkage in your 12V Cummins engine can experience wear and tear. This can be caused by regular use, exposure to extreme weather conditions, or improper maintenance. When the throttle linkage starts to wear down, it can lead to several problems that affect the overall performance of your engine.

- Sticky Throttle: A worn-out throttle linkage can cause the throttle to stick, making it difficult to control the speed of your vehicle. This can be dangerous, especially when driving at high speeds or in traffic.

- Delayed Response: As the throttle linkage wears down, it may lose its responsiveness, leading to a delayed throttle response. This can result in sluggish acceleration and a decrease in overall engine performance.

- Inconsistent Idle: Another common issue is an inconsistent or unstable idle. You may notice that your engine idles too high or too low, which can cause rough running and even stalling.

To prevent these issues, it’s important to regularly inspect and maintain your throttle linkage. This includes lubricating the moving parts, checking for loose connections, and replacing any worn-out components.

Inefficient Performance

In addition to wear and tear, the throttle linkage can also contribute to inefficient engine performance. If the throttle linkage is not properly adjusted or connected, it can affect the fuel-to-air ratio, leading to poor fuel efficiency and decreased power output.

Common signs of inefficient performance include:

- Decreased Fuel Mileage: If your engine is not receiving the correct amount of fuel due to an improperly adjusted throttle linkage, you may notice a decrease in fuel mileage.

- Lack of Power: An inefficient throttle linkage can also result in a lack of power, making it difficult for your vehicle to accelerate or climb hills.

- Engine Misfires: The incorrect fuel-to-air ratio caused by an inefficient throttle linkage can lead to engine misfires, resulting in rough running and a loss of power.

To address these issues, it’s crucial to ensure that your throttle linkage is properly adjusted and functioning correctly. Regularly inspecting and maintaining the throttle linkage can help optimize engine performance, improve fuel efficiency, and extend the lifespan of your Cummins engine.

Maximizing Performance With Throttle Linkage

When it comes to maximizing performance in a 12V Cummins engine, optimizing the throttle linkage is essential for achieving optimal throttle response and fuel efficiency. The throttle linkage plays a crucial role in controlling the engine’s power output and fuel consumption. By understanding the tips for optimizing throttle response and enhancing fuel efficiency, you can unleash the full potential of your 12V Cummins engine.

Tips For Optimizing Throttle Response

To enhance throttle response in a 12V Cummins engine, it’s important to ensure that the throttle linkage is properly adjusted and free from any restrictions. Inspect the throttle linkage for any signs of wear or binding and make necessary adjustments to ensure smooth and precise throttle operation. Additionally, consider upgrading to high-quality throttle linkage components that are designed to withstand the demands of high-performance applications. By maintaining a responsive throttle linkage, you can experience improved acceleration and drivability.

Enhancing Fuel Efficiency

Efficient fuel consumption is key to maximizing the performance of a 12V Cummins engine. With a well-adjusted throttle linkage, you can achieve better control over the engine’s fuel delivery, leading to improved fuel efficiency. It’s important to regularly inspect and clean the throttle linkage components to prevent any obstructions that may hinder smooth operation. Furthermore, investing in quality throttle linkage components can contribute to more precise fuel management, optimizing the engine’s performance while conserving fuel.

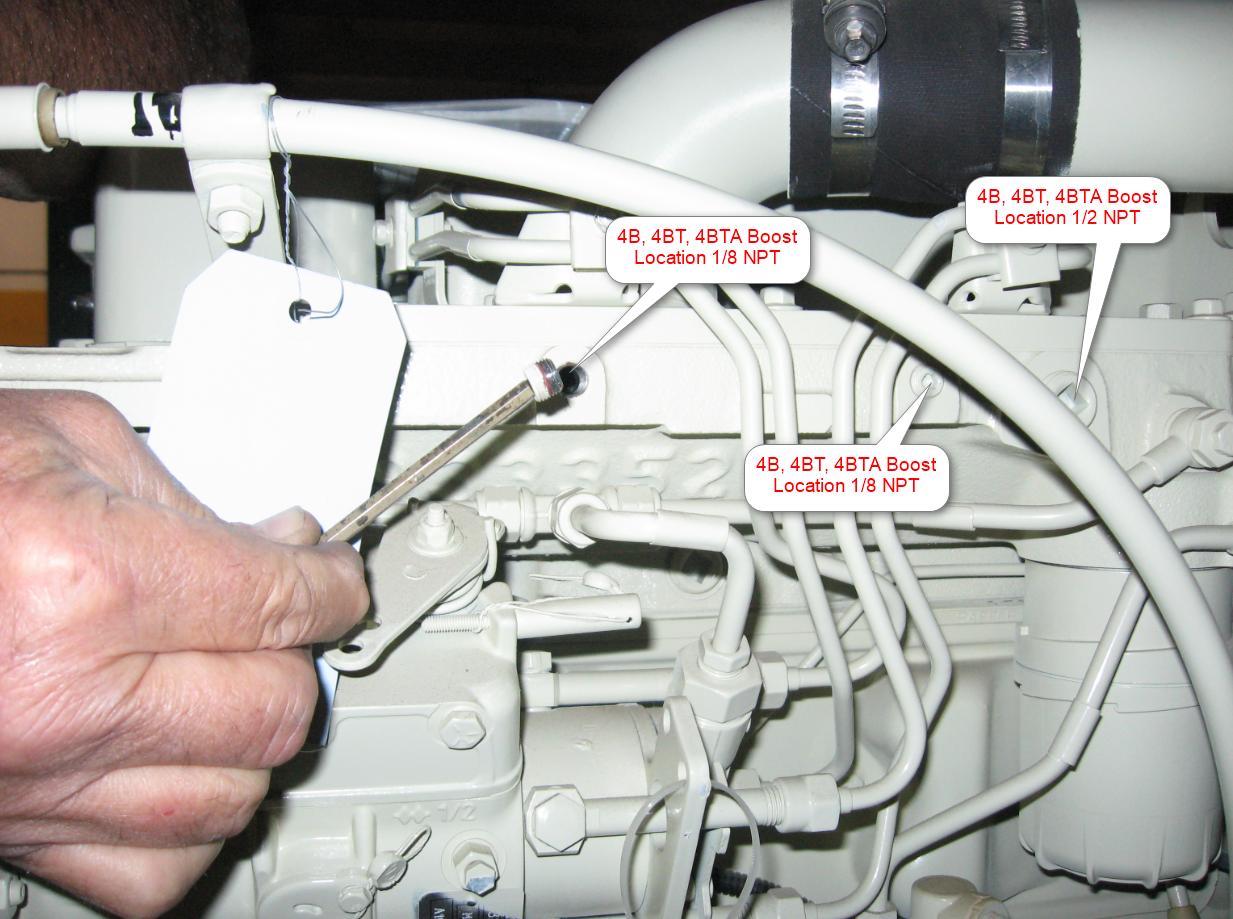

Credit: www.sbmar.com

Sourcing Throttle Linkage Components

When searching for throttle linkage components for your 12V Cummins, it’s crucial to find reliable sources for quality parts.

Pricing And Availability

| Supplier | Price |

|---|---|

| Pure Diesel Power | $0.01 – $177.41 |

| CPP Diesel | $25.95 – $123.75 |

| Diesel Power Products | $35.99 – $1,482.00 |

| crazycarlsturbos.com | $85.00 |

Popular Brands And Suppliers

- Amazon offers Throttle Linkage Kits starting from $29.99.

- Pure Diesel Power provides a variety of Throttle Linkages & Cables at competitive prices.

- Crazy Carls Turbos offers Complete Throttle Linkage made of Unobtanium.

- CP Diesel offers a simple setup with a universal throttle cable for engine swaps.

Frequently Asked Questions On 12v Cummins Throttle Linkage

Does A 12-valve Cummins Have A Throttle Position Sensor?

Yes, a 12-valve Cummins engine does not have a throttle position sensor.

What Year Cummins 12v Is Best?

The best year for the Cummins 12V is the 1997 model due to its reliability and power.

How Do You Adjust The Idle On A 12-valve Cummins?

To adjust the idle on a 12-valve Cummins, follow these steps: 1. Locate the idle adjustment screw on the throttle linkage. 2. Start the engine and let it warm up. 3. Turn the idle adjustment screw clockwise to increase the idle speed or counterclockwise to decrease it.

4. Make small adjustments and listen to the engine for changes in speed and sound. 5. Repeat until you achieve the desired idle speed.

What Rpm Should A 12-valve Cummins Idle At?

A 12-valve Cummins should idle at an RPM (Rotations Per Minute) of around 750 to 800.

Conclusion

Maintaining and adjusting the throttle linkage on your 12V Cummins engine is essential for optimal performance. By using quality components and regularly inspecting the linkage, you can ensure smooth acceleration and responsive throttle control. Consider investing in a reliable throttle linkage kit, which can simplify the setup and enhance your overall driving experience.