What To Do After Replacing MAF Sensor & When To Replace?

Your vehicle’s engine is a complex system that relies on various components working harmoniously to deliver optimal performance. One crucial component that plays a significant role in this equation is the Mass Air Flow (MAF) sensor. The MAF sensor measures the amount of air entering the engine, providing essential data for calculating the correct fuel-to-air ratio.

However, over time, the MAF sensor can deteriorate or malfunction due to various factors such as dirt accumulation, sensor wear, or electrical issues. When this happens, it can lead to a host of performance problems, including reduced fuel efficiency, rough idling, and diminished engine power.

Fortunately, replacing a faulty MAF sensor is a relatively straightforward task that can greatly improve your vehicle’s performance. But what should you do once you’ve replaced the MAF sensor? Moreover, how can you determine if it’s time for a replacement in the first place?

In this blog post, we will guide you through the necessary steps to take after replacing your MAF sensor, ensuring that your vehicle is operating optimally. We will also discuss the signs indicating a potential MAF sensor issue and when it’s appropriate to consider replacing it. By understanding these crucial aspects, you can proactively maintain your vehicle’s health and enjoy a smoother driving experience.

So, let’s dive in and explore what you should do after replacing your MAF sensor and gain insights into when it’s the right time for a replacement.

Signs of a Faulty MAF Sensor

A faulty Mass Air Flow (MAF) sensor can have a significant impact on your vehicle’s performance and fuel efficiency. Recognizing the signs of a malfunctioning MAF sensor is essential for timely diagnosis and repair. Here are some common indicators that suggest your MAF sensor may be faulty:

Poor Engine Performance

One of the primary symptoms of a faulty MAF sensor is a noticeable decline in engine performance. You may experience sluggish acceleration, reduced power output, or difficulty maintaining consistent speeds. The engine may also feel rough or hesitate during acceleration.

Decreased Fuel Efficiency

A malfunctioning MAF sensor can disrupt the air-to-fuel ratio, leading to inefficient combustion. As a result, your vehicle’s fuel efficiency may significantly decrease. If you find yourself visiting the gas station more frequently despite normal driving habits, it could be a sign of a faulty MAF sensor.

Rough Idling and Stalling

When the MAF sensor fails to accurately measure the air entering the engine, it can cause irregular idling or stalling. The engine may idle roughly, fluctuating in RPMs (revolutions per minute), or even stall unexpectedly when at a stop.

Check Engine Light Illumination

A malfunctioning MAF sensor often triggers the illumination of the check engine light on your vehicle’s dashboard. Although this warning light can indicate various issues, it is commonly associated with MAF sensor problems. To accurately diagnose the problem, it’s recommended to retrieve the specific error code using a diagnostic tool.

Issues with Acceleration and Response Time

A faulty MAF sensor can disrupt the engine’s response to throttle inputs. You may experience delayed or uneven acceleration, making it challenging to reach desired speeds promptly. This can impact overall driving performance and safety.

Diagnostic Process

The diagnostic process for identifying a faulty Mass Air Flow (MAF) sensor involves a systematic approach to pinpoint the root cause of the issue. Here’s an overview of the diagnostic process:

Initial Inspection

Begin by conducting a visual inspection of the MAF sensor and its associated components. Look for any signs of physical damage, loose connections, or debris accumulation that could affect its performance. Inspect the wiring harness and connectors for any signs of wear or corrosion.

Diagnostic Tools

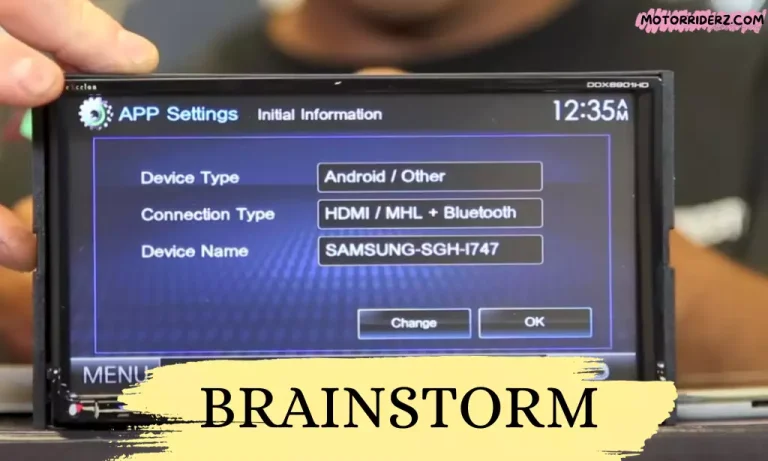

To accurately diagnose the MAF sensor, you’ll need access to diagnostic tools. A scan tool or OBD-II (On-Board Diagnostic) scanner can retrieve error codes stored in the vehicle’s computer system. These codes provide valuable information about potential malfunctions, including MAF sensor-related issues.

Error Code Retrieval

Connect the scan tool or OBD-II scanner to the vehicle’s diagnostic port, typically located under the dashboard. Follow the instructions provided by the tool to retrieve the error codes. Pay specific attention to codes related to the MAF sensor, such as “MAF sensor circuit low input” or “MAF sensor performance.”

Additional Testing

While error codes can provide valuable insights, they are not always definitive proof of a faulty MAF sensor. Perform additional tests to rule out other possible causes of the symptoms. This may include checking the air filter for cleanliness, inspecting the intake system for leaks or obstructions, and verifying the functionality of related components like the throttle position sensor or oxygen sensors.

MAF Sensor Testing

If the initial inspection and additional tests indicate a potential issue with the MAF sensor, further testing is necessary. Specific testing procedures may vary depending on the vehicle make and model. Common methods include using a multimeter to measure voltage or frequency output, comparing the readings to manufacturer specifications, and performing a sensor response test using specialized equipment.

Comparison and Analysis

Compare the test results with the manufacturer’s specifications for the MAF sensor. If the readings are outside the acceptable range or show significant deviations, it is likely that the MAF sensor is faulty and requires replacement.

Steps for Replacing MAF Sensor

Replacing a Mass Air Flow (MAF) sensor is a relatively straightforward process. However, it’s important to follow the correct steps to ensure a proper installation. Here are the general steps to replace a MAF sensor:

1. Gather the necessary tools and replacement parts: Before starting the replacement process, gather the required tools, which may include a screwdriver or socket set, pliers, and a clean cloth. Additionally, ensure you have the correct replacement MAF sensor compatible with your vehicle’s make and model.

2. Locate the MAF sensor: The MAF sensor is typically located between the air filter housing and the engine’s throttle body. Consult your vehicle’s service manual or search online resources for the exact location specific to your vehicle.

3. Disconnect the electrical connector: Carefully disconnect the electrical connector attached to the MAF sensor. Depending on the connector type, you may need to press or squeeze tabs or release a locking mechanism to detach it. Take note of the connector’s orientation for proper reconnection later.

4. Remove the MAF sensor: Inspect the MAF sensor housing for any retaining screws or clips holding it in place. Use the appropriate tool (screwdriver or socket set) to remove these fasteners. Once the fasteners are removed, gently pull the MAF sensor out of its housing. If it seems stuck, you can try twisting it slightly while pulling to release it.

5. Clean the MAF sensor housing (optional): While not always necessary, it’s a good practice to clean the MAF sensor housing before installing the new sensor. Use a clean cloth or a specialized MAF sensor cleaner to carefully remove any dirt or debris. Be cautious not to damage the delicate wire elements inside the MAF sensor.

6. Install the new MAF sensor: Take the new MAF sensor and align it with the housing. Insert it carefully, ensuring it fits snugly into place. If there are retaining screws or clips, reinstall them securely. Double-check that the sensor is properly seated and aligned.

7. Reconnect the electrical connector: Align the electrical connector with the sensor’s connection point and firmly push it in until it clicks or locks into place. Make sure the connector is fully seated and secure.

8. Test the installation: Start the engine and let it idle for a few minutes to allow the new MAF sensor to initialize. Observe the engine’s behavior for any irregularities, such as rough idling or warning lights. Take the vehicle for a short test drive to ensure the MAF sensor is functioning correctly.

Calibration and Testing

After replacing the Mass Air Flow (MAF) sensor, it is important to perform calibration and testing to ensure proper functionality and optimize your vehicle’s performance. Here are the steps to calibrate and test the newly replaced MAF sensor:

1. Start the engine and allow it to idle: After installing the new MAF sensor, start the engine and let it idle for a few minutes. This allows the sensor to warm up and begin operating within its normal range.

2. Monitor engine behavior: While the engine is idling, pay close attention to its behavior. Look for any signs of rough idling, stalling, or abnormal fluctuations in RPM (revolutions per minute). These could indicate a potential issue with the MAF sensor or other related components.

3. Conduct a road test: Once the engine has idled for a few minutes without any noticeable issues, take the vehicle for a short road test. Drive under normal operating conditions, including various speeds and acceleration levels. Observe the engine’s response, smoothness of acceleration, and overall performance.

4. Monitor performance and behavior: During the road test, closely monitor the vehicle’s performance. Pay attention to any irregularities such as hesitation during acceleration, lack of power, or poor fuel efficiency. If you notice any persistent issues, it may indicate a need for further inspection or adjustment of the MAF sensor.

5. Scan for error codes: After the road test, use a scan tool or OBD-II (On-Board Diagnostic) scanner to check for any stored error codes. Even if the check engine light is not illuminated, there may be pending or history codes that can provide valuable insights into the performance of the MAF sensor and other related systems.

6. Make necessary adjustments: If you encounter persistent issues or find error codes related to the MAF sensor, you may need to make further adjustments. This could include repositioning the sensor, ensuring a proper connection, or consulting a professional mechanic for more advanced troubleshooting.

7. Repeat calibration and testing if needed: In some cases, additional calibration or testing may be required to fine-tune the MAF sensor’s performance. This could involve using specialized diagnostic equipment or software to adjust sensor parameters within manufacturer specifications. If you are not experienced with this level of calibration, it is advisable to seek assistance from a qualified professional.

Maintenance Tips to Prolong MAF Sensor Life

Proper maintenance of your Mass Air Flow (MAF) sensor is crucial to ensure its longevity and optimal performance. Here are some essential tips to help prolong the life of your MAF sensor:

Regular Inspection and Cleaning

Periodically inspect the MAF sensor for any dirt, debris, or oil buildup. These contaminants can affect the sensor’s accuracy and performance. If you notice any buildup, clean the sensor using specialized MAF sensor cleaner or electronic component cleaner. Follow the manufacturer’s instructions and exercise caution to avoid damaging the delicate components.

Use High-Quality Air Filters

The air filter protects the MAF sensor from debris and contaminants. Ensure that you use high-quality air filters and replace them at the recommended intervals. A clogged or dirty air filter can affect the airflow and cause additional strain on the MAF sensor.

Avoid Excessive Aftermarket Modifications

Excessive modifications to the intake or exhaust system, such as aftermarket air filters or cold air intakes, can potentially disrupt the airflow and affect the MAF sensor’s readings. If you decide to modify your vehicle, choose reputable brands and consult with experts to ensure compatibility and proper installation.

Follow Manufacturer’s Maintenance Schedule

Adhere to the manufacturer’s recommended maintenance schedule for your vehicle. This includes regular engine tune-ups, air filter replacements, and inspections. Following the prescribed maintenance intervals will help keep the entire engine system, including the MAF sensor, in optimal condition.

Avoid Harsh Driving Conditions

Excessive driving in harsh conditions, such as dusty or sandy environments, can increase the chances of debris buildup on the MAF sensor. Whenever possible, try to avoid driving in such conditions or take necessary precautions to protect the MAF sensor, such as using an air filter with enhanced filtration capabilities.

Ensure Secure Electrical Connections

Periodically check the electrical connections to the MAF sensor for tightness and security. Loose or faulty connections can lead to inaccurate readings and potential performance issues. If you notice any loose connections, ensure they are properly seated and fastened.

Address Engine Issues Promptly

If you experience any engine performance issues, such as rough idling, poor acceleration, or decreased fuel efficiency, address them promptly. Delayed repairs can put additional strain on the MAF sensor and potentially lead to further damage.

FAQ:

Q1: What should I do after replacing the MAF sensor in my vehicle?

A1: After replacing the MAF sensor, it is important to follow a few steps. First, start the engine and let it idle for a few minutes to allow the sensor to initialize. Monitor the engine’s behavior, including idling, acceleration, and overall performance. Take the vehicle for a short test drive to ensure the MAF sensor is functioning correctly. If any issues persist, consult a professional mechanic for further inspection and adjustment if needed.

Q2: When should I consider replacing the MAF sensor?

A2: There are several signs that may indicate a need for MAF sensor replacement. These include poor engine performance, decreased fuel efficiency, rough idling, stalling, or the illumination of the check engine light. If you experience any of these symptoms and diagnostics point to a faulty MAF sensor, it is advisable to consider replacement. However, it’s important to consult a professional mechanic or use diagnostic tools for accurate diagnosis before replacing the sensor.

Q3: Can I clean the MAF sensor instead of replacing it?

A3: In some cases, cleaning the MAF sensor can help restore its functionality. If the sensor is dirty or contaminated with debris, using specialized MAF sensor cleaner or electronic component cleaner may resolve the issue. However, if the sensor is damaged or has internal failures, cleaning may not be sufficient, and replacement may be necessary. It is recommended to inspect and clean the MAF sensor first before considering replacement.

Q4: How often should the MAF sensor be replaced?

A4: The lifespan of a MAF sensor can vary depending on factors such as driving conditions, vehicle make and model, and maintenance practices. In general, the MAF sensor does not have a specific replacement interval like other maintenance components. It is best to monitor the sensor’s performance regularly and replace it when signs of failure, such as reduced performance or persistent issues, become evident.

Q5: Can I replace the MAF sensor myself, or should I seek professional assistance?

A5: While replacing the MAF sensor is generally a straightforward task, it is recommended to seek professional assistance if you are not experienced with automotive repairs. A qualified mechanic can ensure proper installation, perform necessary calibration and testing, and address any underlying issues. This will help avoid potential errors and ensure optimal performance of the MAF sensor and the overall engine system.

One Comment

Comments are closed.