Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Featured image for this comprehensive guide about Torque specifications for 7.3 Powerstroke cylinder head

Image source: figures.academia-assets.com

The legendary 7.3 Powerstroke diesel engine holds a special place in the hearts of truck enthusiasts and heavy-duty workers alike. Renowned for its unparalleled durability, simplicity, and the ability to rack up hundreds of thousands of miles, this powerhouse defined an era of Ford trucks. From the rumble of its direct-injection turbo-diesel to its incredible towing capabilities, the 7.3L engine has earned its reputation as one of the most reliable and beloved diesel motors ever built. However, even legends require meticulous care, especially when it comes to critical engine components.

One of the most crucial aspects of maintaining or rebuilding a 7.3 Powerstroke, particularly after any work involving the cylinder heads, is adhering to precise torque specifications for 7.3 Powerstroke cylinder head bolts or studs. Neglecting these specifications can lead to catastrophic engine failure, ranging from blown head gaskets and coolant leaks to major internal damage. It’s not just about tightening bolts; it’s about achieving the perfect clamping force, distributing stress evenly, and ensuring the long-term integrity of your engine’s most vital seals.

This comprehensive guide dives deep into everything you need to know about 7.3 Powerstroke head bolt torque. We’ll explore why these specifications are so important, differentiate between OEM bolts and aftermarket ARP studs, detail the exact torque sequences and values, and provide invaluable tips to ensure your 7.3 Powerstroke continues to run strong for many more miles. Whether you’re a seasoned diesel mechanic or a dedicated DIYer, understanding and applying these precise 7.3 Powerstroke cylinder head torque specs is paramount for the health and performance of your iconic truck.

Quick Answers to Common Questions

Why are the torque specifications for 7.3 Powerstroke cylinder head so critical?

Getting the **torque specifications for 7.3 Powerstroke cylinder head** just right ensures an even clamping force across the head gasket, preventing leaks and catastrophic engine damage. It’s the foundation for a reliable and long-lasting repair.

Are the torque specifications for 7.3 Powerstroke cylinder head different if I’m using ARP studs?

Yes, absolutely! When upgrading to ARP studs instead of factory bolts, the **torque specifications for 7.3 Powerstroke cylinder head** will change, and you must always follow ARP’s specific recommendations for their hardware.

What happens if I over-torque or under-torque my 7.3 Powerstroke cylinder head bolts?

Incorrect torque can lead to serious issues; over-torquing can stretch bolts and damage threads, while under-torquing won’t provide enough clamping force, leading to head gasket failure and costly leaks. Precise **torque specifications for 7.3 Powerstroke cylinder head** are non-negotiable for reliability.

Do I need a specific tightening sequence for the 7.3 Powerstroke cylinder head bolts?

Definitely! A specific tightening sequence is crucial for evenly distributing the clamping force across the head gasket, preventing warpage. Following the manufacturer’s recommended pattern is just as important as hitting the correct **torque specifications for 7.3 Powerstroke cylinder head**.

Can I reuse my old 7.3 Powerstroke cylinder head bolts?

It’s strongly advised against reusing old 7.3 Powerstroke cylinder head bolts. They are typically “torque-to-yield” bolts, meaning they stretch when tightened and lose their ability to provide accurate clamping force if reused, making proper **torque specifications for 7.3 Powerstroke cylinder head** impossible to achieve. Always use new bolts or upgrade to ARP studs.

📋 Table of Contents

- Why Proper Torque Matters for Your 7.3 Powerstroke’s Longevity

- Understanding 7.3 Powerstroke Head Bolts: OEM vs. ARP Studs

- Essential Pre-Installation Steps and Preparation for 7.3 Head Torque

- The Definitive 7.3 Powerstroke Cylinder Head Torque Sequence and Specifications

- Common Pitfalls and Troubleshooting During 7.3 Powerstroke Head Installation

- Post-Installation Care and Long-Term Reliability for Your 7.3

- Conclusion

Why Proper Torque Matters for Your 7.3 Powerstroke’s Longevity

When you consider the immense pressures and temperatures generated within a diesel engine, especially one as powerful as the 7.3 Powerstroke, it becomes clear why every component must be installed with absolute precision. The cylinder head, which forms the top of the combustion chamber, is subjected to incredible forces during operation. Proper head bolt torque isn’t just a recommendation; it’s a fundamental requirement for engine survival and optimal performance.

Learn more about Torque specifications for 7.3 Powerstroke cylinder head – Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Image source: dieselpro.com

The primary purpose of tightening cylinder head bolts or studs to specific torque specifications for 7.3 Powerstroke cylinder head is to create a precise and even clamping force between the cylinder head, the head gasket, and the engine block. This clamping force is what seals the combustion chambers, preventing combustion gases, coolant, and oil from escaping. An evenly distributed clamping force ensures the head gasket can perform its job effectively across the entire surface area, without hot spots or areas of excessive stress.

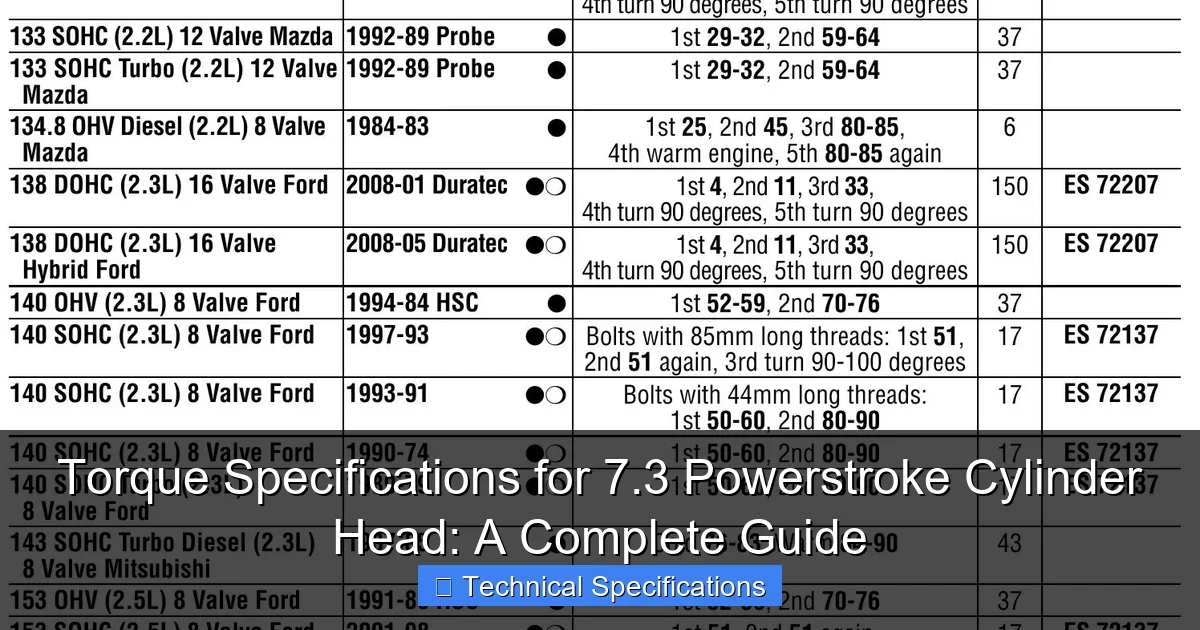

| Stage / Bolt Type | Torque (ft-lbs) | Torque (Nm) | Notes / Procedure |

|---|---|---|---|

| Cylinder Head Bolts | N/A | N/A | *Always replace Torque-to-Yield (TTY) bolts with new ones.* |

| Initial Torque (Stage 1) | 25 | 34 | Torque all bolts in the specified sequence (typically 1-26). |

| Final Torque Pass (Stage 2) | 65 | 88 | Torque all bolts again in the specified sequence. |

| Angle Torque (Stage 3) | +90° | +90° | Turn each bolt an additional 90 degrees (1/4 turn) in sequence. |

| Pre-Installation Notes | N/A | N/A | Ensure bolt holes and threads are clean, and apply a small amount of clean engine oil to bolt threads and under the bolt heads. |

Failure to adhere to the correct 7.3 Powerstroke head bolt torque can lead to a cascade of expensive and frustrating problems:

- Head Gasket Failure: This is arguably the most common and immediate consequence. Uneven or insufficient torque allows combustion gases to blow past the gasket, leading to coolant loss, overheating, decreased power, and internal engine damage.

- Coolant and Oil Leaks: Beyond the combustion chamber, the head gasket also seals critical coolant and oil passages. Incorrect torque can lead to external leaks that are not only messy but can also cause fluid starvation and severe engine damage if not addressed.

- Cylinder Head or Block Distortion: Over-torquing can permanently warp or crack the cylinder head or even the engine block itself, leading to costly repairs or even necessitating engine replacement. Under-torquing can also allow movement that causes wear and distortion over time.

- Reduced Engine Performance: Leaking combustion gases reduce cylinder compression, leading to a noticeable drop in power, increased fuel consumption, and rough idling.

- Bolt or Stud Failure: Over-torquing can stretch or snap head bolts/studs, requiring drilling and extraction, which is a time-consuming and often damaging process. Reusing torque-to-yield (TTY) bolts can also lead to failure as they are designed for a single stretch cycle.

In essence, applying the correct Powerstroke 7.3 head torque sequence and specifications is a preventative measure, safeguarding your engine against failures that stem from the core mechanical integrity of the cylinder head assembly. It’s an investment in the longevity and reliability that the 7.3 Powerstroke is famous for.

Understanding 7.3 Powerstroke Head Bolts: OEM vs. ARP Studs

Before you even begin the process of tightening, it’s crucial to understand the type of fasteners you’re working with. The choice between OEM bolts and aftermarket ARP studs significantly impacts the torque specifications for 7.3 Powerstroke cylinder head and the overall procedure.

Learn more about Torque specifications for 7.3 Powerstroke cylinder head – Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Image source: venturerider.org

OEM (Original Equipment Manufacturer) Head Bolts

From the factory, the 7.3 Powerstroke utilizes torque-to-yield (TTY) head bolts. These bolts are designed to be tightened to a specific initial torque, and then turned an additional number of degrees (e.g., two additional 90-degree turns). When tightened this way, the bolts are stretched beyond their elastic limit and into their plastic deformation range. This controlled stretching provides a very consistent clamping force, which is excellent for factory production.

However, TTY bolts have a critical drawback: they are designed for a single use. Once stretched, they lose their ability to provide the same consistent clamping force if reused. Attempting to re-torque a used TTY bolt is a recipe for disaster, as it can easily break or fail to provide adequate clamping. Therefore, if you’re reinstalling cylinder heads with OEM-style bolts, it is absolutely imperative to use a completely new set of bolts.

ARP (Automotive Racing Products) Head Studs

For many 7.3 Powerstroke owners, especially those running higher boost, making performance modifications, or simply seeking ultimate reliability, upgrading to ARP head studs 7.3 Powerstroke is a popular choice. ARP studs offer several advantages over OEM bolts:

- Superior Clamping Force: Studs generally provide a significantly higher and more consistent clamping force than bolts, which is crucial for preventing head lift and gasket failure, particularly under high cylinder pressures.

- Eliminates Torsional Stress: With bolts, the act of turning the bolt itself introduces torsional stress, which can affect the accuracy of the torque reading and the actual clamping force. Studs are simply threaded into the block, and the nuts are torqued down, eliminating this torsional stress and allowing for a more accurate and consistent clamp.

- Reusability: ARP studs are designed to be reusable (assuming they are not damaged) and do not stretch like TTY bolts. This makes future engine work easier and more cost-effective in the long run.

- Easier Assembly and Disassembly: Studs guide the cylinder head into place, simplifying installation.

The key takeaway here is that the 7.3 Powerstroke cylinder head torque specs for ARP studs are vastly different from OEM bolts. You cannot apply OEM torque specs to ARP studs or vice-versa. Always use the specific instructions and lubricant provided by ARP with their stud kits.

Essential Pre-Installation Steps and Preparation for 7.3 Head Torque

Achieving the correct torque specifications for 7.3 Powerstroke cylinder head is not just about turning a wrench; it’s about meticulous preparation. Skipping these crucial steps can lead to inaccurate torque readings, compromised sealing, and eventual failure. Think of these as the foundation upon which your engine’s reliability will be built.

1. Absolute Cleanliness is King

This cannot be stressed enough. Any debris, old gasket material, oil, or coolant on mating surfaces or in bolt holes can lead to inaccurate torque readings and an improper seal.

- Engine Block Deck: Ensure the block deck surface is spotlessly clean, flat, and free of any scratches or pitting. Use a soft scraper (plastic or brass) for gasket material, followed by a fine abrasive pad (e.g., Scotch-Brite) and solvent. Air blow all debris away.

- Cylinder Head Surfaces: The bottom surface of the cylinder head must also be perfectly clean and flat. If the heads have been resurfaced, ensure they are thoroughly cleaned to remove any machining residue.

- Bolt Holes in the Block: This is critical. Residual oil, coolant, or thread locker in the bolt holes can hydraulic and give false torque readings, or even crack the block. Use a thread chaser (not a tap, as a tap removes material) to clean out all bolt holes. Follow this by blowing compressed air into each hole to ensure it’s completely dry and clear. Protect your eyes!

2. Inspection and Verification

- Cylinder Head Flatness: Before installing, check your cylinder heads for warpage using a straight edge and feeler gauges. Even minor warpage can compromise the head gasket seal, regardless of perfect torque. If warped, have them machined or replace them.

- Block Flatness: While less common, the engine block deck can also warp. Check it with a straight edge if you suspect an issue.

- Head Gaskets: Always use new head gaskets. Ensure you have the correct left and right gaskets (if applicable) and that they are oriented correctly.

- New Fasteners: As mentioned, always use new OEM head bolts 7.3 Powerstroke if you’re using factory-style bolts. If using ARP studs, ensure you have the complete kit, including the correct nuts and washers.

3. Lubrication: The Unsung Hero

Proper lubrication of the bolt threads and under the head of the bolt/nut is absolutely crucial for accurate torque readings. Friction can drastically skew readings, meaning the desired clamping force isn’t achieved even if your torque wrench clicks.

- OEM Bolts: Typically, a light coating of clean engine oil on the bolt threads and under the head of the bolt is recommended. Consult your specific service manual for the exact lubricant type.

- ARP Studs: Always use the specialized ARP Moly Assembly Lubricant provided with their kits. This lubricant has a very low and consistent friction coefficient, which is critical for achieving the precise clamping force ARP specifies. Apply it to the stud threads that receive the nut and to both sides of the washers.

4. Tools of the Trade

- Calibrated Torque Wrench: This is non-negotiable. Use a high-quality torque wrench (clicker, beam, or digital). For TTY bolts, an angle meter is also essential for accurate degree turns. Ensure your wrench is calibrated and covers the required torque range.

- Sockets and Extensions: Use good quality, 6-point sockets that fit snugly. Avoid universal joints or long extensions that can flex and absorb torque, leading to inaccurate readings. If extensions are necessary, use sturdy, short ones.

By investing time and attention into these pre-installation steps, you lay the groundwork for a successful and long-lasting cylinder head installation, ensuring the integrity of your 7.3 Powerstroke cylinder head torque specs.

The Definitive 7.3 Powerstroke Cylinder Head Torque Sequence and Specifications

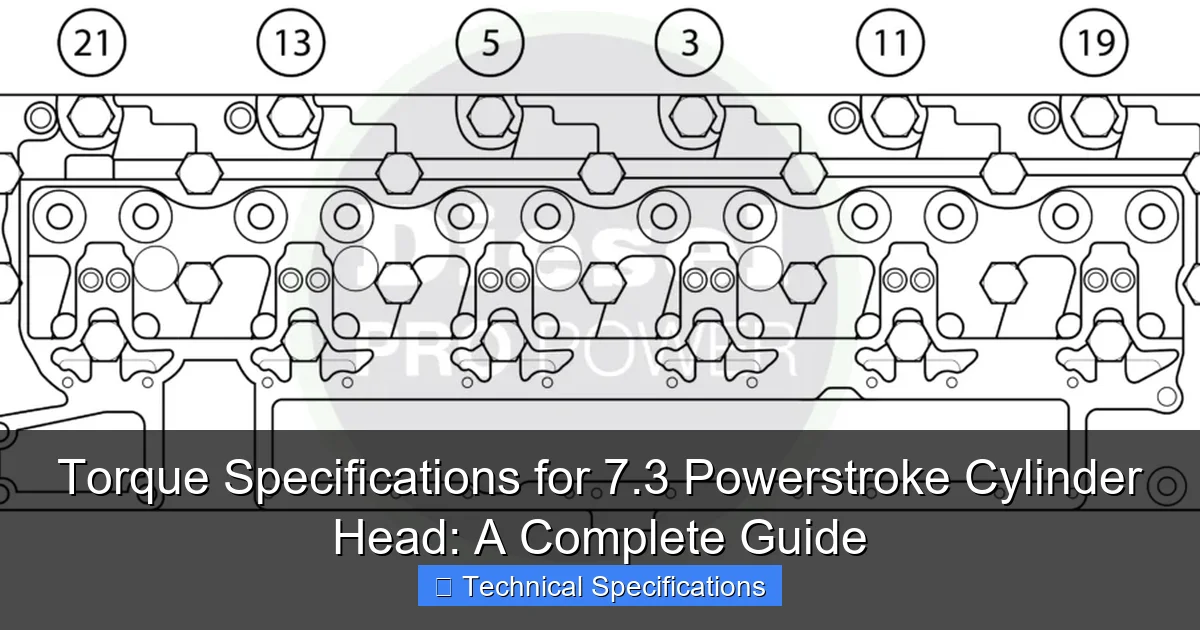

This is where the rubber meets the road. Following the correct Powerstroke 7.3 head torque sequence and applying the precise torque specifications for 7.3 Powerstroke cylinder head is critical. The sequence ensures that the clamping force is applied gradually and evenly across the cylinder head, preventing warping and creating a perfect seal. Always work from the center outwards, gradually moving towards the ends of the head.

General Torque Sequence Pattern (for both OEM bolts and ARP studs):

- Start with the innermost bolts/studs (typically 2-4).

- Work your way outwards in a spiral or cross-hatch pattern.

- Finish with the outermost bolts/studs.

A typical 7.3 Powerstroke cylinder head bolt pattern involves 18 bolts per head. You’ll generally start in the middle, then move to the middle outer, then middle inner, and so on. Always refer to a diagram in a reputable service manual for the exact numbered sequence.

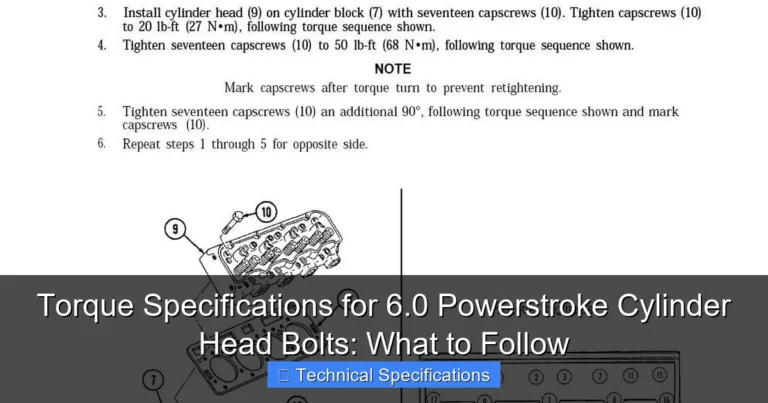

OEM 7.3 Powerstroke Head Bolt Torque Specifications (Torque-to-Yield)

These specifications are for new, OEM-style torque-to-yield bolts. **Never reuse TTY bolts.** Use a high-quality angle meter for the degree turns, as these are critical for achieving the correct stretch and clamping force.

Lubricant: Light coating of clean engine oil on threads and under bolt heads.

| Stage | Specification (per bolt/stud) | Notes |

|---|---|---|

| Stage 1 | 65 ft-lbs (88 Nm) | Torque all bolts in the specified sequence to this value. |

| Stage 2 | Turn an additional 90 degrees | Using an angle meter, turn each bolt an additional 90 degrees in the specified sequence. |

| Stage 3 | Turn an additional 90 degrees | Using an angle meter, turn each bolt an additional 90 degrees in the specified sequence. |

Important Note: Some earlier 7.3L engines (specifically some 1994-1997 models) might have slightly different initial torque specs, though the angle turns are generally consistent. Always consult the specific Ford workshop manual for your vehicle’s year and model to confirm the exact 7.3 Powerstroke head bolt torque. Allow for a short pause (5-10 minutes) between stages to allow the gasket and materials to settle, though this isn’t always explicitly stated by Ford, it’s good practice.

ARP 7.3 Powerstroke Head Stud Torque Specifications

These specifications are for ARP head studs 7.3 Powerstroke kits. The key to accurate torque with ARP studs is using their provided ARP Moly Assembly Lubricant.

Lubricant: ARP Moly Assembly Lubricant on stud threads (that receive the nut) and on both sides of the washers.

| Stage | Specification (per stud) | Notes |

|---|---|---|

| Stage 1 | 70 ft-lbs (95 Nm) | Torque all nuts in the specified sequence to this value. |

| Stage 2 | 100 ft-lbs (136 Nm) | Torque all nuts in the specified sequence to this value. |

| Stage 3 | 125 ft-lbs (170 Nm) | Torque all nuts in the specified sequence to this final value. |

Critical ARP Notes:

- ARP Moly Lube is Non-Negotiable: Do NOT substitute engine oil or other lubricants. ARP’s torque specs are calibrated specifically for the low friction coefficient of their moly lube. Using anything else will result in significantly different and inaccurate clamping forces.

- Follow ARP’s Instructions: Always refer to the specific instructions included with your ARP head stud kit, as specifications can vary slightly based on stud material, diameter, or specific design changes.

- Three Passes: The three-stage torque procedure ensures even loading and allows the studs to settle.

Regardless of whether you use OEM bolts or ARP studs, patience and precision are your best allies. Double-check your work, ensure your tools are accurate, and follow the sequence religiously. This dedication to detail ensures your 7.3 Powerstroke cylinder head torque specs are met, leading to a long-lasting and reliable repair.

Common Pitfalls and Troubleshooting During 7.3 Powerstroke Head Installation

Even with the best intentions, mistakes can happen during cylinder head installation. Being aware of common pitfalls and knowing how to troubleshoot them can save you significant time, money, and frustration. Precision in applying torque specifications for 7.3 Powerstroke cylinder head is key, but several factors can undermine even the most careful effort.

1. Dirty or Damaged Bolt Holes

- Pitfall: Bolt holes in the engine block that contain old oil, coolant, thread locker residue, or damaged threads.

- Consequence: False torque readings (bolt binds before achieving proper clamping force), stripped threads, cracked block, or insufficient clamping.

- Troubleshooting/Prevention: Always chase all bolt holes with a thread chaser (not a tap) and blow them out with compressed air until perfectly clean and dry. Inspect threads for damage. If threads are stripped, a Time-Sert or Helicoil repair might be necessary.

2. Incorrect Lubrication

- Pitfall: Using the wrong type or amount of lubricant on threads and under bolt heads/nuts (e.g., using engine oil with ARP studs, or no lubricant at all).

- Consequence: Highly inaccurate torque readings, leading to either over- or under-torquing, and thus improper clamping force.

- Troubleshooting/Prevention: Strictly follow the lubricant recommendations for your fasteners. Use ARP Moly Lube for ARP studs. Use clean engine oil for OEM bolts (unless otherwise specified by Ford). Apply a thin, even coat.

3. Reusing Torque-to-Yield (TTY) Bolts

- Pitfall: Attempting to reuse OEM 7.3 Powerstroke head bolts.

- Consequence: TTY bolts are designed to stretch plastically during their first use. Reusing them means they have already yielded, cannot achieve proper clamping force again, and are highly prone to breaking during torquing or shortly after engine operation.

- Troubleshooting/Prevention: Always, without exception, use new OEM head bolts when reassembling the cylinder heads with factory-style fasteners. This is a non-negotiable step for reliability.

4. Incorrect Torque Wrench Usage or Calibration

- Pitfall: Using an uncalibrated torque wrench, an inappropriate type of torque wrench for the task, or incorrect technique.

- Consequence: Inaccurate torque values, leading to over or under-torquing, and ultimately, head gasket failure or fastener damage.

- Troubleshooting/Prevention: Invest in a quality, calibrated torque wrench. For TTY bolts, an angle meter is crucial. Pull the torque wrench smoothly and consistently; avoid jerky movements. Do not use a torque wrench to loosen bolts. Have your torque wrench checked for calibration periodically.

5. Not Following the Sequence

- Pitfall: Torquing bolts randomly or not adhering strictly to the center-outwards, multi-stage Powerstroke 7.3 head torque sequence.

- Consequence: Uneven clamping force, leading to head warpage, head gasket hot spots, and premature failure.

- Troubleshooting/Prevention: Always follow the specified sequence religiously for each stage of torquing. Use a diagram to mark off each bolt as you complete it. Patience and methodical work are key here.

6. Foreign Material on Mating Surfaces

- Pitfall: Gasket material, dirt, or debris left on the engine block deck or cylinder head mating surfaces.

- Consequence: Prevents the head gasket from seating properly, leading to leaks, blow-by, and gasket failure even with correct torque.

- Troubleshooting/Prevention: Thoroughly clean all mating surfaces until pristine. Use appropriate cleaning tools and solvents, and air-blow away all residue.

By being mindful of these common issues and implementing the preventive measures, you significantly increase the chances of a successful and leak-free cylinder head installation, ensuring your 7.3 Powerstroke cylinder head torque specs translate into long-term engine reliability.

Post-Installation Care and Long-Term Reliability for Your 7.3

Once you’ve meticulously followed the torque specifications for 7.3 Powerstroke cylinder head and completed the installation, your work isn’t quite done. Proper post-installation care and attention to detail are vital to ensure the longevity and reliability of your newly assembled engine. This final phase consolidates all your hard work and allows your 7.3 Powerstroke to perform at its best for years to come.

1. Initial Fluid Fills and System Checks

- Coolant System: Refill the coolant system with the specified coolant (typically a diesel-rated ELC – Extended Life Coolant). Bleed the system thoroughly to remove any trapped air, which can cause overheating and compromise head gasket integrity. Run the engine with the heater on high, allow it to reach operating temperature, and top off the coolant as needed.

- Oil: Ensure engine oil is at the correct level. Check for any leaks immediately after the first start-up.

- Fuel System: Bleed the fuel system if necessary to ensure easy starting and smooth operation.

2. Engine Break-in (Post-Rebuild)

If you’ve performed a significant rebuild, including cylinder head work, a proper break-in procedure is beneficial:

- First Start: Monitor oil pressure, coolant temperature, and listen for any unusual noises. Address any immediate issues.

- Initial Run Cycle: Drive the truck gently for the first 50-100 miles, avoiding heavy loads, wide-open throttle, or sustained high RPMs. This allows the new head gasket to fully seat and compress under heat and pressure.

- Vary RPMs: During this period, vary the engine RPMs rather than maintaining a constant speed. This helps with proper seating of all new components.

3. Monitoring and Inspection

- Regular Checks: For the first few hundred miles, frequently check coolant levels, oil levels, and look for any signs of leaks around the cylinder heads. A slight drop in coolant level during the first few drive cycles is normal as air pockets work their way out and the gasket fully compresses.

- Temperature Gauge: Pay close attention to your engine’s temperature gauge. Any unusual spikes could indicate an issue.

- Performance: Note any changes in engine performance, idle quality, or exhaust smoke. These can be early indicators of problems.

4. Re-torquing: When is it Necessary?

- OEM TTY Bolts: Generally, re-torquing is NOT recommended for OEM 7.3 Powerstroke head bolts after their initial installation. TTY bolts are stretched into their plastic range and re-torquing can lead to overstretching, weakening, or breakage.

- ARP Head Studs: While ARP studs are far more robust, ARP generally states that if the initial installation was performed correctly with their moly lube and specified torque, re-torquing after a heat cycle is not typically required. However, some experienced builders may opt for a light re-check after a few heat cycles, especially in high-performance applications, just to ensure everything is settled. If you do re-torque studs, perform it carefully and follow the previous sequence.

5. Long-Term Maintenance

Continue to follow your 7.3 Powerstroke’s regular maintenance schedule, including:

- Regular oil and filter changes.

- Coolant system flushes and inspections.

- Monitoring for any unusual noises or fluid consumption.

By diligently adhering to these post-installation procedures, you ensure that the effort put into correctly applying the 7.3 Powerstroke cylinder head torque specs translates into years of trouble-free operation. Your 7.3 Powerstroke is a workhorse, and with proper care, it will continue to live up to its legendary status.

Conclusion

The 7.3 Powerstroke diesel engine remains a testament to robust engineering, but its longevity and legendary reliability are not achieved by chance. They are the result of meticulous maintenance, quality parts, and precise assembly, particularly when it comes to the heart of the engine: the cylinder heads. Understanding and rigorously applying the correct torque specifications for 7.3 Powerstroke cylinder head bolts or studs is paramount for anyone working on this iconic engine.

We’ve explored the critical “why” behind proper torque, highlighting how it safeguards against common failures like head gasket leaks and ensures the even distribution of clamping force. We delved into the distinct requirements of OEM torque-to-yield bolts versus the superior clamping and reusability of ARP head studs 7.3 Powerstroke, emphasizing that their respective 7.3 Powerstroke cylinder head torque specs are not interchangeable. The detailed pre-installation steps, from absolute cleanliness to correct lubrication and tool selection, form the bedrock of a successful installation.

The definitive Powerstroke 7.3 head torque sequence and the precise, multi-stage torque values for both OEM bolts and ARP studs, complete with their specific lubricants, are the blueprint for preventing costly engine damage. Furthermore, anticipating common pitfalls and committing to diligent post-installation care will ensure your efforts culminate in a dependable, high-performing 7.3 Powerstroke that continues to turn heads and tackle tough jobs for years to come.

Ultimately, whether you’re performing a full rebuild or simply addressing a head gasket issue, your attention to these crucial 7.3 Powerstroke head bolt torque details will dictate the success and longevity of your repair. Invest in the right tools, follow the instructions meticulously, and never compromise on quality. Your 7.3 Powerstroke deserves nothing less to maintain its legendary status.

🎥 Related Video: 7.3 powerstroke cylinder head installation tips and tricks

📺 Barrett Reece

powerstroke head install.

Frequently Asked Questions

What are the correct torque specifications for the 7.3 Powerstroke cylinder head bolts?

The standard torque specifications for the 7.3 Powerstroke cylinder head typically involve a multi-stage process to ensure even clamping force. This usually begins with torquing all bolts to a specific foot-pound value (e.g., 65 ft-lbs), followed by an additional angular turn (e.g., 90 degrees) or a second foot-pound stage. Always refer to your specific year’s service manual for the most accurate and up-to-date figures.

Is there a specific torque sequence for installing the 7.3 Powerstroke cylinder head?

Yes, following a precise torque sequence is crucial for properly seating the 7.3 Powerstroke cylinder head and preventing warpage or gasket leaks. The sequence generally involves starting from the center bolts and working outwards in a spiral or cross-hatch pattern. This method distributes the clamping load evenly across the head surface.

Should I replace the cylinder head bolts when working on a 7.3 Powerstroke engine?

Absolutely, it is highly recommended to replace the cylinder head bolts with new ones whenever you remove and reinstall the 7.3 Powerstroke cylinder head. Many modern engines, including the Powerstroke, use “torque-to-yield” or “stretch-to-yield” bolts which are designed to stretch permanently upon initial torquing. Reusing old bolts significantly increases the risk of head gasket failure, insufficient clamping force, or even bolt breakage.

What happens if the 7.3 Powerstroke cylinder head bolts are not torqued correctly?

Improperly torqued 7.3 Powerstroke cylinder head bolts can lead to severe engine problems. Under-torquing can cause head gasket leaks, coolant or oil loss, and reduced engine compression, while over-torquing can stretch or break the bolts, damage the cylinder head or block threads, and potentially warp the cylinder head itself. Adhering to the factory specifications is critical for engine integrity.

Do all 7.3 Powerstroke engines use the same cylinder head torque specifications across all years?

While the core torque specifications for the 7.3 Powerstroke cylinder head are largely consistent across its production run, it’s always best to verify with the specific service manual for your truck’s exact year and model. Minor variations or updated procedures could exist. Consulting the correct manual ensures you’re applying the most accurate specifications for your engine.

What type of torque wrench is recommended for torquing 7.3 Powerstroke cylinder head bolts?

For torquing 7.3 Powerstroke cylinder head bolts, a high-quality, calibrated click-type or beam-type torque wrench capable of measuring the specified foot-pound values is essential. If the procedure includes an angular turn after the initial foot-pound torque, you will also need an angle torque gauge. Ensure your torque wrench covers the required range and is accurate to prevent errors.