Symptoms of a Bad Solenoid

As a vital component in many systems, a solenoid plays a crucial role in the operation of various mechanical and electrical systems. From automotive engines to industrial machinery, a solenoid is responsible for controlling the flow of fluids, gases, and electrical currents. When a solenoid malfunctions, it can lead to significant issues and potentially costly repairs. Understanding the symptoms of a bad solenoid can help identify and address potential problems before they escalate.

What is a Solenoid?

Before we delve into the symptoms of a bad solenoid, let’s first understand what a solenoid is and how it works. A solenoid is an electromechanical device that consists of a coil of wire wrapped around a magnetic core. When an electrical current is passed through the coil, it creates a magnetic field that moves a plunger or valve within the solenoid. This movement controls the flow of fluid or electricity within the system, allowing for precise and efficient operation.

Common Symptoms of a Bad Solenoid

Identifying the symptoms of a bad solenoid early on can prevent further damage to your machinery or system. Here are some common signs that indicate a potential issue with a solenoid:

| Symptom | Description |

|---|---|

| 1. Engine Starting Issues | When a solenoid in a vehicle’s starter system fails, it can result in difficulty starting the engine or intermittent starting problems. |

| 2. Irregular Shifting in Automatic Transmissions | In automobiles, a faulty transmission solenoid can cause erratic shifting, delayed gear engagement, or failure to shift into specific gears. |

| 3. Clicking or Grinding Noises | A clicking or grinding noise during the operation of a solenoid-controlled system may indicate a problem with the solenoid itself or its associated components. |

| 4. Inconsistent Operation of Hydraulic Systems | For industrial machinery and equipment that rely on hydraulic solenoids, irregular or jerky movement can signal a malfunctioning solenoid. |

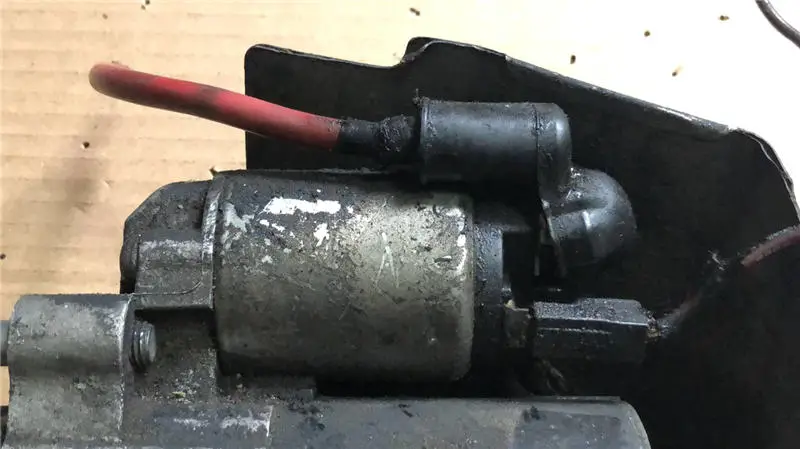

Credit: m.youtube.com

Additional Signs of Solenoid Troubles

While the aforementioned symptoms are common indicators of a bad solenoid, there are additional signs to watch out for:

- Diminished performance or operation of the system controlled by the solenoid.

- Warning lights or error codes on the dashboard or control panel of your equipment or vehicle.

- Burnt or melted electrical connections near the solenoid, suggesting an electrical fault.

What Causes Solenoid Failure?

Understanding the potential causes of solenoid failure can aid in preventative maintenance and troubleshooting. Some common reasons for solenoid problems include:

- Excessive wear and tear over time due to frequent use.

- Dirt, debris, or contaminants affecting the solenoid’s operation and performance.

- Electrical issues such as short circuits, loose connections, or voltage spikes.

- Mechanical damage from impacts, vibration, or improper installation.

Addressing Solenoid Issues

When experiencing symptoms of a bad solenoid, it’s essential to address the issue promptly to prevent further complications. Depending on the severity of the problem, solutions may range from simple maintenance tasks to component replacement. It’s advisable to consult with a qualified technician or mechanic to diagnose and resolve solenoid-related issues effectively.

Frequently Asked Questions On Symptoms Of A Bad Solenoid

What Are The Common Symptoms Of A Bad Solenoid?

A bad solenoid may cause starting issues, clicks, or stalling of the vehicle.

Why Does A Bad Solenoid Cause Starting Problems?

A deteriorated solenoid may fail to transmit electrical currents, resulting in starting issues.

How Can I Diagnose A Faulty Solenoid?

Use a multimeter to test the solenoid’s resistance and continuity to determine its condition.

Can A Bad Solenoid Affect Other Vehicle Components?

Yes, a malfunctioning solenoid can impact the proper functioning of the starter, causing related issues.

Conclusion

Awareness of the symptoms of a bad solenoid is crucial for maintaining the proper functioning of various systems and equipment. Regular inspection and maintenance can help identify solenoid issues early on and prevent costly repairs or downtime. By understanding the signs of a malfunctioning solenoid and addressing issues promptly, you can ensure the reliability and efficiency of your machinery and systems.