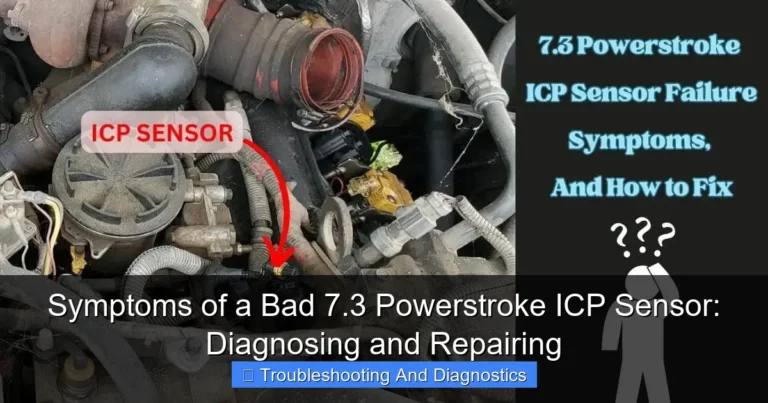

Symptoms of a Bad 7.3 Powerstroke IPR Valve: Diagnosis and Solutions

Featured image for this comprehensive guide about Symptoms of a bad 7.3 Powerstroke IPR valve

Image source: motoraudit.com

The legendary 7.3 Powerstroke engine, a true workhorse celebrated for its robust design and incredible longevity, has powered countless Ford trucks for millions of miles. Many owners attest to its bulletproof nature, yet even the toughest machines have their Achilles’ heel. One critical component that often goes overlooked until trouble strikes is the IPR (Injector Pressure Regulator) valve. This unassuming part plays a pivotal role in your engine’s ability to start, idle smoothly, and deliver power efficiently.

When your trusty 7.3 Powerstroke IPR valve starts to falter, it can manifest in a frustrating array of symptoms, ranging from minor annoyances to complete engine shutdown. Diagnosing a failing IPR valve can be a perplexing task, as its symptoms often mimic those of other high-pressure oil system components. However, understanding the tell-tale signs and having a systematic diagnostic approach can save you significant time, money, and headaches. This comprehensive guide will arm you with the knowledge to identify a bad 7.3 Powerstroke IPR valve, differentiate its symptoms from other issues, and outline effective solutions to get your truck back to peak performance.

Whether you’re a seasoned diesel mechanic or a proud 7.3 Powerstroke owner looking to tackle repairs yourself, recognizing the early warnings of a problematic IPR valve is key. Let’s dive deep into the world of this vital component, uncovering its secrets and empowering you to diagnose and address any issues head-on.

Quick Answers to Common Questions

What’s the most common sign of a bad 7.3 Powerstroke IPR valve?

Hard starting, especially when the engine is hot, is a classic giveaway that your 7.3 Powerstroke IPR valve might be failing. You might also experience a “crank no start” condition.

Can a failing IPR valve cause my 7.3 Powerstroke to stall?

Absolutely! A faulty 7.3 Powerstroke IPR valve can lead to erratic high-pressure oil control, causing rough idling and even stalling, particularly at stop lights or low speeds.

Will a bad 7.3 Powerstroke IPR valve affect my engine’s power?

Yes, you’ll likely notice a significant loss of power or reduced acceleration. The engine struggles to maintain proper oil pressure for the injectors, leading to poor performance from a bad 7.3 Powerstroke IPR valve.

What kind of check engine light codes might I see with a bad IPR valve?

When your 7.3 Powerstroke IPR valve is acting up, common diagnostic trouble codes like P1211 (ICP Actual vs. Desired) or P1212 (ICP Lower Than Desired) often appear. These indicate issues with your high-pressure oil system.

Could a bad 7.3 Powerstroke IPR valve cause excessive smoke?

While not always the primary symptom, a failing 7.3 Powerstroke IPR valve can contribute to excessive white or gray smoke from the exhaust, especially during cold starts or under acceleration, due to incomplete fuel combustion.

📋 Table of Contents

- Understanding the IPR Valve’s Role in Your 7.3 Powerstroke

- Key Symptoms of a Failing 7.3 Powerstroke IPR Valve

- Distinguishing IPR Valve Issues from Other 7.3 Powerstroke Problems

- Diagnosing a Faulty 7.3 Powerstroke IPR Valve: Step-by-Step

- Solutions: Replacing Your 7.3 Powerstroke IPR Valve

- Conclusion: Empowering Your 7.3 Powerstroke’s Longevity

Understanding the IPR Valve’s Role in Your 7.3 Powerstroke

Before we delve into symptoms, it’s crucial to grasp what the IPR valve does and why it’s so vital for your 7.3 Powerstroke. The IPR valve is a solenoid-controlled valve located on the High-Pressure Oil Pump (HPOP). Its primary function is to regulate the oil pressure within the high-pressure oil system, which is essential for actuating the fuel injectors. Unlike traditional gasoline engines, your 7.3 Powerstroke uses high-pressure engine oil, not just fuel pressure, to fire the injectors.

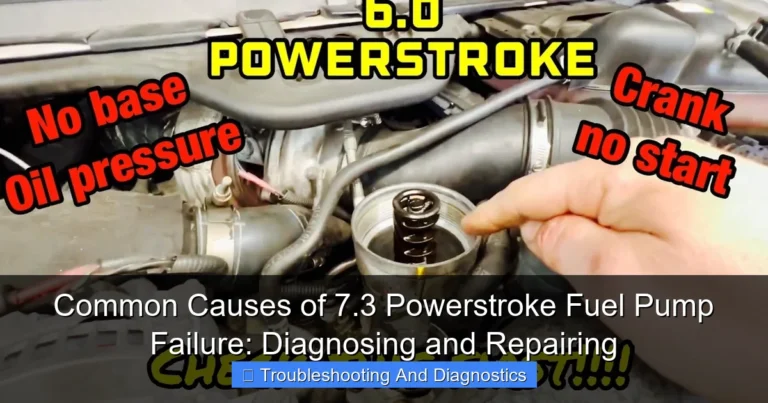

Learn more about Symptoms of a bad 7.3 Powerstroke IPR valve – Symptoms of a Bad 7.3 Powerstroke IPR Valve: Diagnosis and Solutions

Image source: i.ytimg.com

Here’s how it generally works: The HPOP draws oil from the engine’s crankcase and pressurizes it. The IPR valve, controlled by the Powertrain Control Module (PCM), modulates this pressure by opening and closing to allow excess oil to drain back to the crankcase. This precise control ensures the optimal oil pressure (ICP – Injector Control Pressure) required by the injectors for proper fuel atomization and combustion. If the 7.3 Powerstroke IPR valve can’t maintain the correct pressure, your engine simply won’t run efficiently, or in some cases, won’t run at all.

| Symptom | Description / Observation | IPR Valve Impact / Diagnostic Clue |

|---|---|---|

| Hard Start / No Start (Hot) | Engine cranks excessively before starting, or fails to start. Often more severe after the engine reaches operating temperature and then sits for a short period. | Internal leakage in the IPR valve prevents sufficient high-pressure oil (HPO) buildup (<500 PSI) for injector firing, especially when hot oil is thinner. Monitor IPR % duty cycle and HPOP pressure during cranking. |

| Rough Idle / Stalling | Engine runs erratically at idle, shudders, or frequently stalls after starting or coming to a stop. | Intermittent control or sticking of the IPR valve can cause HPO pressure fluctuations. An IPR duty cycle that fluctuates erratically at idle (not stable ~10-15% warm) is a strong indicator. |

| Lack of Power / Hesitation | Engine feels sluggish under acceleration, struggles to maintain speed, or experiences noticeable hesitation during throttle input. | A partially stuck or malfunctioning IPR valve fails to maintain commanded HPO pressure for optimal injector operation, leading to a “defueling” effect. Compare commanded vs. actual HPOP pressure during load. |

| Check Engine Light (CEL) / DTCs | Illumination of the CEL. Common codes: P1211 (ICP Actual vs. Desired Difference), P1212 (ICP Volts Too Low), P1280 (ICP Sensor Out of Range Low). | These codes indicate a problem with the high-pressure oil system. While the ICP sensor can be at fault, these often point to the IPR valve failing to regulate/maintain the commanded ICP. |

| Oil in IPR Connector / Visible Leak | Engine oil found inside the electrical connector for the IPR valve, or visible oil leaks around the IPR valve body. | Degraded internal O-rings or seals allow oil to wick into the electrical connector, causing intermittent signals, or external leaks. A visual inspection and cleaning may temporarily help but replacement is usually necessary. |

Think of the IPR valve as the gatekeeper of your engine’s high-pressure oil system. It’s constantly adjusting to maintain the precise pressure needed for the injectors to fire correctly across all engine speeds and loads. Given its critical role in the heart of your engine’s operation, it’s no wonder that a failing 7.3 Powerstroke IPR valve can lead to such a wide range of debilitating problems.

Key Symptoms of a Failing 7.3 Powerstroke IPR Valve

A failing 7.3 Powerstroke IPR valve can manifest in a variety of ways, some subtle and others quite dramatic. Recognizing these symptoms early can help prevent further damage and costly repairs. Here are the most common indicators that your IPR valve might be on its way out:

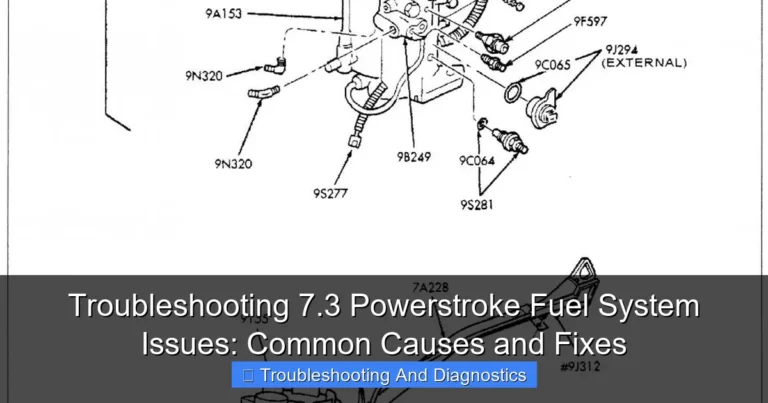

Learn more about Symptoms of a bad 7.3 Powerstroke IPR valve – Symptoms of a Bad 7.3 Powerstroke IPR Valve: Diagnosis and Solutions

Image source: i.ytimg.com

Hard Starts, No Starts, or Extended Cranking

One of the most frustrating and common symptoms of a bad 7.3 Powerstroke IPR valve is difficulty starting the engine. If your truck cranks for an unusually long time before firing up, or if it refuses to start altogether, a faulty IPR valve is a prime suspect. For the engine to start, the PCM needs to see approximately 500 PSI of injector control pressure. If the IPR valve is stuck open, or cannot build and maintain this pressure due to internal wear or debris, the engine won’t start. This symptom is often more pronounced when the engine is warm, as hot oil is thinner and can leak past a worn IPR valve more easily.

Rough Idle and Stalling

Once started, if your 7.3 Powerstroke idles roughly, shakes, or even stalls, the IPR valve could be at fault. The PCM constantly adjusts the IPR duty cycle to maintain a steady ICP at idle. A malfunctioning IPR valve might struggle to hold this consistent pressure, leading to an erratic idle as the injectors receive fluctuating oil pressure. In severe cases, the pressure may drop so low that the engine simply shuts off, especially after coming to a stop or during deceleration.

Reduced Power and Acceleration

A common complaint among owners with a failing 7.3 Powerstroke IPR valve is a noticeable drop in power and sluggish acceleration. When you press the accelerator, the engine requires a rapid increase in injector control pressure to inject more fuel and produce more power. If the IPR valve can’t respond quickly enough or maintain the necessary high pressure, your engine will feel “flat,” lacking its usual responsiveness and grunt. You might experience a significant loss of towing capacity or struggle to maintain speed on inclines.

Engine Misfires or Hesitation

When the high-pressure oil system isn’t delivering consistent pressure to all injectors, individual cylinders can misfire. This can feel like a stutter, stumble, or hesitation, especially under load. A bad 7.3 Powerstroke IPR valve can lead to these inconsistencies, causing the engine to run roughly or feel like it’s “missing” at various RPMs. These misfires can sometimes trigger a Check Engine Light and related Diagnostic Trouble Codes (DTCs).

Poor Fuel Economy

While not always the most obvious symptom, a failing IPR valve can indirectly impact your fuel economy. When the engine isn’t receiving the optimal injector control pressure, the PCM may try to compensate in various ways, potentially leading to less efficient fuel injection. Additionally, rough running conditions, misfires, and reduced power all contribute to the engine working harder than it should, consuming more fuel in the process. If you notice a sudden, unexplained drop in MPG, it’s worth considering the 7.3 Powerstroke IPR valve as a possible culprit.

Diagnostic Trouble Codes (DTCs)

The PCM is designed to monitor critical engine parameters, and when something goes awry, it often stores a DTC and illuminates the Check Engine Light. For a faulty 7.3 Powerstroke IPR valve, you might encounter codes related to the high-pressure oil system. Common codes include:

- P1211: ICP (Injector Control Pressure) higher/lower than desired (Engine running)

- P1212: ICP (Injector Control Pressure) sensor low input

- P1280: ICP sensor out of range low

- P1281: ICP sensor out of range high

- P1282: Excessive ICP

While these codes often point to an ICP sensor issue, a failing 7.3 Powerstroke IPR valve is frequently the underlying cause of incorrect ICP readings. The PCM commands the IPR valve, and if the actual pressure doesn’t match the commanded pressure, it flags a problem. Always treat these codes as a strong indicator to investigate the entire high-pressure oil system, including the IPR valve.

Distinguishing IPR Valve Issues from Other 7.3 Powerstroke Problems

Diagnosing problems in the 7.3 Powerstroke can be tricky because many components within the high-pressure oil system can exhibit similar symptoms. It’s crucial to differentiate a failing IPR valve from other common culprits:

- ICP Sensor (Injector Control Pressure Sensor): The ICP sensor directly measures the high-pressure oil in the system. A faulty ICP sensor can send incorrect readings to the PCM, leading to commanded IPR duty cycles that don’t match the actual pressure. Symptoms can be identical to a bad IPR valve (hard starts, rough idle, stalling). Often, the best way to rule out the ICP sensor is to unplug it. If the truck starts or runs better with the ICP unplugged (the PCM will then use a default value), the ICP sensor is likely faulty. If there’s no change, the IPR valve or HPOP is more likely.

- High-Pressure Oil Pump (HPOP): The HPOP is the heart of the system, responsible for generating the high pressure. If the HPOP itself is worn or failing, it simply can’t produce enough pressure, regardless of the IPR valve’s condition. Symptoms mirror IPR valve issues (no start, low power). HPOP failure often presents with a noticeable decrease in pressure readings across the board when monitored with a scan tool.

- Camshaft Position Sensor (CPS): A failing CPS can cause intermittent stalling, hard starting, or no-start conditions, as the PCM loses engine position information. However, CPS issues rarely present with rough idling or low power once the engine is running.

- Fuel Delivery Issues: Low fuel pressure from a faulty fuel pump or clogged fuel filter can cause similar performance issues like misfires, low power, and hard starts. Always ensure your fuel pressure is within specification (typically 45-70 PSI at idle) before diving deep into the high-pressure oil system.

- Injector O-rings or Internal Leaks: Worn injector O-rings or internal injector leaks can cause high-pressure oil to escape, leading to a loss of ICP. This will often present similarly to an IPR valve issue, with hard starts (especially warm), rough idle, and low power. A “bubble test” using compressed air can sometimes help identify these leaks.

Because of these overlaps, simply replacing parts based on symptoms is often an expensive guessing game. A systematic diagnostic approach is essential.

Diagnosing a Faulty 7.3 Powerstroke IPR Valve: Step-by-Step

Accurately diagnosing a faulty 7.3 Powerstroke IPR valve requires more than just listening for symptoms. You’ll need a combination of visual inspection, specialized tools, and a good understanding of the system.

Visual Inspection

Start with the basics. The IPR valve is located at the front of the HPOP, usually on the passenger side of the engine. It’s often difficult to see without removing some components, but you might be able to spot obvious issues:

- Wiring Harness: Check the electrical connector for the IPR valve. Look for any signs of corrosion, frayed wires, or a loose connection. A poor electrical connection can mimic a failing valve.

- Oil Leaks: While not common directly from the IPR valve itself, excessive oil leaks in the valley of the engine can sometimes indicate a high-pressure oil system leak, which could indirectly affect the IPR valve’s ability to maintain pressure.

Using a Scan Tool (Monitoring ICP and IPR Duty Cycle)

This is arguably the most crucial diagnostic step. A good scan tool (such as Forscan, AutoEnginuity, or a high-end professional scanner) allows you to monitor live data from your 7.3 Powerstroke‘s PCM:

- Monitor ICP (Injector Control Pressure): With the engine cranking (but not starting) or idling, observe the ICP reading. You should see a minimum of around 500 PSI during cranking for the engine to fire. At idle, ICP typically ranges from 500-750 PSI, increasing with RPM. If ICP is consistently low, fluctuating wildly, or won’t build at all, it indicates a problem in the high-pressure oil system (IPR, HPOP, or leaks).

- Monitor IPR Duty Cycle: The IPR duty cycle is the percentage of time the PCM is commanding the IPR valve open. At idle, it typically hovers around 8-15%. During cranking, it will usually jump to 65% or higher to try and build pressure. If you see a high IPR duty cycle (e.g., 65%+) but low ICP (under 500 PSI during cranking, or under 500 PSI at idle), it suggests a major leak in the high-pressure oil system or a failed IPR valve that cannot maintain pressure. Conversely, if the IPR duty cycle is low but ICP is also low, the PCM might not be commanding enough pressure, or the IPR valve is stuck closed (less common).

Comparing commanded ICP with actual ICP, and correlating with IPR duty cycle, provides a powerful diagnostic picture. If the PCM commands an IPR duty cycle, but the ICP doesn’t respond as expected, the 7.3 Powerstroke IPR valve is a prime suspect.

Electrical Testing (Resistance and Voltage)

You can test the electrical integrity of the IPR valve‘s solenoid:

- Resistance Test: Disconnect the IPR valve’s electrical connector. Using a multimeter, measure the resistance across the two pins on the IPR valve itself. A healthy IPR valve typically reads between 10.2 and 10.8 ohms at room temperature (values can vary slightly by manufacturer, but should be within this ballpark). If the resistance is extremely high (open circuit) or extremely low (short circuit), the solenoid is bad.

- Voltage Test: With the key ON (engine OFF), measure the voltage between the IPR valve’s supply wire (typically the red wire with a green stripe) and ground. You should see battery voltage (around 12V). This confirms the PCM is providing power to the valve. The other wire (typically a brown wire with a white stripe) is the control wire from the PCM, which pulses ground to operate the valve.

These electrical tests help rule out issues with the IPR valve’s internal solenoid or the truck’s wiring harness.

The “Stall Test” (Advanced)

For some cases of low power, a stall test can be performed (with caution!). This involves monitoring ICP and IPR duty cycle under full load (e.g., foot on the brake, transmission in drive, accelerating to stall speed). A healthy 7.3 Powerstroke should build significant ICP (e.g., 2500-3000 PSI) with a high IPR duty cycle. If pressure remains low despite a high IPR duty cycle, it further points to an HPOP issue, a significant oil leak, or a failing IPR valve unable to maintain pressure.

Common 7.3 Powerstroke DTCs and IPR Valve Relevance

| DTC Code | Description | Potential IPR Valve Relevance |

|---|---|---|

| P1211 | ICP (Injector Control Pressure) higher/lower than desired (Engine running) | High likelihood. Indicates the IPR valve is not maintaining desired pressure, either stuck open (low pressure) or stuck closed (high pressure). |

| P1212 | ICP Sensor Low Input | Possible. While often an ICP sensor failure, a severely low-pressure condition (due to faulty IPR) can trigger this if pressure is below sensor’s operating range. |

| P0476 | Exhaust Pressure Control Valve Performance | Unlikely directly. This relates to the EBPV, but general engine performance issues from a bad IPR can sometimes indirectly affect other systems. |

| P1668 | PCM – IDM Communication Error | Unlikely directly. This is a communication error, not typically a direct IPR issue. |

| P0340 | Camshaft Position Sensor (CPS) Circuit Malfunction | Unlikely directly. A separate system, but often confused with IPR due to similar starting symptoms. |

| P0500 | Vehicle Speed Sensor Malfunction | Unlikely directly. Another separate system. |

Always remember that DTCs are guides, not definitive diagnoses. Thorough testing is always recommended.

Solutions: Replacing Your 7.3 Powerstroke IPR Valve

Once you’ve confidently diagnosed a failing 7.3 Powerstroke IPR valve, the solution is typically replacement. This is a common repair for these engines, and with the right tools and patience, it can often be a DIY project.

DIY vs. Professional Replacement

- DIY: If you’re comfortable working on your truck, have the necessary tools (including an IPR socket, which is highly recommended due to limited space), and can follow instructions, replacing the IPR valve is a manageable task. It involves removing the turbocharger, heat shield, and sometimes other components to gain access to the valve.

- Professional: If you’re not confident in your mechanical skills, lack the specific tools, or are short on time, taking your truck to a reputable diesel mechanic is a wise choice. They have the experience and equipment to perform the replacement efficiently and ensure proper installation.

Choosing the Right Replacement Part

When replacing your 7.3 Powerstroke IPR valve, quality matters. Opt for a reputable brand, ideally an OEM (Original Equipment Manufacturer) or a high-quality aftermarket equivalent. Cheap, no-name IPR valves are known to fail prematurely or not function correctly from the start, leading to repeated frustration and work. Remember, access to the IPR valve is challenging, so you only want to do this job once for a long time.

Post-Replacement Checks and Best Practices

After installing a new IPR valve:

- Bleed the System: It’s crucial to crank the engine several times for 10-15 seconds (with short breaks to let the starter cool) to allow the high-pressure oil system to prime and purge any air. The engine may run rough or be difficult to start initially.

- Monitor with Scan Tool: Once the engine starts, use your scan tool to monitor ICP and IPR duty cycle. Ensure ICP builds correctly, stabilizes at idle, and responds smoothly to throttle input. The IPR duty cycle should be within normal operating ranges.

- Check for Leaks: Visually inspect for any oil leaks around the new IPR valve and HPOP.

- Clear DTCs: Clear any stored Diagnostic Trouble Codes and drive the truck to ensure no new codes appear.

Timely replacement of a failing 7.3 Powerstroke IPR valve can restore your engine’s performance, improve reliability, and prevent potential damage to other high-pressure oil system components that might be working overtime to compensate for a weak valve.

Conclusion: Empowering Your 7.3 Powerstroke’s Longevity

The 7.3 Powerstroke IPR valve, though small in size, plays an immensely critical role in the operation of your legendary diesel engine. From ensuring smooth starts and stable idling to delivering robust power and efficiency, its proper function is paramount. Recognizing the symptoms of a bad 7.3 Powerstroke IPR valve – be it hard starting, rough idle, reduced power, or diagnostic trouble codes – is the first step towards an accurate diagnosis and effective repair.

By understanding the intricacies of the high-pressure oil system, utilizing diagnostic tools like a scan tool and multimeter, and knowing how to differentiate IPR issues from other common 7.3 Powerstroke ailments, you can approach troubleshooting with confidence. Whether you choose to tackle the replacement yourself or enlist the help of a professional, investing in a quality replacement IPR valve will ensure your truck continues to perform reliably for years to come.

Don’t let a failing IPR valve sideline your cherished 7.3 Powerstroke. With the knowledge gained from this guide, you are now better equipped to diagnose, address, and prevent future issues, keeping your powerhouse on the road where it belongs, tackling any challenge thrown its way.

🎥 Related Video: How to diagnose your truck's IPR | Symptoms of bad IPR

📺 Driven Diesel Media

Learn all about how we diagnose and fix an IPR issue. OBD Connector https://amzn.to/3oVmsgx IPR Tool https://amzn.to/33plrVv …

Frequently Asked Questions

What are the common symptoms of a failing 7.3 Powerstroke IPR valve?

Common signs include a rough idle, stalling, hard starting (especially when the engine is warm), and a noticeable loss of power. You might also experience an intermittent no-start condition or the engine dying unexpectedly while driving.

How does a faulty 7.3 Powerstroke IPR valve affect engine starting?

A bad IPR valve can make your 7.3 Powerstroke very difficult to start, particularly when the engine is hot, or cause a complete no-start condition. This occurs because the valve struggles to build or maintain the necessary high-pressure oil for the injectors to fire efficiently.

Will a bad IPR valve cause my 7.3 Powerstroke to run rough or stall?

Yes, a malfunctioning 7.3 Powerstroke IPR valve often leads to a rough or erratic idle and frequent stalling. It cannot properly regulate the oil pressure required for consistent fuel injection, causing the engine to misfire or shut down unexpectedly.

Can I diagnose a bad 7.3 Powerstroke IPR valve at home?

While you can visually inspect for oil leaks around the valve, a definitive diagnosis typically requires a scan tool to monitor ICP (Injection Control Pressure) and IPR duty cycle. Observing these parameters helps determine if the IPR valve is failing to maintain commanded pressure.

What is the primary function of the IPR valve in a 7.3 Powerstroke?

The IPR (Injection Pressure Regulator) valve is crucial for controlling the high-pressure oil that powers the fuel injectors in your 7.3 Powerstroke. It regulates the oil pressure within the HPOP (High-Pressure Oil Pump) system, directly impacting engine performance and starting.

Is it safe to continue driving my 7.3 Powerstroke with symptoms of a bad IPR valve?

It is not recommended to continue driving your 7.3 Powerstroke with symptoms of a bad IPR valve for an extended period. The inconsistent oil pressure can lead to further engine issues, cause a breakdown, and potentially leave you stranded. Prompt diagnosis and replacement are advisable.