Symptoms of a Bad 7.3 Powerstroke ICP Sensor: Diagnosing and Repairing

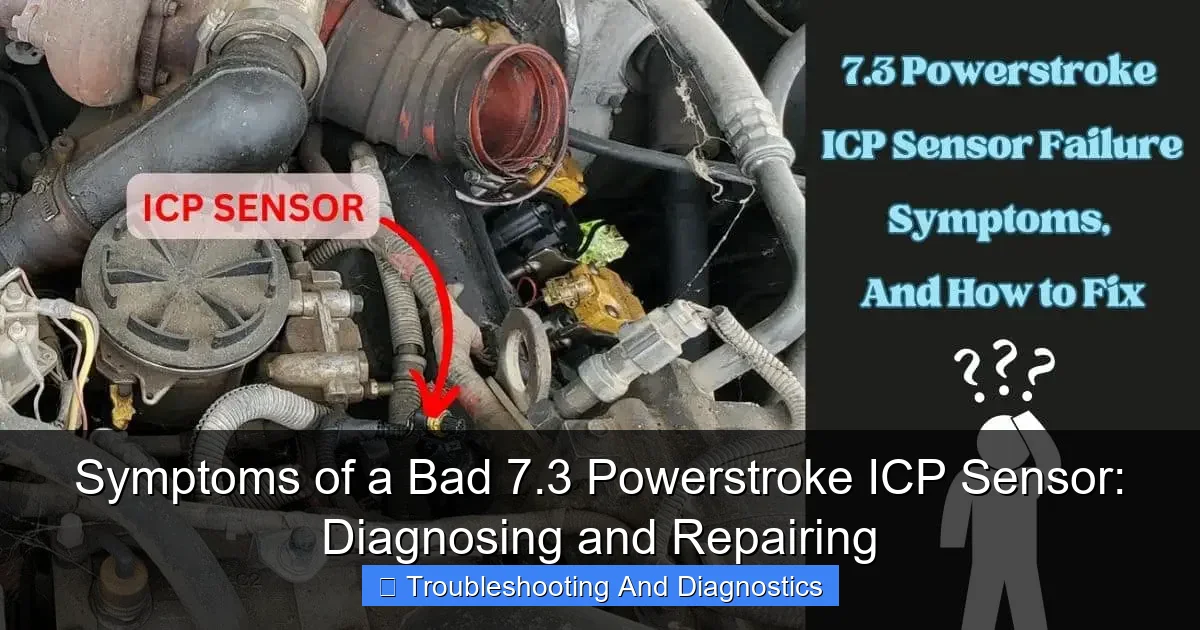

Featured image for this comprehensive guide about Symptoms of a bad 7.3 Powerstroke ICP sensor

Image source: drivenowautomotive.com

The legendary 7.3 Powerstroke engine holds a revered status among diesel enthusiasts. Known for its robust design, incredible durability, and impressive power, this V8 beast has powered countless Ford trucks and vans through millions of miles. However, even the most legendary engines have their Achilles’ heel, and for the 7.3, one critical component that can lead to frustrating drivability issues is the Injector Control Pressure (ICP) sensor. When this small but mighty sensor starts to falter, it can turn your reliable workhorse into a temperamental beast, exhibiting a range of bewildering symptoms.

If your beloved 7.3 Powerstroke is acting up—struggling to start, losing power, or idling erratically—the **ICP sensor** should be high on your diagnostic checklist. This sensor is a cornerstone of the engine’s High-Pressure Oil Pump (HPOP) system, which is essential for precisely firing the fuel injectors. A failing **7.3 Powerstroke ICP sensor** can throw the entire fuel delivery system into disarray, leading to performance woes and potential breakdowns. Understanding the **symptoms of a bad 7.3 Powerstroke ICP sensor** is the first step toward accurate diagnosis and getting your truck back to its peak performance.

This comprehensive guide will delve deep into the function of the ICP sensor, detail the most common **symptoms of a failing ICP sensor on a 7.3 Powerstroke**, walk you through diagnostic procedures, and provide actionable steps for replacement. Whether you’re a seasoned mechanic or a DIY enthusiast, this information will equip you to identify and address **ICP sensor problems 7.3 Powerstroke** with confidence, ensuring your truck continues to run strong for years to come.

Quick Answers to Common Questions

What are the most common symptoms of a failing 7.3 Powerstroke ICP sensor?

You’ll often notice rough idling, extended cranking, sudden stalling, or a noticeable loss of power. Your truck might feel sluggish or hesitant, especially under acceleration.

Can a bad 7.3 Powerstroke ICP sensor prevent my truck from starting altogether?

Yes, absolutely! If the 7.3 Powerstroke ICP sensor sends incorrect or no pressure signals, the engine control module won’t know how to properly fire the injectors, leading to a no-start condition.

Will I see a Check Engine Light (CEL) if my 7.3 Powerstroke ICP sensor is bad?

Often, yes! A failing 7.3 Powerstroke ICP sensor commonly triggers codes like P1211 (ICP Actual vs. Desired) or P1281 (ICP circuit out of range), illuminating your CEL.

Does a bad 7.3 Powerstroke ICP sensor affect performance while driving?

Definitely! You might experience significant power loss, poor throttle response, and even sudden engine cut-outs or stalling, making driving frustrating and potentially unsafe.

What kind of driving experience can I expect with a failing 7.3 Powerstroke ICP sensor?

Get ready for a frustrating ride! You’ll likely experience inconsistent power delivery, sputtering, or the engine feeling like it’s “missing” under load, making for an unpredictable drive.

📋 Table of Contents

- Understanding the 7.3 Powerstroke ICP Sensor and Its Crucial Role

- Common Symptoms of a Bad 7.3 Powerstroke ICP Sensor

- Diagnosing a Failing 7.3 Powerstroke ICP Sensor

- Common Causes of ICP Sensor Failure

- Replacing the 7.3 Powerstroke ICP Sensor

- Preventing Future ICP Sensor Issues and Related Drivability Problems

- Conclusion

Understanding the 7.3 Powerstroke ICP Sensor and Its Crucial Role

Before we dive into the **symptoms of a bad 7.3 Powerstroke ICP sensor**, it’s vital to grasp what this sensor does and why it’s so critical to your engine’s operation. The 7.3 Powerstroke utilizes a unique fuel injection system known as HEUI (Hydraulically-Actuated Electronically-Controlled Unit Injector). Unlike traditional systems that use mechanical pumps, HEUI injectors are fired by high-pressure engine oil, not fuel pressure.

Learn more about Symptoms of a bad 7.3 Powerstroke ICP sensor – Symptoms of a Bad 7.3 Powerstroke ICP Sensor: Diagnosing and Repairing

Image source: autocarneed.com

What is the ICP Sensor?

The Injector Control Pressure (ICP) sensor is a vital component within this HEUI system. It measures the oil pressure in the high-pressure oil galleries, sending this data as a voltage signal to the Powertrain Control Module (PCM). The PCM then uses this information, along with other sensor inputs, to precisely control the Injection Pressure Regulator (IPR) valve. The IPR, in turn, regulates the amount of oil pressure available to fire the injectors.

| Symptom Observed | Likely Cause/Impact | Diagnostic Action/Indicator |

|---|---|---|

| Hard Starting or No Start | Sensor sends incorrect low-pressure signal to ECM, preventing adequate high-pressure oil for injector firing. | ICP reading below ~500 PSI during cranking (scan tool). |

| Rough Idle or Stalling | Erratic ICP signal causes unstable injection pressure, leading to misfires and poor combustion. | Fluctuating or stuck ICP voltage/pressure readings (scan tool), IPR duty cycle may be high. |

| Loss of Power / Poor Acceleration | ECM defuels engine or cannot maintain desired injection pressure due to bad ICP feedback, limiting power output. | Actual ICP significantly lower than Desired ICP under load (scan tool). |

| Check Engine Light (CEL) Illumination | ECM detects an out-of-range sensor voltage or a discrepancy between ICP and IPR operation. | Common DTCs: P1211, P1212, P1280 (scan tool). |

| Excessive Black or White Smoke | Incorrect injection pressure leads to poor fuel atomization and incomplete combustion. | Often accompanies rough running; visually inspect exhaust during symptom. |

How Does It Work?

In essence, the ICP sensor tells the PCM how much oil pressure is actually available for injection. The PCM compares this actual pressure to the desired pressure (based on engine load, RPM, and other factors) and adjusts the IPR valve to maintain the optimal pressure. This precise control ensures that the injectors fire at the correct time and with the right force, leading to efficient combustion, optimal power delivery, and reduced emissions.

Why Is It So Important?

If the **7.3 Powerstroke ICP sensor** provides inaccurate readings or fails completely, the PCM will receive faulty information. This can cause the PCM to make incorrect adjustments to the IPR, leading to either too much or too little injection pressure. The consequences can range from minor drivability annoyances to a complete no-start condition. Because the PCM relies heavily on the ICP signal for proper engine operation, a malfunctioning sensor effectively cripples the engine’s ability to run smoothly and efficiently.

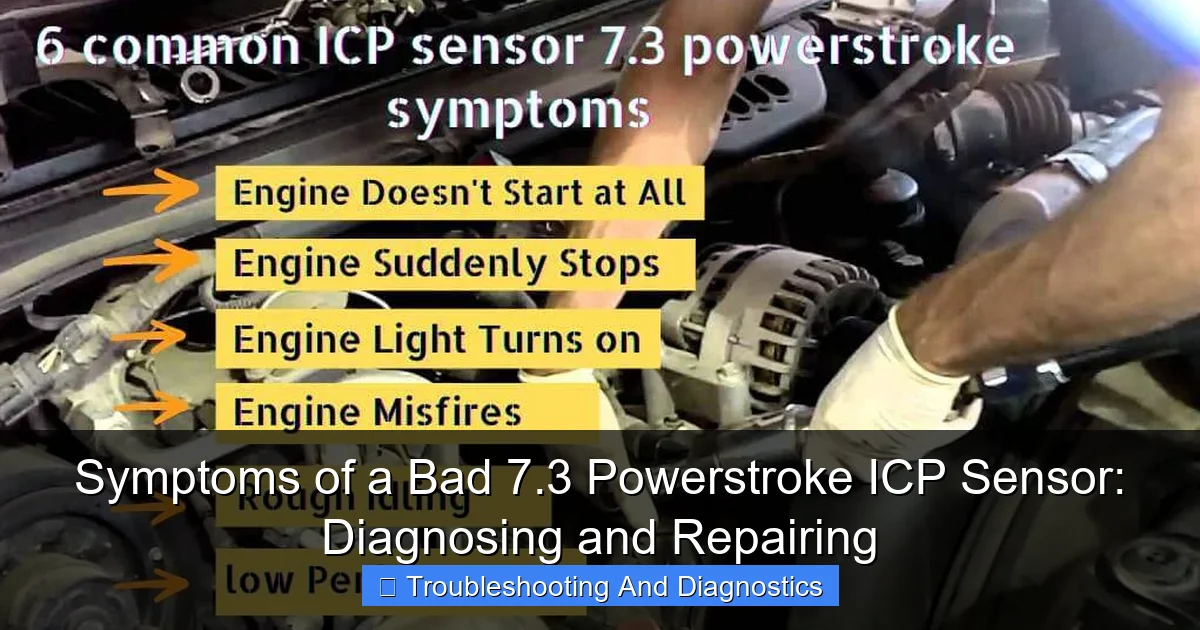

Common Symptoms of a Bad 7.3 Powerstroke ICP Sensor

Identifying the **symptoms of a bad 7.3 Powerstroke ICP sensor** is key to a swift and accurate repair. While some symptoms can overlap with other engine issues, a combination of these signs often points directly to a failing ICP sensor. Here are the most common indicators to watch out for:

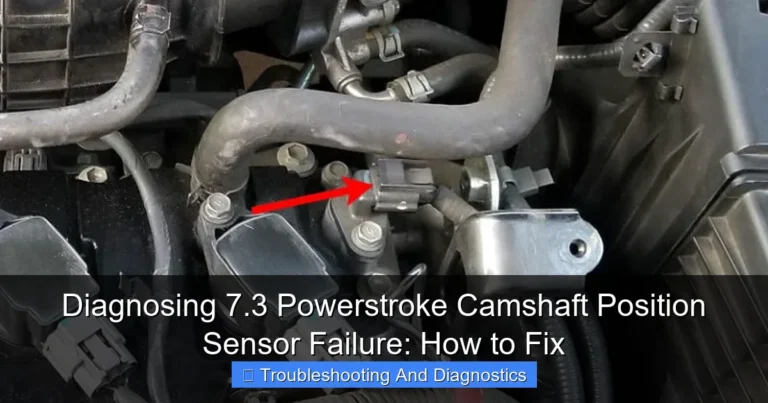

Learn more about Symptoms of a bad 7.3 Powerstroke ICP sensor – Symptoms of a Bad 7.3 Powerstroke ICP Sensor: Diagnosing and Repairing

Image source: motorriderz.com

1. Engine Cranking, No Start or Hard Start

One of the most frustrating and definitive **symptoms of a failing ICP sensor on a 7.3 Powerstroke** is an engine that cranks but refuses to start, or takes an excessive amount of cranking to fire up. This often occurs because the PCM isn’t receiving an accurate (or any) ICP reading. Without this critical data, the PCM cannot command the IPR to build sufficient high-pressure oil to fire the injectors.

- No Start: The engine turns over vigorously, but never catches. This is particularly common when the sensor fails completely or sends a consistently low-voltage signal.

- Hard Start: The engine cranks for an extended period, perhaps with a few sputtering attempts, before finally starting. This can be worse when the engine is hot, as the oil thins out and pressure retention might be more difficult for a compromised system.

2. Rough Idling and Stalling

A fluctuating or incorrect ICP signal can wreak havoc on your engine’s idle quality. The PCM constantly tries to maintain a smooth idle by adjusting injection pressure. If the ICP sensor is giving bad data, the PCM will be “hunting” for the right pressure, leading to an unstable idle.

- Rough Idle: The engine may shake, vibrate, or sound inconsistent at idle. It might feel like it’s struggling to stay running.

- Stalling: In severe cases, especially when coming to a stop or at very low RPMs, the engine might stall completely due to wildly inaccurate pressure control.

- Engine “Hunting”: The RPMs may dip and surge uncontrollably at idle.

3. Loss of Power and Poor Acceleration

If your 7.3 Powerstroke feels sluggish, lacks its usual punch, or struggles to accelerate, a failing ICP sensor could be the culprit. The PCM limits fuel delivery and injection timing if it perceives a lack of sufficient injection pressure, leading to a noticeable reduction in performance.

- Reduced Horsepower: The truck feels significantly weaker, particularly under load or when climbing hills.

- Slow Acceleration: Taking longer than usual to get up to speed.

- Lagging Throttle Response: A delay between pressing the accelerator and feeling the engine respond.

4. Engine Misfires or Hesitations

Inconsistent or improperly timed injection events, caused by faulty ICP data, can lead to your engine misfiring or hesitating during operation.

- Misfires: A noticeable skip or stumble in the engine’s rhythm, often accompanied by a change in exhaust note.

- Hesitations: Brief moments where the engine seems to lose power or “buck” before resuming normal operation, especially under acceleration.

5. Black or White Smoke from Exhaust

While exhaust smoke can indicate various issues, it can also be one of the **symptoms of a bad 7.3 Powerstroke ICP sensor**, particularly if accompanied by other drivability issues.

- Black Smoke: Often indicates over-fueling. If the ICP sensor reports falsely low pressure, the PCM might command more fuel than necessary to try and achieve the “desired” pressure, leading to incomplete combustion.

- White Smoke: Can indicate unburnt fuel. If the injectors aren’t firing correctly due to insufficient or erratic injection pressure, fuel might be expelled from the exhaust without proper combustion. (Note: White smoke can also indicate coolant, so further diagnosis is crucial).

6. Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs)

Perhaps the most direct indicator of an **ICP sensor problem 7.3 Powerstroke** is an illuminated Check Engine Light (CEL) on your dashboard. When the PCM detects an issue with the ICP sensor’s signal, it will log a specific Diagnostic Trouble Code (DTC).

- P1211: ICP Actual Pressure Not Equal To Desired Pressure (Under/Over Budget). This is a very common code indicating a discrepancy between what the PCM expects and what the ICP sensor reports.

- P1212: ICP Voltage Low. Often points to a short to ground or a failed sensor.

- P1213: ICP Circuit High/Low. Can indicate issues with the sensor’s wiring, connector, or internal failure.

- P0476: Exhaust Pressure Control Valve. While not directly an ICP sensor code, problems with ICP can sometimes indirectly affect exhaust pressure control or cause cascading issues.

Diagnosing a Failing 7.3 Powerstroke ICP Sensor

Once you suspect a **bad 7.3 Powerstroke ICP sensor** based on the symptoms, accurate diagnosis is crucial before you start replacing parts. A systematic approach will save you time, money, and frustration.

1. Visual Inspection

Begin with a thorough visual inspection of the sensor and its wiring harness. The location of the ICP sensor varies slightly by year model:

- 1994.5-1997 Models: Located on the front of the High-Pressure Oil Pump (HPOP) reservoir, typically on the driver’s side of the engine valley. Relatively easy to access.

- 1999-2003 Models: Located at the back of the engine, under the turbocharger, on the passenger side. This location is much more difficult to access and often requires removing the turbo.

Look for:

- Oil Leaks: Is there oil weeping or saturating the ICP sensor connector? This is a very common failure mode where oil wicks into the sensor’s electrical pins, shorting it out.

- Wiring Damage: Check the wiring harness leading to the ICP sensor for frayed wires, cuts, or insulation damage.

- Corrosion: Inspect the electrical connector pins for signs of corrosion or bent pins.

2. Using a Scan Tool (OBD-II Scanner)

An OBD-II scan tool, especially one capable of reading live data, is your most powerful diagnostic weapon for **ICP sensor problems 7.3 Powerstroke**. Connect the scanner and monitor the following parameters:

- DTCs: Retrieve any stored diagnostic trouble codes. P1211, P1212, and P1213 are primary indicators.

- ICP Voltage (KOEO): With the Key On, Engine Off (KOEO), the ICP sensor should read approximately 0.8-1.0 Volts. If it’s 0V or 5V, the sensor or its circuit is likely shorted or open.

- ICP Pressure (KOEO): With KOEO, the ICP pressure should be near 0 PSI.

- ICP Voltage & Pressure (Idling): At a warm idle, look for ICP voltage around 1.0-1.5 Volts and pressure between 500-750 PSI. The desired and actual ICP values should closely match.

- ICP Voltage & Pressure (WOT): During wide-open throttle (WOT) acceleration, ICP pressure should climb to 2800-3000 PSI, with voltage peaking around 4.0-4.5 Volts.

- Monitor Fluctuations: Observe if the ICP readings are erratic, stuck at a certain value, or drop out completely when the engine is experiencing symptoms.

3. The “Unplug Test” (Use with Caution)

For some 7.3 Powerstroke models, if the ICP sensor has completely failed and is providing wildly inaccurate data, unplugging it can sometimes allow the engine to start or run better. When the ICP sensor is unplugged, the PCM defaults to a pre-programmed “limp home” mode, using estimated pressure values. If the engine starts or runs significantly better with the sensor unplugged, it strongly suggests a bad ICP sensor. However, this is NOT a permanent fix and should only be used as a diagnostic step. *Always exercise caution and ensure safety before performing this test.*

4. Multimeter Testing (Advanced)

If you suspect wiring issues or want to verify sensor power, a multimeter can be used to test the ICP sensor circuit. Refer to a wiring diagram for your specific year model for pinouts and expected voltages:

- Power Supply: Check for 5V reference voltage at the appropriate pin with KOEO.

- Ground: Verify good ground continuity at the ground pin.

- Signal Wire: Measure voltage on the signal wire. It should correlate with pressure readings (e.g., ~0.8V KOEO, increasing with pressure).

ICP Sensor Readings Comparison Table

Here’s a quick reference table for expected ICP sensor readings:

| Condition | ICP Pressure (PSI) | ICP Voltage (V) | Notes |

|---|---|---|---|

| Key On, Engine Off (KOEO) | 0-15 PSI | 0.8 – 1.0 V | Reference voltage, indicates sensor is powered. |

| Engine Idling (Warm) | 500-750 PSI | 1.0 – 1.5 V | Fluctuations indicate injector demand. |

| Wide Open Throttle (WOT) | 2800-3000 PSI | 4.0 – 4.5 V | Maximum pressure and voltage output. |

| Faulty/Failing Sensor (Example) | Fluctuating/Stuck Low/High | 0 V (short) or 5 V (open) or Erratic | Correlates with P1211, P1212, P1213 DTCs. |

Common Causes of ICP Sensor Failure

Understanding why **7.3 Powerstroke ICP sensor failure** occurs can help you take preventative measures and better understand the nature of the problem.

1. Oil Contamination and Leaks

This is arguably the most common cause. The ICP sensor is constantly exposed to high-pressure oil. Over time, the internal seals of the sensor can degrade, allowing oil to seep into the electrical connector. This oil contamination can short out the internal electronics, leading to erratic readings or complete failure. Visibly oily connectors are a tell-tale sign.

2. Electrical Issues

Beyond oil contamination, the electrical wiring and connector itself can cause problems. Frayed wires, corrosion on the pins, or loose connections can interrupt the signal to the PCM, mimicking a failed sensor. Sometimes, the internal components of the sensor simply wear out or short circuit.

3. Vibration and Heat

The 7.3 Powerstroke engine generates significant heat and vibration. Over decades of operation, these harsh conditions take a toll on all components, including the ICP sensor. The internal components can degrade, and solder joints can weaken due to constant thermal cycling and mechanical stress.

4. Age and Mileage

Simply put, parts wear out. The ICP sensor is a critical electronic component that is constantly working under demanding conditions. After hundreds of thousands of miles, it’s not uncommon for the sensor to reach the end of its service life.

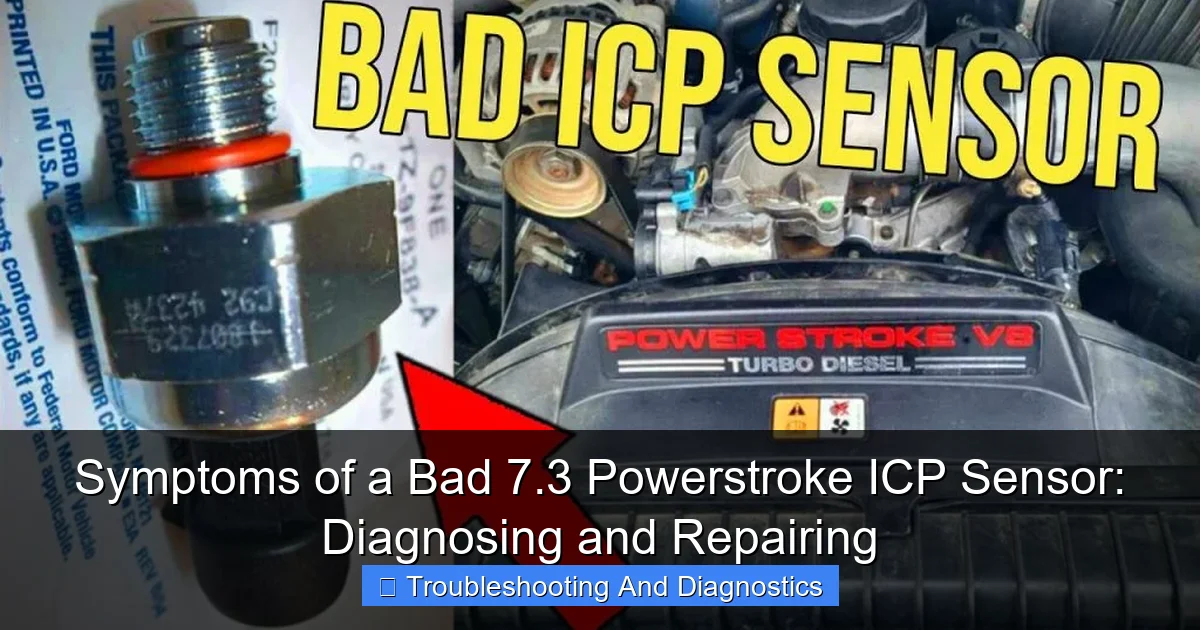

Replacing the 7.3 Powerstroke ICP Sensor

Once you’ve confirmed that a **bad 7.3 Powerstroke ICP sensor** is the issue, replacing it is the next step. While straightforward for early models, later models require more effort. Always ensure you have the correct sensor for your truck’s year.

Safety First

- Disconnect Battery: Always disconnect the negative battery terminals before starting any electrical work.

- Allow Engine to Cool: The high-pressure oil system operates at very high temperatures. Allow the engine to cool down completely to prevent burns and reduce oil pressure.

- Wear Safety Glasses: Oil may spray when the old sensor is removed.

Tools and Parts Required

- New ICP Sensor (OEM or high-quality aftermarket recommended, e.g., Motorcraft, Navistar)

- Wrench or Socket (typically 1-1/16″ or 1-1/8″, confirm for your sensor)

- Rag or Catch Pan (for oil spillage)

- Dielectric Grease (for new connector)

- Torque Wrench (optional, but recommended for proper installation)

- For 1999-2003 models: Tools for turbo removal/loosening (various sockets, wrenches, hose clamps, possibly gaskets)

Step-by-Step Replacement Guide

For 1994.5-1997 Models (Front HPOP location):

- Locate Sensor: Find the ICP sensor on the front of the HPOP reservoir, driver’s side.

- Disconnect Connector: Carefully disconnect the electrical connector from the sensor. Inspect it for oil or damage.

- Remove Old Sensor: Using the appropriate wrench or socket, loosen and remove the old ICP sensor. Be prepared for some oil to drain out.

- Clean Area: Wipe down any spilled oil and ensure the mounting area is clean.

- Install New Sensor: Thread the new ICP sensor into the port by hand to prevent cross-threading. Tighten it with your wrench/socket. Refer to a service manual for specific torque specs (typically around 15-20 ft-lbs). Do NOT overtighten.

- Reconnect Connector: Apply a small amount of dielectric grease to the pins of the new sensor and securely reconnect the electrical connector.

- Reconnect Battery: Reconnect the negative battery cables.

- Test Drive: Start the engine and check for leaks. Monitor engine performance and ensure the CEL is off.

For 1999-2003 Models (Under Turbo location):

This procedure is significantly more involved and often requires removing or at least loosening the turbocharger assembly for access. It’s recommended for experienced DIYers or professional mechanics.

- Access Turbo: You’ll likely need to remove the air intake, downpipe, and possibly exhaust manifold bolts to gain sufficient access to the turbo and the sensor beneath it. This may involve draining coolant and disconnecting numerous hoses and wires.

- Locate Sensor: The ICP sensor is typically located on the passenger side, towards the back of the engine, buried beneath the turbo.

- Follow Steps 2-8 from above: Once you have clear access, the sensor removal and installation process is similar to the earlier models.

- Reassemble Turbo and Components: Carefully reassemble all components, ensuring all connections are secure and torque specifications are met. Check for leaks of oil, boost, and exhaust.

Tips for Success

- Quality Matters: Invest in a good quality ICP sensor. Cheap aftermarket sensors are known to fail quickly or provide inaccurate readings, leading to repeat issues. OEM (Motorcraft, Navistar) is generally preferred.

- Clean Connection: Always ensure the electrical connector is clean and dry. If there’s oil in the connector, clean it thoroughly with electrical contact cleaner.

- New O-ring: Ensure the new sensor comes with a fresh O-ring to prevent leaks.

Preventing Future ICP Sensor Issues and Related Drivability Problems

While an ICP sensor is a wear item and can fail regardless of perfect maintenance, certain practices can help extend its life and prevent related problems. By focusing on preventative maintenance and understanding your engine’s health, you can minimize the chances of dealing with **7.3 Powerstroke ICP sensor problems**.

1. Regular Oil Changes with Quality Oil

The 7.3 Powerstroke’s HEUI system relies entirely on engine oil. Dirty or degraded oil can accelerate wear on all components within the high-pressure oil system, including the ICP sensor. Always use the manufacturer-recommended viscosity (typically 15W-40) and change your oil and filter at the prescribed intervals (e.g., every 3,000-5,000 miles or as per your owner’s manual).

2. Maintain a Clean Electrical System

Periodically inspect the wiring harnesses, especially those exposed to heat and oil, for any signs of chafing, cracks, or corrosion. Keep electrical connectors clean and apply dielectric grease to sensitive connections like the ICP sensor, IPR, and Camshaft Position Sensor (CPS).

3. Address Oil Leaks Promptly

Any oil leaks, especially around the engine valley or the HPOP, should be addressed quickly. Oil leaks can lead to contamination of electrical connectors, including the ICP sensor, as well as indicating other underlying issues that could impact the HEUI system.

4. Pay Attention to Early Warning Signs

Don’t ignore subtle changes in your truck’s behavior. A slight hesitation, a barely noticeable rough idle, or an occasional hard start can be early **symptoms of a bad 7.3 Powerstroke ICP sensor**. Addressing these early can prevent more severe issues and potential breakdowns.

5. Use a Scan Tool for Proactive Monitoring

If you own a 7.3 Powerstroke, investing in a basic OBD-II scanner that can read live data is highly recommended. Periodically check for pending codes and monitor ICP voltage and pressure readings. This proactive approach can catch a failing sensor before it leaves you stranded.

Conclusion

The 7.3 Powerstroke engine is a marvel of engineering, known for its longevity and performance. However, like any complex machine, it relies on the proper functioning of all its components. The Injector Control Pressure (ICP) sensor plays an indispensable role in ensuring your engine’s HEUI system operates efficiently and delivers reliable power. Understanding the **symptoms of a bad 7.3 Powerstroke ICP sensor** is not just about troubleshooting; it’s about maintaining the health and longevity of your cherished truck.

From frustrating no-start conditions and rough idling to a noticeable loss of power and the dreaded Check Engine Light, the signs of a failing ICP sensor are clear indicators that your engine needs attention. By following the diagnostic steps outlined in this guide and taking proactive measures, you can confidently identify and address **ICP sensor problems 7.3 Powerstroke**. Timely diagnosis and replacement with a quality part will ensure your legendary 7.3 Powerstroke continues to perform reliably, keeping you on the road and enjoying its iconic power for many miles to come. Don’t let a small sensor sideline your powerful diesel—diagnose, repair, and drive on!

🎥 Related Video: HOW TO DIAGNOSE A BAD ICP SENSOR & INSTALL A NEW ICP SENSOR, FORD F350 SUPERDUTY 7.3 TURBO DIESEL

📺 2Guys How2 The Fish Kingz

If you are having hard starts, check engine light is on or you can see oil leaking from the ICP plug itself…time for a new sensor.

Frequently Asked Questions

What does an ICP sensor do in a 7.3 Powerstroke, and why is it important?

The ICP (Injector Control Pressure) sensor is a crucial component in your 7.3L Powerstroke that measures the high-pressure oil needed to fire the fuel injectors. It sends this pressure data to the Powertrain Control Module (PCM), which then uses this information to precisely control injection timing and fuel delivery. Without accurate readings from the ICP sensor, the engine cannot run efficiently or, in some cases, at all.

What are the most common symptoms of a bad 7.3 Powerstroke ICP sensor?

Common symptoms of a failing 7.3 Powerstroke ICP sensor include rough idling, stalling (especially when the engine is warm), and a no-start condition. You might also experience a significant loss of power, poor acceleration, or the engine going into a “limp mode.” These issues stem from the PCM not receiving accurate pressure data to command the injectors correctly.

Can a faulty ICP sensor prevent my 7.3 Powerstroke from starting?

Yes, a bad ICP sensor can absolutely cause a no-start condition for your 7.3 Powerstroke. If the sensor is providing incorrect or no data to the PCM, the module won’t know the proper oil pressure to command the injectors to fire fuel into the cylinders. This lack of critical information will prevent the engine from starting, even if all other systems are working correctly.

What diagnostic trouble codes (DTCs) might indicate a problem with the 7.3 Powerstroke ICP sensor?

When the 7.3 Powerstroke ICP sensor malfunctions, your check engine light may illuminate, accompanied by specific diagnostic trouble codes (DTCs). Common codes associated with an ICP sensor issue include P1280 (ICP circuit out of range low), P1281 (ICP circuit out of range high), P1282 (Excessive ICP), or P1283 (ICP out of range fault). These codes are strong indicators of a sensor or circuit problem.

How can I temporarily diagnose if my ICP sensor is the cause of my 7.3 Powerstroke’s issues?

A common diagnostic trick for a suspected bad 7.3 Powerstroke ICP sensor is to unplug it while the engine is off. If your truck then starts and runs better (though usually in a default mode with potentially reduced power), it strongly suggests the sensor was faulty. The PCM uses a default pressure value when the sensor is disconnected, which can sometimes allow the engine to run more smoothly than with a failed, erratic sensor.

Is the 7.3 Powerstroke ICP sensor difficult to replace, and where is it located?

The difficulty of replacing the 7.3 Powerstroke ICP sensor depends on your truck’s model year. On early 7.3L models (pre-1999.5), it is relatively easy to access on the passenger side valve cover. However, on later models (1999.5 and up), the sensor is typically located under the turbocharger pedestal at the back of the engine, making it a more challenging and time-consuming replacement that may require special tools or partial turbo removal.