Symptoms of 6.0 Powerstroke High Pressure Oil Pump Failure: Signs and Fixes

Featured image for this comprehensive guide about Symptoms of 6.0 Powerstroke high pressure oil pump failure

Image source: bostechauto.com

Ah, the legendary Ford 6.0 Powerstroke diesel engine. A powerhouse when it’s running right, but a notorious challenge when things go wrong. Among the many potential headaches, one of the most critical and often misunderstood is the failure of the High-Pressure Oil Pump (HPOP). This component is the heart of your 6.0 Powerstroke‘s fuel injection system, and when it falters, your truck can go from a mighty workhorse to an expensive paperweight in the blink of an eye.

For any owner of a 2003-2007 Ford F-Series or E-Series with the 6.0 Powerstroke, understanding the symptoms of 6.0 Powerstroke high pressure oil pump failure isn’t just helpful; it’s essential. Early detection can save you thousands in further damage and diagnostic time. Ignoring these signs can leave you stranded, facing a much more complex and costly repair. This comprehensive guide will walk you through everything you need to know, from the subtle hints to the undeniable declarations that your HPOP is failing, along with actionable steps for diagnosis and resolution.

So, buckle up, because we’re about to dive deep into the intricate world of your 6.0 Powerstroke‘s high-pressure oil system. By the end of this post, you’ll be better equipped to identify, diagnose, and address a failing HPOP, keeping your trusty diesel running strong for years to come. Let’s explore the critical signs of HPOP failure in your 6.0 Powerstroke and what you can do about it.

Quick Answers to Common Questions

What’s the most common symptom of 6.0 Powerstroke high pressure oil pump failure?

The most common sign you’re experiencing a 6.0 Powerstroke high pressure oil pump failure is a no-start condition when the engine is warm, or a very long crank time before it finally fires up. You might also notice rough idling or stalling.

Will my truck start at all if the HPOP is failing?

Often, a failing high pressure oil pump will lead to extended cranking times or a complete no-start situation, especially after the engine has warmed up. Cold starts might be okay initially, but the problem usually worsens as the pump loses efficiency.

Does a failing HPOP make any strange noises?

While a failing 6.0 Powerstroke high pressure oil pump itself doesn’t typically make distinct noises, the engine might run rough, miss, or even stall due to insufficient oil pressure, which can sound like a struggling engine. You might hear the engine cranking excessively without firing.

Can I still drive my 6.0 Powerstroke with a bad high pressure oil pump?

It’s strongly advised not to drive your 6.0 Powerstroke with symptoms of high pressure oil pump failure. Continuing to drive could lead to more severe engine damage, leaving you stranded, and potentially causing other components to wear out prematurely.

How serious is a 6.0 Powerstroke high pressure oil pump failure?

A 6.0 Powerstroke high pressure oil pump failure is quite serious as the HPOP is crucial for fuel injector operation and overall engine performance. If left unaddressed, it will eventually lead to a complete no-start condition and can contribute to further engine issues.

📋 Table of Contents

- The Critical Role of the HPOP in Your 6.0 Powerstroke and Why it Fails

- The Dreaded No-Start Condition: A Primary Symptom of HPOP Failure

- Performance Degradation and Driveability Issues

- Visual Cues and Diagnostic Trouble Codes (DTCs)

- Diagnosing HPOP Failure: Step-by-Step Action Plan

- What to Do When HPOP Failure is Confirmed: Fixes and Prevention

- Common Diagnostic Values for 6.0 Powerstroke HPOP

- Conclusion: Stay Ahead of 6.0 Powerstroke HPOP Failure

The Critical Role of the HPOP in Your 6.0 Powerstroke and Why it Fails

Before we dissect the symptoms, it’s crucial to understand what the High-Pressure Oil Pump (HPOP) actually does in your 6.0 Powerstroke. Unlike traditional diesel engines that use a mechanical injection pump, the 6.0 Powerstroke utilizes a HEUI (Hydraulically Electronic Unit Injector) system. This system relies on pressurized engine oil, not fuel, to actuate the fuel injectors.

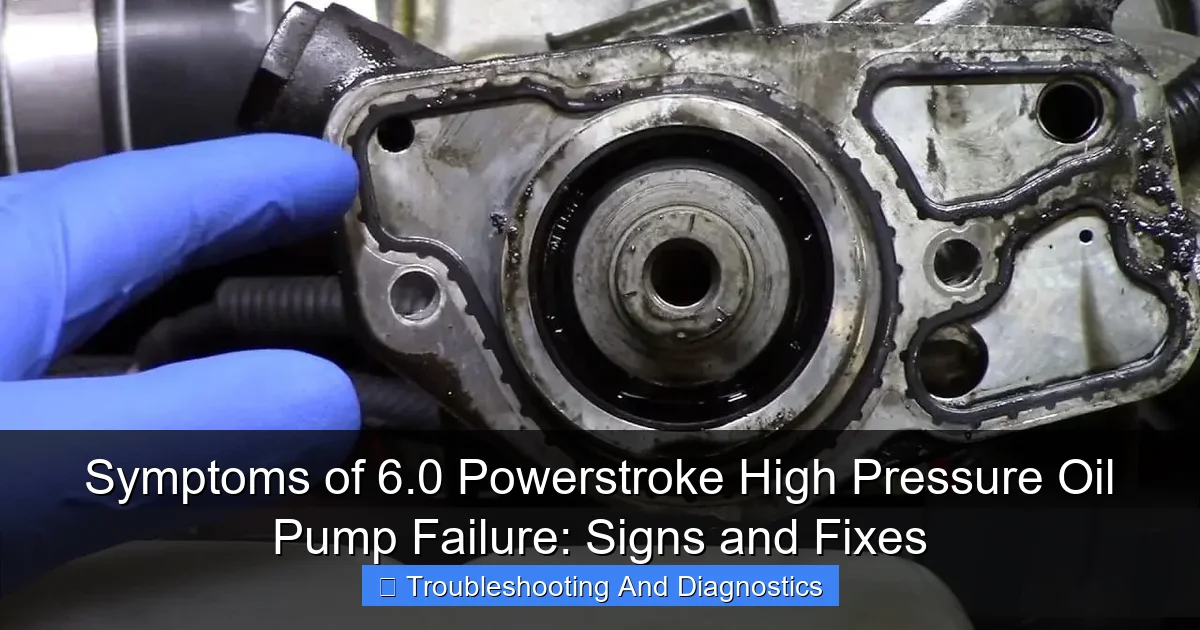

Learn more about Symptoms of 6.0 Powerstroke high pressure oil pump failure – Symptoms of 6.0 Powerstroke High Pressure Oil Pump Failure: Signs and Fixes

Image source: oilfiltersonline.com

The HPOP is responsible for taking engine oil, raising its pressure to an astounding 500-4,000+ PSI (depending on demand), and delivering it to the injectors via a complex manifold of standpipes, dummy plugs, and supply tubes. This high-pressure oil then pushes on a intensifier piston within each injector, which in turn pressurizes the fuel for injection into the combustion chamber. Without adequate high-pressure oil, the injectors simply cannot fire, leading to a variety of engine issues, from performance degradation to a complete no-start condition.

| Symptom | Driver Observation / Description | Diagnostic Clue / Common DTCs |

|---|---|---|

| No-Start / Hard Start | Engine cranks but won’t fire, or requires extended cranking to start (especially when hot or after sitting). | Low ICP (Injection Control Pressure) during cranking (e.g., less than 500 PSI). DTCs: P2285, P2287. |

| Rough Idle / Stalling | Engine runs rough, shakes, or unexpectedly stalls, particularly after warming up. | Fluctuating or insufficient ICP at idle. Erratic ICP actual vs. desired. DTCs: P0094. |

| Loss of Power / Hesitation | Noticeable decrease in acceleration, sluggish performance under load, or “bucking” during throttle application. | ICP drops significantly under load, unable to maintain desired pressure. Insufficient fuel atomization. |

| Check Engine Light (CEL) | Malfunction Indicator Lamp (MIL) illuminates on the dashboard. | Common DTCs: P2285 (ICP Sensor Circuit Low), P2287 (ICP Sensor No Signal), P0094 (Fuel System Leak – HPOP related). |

Common Causes of HPOP Failure in the 6.0 Powerstroke

- STC (Standpipe-to-Cover) Fitting Failure: This is arguably the most common culprit. The original STC fitting was a two-piece design that could separate under engine vibration and oil pressure cycles, leading to a catastrophic loss of high-pressure oil. Ford later updated this to a more robust one-piece design.

- Internal Wear and Tear: Like any mechanical pump, the HPOP itself can wear out over time, especially if the engine oil isn’t changed regularly or if contaminated oil is used. The internal gears, housing, and seals can degrade, reducing its ability to generate or maintain pressure.

- Degradation of O-Rings and Seals: Numerous O-rings and seals within the high-pressure oil system (standpipes, dummy plugs, branch tube, ICP sensor) can harden, crack, or fail, causing external or internal oil leaks that compromise the system’s ability to hold pressure.

- Oil Contamination: Debris or sludge in the engine oil can damage the precision components of the HPOP, accelerating wear and reducing its efficiency. This is why regular oil changes with the correct viscosity are paramount.

- Excessive Heat: Prolonged exposure to high engine temperatures can degrade the seals and components within the HPOP and related parts, leading to premature failure.

The Dreaded No-Start Condition: A Primary Symptom of HPOP Failure

When your 6.0 Powerstroke suddenly refuses to start, especially after the engine has cooled down, a failing HPOP should be high on your suspicion list. This is often the most dramatic and frustrating symptom of 6.0 Powerstroke high pressure oil pump failure because it means your truck is effectively dead in the water.

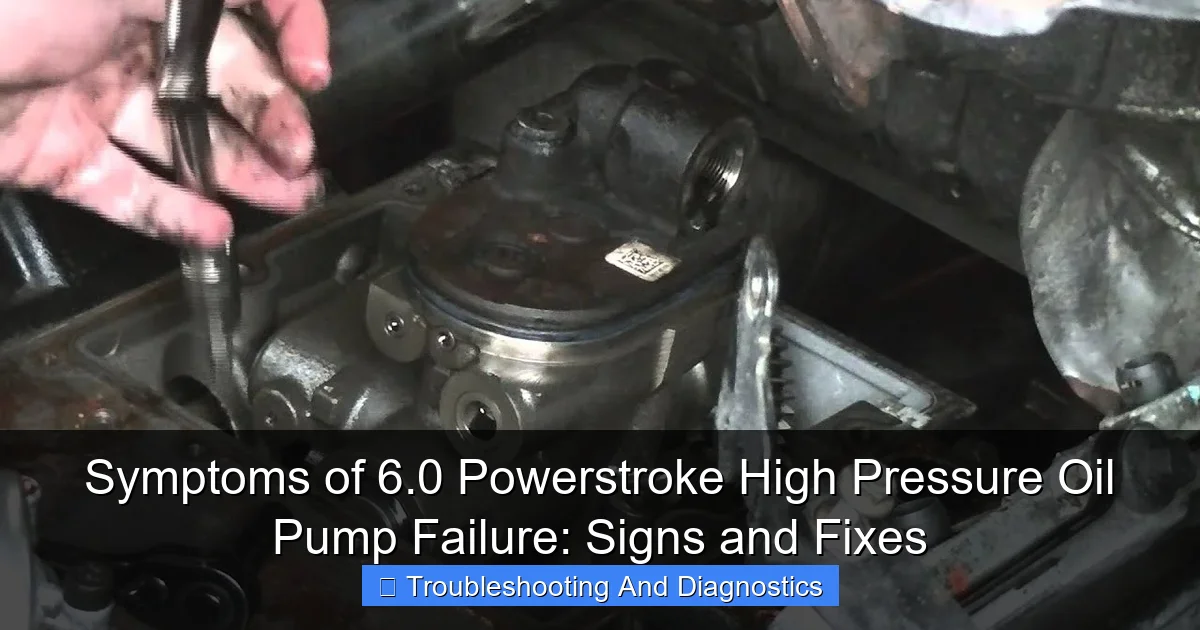

Learn more about Symptoms of 6.0 Powerstroke high pressure oil pump failure – Symptoms of 6.0 Powerstroke High Pressure Oil Pump Failure: Signs and Fixes

Image source: i.ytimg.com

Cranking But No Start

This is the classic scenario. You turn the key, the engine cranks robustly, sounds like it’s trying, but it just won’t catch and fire up. Why? Because the injectors aren’t receiving enough high-pressure oil to actuate. The engine needs a minimum of 500 PSI (pounds per square inch) of oil pressure to fire the injectors and start. If the HPOP or its related components (like the STC fitting) cannot maintain this pressure during cranking, the engine will never start. This can be particularly noticeable after the truck has sat for several hours, allowing any residual oil pressure to bleed off, making it harder for a weak HPOP to build it back up.

Extended Crank Times

Before a complete no-start, you might experience progressively longer cranking times, especially when the engine is cold. A healthy 6.0 Powerstroke should start almost instantly. If you find yourself cranking for 5-10 seconds or more before the engine fires, it’s a strong indicator that the HPOP is struggling to build sufficient pressure quickly. This could be a precursor to a total failure, signifying that the pump is losing efficiency or that there’s a slow leak in the high-pressure oil system.

Performance Degradation and Driveability Issues

A failing HPOP doesn’t always result in an immediate no-start. Often, it manifests as a gradual decline in engine performance and various driveability problems. These symptoms of 6.0 Powerstroke high pressure oil pump failure can be more subtle but are equally important to recognize.

Rough Idling and Stalling

Is your truck idling roughly, shaking more than usual, or even stalling, especially when coming to a stop or at low RPMs? This can be a direct result of inconsistent high-pressure oil supply. If the HPOP cannot maintain a steady pressure, certain injectors might not fire correctly or consistently, leading to an unbalanced engine operation. Stalling indicates that the pressure has dropped below the critical threshold, causing the engine to lose power and shut down.

Loss of Power and Acceleration

One of the most common complaints of a failing HPOP is a noticeable loss of power in your 6.0 Powerstroke. You might feel like your truck is sluggish, struggles to accelerate, or can’t maintain speed on inclines. This is because the injectors aren’t receiving the optimal high-pressure oil needed to achieve full fuel atomization and combustion. The engine might feel “detuned” or simply won’t respond as it should, making towing or hauling particularly challenging. This can also manifest as intermittent power loss, where the truck feels strong one moment and weak the next.

Engine Misfires or Hesitation

Experiencing a stumble, miss, or hesitation during acceleration or steady cruising? This could be due to intermittent drops in high-pressure oil supply. If the pressure temporarily dips, one or more injectors might fail to actuate, causing a misfire. This not only impacts performance but can also lead to increased exhaust gas temperatures (EGTs) and potential damage to other engine components over time.

Poor Fuel Economy

While not a direct symptom, poor fuel economy in your 6.0 Powerstroke can be an indirect indicator of HPOP issues. If the engine isn’t running efficiently due to inconsistent oil pressure and injector operation, it will consume more fuel to produce the same amount of power, or simply to run. So, if you notice a significant drop in your MPG without any other obvious cause, it’s worth considering your HPOP’s health.

Visual Cues and Diagnostic Trouble Codes (DTCs)

Sometimes, your truck will give you direct clues through leaks or by illuminating the dreaded “Check Engine Light.” Understanding these visual and electronic indicators is crucial for diagnosing 6.0 Powerstroke HPOP failure.

Oil Leaks Around the HPOP Cover

While less common for internal HPOP failure, external oil leaks can sometimes originate from the HPOP cover or around the ICP (Injection Control Pressure) sensor. A visible oil leak in this area, especially at the back of the engine valley, should prompt further investigation. These leaks might not directly indicate HPOP failure but could point to failing O-rings or seals within the high-pressure oil system, which can mimic HPOP symptoms by losing pressure.

ICP and IPR Related DTCs

Your 6.0 Powerstroke‘s computer (PCM) constantly monitors the health of its systems. A failing HPOP will often trigger specific Diagnostic Trouble Codes (DTCs) that can be read with an OBD-II scanner. These codes are critical for narrowing down the problem. Here are some common ones related to the high-pressure oil system:

- P2285: ICP Sensor Circuit Low

- P2290: ICP Too Low – Engine Cranking

- P2291: ICP Too Low – Engine Running

- P2292: ICP Intermittent

- P1378: IDM (Injector Driver Module) voltage low (often related to insufficient oil pressure, as the FICM relies on engine run to maintain voltage).

- P0069: Barometric Pressure Sensor/MAP Sensor Correlation (can sometimes be triggered by severe HPOP issues affecting engine vacuum/boost).

- P0611: FICM (Fuel Injection Control Module) performance (indirectly related if HPOP issues affect engine start/run).

- P1211 / P1212 / P1213: Various Injector Control Pressure (ICP) system codes.

It’s important to note that while these codes point to issues in the high-pressure oil system, they don’t *always* mean the HPOP itself is bad. They could also indicate a faulty ICP sensor, IPR valve (Injection Pressure Regulator), or a leak in the system (STC fitting, standpipes, dummy plugs). Professional diagnostics are needed to pinpoint the exact cause.

Oil in the Fuel Filter Housing

This is a less common but extremely serious symptom. If the seals on the high-pressure oil branch tube fail and cause oil to leak into the fuel system, you might find engine oil contaminating your fuel filter housing. This not only indicates a major internal leak but can also damage your fuel injectors and other fuel system components. If you discover oil in your fuel, immediately cease operation and seek professional diagnosis.

Diagnosing HPOP Failure: Step-by-Step Action Plan

Confirming HPOP failure requires careful, methodical diagnosis. Blindly replacing the pump can be costly and won’t fix the problem if the issue lies elsewhere. Here’s a typical diagnostic procedure:

1. Monitor ICP and IPR Values with a Scanner

This is your first and most important step. Using a diagnostic scanner capable of reading live data (e.g., Forscan, AE, IDS), monitor the following parameters:

- ICP (Injection Control Pressure) Actual: This is the actual oil pressure the PCM is seeing.

- ICP Desired: This is the pressure the PCM is requesting.

- IPR (Injection Pressure Regulator) Duty Cycle: This indicates how hard the IPR valve is working to regulate pressure.

- FICM (Fuel Injection Control Module) Voltage: Should be a steady 48V. While not directly HPOP, low FICM voltage can cause no-starts.

- Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT): Ensure these are within normal operating ranges.

During Cranking (No Start):

- A healthy 6.0 Powerstroke should show ICP Actual rapidly climbing to at least 500 PSI, ideally 700-1000 PSI, during cranking.

- If ICP Actual stays below 500 PSI, you have a high-pressure oil system issue.

- IPR Duty Cycle will typically be high (60-85%) as the PCM tries to command pressure.

During Idling (if it starts):

- ICP Actual should closely match ICP Desired (typically 600-750 PSI).

- IPR Duty Cycle should be stable, usually around 20-30% at warm idle. If it’s consistently much higher (e.g., 40-50%+) and ICP is low or fluctuating, it suggests a leak or weak HPOP.

2. The High-Pressure Oil System Air Test

This is the most definitive test for locating a high-pressure oil leak.

- Remove the ICP sensor from the passenger side valve cover.

- Install a specialized air test fitting into the ICP sensor port.

- Apply regulated shop air (100-120 PSI) into the high-pressure oil system.

- Listen for air leaks. Common places to hear leaks include:

- The oil fill spout (indicates a leak at the HPOP itself or the branch tube O-rings).

- Under the turbo (STC fitting, standpipes, dummy plugs).

- Out of the ICP sensor hole (if you removed the fitting too soon or it’s not sealed).

- From the exhaust (a bad injector O-ring could leak into the cylinder, then out the exhaust).

- This test effectively simulates the high-pressure oil, allowing you to hear where the pressure is escaping. If you hear a significant leak from the oil fill tube, it strongly points to the HPOP or the branch tube seals.

3. Check Engine Oil Level and Quality

Ensure your engine oil is at the correct level and isn’t excessively dirty or diluted. Low oil levels can starve the HPOP, and contaminated oil can cause wear.

4. Rule Out Other Components

Before condemning the HPOP, ensure the IPR valve isn’t stuck open or faulty, and that the ICP sensor isn’t giving false readings. Sometimes, a bad ICP sensor or IPR valve can mimic HPOP failure symptoms.

What to Do When HPOP Failure is Confirmed: Fixes and Prevention

So, you’ve diagnosed the symptoms of 6.0 Powerstroke high pressure oil pump failure and confirmed it’s the HPOP or a related component. Now what?

HPOP Replacement Considerations

Replacing the HPOP is a significant job, often requiring removal of the turbocharger, FICM, and other components in the engine valley. It’s recommended to replace several associated parts at the same time:

- Updated STC Fitting: If your truck still has the original two-piece fitting, replace it with the updated one-piece design. This is critical.

- Standpipes and Dummy Plugs: These have O-rings that commonly fail, causing leaks. Replace them with updated versions.

- HPOP Cover Gasket and Seals: Replace all gaskets and O-rings around the HPOP and branch tube.

- IPR Valve Screen: Clean or replace the screen on the IPR valve, as it can get clogged with debris.

- New HPOP: Choose a quality OEM or reputable aftermarket HPOP. Be wary of cheap, low-quality pumps.

Many owners opt for an “HPOP Kit” that includes the updated STC fitting, standpipes, and dummy plugs, as these are common failure points that become accessible during an HPOP replacement.

Preventing Future Failures

While some failures are due to design flaws, good maintenance can significantly extend the life of your 6.0 Powerstroke HPOP:

- Regular Oil Changes: Adhere to Ford’s recommended oil change intervals (typically 5,000 miles or 6 months) using the correct CJ-4 or CK-4 specified 15W-40 or 5W-40 synthetic blend oil. Clean oil is crucial for the HPOP and injectors.

- Use Quality Oil Filters: Always use OEM Ford or equivalent quality oil filters. Aftermarket filters can sometimes have poor fitment or filtration, leading to issues.

- Monitor Your Truck: Pay attention to any changes in engine noise, starting behavior, or performance. Early detection is key.

- Consider an Air Oil Separator: While not directly HPOP related, it keeps engine oil cleaner longer, which can indirectly benefit the HPOP.

Common Diagnostic Values for 6.0 Powerstroke HPOP

Here’s a quick reference table for expected ICP/IPR values, which are key to diagnosing 6.0 Powerstroke HPOP failure:

| Engine State | ICP Actual (PSI) | ICP Desired (PSI) | IPR Duty Cycle (%) | Indications |

|---|---|---|---|---|

| Key On, Engine Off (KOEO) | 0-10 | 0 | 14-16 | Normal for static engine. |

| Cranking (Healthy) | >500 (rapidly climbs) | >500 (commands for start) | ~60-75 | Engine should start quickly. |

| Cranking (Failing HPOP/Leak) | <500 (struggles to climb) | >500 (commands for start) | ~75-85 | No-start condition, indicates high-pressure oil system fault. |

| Warm Idle (Healthy) | 600-750 | 600-750 (matches actual) | 20-30 | Smooth idle, normal operation. |

| Warm Idle (Failing HPOP/Leak) | Fluctuating/Low | Steady/High | 35-50+ | Rough idle, loss of power, indicates leak or weak pump. |

| WOT (Wide Open Throttle) | 3000-4000+ | 3000-4000+ | Up to 85 | Max power. If Actual is much lower than Desired, indicates HPOP weakness. |

These values are general guidelines and can vary slightly based on engine conditions and modifications. However, significant deviations from these ranges, especially low ICP Actual when ICP Desired is high, are strong indicators of a problem within the high-pressure oil system.

Conclusion: Stay Ahead of 6.0 Powerstroke HPOP Failure

The High-Pressure Oil Pump is undeniably a weak link in the otherwise robust 6.0 Powerstroke design, but with the right knowledge, you don’t have to be caught off guard. Understanding the symptoms of 6.0 Powerstroke high pressure oil pump failure is your best defense against unexpected breakdowns and costly repairs. From the tell-tale no-start to subtle performance issues and critical diagnostic trouble codes, knowing what to look for empowers you to act quickly.

Remember, early diagnosis is paramount. If you experience any of the signs discussed – extended crank times, rough idling, loss of power, or relevant DTCs – don’t hesitate. Utilize an OBD-II scanner to monitor your ICP and IPR values, and if possible, perform an air test. Addressing the issue promptly, and always replacing associated components like the STC fitting, standpipes, and dummy plugs, will ensure a more reliable and lasting repair. Stay proactive with your maintenance, use quality fluids and filters, and your 6.0 Powerstroke can continue to be the powerful, dependable truck you know it can be. Drive smart, diagnose accurately, and keep that diesel roaring!

🎥 Related Video: 06 Ford Powerstroke diesel no start low injection pressure. icp ipr

📺 DieselTechRon

Ford tech shows how to use a scan gauge x-gauge to diagnose the reason why this 6.0 powerstroke diesel is a no start. Note no …

Frequently Asked Questions

What are the most common symptoms of a 6.0 Powerstroke high pressure oil pump (HPOP) failure?

The primary indicators often include a hard start or no-start condition, especially when the engine is warm. You might also experience rough idling, stalling, or a noticeable loss of power during acceleration, as the injectors aren’t receiving adequate oil pressure to fire correctly.

My 6.0 Powerstroke cranks but won’t start. Could this be a sign of high pressure oil pump failure?

Yes, a crank-no-start condition is one of the most classic symptoms of a 6.0 Powerstroke high pressure oil pump failure. The HPOP is crucial for generating the pressure needed to operate the fuel injectors, and without it, the engine simply cannot fire up.

How is a 6.0 Powerstroke high pressure oil pump failure typically diagnosed by mechanics?

Mechanics typically diagnose HPOP failure by monitoring ICP (Injector Control Pressure) and IPR (Injector Pressure Regulator) sensor readings with a diagnostic scanner. Low or erratic ICP readings, especially during cranking, are strong indicators, often followed by an air test through the ICP sensor port to check for leaks in the high-pressure oil system.

Can I continue to drive my 6.0 Powerstroke if I suspect HPOP failure?

It is strongly not recommended to drive your 6.0 Powerstroke if you suspect a high pressure oil pump failure. Driving with insufficient oil pressure can lead to further damage to other vital engine components, potentially causing more expensive repairs or leaving you stranded.

Will a failing 6.0 Powerstroke HPOP trigger a “Check Engine” light or specific fault codes?

Yes, a failing 6.0 Powerstroke HPOP often triggers the “Check Engine” light and sets specific diagnostic trouble codes (DTCs). Common codes include P2285 (ICP Sensor Circuit Low), P2288 (ICP Sensor Circuit High), or codes related to insufficient ICP during cranking or running, indicating a problem with the high-pressure oil system.

What are some common reasons why the 6.0 Powerstroke high pressure oil pump fails?

The 6.0 Powerstroke high pressure oil pump can fail due to several reasons, including normal wear and tear over time, cavitation from air in the oil system, or internal leaks in the high-pressure oil circuit itself. Examples of these leaks include a failed STC (Standpipe and Dummy Plug) fitting or branch tube seals, which reduce the pressure the HPOP can generate.