How to Troubleshoot 7.3 Powerstroke Low Boost Pressure: Boost Performance

Featured image for this comprehensive guide about How to troubleshoot 7.3 Powerstroke low boost pressure

Image source: mechanicalboost.com

The 7.3 Powerstroke engine. For many, it’s more than just an engine; it’s a legacy. Renowned for its unparalleled durability, simplicity, and raw power, this iconic diesel has powered countless trucks through millions of miles, earning a reputation as one of the most reliable and beloved power plants ever produced. Whether you use your F-Series for heavy-duty towing, off-road adventures, or simply as a dependable daily driver, the 7.3 delivers a driving experience that’s truly unique. Its distinct rumble and robust performance are a source of pride for owners worldwide.

However, even legends aren’t immune to the occasional hiccup. One of the most common and frustrating issues that can plague a 7.3 Powerstroke owner is `low boost pressure`. When your truck feels sluggish, lacks its characteristic grunt, or struggles to pull a load it once handled with ease, chances are you’re experiencing a dip in boost. This isn’t just about a slight drop in power; it can lead to increased fuel consumption, excessive exhaust smoke, higher exhaust gas temperatures (EGTs), and a generally compromised driving experience. Ignoring `7.3 Powerstroke low boost pressure` can not only diminish your truck’s performance but also potentially lead to more serious, costly damage down the line.

But don’t despair! Diagnosing and resolving `7.3 Powerstroke low boost pressure` is often well within the reach of a determined DIY mechanic. This comprehensive guide will arm you with the knowledge, tools, and step-by-step procedures to pinpoint the root cause of your boost issues and restore your mighty 7.3 Powerstroke to its former glory. We’ll dive deep into the common culprits, equip you with actionable troubleshooting methods, and provide practical solutions to get your truck boosting strong again. Let’s get your Powerstroke performing at its peak!

Quick Answers to Common Questions

What’s the most common culprit for 7.3 Powerstroke low boost pressure?

Often, the culprit is a boost leak! Check your intercooler boots and up-pipes for cracks or loose clamps, as these are frequent failure points that cause significant 7.3 Powerstroke low boost pressure.

How can I quickly tell if my 7.3 Powerstroke is experiencing low boost?

You’ll likely notice a lack of power, slower acceleration, and potentially excessive black smoke, especially when towing. A boost gauge will confirm if your 7.3 Powerstroke low boost pressure is below normal operating ranges.

Is a failing turbo always the reason for 7.3 Powerstroke low boost pressure?

Not necessarily! While a worn turbo can be the cause, many times 7.3 Powerstroke low boost pressure stems from simpler issues like boost leaks, clogged air filters, or even a faulty Exhaust Back Pressure (EBP) valve.

What’s one quick, free check I can do for 7.3 Powerstroke low boost pressure?

Perform a thorough visual inspection of all your intercooler pipes and boots for any obvious tears, cracks, or signs of oil residue. You might even hear a distinctive whooshing sound under acceleration if there’s a significant boost leak causing your 7.3 Powerstroke low boost pressure.

Besides leaks, what’s another simple thing that could cause 7.3 Powerstroke low boost pressure?

Don’t overlook your air filter! A heavily clogged air filter can severely restrict airflow to the turbo, preventing it from building proper boost and directly contributing to 7.3 Powerstroke low boost pressure.

📋 Table of Contents

- Understanding Boost Pressure in Your 7.3 Powerstroke

- The Core Culprits: Common Causes of Low Boost

- Step-by-Step Diagnostic Process for 7.3 Powerstroke Low Boost

- Common Fixes and Preventative Maintenance

- Typical 7.3 Powerstroke Boost & Sensor Values (Approximate)

- When to Seek Professional Help (and What to Expect)

- Conclusion

Understanding Boost Pressure in Your 7.3 Powerstroke

Before we dive into troubleshooting, it’s crucial to understand what boost pressure is and how your 7.3 Powerstroke generates it. This foundational knowledge will make identifying and fixing problems much more intuitive.

Learn more about How to troubleshoot 7.3 Powerstroke low boost pressure – How to Troubleshoot 7.3 Powerstroke Low Boost Pressure: Boost Performance

Image source: blog.garagepro.in

What is Boost Pressure and Why is it Important?

In simple terms, boost pressure is the additional air pressure, above atmospheric pressure, that your turbocharger forces into the engine’s intake manifold. Naturally aspirated engines rely on atmospheric pressure to push air into the cylinders, but turbochargers act like air pumps, cramming more air in. Why is more air important? Because for every measure of fuel your engine burns, it needs a corresponding amount of oxygen. More air means you can inject more fuel, which in turn generates more power and torque. This is especially critical for a heavy-duty diesel engine like the 7.3 Powerstroke, where robust power is essential for towing and hauling. Proper boost ensures efficient combustion, optimal power delivery, and better fuel economy.

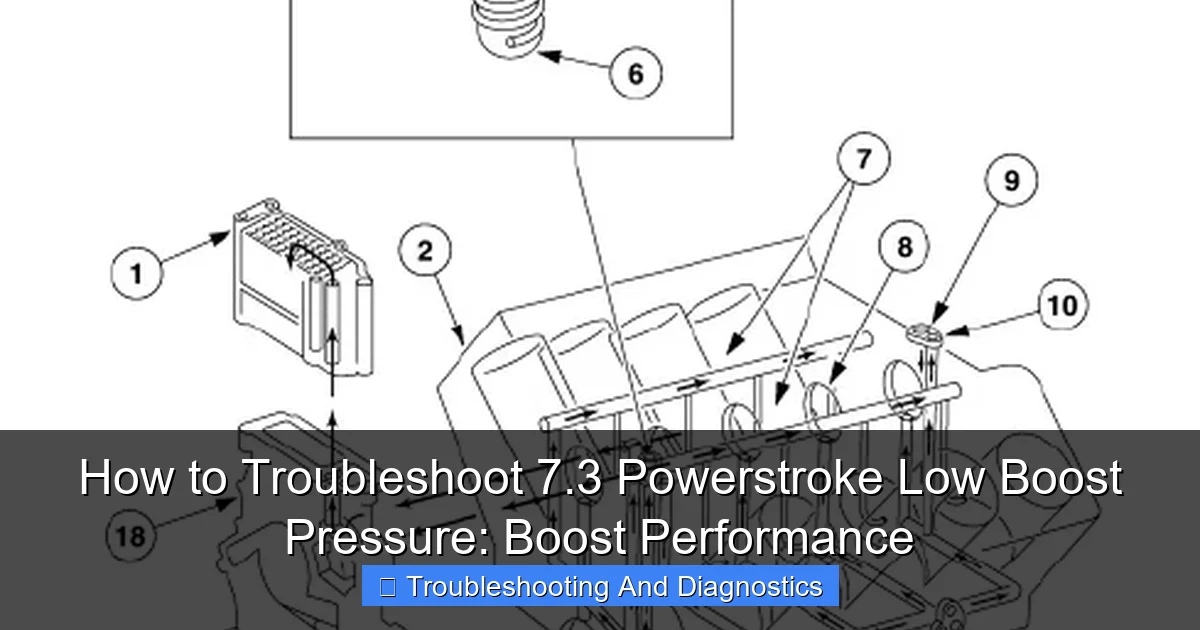

| Potential Cause | Diagnostic Method | Typical Impact / Resolution |

|---|---|---|

| Exhaust Leaks (Up-pipes, Manifold) | Visual inspection for soot, listen for exhaust hiss, perform a smoke test. | Significant power loss, high EGTs; boost reduced by 5-15+ PSI. Replace faulty components/gaskets. |

| Charge Air Cooler (CAC) System Leaks | Visual inspection of intercooler boots, perform a CAC pressure test, listen for air leaks under boost. | Noticeable power loss, increased black smoke; boost reduced by 3-10+ PSI. Replace boots, repair/replace CAC. |

| Turbocharger Wear/Damage | Check turbo shaft for excessive radial/axial play, inspect compressor/turbine wheels for damage. | Excessive smoke, whining/grinding noise; boost severely reduced (0-10 PSI). Rebuild or replace turbocharger. |

| MAP Sensor Malfunction | Compare MAP to BARO (Key On, Engine Off), check MAP hose for clogs, monitor live data for erratic readings. | Incorrect boost reporting (PCM may limit fuel/power); readings can be off by 10-20 PSI. Replace sensor/clean hose. |

| EBPV (Exhaust Back Pressure Valve) Malfunction | Observe EBPV arm movement, monitor EBP sensor readings, unplug EBPV solenoid to disable. | Reduced power, higher EGTs (if stuck closed); boost may be lower by 5-8 PSI. Clean/replace EBPV, replace EBP sensor, or EBPV delete. |

How Your 7.3 Generates Boost

The heart of your 7.3 Powerstroke’s boost system is the Garrett TP38 turbocharger (or the later Super Duty models with the Garrett GTP38). Here’s a simplified breakdown of how it works:

- Exhaust Gas Drive: Hot exhaust gases from the engine are directed through the exhaust housing of the turbocharger, spinning a turbine wheel.

- Compressor Action: The turbine wheel is connected via a shaft to a compressor wheel located in the intake housing. As the turbine spins, it also spins the compressor.

- Air Compression: The rapidly spinning compressor wheel draws in ambient air, compresses it, and then pushes this pressurized, superheated air into the intercooler.

- Cooling & Delivery: The intercooler (or Charge Air Cooler – CAC) cools this compressed air, making it denser. Denser air contains more oxygen, further enhancing combustion efficiency.

- Engine Intake: Finally, this cool, dense, pressurized air is routed into the engine’s intake manifold and then into the cylinders, ready to mix with fuel for a powerful combustion cycle.

Any disruption in this intricate process can lead to `7.3 Powerstroke low boost pressure`.

Symptoms of Low Boost Pressure

Identifying `low boost pressure` often starts with recognizing the symptoms your truck exhibits. Here’s what to look out for:

- Sluggish Acceleration & Lack of Power: This is the most obvious sign. Your truck feels “gutless,” especially when accelerating or going uphill.

- Excessive Black Smoke: If your engine is getting enough fuel but not enough air, incomplete combustion occurs, leading to unburnt fuel exiting as black smoke from the exhaust.

- Increased Exhaust Gas Temperatures (EGTs): Insufficient air to burn all the fuel can cause EGTs to skyrocket, which can be damaging to the turbocharger and engine over time.

- Poor Fuel Economy: Your engine has to work harder to achieve the same speed or power output, leading to a noticeable drop in MPG.

- Check Engine Light (CEL): The Powertrain Control Module (PCM) might detect an anomaly and trigger a CEL, often accompanied by diagnostic trouble codes (DTCs) related to boost, MAP sensor, or EBP sensor readings. Common codes include P0236 (Turbo/Super Charger Boost Sensor A Circuit Range/Performance) or P0470/P0472 (EBP Sensor Circuit).

- Whistling or Hissing Sounds: Often indicative of a boost leak somewhere in the intake system.

The Core Culprits: Common Causes of Low Boost

When you’re facing `7.3 Powerstroke low boost pressure`, there are several usual suspects. Understanding these common failure points will help streamline your diagnostic process.

Learn more about How to troubleshoot 7.3 Powerstroke low boost pressure – How to Troubleshoot 7.3 Powerstroke Low Boost Pressure: Boost Performance

Image source: dieseliq.com

Boost Leaks (The Usual Suspect)

By far, the most common cause of `low boost pressure` in a 7.3 Powerstroke is a boost leak. Anywhere pressurized air is routed, there’s a potential for it to escape. This is because the system relies on sealed connections to maintain pressure. The more pressure, the more likely a leak is to occur at a weak point.

- Charge Air Cooler (CAC) Boots and Pipes: These are flexible silicone or rubber boots connecting the turbocharger, intercooler, and intake manifold. They are subject to high pressure, vibration, and oil residue, leading to cracking, splitting, or loosening over time. This is a primary source of `7.3 Powerstroke low boost pressure`.

- Intercooler Damage: The intercooler itself can develop cracks or holes due to age, road debris, or fatigue.

- Intake Manifold Gaskets: Less common but still possible, the gaskets sealing the intake manifold to the cylinder heads can leak, allowing boost to escape.

- EBPV (Exhaust Back Pressure Valve) Leakage: On earlier 7.3 models (typically up to 1999.5), the EBPV, located within the turbocharger exhaust housing, can fail to fully close or seal properly, leading to exhaust leakage and thus insufficient turbine drive pressure.

Turbocharger Issues

While the Garrett TP38/GTP38 is robust, it’s not invincible. Problems with the turbocharger itself can directly cause `low boost pressure`.

- Worn Compressor/Turbine Wheels: Excessive shaft play can allow the compressor or turbine wheels to make contact with their housings, damaging the blades and reducing their efficiency. Contaminants entering the intake or exhaust can also damage the blades.

- Exhaust Back Pressure Valve (EBPV) Problems: The EBPV actuator or valve mechanism can stick, preventing the valve from fully opening or closing. A partially closed EBPV creates back pressure, which can reduce the turbo’s efficiency. A fully open EBPV (when it should be closing for cold starts) won’t contribute to `low boost pressure`, but a malfunctioning actuator can cause issues.

- Clogged EBP Sensor Tube: This is a very common issue. The tube leading from the exhaust manifold to the EBP sensor frequently clogs with soot, leading to inaccurate readings. The PCM relies on this sensor to help manage engine performance and perceived load, so a false reading can affect fuel delivery and indirectly, boost.

Exhaust System Restrictions

Any restriction downstream of the turbocharger can hinder exhaust flow, preventing the turbine from spinning freely and reducing boost.

- Clogged Catalytic Converter: Over time, catalytic converters can become clogged with soot or partially melt, severely restricting exhaust flow.

- Damaged Muffler or Exhaust Pipe: A crushed pipe or internal muffler collapse can create a significant blockage.

- Up-Pipes and Exhaust Manifold Leaks: Exhaust gas leaks from the up-pipes (which feed exhaust gases to the turbo) or exhaust manifold gaskets will reduce the energy reaching the turbine, leading to `low boost pressure`. These leaks often manifest as an exhaust “huffing” sound and soot stains around the leak point.

Fuel System & Injector Problems

While not a direct cause of `low boost pressure`, issues with fuel delivery or injector performance can mimic low boost symptoms by preventing the engine from generating full power.

- Worn Injector O-rings: The 7.3 Powerstroke uses oil pressure to actuate the fuel injectors. Worn O-rings can allow high-pressure oil or combustion gases to leak, causing a lack of cylinder contribution, misfires, and a perceived lack of power, often mistaken for `low boost pressure`.

- Low Fuel Pressure: While the 7.3’s fuel system is separate from the boost system, insufficient fuel supply means the engine can’t produce its maximum power, even with adequate air, leading to the sensation of `low boost pressure`.

Sensor Malfunctions

The PCM relies on various sensors to determine engine load, air intake, and exhaust back pressure. Faulty readings can lead the PCM to command less fuel, which in turn results in `low boost pressure`.

- MAP (Manifold Absolute Pressure) Sensor: This sensor measures the pressure in the intake manifold. If it reads incorrectly (e.g., constantly low), the PCM might think less air is entering the engine and reduce fuel delivery.

- EBP (Exhaust Back Pressure) Sensor: Located near the EBPV, this sensor measures exhaust back pressure. A faulty sensor, or more commonly, a clogged tube leading to it, can send incorrect data to the PCM, affecting how it manages engine parameters.

- ICP (Injector Control Pressure) Sensor: This sensor measures the oil pressure used to fire the injectors. While not directly related to boost, an inaccurate ICP reading can cause fueling issues that result in a perceived `low boost pressure` problem.

- IAT (Intake Air Temperature) Sensor: Less common, but a faulty IAT sensor can cause the PCM to incorrectly adjust fuel for air density, leading to suboptimal combustion.

Step-by-Step Diagnostic Process for 7.3 Powerstroke Low Boost

Now that we’ve covered the common causes, let’s get hands-on. A systematic approach is key to efficiently diagnosing `7.3 Powerstroke low boost pressure`.

Visual Inspection & Initial Checks

Start with the simplest things. A thorough visual inspection can often reveal obvious culprits without needing special tools.

- Look and Listen: With the engine running (if possible, safely), listen for any unusual hissing, whistling, or whooshing sounds that might indicate a boost leak. Also, listen for a “chuffing” or “huffing” sound from the exhaust side, which could point to up-pipe or exhaust manifold leaks.

- Inspect CAC Boots: Carefully examine all the Charge Air Cooler (CAC) boots between the turbo, intercooler, and intake for cracks, splits, or loose clamps. Pay close attention to the underside of the boots, where damage can be hidden. Look for oil residue around the boots, which can soften the rubber over time.

- Check Intercooler: Inspect the intercooler for any visible damage, bent fins, or signs of leaks (e.g., oil residue).

- Examine Exhaust System: Trace the exhaust system from the turbocharger back. Look for dents, crushes, or black soot stains around pipe joints, flex pipes (up-pipes), catalytic converter, or muffler, indicating exhaust leaks or restrictions.

- EBP Sensor & Tube: Locate the EBP sensor (usually on the passenger side front of the engine) and the metal tube leading to it. Check for severe corrosion and, crucially, assume the tube is at least partially clogged.

Performing a Boost Leak Test

This is arguably the most effective way to identify `boost leaks` – the primary cause of `7.3 Powerstroke low boost pressure`. You’ll need an air compressor, an air hose with a regulator, and a boost leak test kit (or DIY one using PVC caps/plugs and an air fitting).

- Prepare the Intake: Remove the air filter and intake hose from the turbo’s compressor inlet.

- Seal the Intake: Use your boost leak test plug to seal off the turbo’s compressor inlet. Some kits might have you seal the intake manifold after the turbo. The goal is to pressurize the entire intake tract.

- Pressurize the System: Connect your air compressor to the test plug. Start with low pressure (around 5-10 PSI) and slowly increase it, not exceeding 30 PSI to avoid damaging components.

- Listen for Leaks: Listen carefully for hissing sounds. Check all CAC boots, intercooler, intake manifold gaskets, and even the intake heater element seals. You can also spray soapy water on suspect areas; bubbles will indicate a leak. Pay extra attention to the hot-side intercooler pipe (from turbo to intercooler) as it experiences the most pressure.

- Don’t Forget the Up-Pipes: While not a boost leak, exhaust leaks from the up-pipes can be found by listening during the visual inspection or by using a smoke machine, as the pressure differential won’t be as clear with a boost leak test.

Monitoring Key Sensors & Parameters

An OBD-II scanner (like a cheap Bluetooth adapter with Torque Pro for Android, or dedicated software like Forscan on a laptop) is invaluable for monitoring live data. This allows you to see what the PCM sees.

- Connect & Log: Connect your scanner and select relevant PIDs (Parameter IDs) to monitor during a test drive under load.

- Key PIDs to Watch:

- MAP (Manifold Absolute Pressure): This is your actual boost pressure (minus atmospheric pressure). At wide-open throttle (WOT), expect 20-25 PSI.

- EBP (Exhaust Back Pressure): Should track MAP closely, typically 2-5 PSI higher at WOT, but not significantly more.

- ICP (Injector Control Pressure): Critical for fuel. Should build quickly to 2500-3000 PSI under load.

- IPR (Injector Pressure Regulator) Duty Cycle: Shows how hard the IPR valve is working to maintain ICP. High duty cycles (above 60-70% at WOT) can indicate ICP system issues (e.g., oil leaks, weak HPOP).

- Fuel Pressure: While not an OBD-II PID, a mechanical gauge is recommended. Should be 45-70 PSI at all times.

- Analyze Data: If MAP readings are consistently low, it confirms `low boost pressure`. If EBP is significantly higher than MAP (e.g., EBP is 40 PSI while MAP is 20 PSI), it suggests an exhaust restriction or a faulty EBP sensor/clogged tube. If ICP isn’t building or IPR duty cycle is high, your fueling system might be limiting power.

Turbocharger Inspection & EBPV Test

If boost leaks aren’t the primary issue, turn your attention to the turbo itself.

- Shaft Play: With the intake hose removed, reach in and check for shaft play on the compressor wheel. Minimal in-and-out (axial) play is acceptable, but excessive side-to-side (radial) play indicates worn bearings and a failing turbo.

- Compressor Wheel Damage: Inspect the compressor wheel blades for bending, chipping, or other damage from foreign objects.

- EBPV Operation: On earlier 7.3s, cycle the key on and off when cold. You should hear the EBPV actuator cycle the valve. If not, check the wiring and solenoid. Visually confirm the valve opens fully when warm.

- Clean EBP Sensor Tube: This is an easy and common fix. Remove the EBP sensor and the metal tube leading to the exhaust manifold. Use a drill bit (smaller than the tube’s internal diameter) or a thin wire to ream out the carbon buildup. Reinstall and retest. This simple step can often resolve EBP-related `low boost pressure` issues.

Fuel System & Injector Health Check

If all boost components check out, investigate fueling.

- Cylinder Contribution Test: Use your OBD-II scanner to perform a cylinder contribution test. This will identify any weak or misfiring injectors.

- Injector O-Rings: Listen for a distinct “cackle” or diesel knock that might indicate worn injector O-rings, allowing combustion gases to leak into the oil, affecting HPOP performance and causing a loss of power.

- Fuel Pressure Test: Use a mechanical fuel pressure gauge to confirm your fuel pump is delivering adequate pressure (45-70 PSI) at idle and under load.

Common Fixes and Preventative Maintenance

Once you’ve identified the problem causing your `7.3 Powerstroke low boost pressure`, it’s time for the fix. Many of these solutions are straightforward and can be handled in your garage.

Addressing Boost Leaks

The good news about boost leaks is they are usually easy to fix once found:

- Replace Worn CAC Boots and Clamps: This is a very common repair. Always use high-quality, preferably silicone, boots and heavy-duty T-bolt clamps. Silicone boots are more resistant to oil and heat and provide a better seal than standard rubber.

- Seal Exhaust Leaks: For up-pipe leaks, replacement up-pipes with bellows (flexible joints) are a popular upgrade, as the factory “donut” gaskets are prone to failure. Ensure exhaust manifold bolts are tight.

- Repair Intercooler: Small cracks in the intercooler might be repaired with specialized epoxy, but significant damage usually requires replacement.

Turbocharger Service

Depending on the issue, turbo service can range from simple cleaning to full replacement:

- Clean EBP Sensor and Tube: As mentioned, this is a must-do for `7.3 Powerstroke low boost pressure` diagnostics. Regular cleaning (every 50,000 miles or so) can prevent future issues.

- EBPV Delete: If your EBPV is faulty and you live in a warm climate where exhaust back pressure for cold starts isn’t critical, an EBPV delete kit can simplify the system and eliminate a potential failure point. Ensure this aligns with local emissions regulations.

- Turbo Rebuild or Replacement: If there’s excessive shaft play or physical damage to the compressor/turbine wheels, your turbo needs attention. A professional rebuild might be an option, or outright replacement with a new or remanufactured unit. Consider upgrading to a modified GTP38R ball-bearing turbo for enhanced performance and durability if your budget allows.

Sensor Replacement

When a sensor is confirmed faulty through live data or diagnostic codes, replacement is the solution:

- MAP, EBP, ICP Sensors: Always use OEM-quality replacement sensors. Aftermarket sensors can sometimes provide inaccurate readings, leading to continued problems. Ensure the O-rings are lubricated upon installation for a proper seal.

- Calibration: Some sensors, particularly the EBP, may benefit from clearing codes and allowing the PCM to relearn values after replacement.

Exhaust System Repair

If an exhaust restriction is identified, address it directly:

- Unclogging/Replacing Catalytic Converter: A clogged catalytic converter typically requires replacement.

- Repairing Damaged Pipes: Crushed pipes need to be replaced or repaired to restore proper exhaust flow.

Injector Maintenance

For fueling issues affecting power:

- Replacing Worn Injector O-rings: This is a common service that can restore lost power and improve idle quality. It’s a detailed job but well within the scope of a determined DIYer.

- Injector Replacement: If O-rings don’t fix the issue, or if the cylinder contribution test reveals failing injectors, replacement with new or professionally rebuilt units may be necessary.

Typical 7.3 Powerstroke Boost & Sensor Values (Approximate)

Understanding what “normal” looks like can be incredibly helpful when diagnosing `7.3 Powerstroke low boost pressure`. Use this table as a general reference for sensor readings and pressures. Keep in mind that exact values can vary slightly based on modifications, altitude, and engine condition. Always refer to a factory service manual for precise specifications for your specific year and model if available.

| Parameter | Idle (Warm Engine) | WOT (Wide Open Throttle) | Notes |

|---|---|---|---|

| Boost Pressure (MAP – BARO) | 0-1 PSI | 20-25 PSI | Stock values, can be higher with performance tunes/turbos. |

| MAP Sensor (Absolute Pressure) | ~14.7 PSI | ~35-40 PSI | Includes atmospheric pressure (BARO). Check against BARO sensor for offset. |

| EBP Sensor (Exhaust Back Pressure) | ~14.7 PSI | ~25-35 PSI | Should generally track MAP +/- a few PSI. High difference indicates restriction. |

| ICP Sensor (Injector Control Pressure) | 500-750 PSI | 2,500-3,000 PSI | Crucial for injector firing. Low values impact power. |

| IPR Duty Cycle (Injector Pressure Regulator) | 8-15% | 40-60% (up to ~70% max) | Higher % means IPR is working harder to maintain ICP. |

| Fuel Pressure (Mechanical Gauge) | 45-70 PSI | 45-70 PSI | Should remain stable under load. Low pressure can cause misfires. |

When to Seek Professional Help (and What to Expect)

While this guide empowers you to tackle many `7.3 Powerstroke low boost pressure` issues, there are times when calling in a professional is the smartest move.

Recognizing Your Limits

It’s important to be honest about your comfort level and expertise. You might want to seek professional help if:

- You lack the specialized tools (e.g., advanced diagnostic software, specific turbo tools).

- The issue remains unresolved after following the troubleshooting steps, especially if it’s an intermittent problem.

- You suspect internal engine damage or complex fuel injection system failures.

- You simply don’t have the time or space to dedicate to a comprehensive diagnosis and repair.

Choosing a Qualified Diesel Mechanic

Not all mechanics are created equal, especially when it comes to the unique demands of a 7.3 Powerstroke. Look for a shop or technician with:

- Specific 7.3 Powerstroke Experience: Ask if they have technicians who specialize in or have extensive experience with this particular engine.

- Specialized Diagnostic Equipment: A reputable diesel shop will have advanced diagnostic scanners (like Ford IDS) and the ability to perform more intricate tests (e.g., cylinder compression, high-pressure oil system tests).

- Good Reputation: Check online reviews, ask for recommendations from other 7.3 owners, and ensure they have a transparent pricing structure.

What a Mechanic Will Do

A professional mechanic will likely perform many of the steps outlined here, but with access to more advanced tools and deeper experience:

- Advanced Diagnostics: They can use dealer-level software to read more specific codes and access detailed sensor data.

- Specialized Testing: This might include smoke testing the intake system for elusive leaks, performing an HPOP volume test, or conducting a full compression test to rule out internal engine problems.

- Expert Repair: From intricate turbocharger replacements to complex injector repairs, they have the knowledge and tools to carry out the repair efficiently and correctly.

Sometimes, the cost of specialized tools and the time commitment can outweigh the savings of DIY, making a professional diagnosis a worthwhile investment to get your `7.3 Powerstroke low boost pressure` problem fixed right the first time.

Conclusion

The 7.3 Powerstroke is a testament to rugged engineering, and encountering `low boost pressure` can feel like a betrayal of its legendary strength. However, as we’ve explored, most boost-related issues are common, identifiable, and fixable with a systematic approach. From the simple visual checks of CAC boots and the vital cleaning of the EBP sensor tube to the more advanced diagnosis using an OBD-II scanner and boost leak testing, you now possess the knowledge to pinpoint the source of your `7.3 Powerstroke low boost pressure`.

Remember, patience and methodical troubleshooting are your best allies. By diligently working through the steps outlined in this guide, you’ll not only restore your truck’s power and efficiency but also gain a deeper understanding and appreciation for its remarkable mechanics. There’s immense satisfaction in diagnosing and fixing your own vehicle, and getting your 7.3 Powerstroke back to its optimal performance is a reward in itself. So roll up your sleeves, apply these actionable tips, and enjoy the robust, reliable power that your `7.3 Powerstroke` was born to deliver. Happy boosting!

🎥 Related Video: Quick tips on finding a boost leak! #turbo #boost #boostleak #faultfinding #quicktips #mechanictips

📺 Torque Automotive

Frequently Asked Questions

What are the common symptoms of low boost pressure in a 7.3 Powerstroke?

Your 7.3 Powerstroke might feel sluggish, have reduced power, and struggle to accelerate, especially when towing or under load. You may also notice excessive black smoke from the exhaust, indicating unburnt fuel due to insufficient air.

What are the most common causes of low boost pressure on a 7.3 Powerstroke?

Common culprits include exhaust leaks (up-pipes, manifold), boost leaks in the intercooler boots or pipes, or a worn turbocharger. A malfunctioning Exhaust Back Pressure Valve (EBPV) can also significantly contribute to a lack of boost.

How can I diagnose a 7.3 Powerstroke low boost pressure issue myself?

Begin by visually inspecting all intercooler boots, clamps, and exhaust up-pipes for leaks. A boost leak test using a specialized kit can pinpoint leaks in the charge air system, while monitoring boost levels with a gauge or diagnostic tool during a test drive helps confirm low pressure.

How much boost should a healthy 7.3 Powerstroke typically generate?

A stock 7.3 Powerstroke engine should typically generate between 18-22 PSI of boost under full load. Consistently lower readings indicate a performance issue that needs troubleshooting to restore optimal engine output.

Can the Exhaust Back Pressure Valve (EBPV) cause low boost pressure on my 7.3 Powerstroke?

Yes, a sticking or malfunctioning EBPV can significantly contribute to low boost pressure. If the valve fails to open fully, it restricts exhaust flow to the turbo, preventing it from spooling up properly and reducing overall boost production.

Is it safe to drive my 7.3 Powerstroke with low boost pressure?

While generally not immediately catastrophic, driving with persistent low boost pressure can lead to other issues over time, such as increased exhaust gas temperatures and potential long-term engine wear due to inefficient combustion. It’s best to address the problem promptly to maintain optimal engine health and performance.