How to Troubleshoot 6.0 Powerstroke PCM Failure Symptoms: Common Issues

Featured image for this comprehensive guide about How to troubleshoot 6.0 Powerstroke PCM failure symptoms

Image source: f150advisor.com

How to Troubleshoot 6.0 Powerstroke PCM Failure Symptoms: Common Issues

Category: Troubleshooting and Diagnostics

The Ford 6.0 Powerstroke engine, a true workhorse in its prime, earned a reputation for impressive power and torque. However, it also became infamous for a range of complex issues, many of which can be traced back to or mimicked by problems with its sophisticated electronic brain: the Powertrain Control Module (PCM), also often referred to as the Engine Control Module (ECM).

When your trusty 6.0 Powerstroke starts acting up, exhibiting anything from a frustrating no-start condition to sudden power loss or a persistent Check Engine Light, identifying the root cause can feel like a daunting task. While many components can cause similar symptoms, recognizing the tell-tale 6.0 Powerstroke PCM failure symptoms is crucial for accurate diagnosis and efficient repair. A failing PCM can leave your truck dead in the water, impact fuel efficiency, and even damage other vital engine components if left unaddressed. This comprehensive guide will equip you with the knowledge to understand, diagnose, and address common PCM-related issues, helping you get your Powerstroke back on the road with confidence.

Navigating the intricacies of modern diesel engines requires a systematic approach, especially when dealing with the heart of the electronic control system. In this post, we’ll dive deep into what the PCM does, the most prevalent signs of its malfunction, and a detailed diagnostic pathway to help you determine if your 6.0 Powerstroke PCM is failing. We’ll also cover essential tools, potential repair options, and preventative measures to keep your engine’s brain healthy for miles to come. Let’s get started on pinpointing those elusive 6.0 Powerstroke PCM failure symptoms.

Quick Answers to Common Questions

What are the most common initial 6.0 Powerstroke PCM failure symptoms I should look out for?

You might experience a no-start condition, extended crank times, or a sudden loss of power while driving. Often, dashboard warning lights like the “wrench” or “check engine” will illuminate.

My 6.0 Powerstroke isn’t starting. Could it be PCM failure, and what’s one easy check?

A no-start is a classic sign of 6.0 Powerstroke PCM failure symptoms. First, check your battery and all relevant fuses for the PCM and engine control, as a simple blown fuse can mimic PCM issues.

How can I differentiate 6.0 Powerstroke PCM failure symptoms from other electrical problems?

While many issues can overlap, specific diagnostic trouble codes (DTCs) related to sensor reference voltage or internal PCM faults are strong indicators. Also, if multiple, seemingly unrelated systems appear to be failing simultaneously, the PCM might be the culprit.

Do I need special tools to diagnose 6.0 Powerstroke PCM failure symptoms effectively?

Yes, a good OBD-II scanner capable of reading Powerstroke-specific codes and live data is essential. A multimeter can also help test power supply to the PCM and various sensor voltages.

If I suspect 6.0 Powerstroke PCM failure, is it okay to keep driving my truck?

It’s generally not recommended to drive with suspected 6.0 Powerstroke PCM failure symptoms. The PCM controls vital engine functions, and unpredictable behavior could leave you stranded or even cause further damage.

📋 Table of Contents

- Understanding the Critical Role of Your 6.0 Powerstroke PCM

- Recognizing Key 6.0 Powerstroke PCM Failure Symptoms

- Step-by-Step Diagnostic Process for Suspected PCM Failure

- Essential Tools for 6.0 Powerstroke PCM Diagnostics

- When to Consider PCM Replacement or Repair

- Preventative Measures to Extend Your PCM’s Lifespan

- Common Diagnostic Trouble Codes (DTCs) Associated with PCM or Mimicking PCM Issues

- Conclusion

Understanding the Critical Role of Your 6.0 Powerstroke PCM

Before we can troubleshoot, it’s essential to understand exactly what the PCM is and why it’s so vital to your 6.0 Powerstroke. The PCM is, quite literally, the central computer that manages almost every aspect of your engine’s operation and, in many cases, your automatic transmission. It’s a complex microprocessor responsible for monitoring dozens of sensors and making thousands of calculations per second to ensure optimal performance, fuel efficiency, and emissions control.

Learn more about How to troubleshoot 6.0 Powerstroke PCM failure symptoms – How to Troubleshoot 6.0 Powerstroke PCM Failure Symptoms: Common Issues

Image source: solopcms.com

Key functions of the 6.0 Powerstroke PCM include:

| Symptom Description | Primary Non-PCM Causes (Likely Culprits) | PCM-Specific Diagnostic Insight/Actions |

|---|---|---|

| **No-Start / Cranks but No Start** | FICM failure, low battery, HPOP/IPR issues, fuel supply problems, bad starter. | **High PCM likelihood if:** No communication with scan tool, no FICM SYNC, no IPR duty cycle commanded (0%), or absent sensor data (e.g., ICP, EOT) despite confirmed good sensors/wiring. |

| **Rough Idle / Misfire / Stalling** | Faulty injectors, failing FICM, bad IPR valve, wiring harness issues (UVC), low fuel pressure. | **Moderate PCM likelihood if:** Multiple, unrelated engine management DTCs appear, erratic sensor readings (e.g., ICP fluctuating wildly) that don’t correspond to actual engine conditions, or PCM commands (e.g., IPR %) are inconsistent. |

| **Loss of Power / Limp Mode** | VGT solenoid, EBP sensor, MAP sensor, HPOP/ICP issues, clogged exhaust, turbocharger failure. | **Low-Moderate PCM likelihood if:** PCM does not respond to sensor inputs (e.g., EBP changes) or fails to command actuators (e.g., VGT) despite receiving correct signals, and no communication issues. Less common than sensor/actuator failure. |

| **No Communication with OBD-II Scanner** | Blown OBD-II fuse, faulty OBD-II port wiring, damaged CAN bus wiring, incompatible scan tool. | **High PCM likelihood if:** Verified good power/ground to OBD-II port, CAN bus integrity confirmed (e.g., other modules communicate), and PCM still unresponsive. This often indicates internal PCM failure. |

| **Intermittent Electrical Issues / Erratic Gauges** | Loose grounds, failing battery/alternator, corroded connections, faulty instrument cluster, wiring shorts. | **Moderate PCM likelihood if:** Symptoms occur under specific conditions (e.g., temperature, bumps), and PCM power/ground are stable. Can indicate internal solder joint failures or processor issues. Look for U-codes (communication). |

- Fuel Delivery: Controlling injector timing, pulse width, and fuel pressure based on engine load, RPM, and other factors.

- Ignition Timing: While diesel engines don’t have spark plugs, the PCM controls the high-pressure oil pump (HPOP) and the Fuel Injection Control Module (FICM) which are critical for initiating combustion.

- Transmission Control: Managing shift points, torque converter lock-up, and line pressure for smooth and efficient power transfer.

- Emissions Control: Monitoring and adjusting parameters to meet stringent emission standards, including Exhaust Gas Recirculation (EGR) and Variable Geometry Turbocharger (VGT) control.

- Diagnostic Monitoring: Constantly checking all engine and transmission systems for faults and storing Diagnostic Trouble Codes (DTCs) when issues arise. It’s the reason your Check Engine Light comes on.

- Sensor Interpretation: Receiving data from critical sensors like the ICP (Injection Control Pressure) sensor, IPR (Injection Pressure Regulator) valve, MAP (Manifold Absolute Pressure) sensor, EOT (Engine Oil Temperature) sensor, and many others.

Given its immense responsibilities, it’s clear why any malfunction within the PCM can lead to a wide array of problematic 6.0 Powerstroke PCM failure symptoms. The PCM operates in a harsh under-hood environment, exposed to heat, vibration, and electrical fluctuations, all of which can contribute to its eventual degradation or failure.

Recognizing Key 6.0 Powerstroke PCM Failure Symptoms

Identifying that your 6.0 Powerstroke PCM is failing can be challenging because many of its symptoms overlap with issues caused by other components. However, certain patterns and combinations of symptoms are strong indicators that your PCM might be the culprit. Pay close attention to these common 6.0 Powerstroke PCM failure symptoms:

Learn more about How to troubleshoot 6.0 Powerstroke PCM failure symptoms – How to Troubleshoot 6.0 Powerstroke PCM Failure Symptoms: Common Issues

Image source: dashboardwarning.com

No-Start or Hard-Start Conditions

- Cranking, But No Ignition: Your engine turns over strongly, but it simply won’t fire up. This could indicate the PCM isn’t sending the necessary signals to the FICM and injectors, or isn’t seeing critical inputs from sensors like the Crankshaft Position (CKP) or Camshaft Position (CMP) sensors.

- Delayed Starting: The engine takes an unusually long time to crank before it finally catches. This might point to intermittent PCM communication or internal processing delays.

- Intermittent Starting: The truck starts fine sometimes, but then suddenly refuses to start, only to start again later without any apparent reason. This often suggests a thermal-related PCM issue or a poor electrical connection.

Severe Engine Performance Issues

- Loss of Power and Poor Acceleration: If your Powerstroke feels sluggish, lacks its usual punch, or struggles to accelerate, the PCM might be failing to optimize fuel delivery or turbocharger control. This is a common 6.0 Powerstroke PCM failure symptom.

- Rough Idling or Misfires: An erratic idle, especially if accompanied by shaking or excessive vibration, can indicate that the PCM is not precisely controlling the fuel injectors or is receiving incorrect sensor data.

- Stalling While Driving: Perhaps one of the most dangerous symptoms, an engine that suddenly dies while you’re driving suggests a critical failure in the PCM’s ability to maintain basic engine operation.

- Erratic Shifting or Transmission Problems: Since the PCM often controls the transmission, a failing unit can lead to harsh shifts, delayed engagement, or the transmission staying in the wrong gear.

- Poor Fuel Economy: While many factors affect MPG, a consistently significant drop without other apparent causes could be due to the PCM incorrectly managing fuel injection.

Electrical and Communication Problems

- Persistent or Erratic Check Engine Light (CEL): While a CEL can mean many things, if it’s on with multiple seemingly unrelated codes, or if it comes on and goes off sporadically, it could be a sign of internal PCM trouble.

- No Communication with Diagnostic Tools: When you plug in an OBD-II scanner and it cannot establish communication with the vehicle’s computer, this is a very strong indicator of 6.0 Powerstroke PCM failure symptoms. It means the brain itself isn’t responding.

- Gauges Acting Erratically or Not Working: The PCM processes data for many dashboard gauges. If your speedometer, tachometer, fuel gauge, or temperature gauge start behaving erratically or stop working, a PCM issue could be the cause.

Fuel System Malfunctions

- Incorrect Fuel Pressure Readings: The PCM commands fuel pressure, and if it’s receiving bad data or sending incorrect commands, you might see excessively high or low fuel pressure, even with a good fuel pump.

- Injector Pulse Issues: The PCM determines when and for how long the injectors open. If this control is compromised, you can experience misfires or a complete lack of injection.

Step-by-Step Diagnostic Process for Suspected PCM Failure

When faced with potential 6.0 Powerstroke PCM failure symptoms, it’s crucial to follow a systematic diagnostic process. Many components can mimic a bad PCM, so don’t jump to conclusions without thorough testing.

Initial Checks: Don’t Blame the PCM First!

- Battery and Charging System: A weak battery or alternator can cause a multitude of electrical gremlins that look like PCM issues. Ensure your battery voltage is at least 12.6V fully charged and the alternator is charging correctly (around 13.5-14.5V running). Check for corroded or loose battery terminals and ground connections.

- Fuel and Oil Levels: Sounds simple, but a low fuel tank or insufficient engine oil (which the 6.0 Powerstroke uses for injection) can easily lead to a no-start condition or poor performance.

- Visual Inspection of Wiring Harnesses: The 6.0 Powerstroke is notorious for wiring harness chafing, especially around the FICM, fuel bowls, and engine valley. Look for any exposed, frayed, or burnt wires. Corrosion in connectors can also disrupt signals.

- Fuses and Relays: Check all relevant fuses and relays in both the under-hood and cabin fuse boxes that pertain to the engine, PCM, and fuel system.

Scan Tool Diagnostics

An advanced OBD-II scan tool capable of reading Ford-specific codes and live data is indispensable for diagnosing 6.0 Powerstroke PCM failure symptoms.

- Checking for Diagnostic Trouble Codes (DTCs): While DTCs don’t always point directly to the PCM, they provide invaluable clues. Pay attention to codes that indicate internal PCM faults (e.g., P0603, P0605, P0606) or codes related to critical sensors that show implausible readings. See our table below for common PCM-related DTCs.

- Monitoring Live Data: This is where a good scan tool shines. Key parameters to observe include:

- FICM Sync/Voltage: The FICM needs 48V to operate correctly. If the voltage is low, the FICM is usually the problem, not the PCM.

- ICP (Injection Control Pressure) Sensor Reading: Look for consistent pressure during cranking (500 PSI minimum) and running. Unstable or no reading could indicate a bad sensor, IPR, HPOP, or wiring. Try disconnecting the ICP sensor to see if it starts – if it does, the sensor is likely faulty.

- IPR (Injection Pressure Regulator) Valve Duty Cycle: The PCM controls the IPR. A high duty cycle with low ICP suggests an HPOP or leak issue.

- Engine RPM (CKP/CMP Sync): Ensure the PCM is seeing both crankshaft and camshaft position signals. No sync means no start.

- Fuel Pressure: Monitor actual fuel pressure (should be 45-70 PSI).

Testing Key Components that Mimic PCM Failure

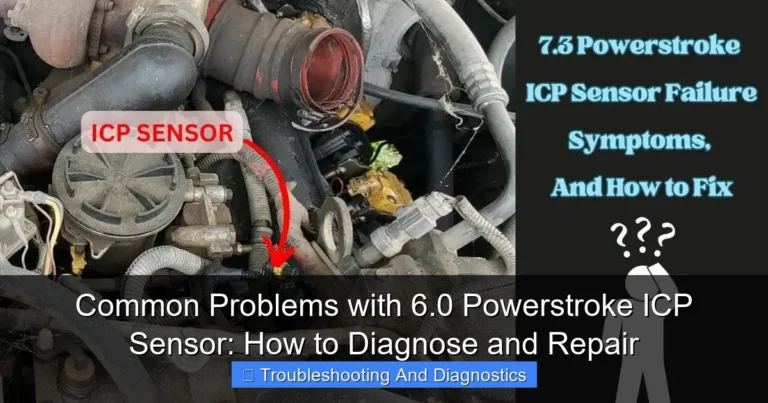

Several notorious 6.0 Powerstroke components can present 6.0 Powerstroke PCM failure symptoms. Always test these before condemning the PCM.

- FICM (Fuel Injection Control Module): This module often fails, leading to no-start or rough running conditions that are frequently mistaken for PCM issues. Test the FICM’s output voltage (should be a steady 48V).

- ICP Sensor (Injection Control Pressure): A faulty ICP sensor can send incorrect data, causing no-starts or stalling. As mentioned, disconnecting it can be a quick test.

- IPR Valve (Injection Pressure Regulator): This valve controls the oil pressure for the injectors. A sticking or failed IPR can prevent the engine from building enough ICP, leading to no-start or stalling.

- CKP (Crankshaft Position) and CMP (Camshaft Position) Sensors: These sensors provide vital timing information to the PCM. A bad sensor can lead to a no-start or sudden engine shutdown.

- Wiring Harness Integrity: Perform continuity and resistance checks on critical circuits (e.g., FICM power, ICP/IPR signals) if visual inspection isn’t conclusive. The harness that goes through the engine valley (under the turbo) is a common failure point.

Essential Tools for 6.0 Powerstroke PCM Diagnostics

Having the right tools is paramount for effectively diagnosing 6.0 Powerstroke PCM failure symptoms and ruling out other possibilities.

Basic Hand Tools & Multimeter

- Multimeter: Essential for checking battery voltage, continuity, resistance, and performing basic voltage drop tests. A good quality digital multimeter is a must.

- Test Light: For quickly checking for power or ground at various points.

- Basic Socket and Wrench Set: For accessing components and checking connections.

OBD-II Scan Tool

- Advanced OBD-II Scanner: A generic code reader is insufficient. You need a scanner capable of reading Ford-specific codes, monitoring live data (PIDs), and potentially performing active tests (e.g., injector buzz test, IPR duty cycle control). Popular options include ForScan (with an OBD-II adapter), AutoEnginuity, or professional-grade tools like the Ford IDS.

- Live Data Capabilities: This is crucial. The ability to view ICP, IPR duty cycle, FICM voltage, battery voltage, engine RPM, fuel pressure, and other parameters in real-time will dramatically speed up your diagnostic process when tackling 6.0 Powerstroke PCM failure symptoms.

Other Specialized Tools

- Fuel Pressure Gauge: To verify actual fuel pressure delivery to the engine.

- Oil Pressure Gauge: To confirm high-pressure oil pump output if ICP readings are suspicious.

- No-IDM (Injector Driver Module) Test Light: This tool helps confirm if the FICM is sending pulse signals to the injectors, bypassing the need for an injector buzz test in some cases.

When to Consider PCM Replacement or Repair

After diligently following the diagnostic steps and ruling out all other common issues, if you’re consistently left with strong evidence of 6.0 Powerstroke PCM failure symptoms, then considering a replacement or repair becomes necessary.

Verifying the Diagnosis

Before spending money on a new or remanufactured PCM, make absolutely certain your diagnosis is correct. PCM failures, while they do occur, are less common than issues with sensors, wiring, or other modules like the FICM. If you’re unsure, or if the symptoms are ambiguous, consider taking your truck to a reputable Ford specialist or a diesel mechanic who has experience with 6.0 Powerstrokes. A second opinion can save you time and money.

Options for a Failing PCM

- New PCM: Purchased directly from Ford or a reputable supplier. This is often the most expensive option but ensures you get a new, factory-programmed unit. It will still need to be programmed to your specific vehicle’s VIN and immobilizer (PATS) system.

- Remanufactured PCM: These units are often cheaper and are rebuilt with common failure points addressed. They typically come with a warranty. Like new units, they will require programming.

- Used PCM: The cheapest option, but also the riskiest. A used PCM may have unknown history or be prone to similar failures. It also absolutely requires programming to your VIN and PATS system, which can be complicated and costly, often negating the initial savings. Make sure it comes from a matching year/model/calibration.

- PCM Repair Services: Some specialized companies offer repair services for your existing PCM. This can be a cost-effective solution if the damage is repairable, especially for rare or older modules. This eliminates the need for programming the VIN and PATS as you’re sending your original module.

The Replacement Process (Brief Overview)

Replacing a PCM typically involves:

- Battery Disconnect: Always disconnect the negative battery cables before working on any electrical components.

- Locate and Remove Old PCM: On the 6.0 Powerstroke, the PCM is usually located in the engine bay on the driver’s side firewall. It’s secured by bolts and has large electrical connectors.

- Install New/Remanufactured PCM: Secure the new unit and reconnect the electrical connectors, ensuring they click securely into place.

- Programming: This is the most critical step. The new PCM must be programmed with your vehicle’s VIN, injector flow rates (if required, some 6.0 PCMs don’t directly store this but rely on the FICM), and the Passive Anti-Theft System (PATS) information. This usually requires a Ford-specific diagnostic tool (like Ford IDS or ForScan with extended license). Without proper programming, your truck will not start or will run very poorly.

- Initial Startup and Re-learn Procedures: After programming, perform an initial start-up. The PCM may need some drive cycles to “re-learn” various engine parameters.

Preventative Measures to Extend Your PCM’s Lifespan

While some PCM failures are simply due to age or manufacturing defects, proactive maintenance can significantly extend the life of your module and prevent common 6.0 Powerstroke PCM failure symptoms from developing.

- Maintain Battery and Charging System Health: Voltage spikes and drops from a failing alternator or weak battery are a leading cause of damage to sensitive electronics like the PCM. Regularly check your battery’s charge and your alternator’s output. Ensure all grounds are clean and secure.

- Inspect Wiring Regularly: Periodically check critical wiring harnesses for chafing, rodent damage, or corrosion. The 6.0 Powerstroke’s engine bay can be harsh, and damaged wiring can cause shorts or open circuits that put stress on the PCM.

- Address Other Engine Issues Promptly: Don’t ignore Check Engine Lights or drivability issues. Problems with sensors, injectors, or other modules can sometimes put undue stress on the PCM as it tries to compensate, potentially leading to its premature failure.

- Avoid Aftermarket Modifications that Stress the Electrical System: Be cautious with poorly installed aftermarket electronics or “tunes” that significantly alter engine parameters without proper understanding.

- Keep the PCM Area Clear: Ensure the PCM and its connectors are free from debris, moisture, or excessive heat sources. While designed to be robust, keeping the environment clean can help.

Common Diagnostic Trouble Codes (DTCs) Associated with PCM or Mimicking PCM Issues

Understanding these codes can guide your diagnostic process when encountering 6.0 Powerstroke PCM failure symptoms.

| DTC Code | Description | Potential PCM Link |

|---|---|---|

| P0603 | Internal Control Module Keep Alive Memory (KAM) Error | Direct internal PCM issue |

| P0605 | Internal Control Module Read Only Memory (ROM) Error | Direct internal PCM issue |

| P0611 | Fuel Injector Control Module Performance | PCM communication/control to FICM, or FICM issue |

| P0606 | PCM Processor Fault | Direct internal PCM issue, often critical |

| P2285 | Injector Control Pressure Sensor Circuit Low | PCM relies on this input; potential sensor, wiring, or PCM input circuit issue |

| P2287 | Injector Control Pressure Sensor Circuit Intermittent | PCM relies on this input; potential sensor, wiring, or PCM input circuit issue |

| P1211 | ICP Too High/Low During Crank/Run | PCM control of IPR or ICP sensor input, HPOP, or oil leaks |

| U0100 | Lost Communication With Engine Control Module (ECM/PCM) | Strong indicator of direct PCM communication failure, power/ground issue to PCM, or CAN bus issue |

| P0335 | Crankshaft Position Sensor ‘A’ Circuit | PCM input, critical for engine timing; potential sensor, wiring, or PCM input circuit |

| P0340 | Camshaft Position Sensor Circuit | PCM input, critical for engine timing; potential sensor, wiring, or PCM input circuit |

Remember, a DTC only points to a circuit or condition, not necessarily the faulty part. Further diagnosis is always required.

Conclusion

Troubleshooting 6.0 Powerstroke PCM failure symptoms can undoubtedly be a challenging endeavor, requiring patience, the right tools, and a systematic approach. However, by understanding the PCM’s critical role and recognizing the common signs of its failure, you empower yourself to diagnose issues more accurately and avoid costly misdiagnoses.

Whether you’re dealing with a frustrating no-start, inexplicable performance drops, or persistent electrical glitches, remember to always perform thorough checks of simpler components like batteries, wiring, and crucial sensors before condemning the PCM. Utilizing an advanced scan tool for live data and DTC analysis is your best friend in this process.

Ultimately, a healthy PCM is vital for the longevity and optimal performance of your 6.0 Powerstroke. By being vigilant about potential 6.0 Powerstroke PCM failure symptoms and engaging in preventative maintenance, you can significantly reduce your chances of encountering these complex problems. Should you identify a true PCM failure, knowing your options for replacement or repair will ensure you make an informed decision to get your powerful Powerstroke back on the road and performing as it should.

🎥 Related Video: Top 8 Symptoms and Causes of a Bad PCM

📺 Mechanical Boost

What is Powertrain Control Module? The PCM is known as the brain of the vehicle. The PCM is also known as the engine control …

Frequently Asked Questions

What are the most common symptoms of a failing 6.0 Powerstroke PCM?

A failing 6.0 Powerstroke PCM can manifest as various engine performance issues. You might experience a “no start” condition, rough idle, stalling, poor fuel economy, or erratic shifting in automatic transmissions. Often, the “Check Engine Light” (CEL) will illuminate with specific diagnostic trouble codes (DTCs).

How can I confirm if my 6.0 Powerstroke PCM is truly failing, or if it’s another component?

The best way to confirm a 6.0 Powerstroke PCM failure is through comprehensive diagnostic testing. This involves using a professional-grade scan tool to check for specific PCM-related DTCs, monitoring live data streams, and performing component tests on sensors and actuators that the PCM controls. Don’t rule out wiring harness issues or sensor failures, as these can mimic PCM problems.

What diagnostic tools are essential for troubleshooting 6.0 Powerstroke PCM issues?

You’ll primarily need a good quality OBD-II scan tool capable of reading manufacturer-specific codes and live data for your 6.0 Powerstroke. A multimeter is also crucial for checking power, ground, and circuit continuity to the PCM. In some cases, a breakout box might be used for more in-depth electrical testing.

What are common causes of 6.0 Powerstroke PCM failure?

Common causes for a 6.0 Powerstroke PCM to fail include exposure to extreme heat, electrical shorts or surges within the vehicle’s system, and sometimes physical damage from vibrations or water intrusion. Age and manufacturing defects can also contribute to component degradation over time.

If my 6.0 Powerstroke PCM is faulty, can it be repaired or does it always need replacement and reprogramming?

While some specialized shops might attempt certain repairs, a severely faulty 6.0 Powerstroke PCM typically requires replacement. A new or remanufactured PCM will need to be programmed to your specific vehicle’s VIN and options, often requiring specialized diagnostic equipment from a dealership or qualified repair shop.

How do I differentiate 6.0 Powerstroke PCM symptoms from other common 6.0 engine problems, like injector or FICM issues?

Differentiating requires careful diagnosis, as symptoms can overlap. PCM failures often present a broader range of electrical or communication-related codes, or a complete lack of control over multiple systems. Injector or FICM (Fuel Injection Control Module) issues usually point to specific misfire codes or fuel delivery problems, but it’s important to test all components thoroughly as the PCM controls the FICM and injectors.