How to Fix 7.3 Powerstroke P1211 Code: Diagnostic and Repair Steps

Featured image for this comprehensive guide about How to fix 7.3 Powerstroke P1211 code

Image source: motorriderz.com

Few engines command the respect and loyalty of the Ford 7.3 Powerstroke diesel. Renowned for its legendary durability and robust performance, it’s a workhorse that has powered countless trucks for hundreds of thousands of miles. However, even the toughest engines encounter their share of quirks, and one common head-scratcher that can leave 7.3 owners scratching their heads is the dreaded P1211 code.

If your beloved Super Duty, Excursion, or E-Series van with the iconic 7.3 Powerstroke has thrown a Check Engine Light (CEL) and displayed the P1211 code, you’re not alone. This code specifically points to an “Insufficient Fuel Injection Control Pressure (ICP) during crank or run condition.” In simpler terms, your engine isn’t getting the right amount of high-pressure oil to fire the injectors correctly, which can lead to a host of frustrating symptoms, from rough idling and lack of power to no-start conditions.

Don’t panic! While the P1211 code 7.3 Powerstroke can seem intimidating, it’s a very common issue with well-established diagnostic and repair procedures. This comprehensive guide will walk you through the necessary steps to understand, diagnose, and ultimately fix this problem, getting your 7.3 Powerstroke back to its reliable self. We’ll dive deep into the heart of the problem, explore the most common culprits, and provide actionable tips to tackle this issue like a seasoned pro.

Quick Answers to Common Questions

What does the 7.3 Powerstroke P1211 code actually mean?

The P1211 code indicates a problem where your Injector Control Pressure (ICP) is either too high or too low compared to what the engine’s computer (PCM) is commanding. Essentially, your truck isn’t getting the right amount of high-pressure oil needed to fire the injectors correctly.

What symptoms should I look for if my 7.3 Powerstroke has a P1211 code?

You’ll likely experience rough idling, a significant loss of power, stalling, or difficulty starting, especially when the engine is warm. Of course, your “Check Engine” light will also be illuminated.

Is it safe to drive my 7.3 Powerstroke with a P1211 code?

While your truck might still run, it’s generally not recommended to drive long distances with a P1211 code. This code points to a critical issue with your high-pressure oil system, and continuing to drive could lead to more serious damage or leave you stranded.

What are the most common causes for a 7.3 Powerstroke P1211 code?

The usual suspects for a P1211 code are a faulty Injector Pressure Regulator (IPR) valve, a failing Injector Control Pressure (ICP) sensor, or leaks within the high-pressure oil system itself. Don’t forget to check for low engine oil too, as that’s fundamental!

Where should I start looking to fix my 7.3 Powerstroke P1211 code?

A great first step is to check your engine oil level and condition; dirty or low oil can heavily impact the system. Then, visually inspect the ICP sensor and IPR valve for any obvious oil leaks or damage.

📋 Table of Contents

- Understanding the P1211 Code: The Heart of the 7.3 Powerstroke High-Pressure Oil System

- Initial Diagnostic Steps for P1211: Your First Line of Defense

- Common Culprits Behind P1211 and Their Fixes

- Advanced Troubleshooting Techniques and Data Interpretation

- Troubleshooting Flowchart and Common Repair Scenarios

- Preventative Maintenance and Best Practices for Your 7.3 Powerstroke

- Conclusion: Conquering the P1211 Code on Your 7.3 Powerstroke

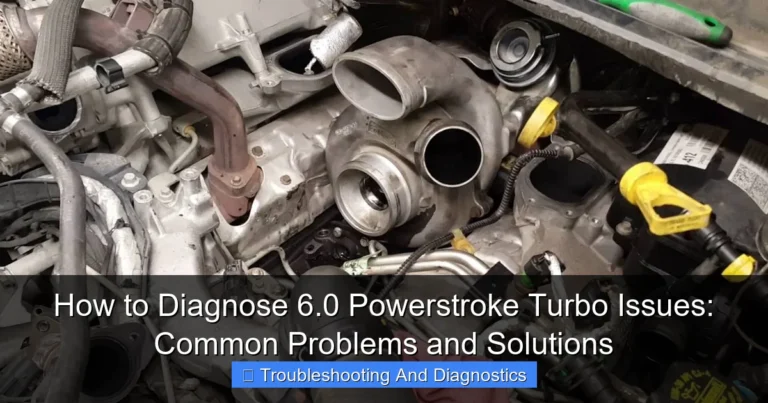

Understanding the P1211 Code: The Heart of the 7.3 Powerstroke High-Pressure Oil System

To effectively fix the 7.3 Powerstroke P1211 code, you first need to grasp how the 7.3 Powerstroke‘s unique fuel injection system works. Unlike many other diesels, the 7.3 uses a “HEUI” (Hydraulically Actuated Electronically Controlled Unit Injector) system. This means your engine oil isn’t just for lubrication; it’s also a crucial hydraulic fluid that literally fires your fuel injectors.

Learn more about How to fix 7.3 Powerstroke P1211 code – How to Fix 7.3 Powerstroke P1211 Code: Diagnostic and Repair Steps

Image source: motorriderz.com

Here’s a simplified breakdown of the components involved in the high-pressure oil system:

| Common Cause | Key Diagnostic Check / Symptoms | Typical Fix / Action |

|---|---|---|

| Low Engine Oil Level/Quality | Check dipstick (oil is primary fluid for ICP). Engine may run rough, stall, or have extended crank times. | Top off oil to proper level or perform an oil change using correct 15W-40 weight. |

| Faulty Injector Control Pressure (ICP) Sensor | Unplug sensor (engine may run better or worse). Monitor ICP voltage with a multimeter or scan tool (erratic readings). | Replace the ICP sensor (located on the driver’s side cylinder head, often near the front). |

| Faulty Injector Pressure Regulator (IPR) Valve | Monitor IPR duty cycle (should fluctuate with RPM) and ICP desired vs. actual with a scan tool. Listen for buzzing/ticking. Hard starts, poor acceleration, stalling. | Replace the IPR valve (located on the back of the High-Pressure Oil Pump, HPOP). |

| High-Pressure Oil System Leaks | Perform an HPOP air test (listen for air escaping from valve covers, oil rails, or dipstick tube). Visual inspection for oil leaks. Rough running, misfires. | Pinpoint leak source (e.g., injector O-rings, standpipes, dummy plugs, HPOP lines) and replace components. |

| Worn High-Pressure Oil Pump (HPOP) | After eliminating other causes, check ICP desired vs. actual; if actual ICP remains significantly lower than desired, especially during cranking. No start or very difficult start. | Replace the HPOP. It’s often recommended to also replace HPOP lines and fittings during this repair. |

- High-Pressure Oil Pump (HPOP): This is the workhorse that pressurizes the engine oil, taking it from lubrication pressure (around 60-80 PSI) up to incredibly high injection pressures (500 PSI at idle, up to 3,000 PSI under load).

- Injection Pressure Regulator (IPR) Valve: The IPR valve is an electronically controlled solenoid that regulates the output pressure of the HPOP. The Powertrain Control Module (PCM) commands the IPR to open or close, adjusting the pressure in the high-pressure oil galleries that feed the injectors. This is a very common failure point when you have a P1211 code.

- Injection Control Pressure (ICP) Sensor: This sensor measures the actual oil pressure in the high-pressure oil system. It sends this critical data back to the PCM, which then uses it to adjust the IPR valve, ensuring the correct pressure for optimal injection. A faulty ICP sensor can send incorrect readings, leading the PCM to mismanage the IPR, even if the actual pressure is fine.

- Injector O-Rings: Each injector has multiple O-rings that seal it within the cylinder head and separate the high-pressure oil from the low-pressure oil and combustion gases. If these O-rings fail, high-pressure oil can leak, leading to a loss of pressure in the system.

- High-Pressure Oil Hoses/Lines: These robust hoses connect the HPOP to the cylinder heads, carrying the high-pressure oil. Leaks in these lines, though less common, can also cause pressure drops.

The P1211 code specifically means that the PCM has detected that the actual ICP is significantly lower than the desired ICP for a certain period, or that it is struggling to reach the desired ICP. This could be due to a failure in any of the components listed above, or a related electrical issue. Understanding this fundamental system is the first step in successful 7.3 Powerstroke P1211 troubleshooting.

Initial Diagnostic Steps for P1211: Your First Line of Defense

Before you start replacing parts, a methodical approach to P1211 diagnostic steps is crucial. Many issues can trigger this code, and often, the fix is simpler than you might imagine.

Learn more about How to fix 7.3 Powerstroke P1211 code – How to Fix 7.3 Powerstroke P1211 Code: Diagnostic and Repair Steps

Image source: dashlights.net

Visual Inspection and Basic Checks

Start with the basics. A thorough visual inspection can reveal obvious problems without any special tools.

- Check Engine Oil Level and Condition: This is paramount. The HPOP relies on clean, sufficient engine oil. Low oil or old, degraded oil can cause pressure issues. Ensure your oil is topped off and relatively clean. A 7.3 Powerstroke needs 15W-40 oil for most conditions.

- Inspect for Oil Leaks: Look around the HPOP, IPR valve, ICP sensor, and along the high-pressure oil lines for any signs of external oil leaks. Even a small leak can cause a significant pressure drop in a high-pressure system.

- Examine Wiring and Connectors: Critically inspect the wiring harnesses and connectors for the IPR valve, ICP sensor, and even the Injector Control Pressure (ICP) sensor. Look for chafing, frayed wires, corrosion, or loose connections. The Under Valve Cover Harness (UVCH) is notorious for issues, especially for its connection to the injectors.

- Battery Voltage: Believe it or not, weak batteries can cause a low cranking speed, which can make the HPOP struggle to build sufficient pressure. Ensure your batteries are fully charged and in good health. A healthy 7.3 needs strong cranking to build oil pressure.

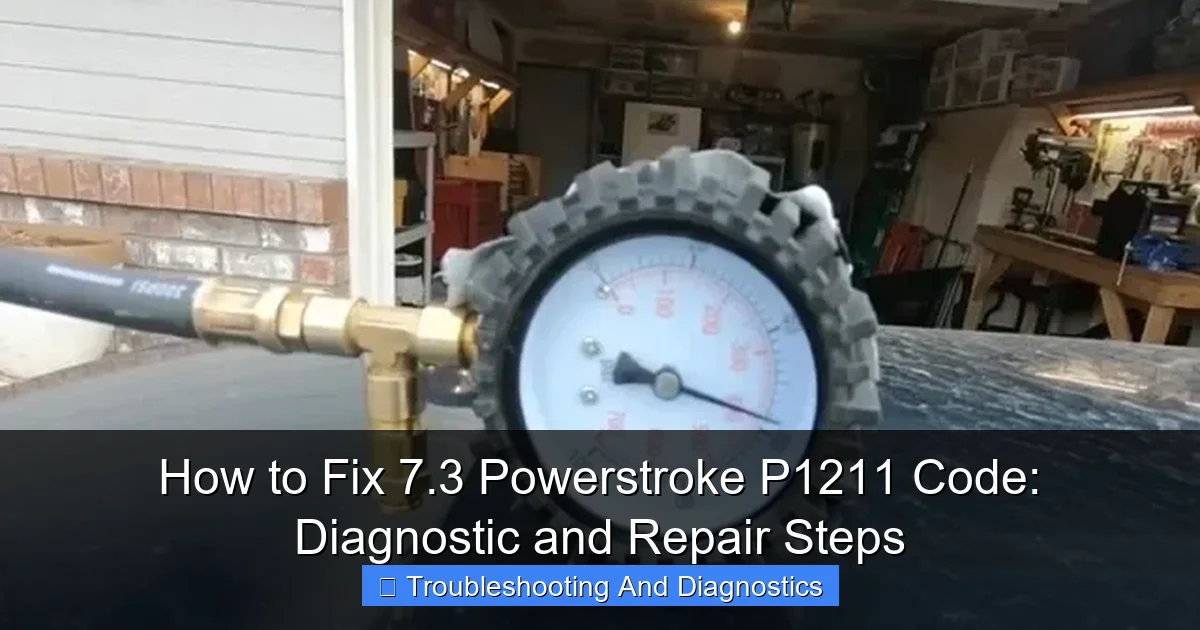

Scan Tool Data Analysis: The Digital Eye

A quality OBD-II scan tool capable of reading live data is your most powerful diagnostic weapon for the P1211 code.

- Monitor ICP Actual vs. ICP Desired: Connect your scan tool and monitor these two parameters while cranking the engine (if it’s a no-start) or at idle.

- During Cranking: You should see the ICP Actual pressure rise steadily. A healthy 7.3 Powerstroke typically needs at least 500 PSI (some say 450 PSI minimum) to fire the injectors. If ICP Actual remains low (e.g., under 100 PSI) while ICP Desired is high (e.g., 500+ PSI), you have a significant pressure loss.

- At Idle: ICP Actual should closely match ICP Desired, typically around 500-650 PSI. If there’s a large discrepancy, especially with the actual pressure being lower, it confirms a pressure problem.

- IPR Duty Cycle: This parameter indicates how hard the PCM is commanding the IPR valve to work to maintain pressure.

- During Cranking: The IPR duty cycle will often go to 65% or higher as the PCM tries desperately to build pressure. If it hits 65% or more and ICP Actual is still low, it strongly suggests a pressure leak or a failing HPOP.

- At Idle: A healthy IPR duty cycle at idle is typically around 10-15%. If it’s consistently much higher (e.g., 25-30% or more) just to maintain idle pressure, it’s working overtime, indicating a leak or a weak HPOP.

- Engine RPM: Ensure your engine is cranking at a sufficient RPM (typically 150-200 RPM) for the HPOP to build pressure.

Common Culprits Behind P1211 and Their Fixes

Once you’ve done your initial checks and reviewed live data, you can start to narrow down the potential causes of your 7.3 Powerstroke P1211 code. Here are the most frequent offenders:

The IPR Valve (Injection Pressure Regulator)

This is, arguably, the most common cause of the P1211 code. The IPR valve can fail electrically or mechanically.

- Symptoms: Rough idle, stalling, hard start/no start, lack of power, and, of course, the P1211 code.

- Testing:

- Electrical Test: Unplug the IPR connector. Using a multimeter, check the resistance across the two pins on the IPR valve itself. It should typically be between 10-12 ohms. An open circuit (infinite resistance) or a short circuit (0 ohms) indicates a faulty IPR solenoid.

- Visual Inspection: Sometimes, the screen on the IPR valve can become clogged with debris, preventing it from functioning correctly. Remove the valve and inspect the screen for damage or blockages.

- Live Data: As mentioned, a high IPR duty cycle (e.g., 65% during crank, 25%+ at idle) coupled with low ICP actual pressure is a strong indicator of an IPR struggling to regulate, or a significant leak it’s trying to compensate for.

- Replacement: The IPR valve is located on the back of the HPOP, often requiring a specialized socket for removal. It’s generally a straightforward replacement, but can be tricky due to its location under the intake manifold on some models. Ensure you get a quality OEM or reputable aftermarket replacement.

The ICP Sensor (Injection Control Pressure Sensor)

A faulty ICP sensor can send incorrect pressure readings to the PCM, causing it to mismanage the IPR, leading to the P1211 code even if the actual pressure is good.

- Symptoms: Symptoms are very similar to a bad IPR – rough idle, stalling, hard start/no start, sudden loss of power, and P1211. A key indicator of a bad ICP sensor can be oil found in its electrical connector, which indicates an internal leak.

- Testing:

- Visual: Look for oil in the electrical connector. If oil is present, the sensor is definitely bad and needs replacement.

- Live Data: If your scan tool shows wild, erratic ICP readings, or if the ICP drops to 0 PSI seemingly randomly, it often points to a failing sensor. You can also try unplugging the ICP sensor; if the truck starts and runs better (though likely still with a P1211), the sensor is bad. The PCM will default to a predetermined pressure in its absence.

- Replacement: The ICP sensor is typically located on the driver’s side cylinder head, towards the front, or sometimes on the HPOP reservoir. It’s generally easy to replace, just unscrew the old one and screw in the new one.

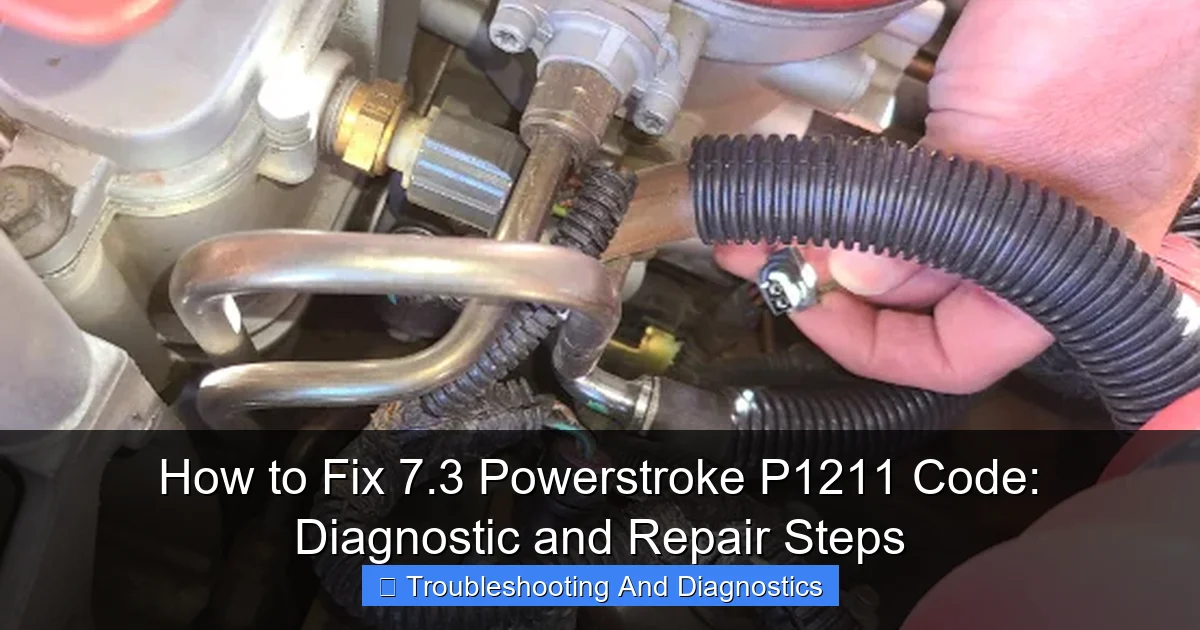

High-Pressure Oil Pump (HPOP)

While less common than IPR or ICP issues, a failing HPOP can absolutely cause a P1211 code by simply not being able to generate enough high-pressure oil.

- Symptoms: Extreme difficulty starting, no start, very low ICP readings even with a good IPR duty cycle.

- Testing:

- Air Test (Bubble Test): This is the definitive test for HPOP and internal oil leaks. You remove the IPR valve and install a special air fitting. Apply shop air (100-120 PSI) to the high-pressure oil system. Then listen for leaks.

- Listen under the valve covers for hissing, indicating leaky injector O-rings or a faulty UVCH connection.

- Listen at the HPOP area for leaks, which could indicate a faulty HPOP or its seals/gaskets.

- Listen to the oil fill tube (with the cap off) for bubbling, which also indicates a leak into the crankcase.

- Live Data: If your IPR duty cycle is maxed out (65%+) and you still get very low ICP during cranking, and you’ve confirmed the IPR is good and there are no external leaks, a weak HPOP is a strong possibility.

- Air Test (Bubble Test): This is the definitive test for HPOP and internal oil leaks. You remove the IPR valve and install a special air fitting. Apply shop air (100-120 PSI) to the high-pressure oil system. Then listen for leaks.

- Replacement: Replacing the HPOP is a more involved job, often requiring the removal of the serpentine belt, fan, and other accessories to gain access. It’s a significant repair but often necessary if the pump is truly failing.

Injector O-Rings and the Under Valve Cover Harness (UVCH)

Leaking injector O-rings are a very common cause of high-pressure oil leaks, directly leading to a P1211 code. The UVCH can also be an issue.

- Symptoms: Rough idle (especially when cold), misfires, excessive smoke, loss of power, hard start/no start, and the P1211 code. The symptoms can often worsen as the engine warms up due to oil thinning.

- Testing: The HPOP air test (described above) is excellent for diagnosing leaky injector O-rings. You’ll hear distinct hissing from under the valve covers. An intermittent or loose UVCH connection can also mimic injector or ICP/IPR issues.

- Replacement: Replacing injector O-rings involves removing the valve covers, disconnecting the UVCH, and carefully pulling the injectors. It’s a labor-intensive but manageable DIY job. Always replace all O-rings on all injectors once you’re in there. While the valve covers are off, inspect the UVCH for any signs of heat damage, chafing, or loose connections. Many owners opt to replace the UVCH as a preventative measure.

Advanced Troubleshooting Techniques and Data Interpretation

For stubborn 7.3 Powerstroke P1211 issues, you might need to dig a little deeper than just component swaps.

The HPOP Air Test (Detailed)

This test is invaluable. To perform it:

- Remove the IPR valve from the HPOP reservoir.

- Insert a specialized IPR air test fitting into the IPR’s port.

- Apply regulated shop air (100-120 PSI) to the fitting.

- Listen:

- Under Valve Covers: Listen for a prominent hiss. This indicates leaking injector O-rings or a bad UVCH passthrough gasket. Identify which side is louder; that’s your problem side.

- Oil Fill Tube: Remove the oil cap and listen for bubbling. This also points to internal leaks into the crankcase.

- Front of Engine (HPOP Area): Listen for leaks around the HPOP itself or its high-pressure lines.

- Exhaust: A very rare but possible leak into a cylinder could result in air being pushed out the exhaust, indicating a catastrophic injector failure or crack.

- Time: Allow the air to flow for a few minutes. A slight hiss is normal, but a significant, sustained hiss indicates a problem.

Interpreting Live Data Beyond the Basics

Your scan tool offers a wealth of information.

- ICP Stability: Does the ICP Actual pressure fluctuate wildly or remain rock-solid? Wild fluctuations can point to an intermittent electrical issue, a bad sensor, or a marginal HPOP.

- IPR Duty Cycle vs. Engine Load: Observe how the IPR duty cycle changes under different loads. If the PCM has to command a very high IPR duty cycle just to maintain moderate pressure under light load, it indicates a substantial leak or a weak pump.

- Fuel Pressure: While not directly causing P1211, low fuel pressure can indirectly affect engine performance and put more strain on other systems. Ensure your fuel pressure is within specification (45-70 PSI).

- Crank RPM vs. ICP: If your engine cranks slowly (below 150 RPM), the HPOP may not be turning fast enough to build adequate pressure. This could point to weak batteries, a failing starter, or an electrical issue.

Troubleshooting Flowchart and Common Repair Scenarios

To simplify the diagnostic process, here’s a table summarizing common P1211 causes and their typical solutions:

| Symptom/Observation | Likely Cause | Diagnostic Step | Common Fix |

|---|---|---|---|

| Low ICP (actual) during crank/idle, high IPR % (65% crank, 25%+ idle). | IPR valve stuck open/leaking, or significant internal oil leak. | Electrical test IPR, perform HPOP air test. | Replace IPR valve. If leak persists, address internal leak (O-rings, HPOP). |

| Oil in ICP sensor connector, erratic ICP readings, better run when unplugged. | ICP Sensor failure. | Visual inspection, unplug sensor and test. | Replace ICP sensor. |

| Low ICP, IPR maxed, strong hiss under valve cover during HPOP air test. | Injector O-rings leaking or UVCH issues. | HPOP air test. | Replace injector O-rings (all), inspect/replace UVCH. |

| Very low ICP, IPR maxed, no significant external/internal leaks found, very weak cranking. | Weak HPOP. Also check batteries/starter. | HPOP air test, battery/starter test, confirm engine crank RPM. | Replace HPOP. Address battery/starter if needed. |

| Intermittent P1211, slight power loss, no obvious component failure. | Chafed or damaged wiring harness (IPR, ICP, UVCH). | Thorough visual inspection of all harnesses, wiggle test. | Repair or replace damaged section of harness. |

Preventative Maintenance and Best Practices for Your 7.3 Powerstroke

Preventing the P1211 code from recurring, or appearing in the first place, is always better than reacting to it. The 7.3 Powerstroke is a tough engine, but it thrives on good maintenance.

- Regular Oil Changes: This cannot be stressed enough. Since your engine oil is also the hydraulic fluid for your injectors, its quality is paramount. Use high-quality 15W-40 diesel-specific oil and change it religiously, along with a good quality filter (e.g., Motorcraft, Wix, Donaldson). Dirty or degraded oil can prematurely wear the HPOP, IPR, and injectors.

- Use Quality Parts: When replacing components like the IPR valve, ICP sensor, or HPOP, invest in OEM or reputable aftermarket parts. Cheap components often lead to repeat failures and more headaches down the road.

- Monitor Your Gauges and Listen to Your Engine: Pay attention to any changes in engine sound, power delivery, or unusual oil pressure fluctuations on your dashboard. Early detection of symptoms can prevent a minor issue from escalating.

- Inspect Wiring Periodically: During oil changes or other routine maintenance, take a few minutes to visually inspect the main engine harnesses, especially those connected to the IPR, ICP, and under the valve covers. Look for any signs of chafing, wear, or loose connections.

- Keep Your Fuel System Healthy: While P1211 is an oil pressure code, a healthy fuel system ensures overall engine health. Use a good quality fuel filter and consider a fuel additive, especially in colder climates, to prevent fuel gelling and keep injectors clean.

By adhering to these preventative measures, you significantly reduce the chances of encountering the P1211 code and ensure your 7.3 Powerstroke continues to be the reliable workhorse you depend on.

Conclusion: Conquering the P1211 Code on Your 7.3 Powerstroke

Dealing with a P1211 code on your 7.3 Powerstroke can be frustrating, especially when it leaves you stranded or with a truck that just won’t run right. However, armed with the knowledge and diagnostic steps outlined in this guide, you now have the tools to systematically approach and resolve this common issue. Remember, patience and a methodical approach are key when tackling automotive diagnostics.

From understanding the intricate high-pressure oil system to performing detailed visual inspections and interpreting live scan tool data, you’re well-equipped to pinpoint the root cause, whether it’s a faulty IPR valve, a compromised ICP sensor, leaking injector O-rings, or a struggling HPOP. The 7.3 Powerstroke P1211 troubleshooting process is a journey, but a rewarding one when your diesel roars back to life.

Don’t let the P1211 code 7.3 Powerstroke intimidate you. With the right information and a bit of elbow grease, you can restore your legendary 7.3 Powerstroke to its full power and reliability, ensuring many more miles of dependable service. Happy wrenching!

🎥 Related Video: 7.3 Powerstroke Rough Idle Fix. #northidaho #sawmill #powerstrokediesel #7.3 #powerstroke

📺 Yukon

Frequently Asked Questions

What does the P1211 code specifically indicate for a 7.3 Powerstroke engine?

The P1211 code for a 7.3 Powerstroke signifies an “Injector Control Pressure (ICP) Sensor Out Of Range – While Cranking or Engine Running.” This means the engine’s computer detects that the actual ICP pressure is either too high or too low compared to the desired pressure needed for proper fuel injection.

What are the most common causes of a P1211 code on a 7.3 Powerstroke?

The primary culprits for a P1211 code typically include a failing Injector Control Pressure (ICP) sensor, a faulty Injector Pressure Regulator (IPR) valve, or problems with the high-pressure oil pump (HPOP). Low engine oil level, contaminated oil, or wiring issues to the ICP or IPR can also contribute to this code.

What symptoms will I experience if my 7.3 Powerstroke throws a P1211 code?

You’ll likely notice a significant loss of power, rough idling, or difficulty starting the engine, especially when warm. The engine may also experience misfires, surging, or even stall, and the Check Engine Light will illuminate on your dashboard.

How do I diagnose the P1211 code on my 7.3 Powerstroke effectively?

Begin by checking your engine oil level and condition, as low or dirty oil can cause this issue. Next, use a diagnostic scanner capable of reading live data to monitor ICP actual and desired pressures, along with IPR duty cycle during cranking and running. Visually inspect the ICP sensor and IPR valve wiring harness for any signs of damage or oil leaks.

Which parts are most frequently replaced when fixing a 7.3 Powerstroke P1211 code?

The ICP sensor and IPR valve are the most common components replaced when diagnosing a P1211 code, as they directly control the high-pressure oil system. In some cases, if these don’t resolve the issue, the high-pressure oil pump (HPOP) or its internal components might be at fault and require replacement.

Can I continue to drive my 7.3 Powerstroke with a P1211 code, or is it urgent to fix?

While you might be able to drive it for a short distance, it’s not recommended to continue driving your 7.3 Powerstroke with an active P1211 code for an extended period. The underlying issue, often related to the high-pressure oil system, can cause further damage to the injectors, HPOP, or other critical engine components if not addressed promptly.