How to Fix 7.3 Powerstroke Fuel Pressure Issues: Diagnosing Low Pressure

Featured image for this comprehensive guide about How to fix 7.3 Powerstroke fuel pressure issues

Image source: diagraminfo.com

The iconic 7.3 Powerstroke engine, a legend in the diesel world, is renowned for its durability and raw power. Owners of these venerable workhorses cherish their trucks, often keeping them on the road for hundreds of thousands of miles. However, even the most robust engines eventually encounter common age-related issues. One of the most critical systems that can falter, leading to significant performance problems, is the fuel system – specifically, maintaining adequate fuel pressure.

When your beloved 7.3 Powerstroke starts exhibiting symptoms like hard starting, a noticeable drop in power, or rough idling, low fuel pressure is often the prime suspect. Understanding the intricacies of your truck’s fuel delivery system and knowing how to diagnose and fix these problems is crucial for keeping your diesel beast running strong. This comprehensive guide will walk you through the common causes of low 7.3 Powerstroke fuel pressure issues, equip you with the knowledge to diagnose them, and provide actionable solutions to get your truck back to peak performance.

Quick Answers to Common Questions

What are the common signs of 7.3 Powerstroke fuel pressure issues?

You might notice sluggish acceleration, rough idling, misfires, or even your truck dying unexpectedly. These are classic indicators that your 7.3 Powerstroke isn’t getting enough fuel.

What should my 7.3 Powerstroke fuel pressure ideally be?

For optimal performance, your 7.3 Powerstroke should maintain a fuel pressure of around 60-65 PSI at idle and under load. Anything consistently below 45-50 PSI is a clear sign of a problem.

What’s the very first thing I should check when dealing with 7.3 Powerstroke fuel pressure issues?

Start by checking your fuel filter! A clogged fuel filter is a super common and easy-to-fix culprit behind low 7.3 Powerstroke fuel pressure.

Is it safe to drive my 7.3 Powerstroke if I suspect low fuel pressure?

It’s really not advisable to drive long distances with suspected low 7.3 Powerstroke fuel pressure. This can lead to further damage to your injectors or fuel pump, so address it quickly.

What essential tool do I need to diagnose 7.3 Powerstroke fuel pressure issues?

A reliable fuel pressure gauge is absolutely critical for accurately diagnosing 7.3 Powerstroke fuel pressure issues. You’ll need to connect it to the fuel bowl port to get a reading.

📋 Table of Contents

- Understanding Your 7.3 Powerstroke Fuel System: The Basics

- Symptoms of Low Fuel Pressure in a 7.3 Powerstroke

- Tools for Diagnosing 7.3 Powerstroke Fuel Pressure Issues

- Common Causes and Solutions for Low 7.3 Powerstroke Fuel Pressure

- Step-by-Step Troubleshooting: A Diagnostic Flow for 7.3 Powerstroke Fuel Pressure Issues

- Preventative Maintenance for Your 7.3 Powerstroke Fuel System

- Conclusion

Understanding Your 7.3 Powerstroke Fuel System: The Basics

Before diving into troubleshooting, it’s essential to have a foundational understanding of how the 7.3 Powerstroke fuel system operates. This knowledge will help you pinpoint potential problems more effectively.

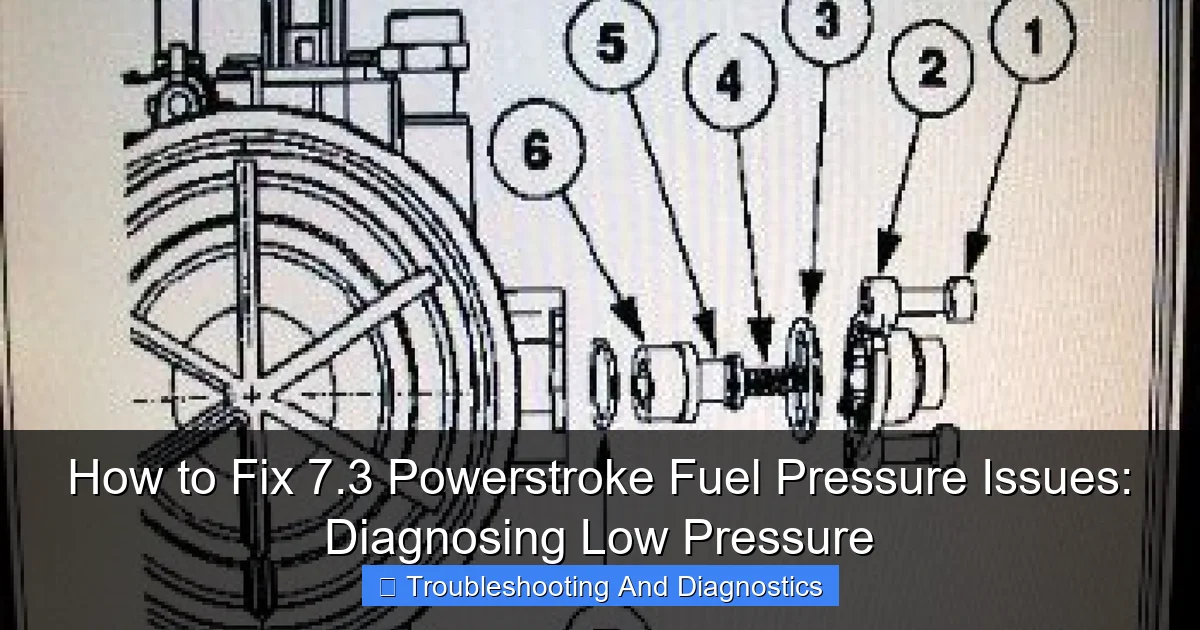

Learn more about How to fix 7.3 Powerstroke fuel pressure issues – How to Fix 7.3 Powerstroke Fuel Pressure Issues: Diagnosing Low Pressure

Image source: motoraudit.com

Key Components of the 7.3 Fuel System

- Fuel Tank and Pickup: Stores the diesel fuel. Inside, a pickup tube draws fuel, often with a screen that can become clogged.

- Electric Fuel Pump (1999-2003 Models): Located on the frame rail, this pump draws fuel from the tank and pushes it forward under pressure. Earlier 7.3L models (pre-1999) used a mechanical lift pump. Our focus here will be on the more common electric pump.

- Fuel Lines: A network of lines transports fuel from the tank to the engine and back. These can degrade or leak over time.

- Fuel Bowl (Filter Housing): Mounted on top of the engine, this houses the primary fuel filter and the fuel pressure regulator. It also serves as a water separator.

- Fuel Filters: The 7.3 Powerstroke typically uses one main fuel filter within the fuel bowl. This filter removes contaminants to protect the injectors. Some aftermarket setups might include a pre-pump filter.

- Fuel Pressure Regulator (FPR): Located in the fuel bowl, the FPR maintains a consistent fuel pressure for the injectors by bypassing excess fuel back to the tank.

- Fuel Injectors: These precision components spray atomized fuel directly into the combustion chambers. They require precise fuel pressure to operate correctly.

How the System Works

Fuel is drawn from the tank by the electric fuel pump, which then pushes it through the fuel lines to the engine compartment. It passes through the fuel bowl, where it’s filtered and regulated by the fuel pressure regulator to a consistent pressure. This pressurized fuel then reaches the fuel rails, which supply each injector. The injectors, controlled by the Powertrain Control Module (PCM), precisely deliver fuel into the cylinders based on engine demands.

| Common Cause / Component | Key Symptoms / Diagnostic Clues | Observed Pressure (PSI) / Target Range | Recommended Fix / Solution |

|---|---|---|---|

| Clogged Fuel Filter | Loss of power under load, sputtering, hard starts, decreased fuel flow. | Drops below 40 PSI, especially under load. Target: 60-70 PSI at idle. | Replace fuel filter (every 10k-15k miles or sooner with poor fuel). |

| Weak/Failing Fuel Pump | Consistently low pressure, engine hesitation, stalling, whining noise from pump. | Consistently 30-50 PSI. Target: 60-70 PSI at idle. | Replace the fuel pump (consider an upgraded pump for better performance). |

| Faulty Fuel Pressure Regulator (FPR) | Erratic or unstable fuel pressure, rough idle, black smoke, poor throttle response. | Unstable, fluctuating, or consistently low (e.g., 35-55 PSI). Target: 60-70 PSI. | Inspect, clean, or replace the Fuel Pressure Regulator assembly. |

| Restrictive Fuel Tank Pickup/Screen | Fuel pressure drops severely below 1/4 tank, engine starvation. | Drops to 0-30 PSI when fuel level is low. Target: 60-70 PSI. | Drop fuel tank, clean/replace “showerhead” pickup screen (consider “Hutch Mod”). |

| Air Intrusion / Leaking Fuel Lines | Hard starts, surging, visible fuel leaks, fuel odor, air bubbles in clear fuel line. | Slightly lower than spec (50-60 PSI) or inconsistent due to air. Target: 60-70 PSI. | Inspect all fuel lines and connections, replace cracked lines or worn O-rings. |

What is “Good” Fuel Pressure?

For a healthy 7.3 Powerstroke, the target fuel pressure at idle and under load should typically be between 50-70 PSI (pounds per square inch). Some enthusiasts aim for the higher end of this range for optimal injector performance. Anything consistently below 45-50 PSI can lead to issues, and a fluctuating pressure is equally problematic. Maintaining proper pressure is absolutely critical for the efficient operation and longevity of your injectors.

Symptoms of Low Fuel Pressure in a 7.3 Powerstroke

Recognizing the signs of low fuel pressure is the first step in diagnosing your 7.3 Powerstroke fuel pressure issues. These symptoms often mimic other problems, so a systematic approach is key.

Learn more about How to fix 7.3 Powerstroke fuel pressure issues – How to Fix 7.3 Powerstroke Fuel Pressure Issues: Diagnosing Low Pressure

Image source: i.pinimg.com

- Hard Starting or No Start: This is one of the most common indicators. If the engine cranks extensively before starting, or simply won’t fire up, insufficient fuel pressure is a strong possibility.

- Rough Idle: The engine may shake, stumble, or have an inconsistent RPM at idle.

- Loss of Power or Lagging Acceleration: Your truck might feel sluggish, struggle to accelerate, or lose power, especially under load (e.g., towing or going uphill). This is because the injectors aren’t getting enough fuel to deliver the required power.

- Engine Misfires or Hesitation: The engine might misfire or hesitate during acceleration, indicating inconsistent fuel delivery to cylinders.

- Excessive Black or White Smoke:

- Black Smoke: Often indicates unburnt fuel due to insufficient atomization or incorrect timing, which can be caused by low pressure.

- White Smoke: Can indicate raw fuel passing through the engine unburnt, especially during cold starts, if fuel pressure is too low for proper ignition.

- Poor Fuel Economy: The engine’s efficiency drops when it’s not receiving consistent and correctly pressurized fuel, leading to more frequent trips to the pump.

- Check Engine Light (CEL): The PCM may trigger diagnostic trouble codes (DTCs) related to injector performance or fuel delivery, such as P1211 (Injector Control Pressure (ICP) higher/lower than desired) or generic misfire codes (P030x). While these aren’t direct fuel pressure codes, low fuel pressure can indirectly cause them.

- Engine Stalling: In severe cases, particularly under load, the engine may stall due to a complete lack of adequate fuel supply.

Tools for Diagnosing 7.3 Powerstroke Fuel Pressure Issues

To accurately diagnose 7.3 Powerstroke fuel pressure issues, you’ll need a few specialized tools in addition to your basic garage equipment.

- Fuel Pressure Gauge Kit (0-100 PSI): This is an absolute must-have. You’ll need a gauge that reads up to at least 100 PSI, along with an adapter that fits the Schrader valve (test port) on your 7.3 Powerstroke’s fuel bowl. This port is typically located on the driver’s side of the fuel bowl.

- OBD-II Scanner/Code Reader: Essential for pulling any diagnostic trouble codes (DTCs) that the PCM may have stored. While it won’t directly read fuel pressure, it can point to related issues.

- Multimeter: Useful for checking electrical continuity, voltage, and resistance in wiring to the fuel pump or its relay.

- Basic Hand Tools: Sockets, wrenches, screwdrivers, and pliers will be needed for accessing components.

- Shop Rags/Catch Pan: Working with fuel inevitably means some spills, so have these handy for safety and cleanliness.

- Safety Glasses and Gloves: Always protect your eyes and hands when working with automotive fluids.

Common Causes and Solutions for Low 7.3 Powerstroke Fuel Pressure

Once you’ve identified the symptoms, it’s time to investigate the common culprits behind low fuel pressure in your 7.3 Powerstroke. Each cause has a specific diagnostic approach and solution.

Clogged Fuel Filters

Problem: This is by far the most common cause of low fuel pressure. A dirty or clogged fuel filter restricts the flow of fuel to the engine, causing a significant pressure drop after the filter. Modern diesel engines are incredibly sensitive to fuel quality, and fine particles can quickly block filters.

Diagnosis:

- First and easiest check. If you don’t know when the filter was last changed, it’s a prime suspect.

- A fuel pressure test will show good pressure before the filter, but significantly lower pressure at the test port in the fuel bowl.

Solution: Replace the fuel filter. This is a relatively inexpensive and straightforward maintenance item. Always use a high-quality OEM or reputable aftermarket filter to ensure proper filtration and flow. It’s generally recommended to change your 7.3 Powerstroke fuel filter every 10,000 to 15,000 miles, or more frequently if you use lower quality fuel.

Failing Electric Fuel Pump

Problem: The electric fuel pump (on 1999-2003 models) is responsible for drawing fuel from the tank and pushing it to the engine under pressure. Over time, the internal motor can wear out, leading to reduced pumping capacity or complete failure.

Diagnosis:

- Listen for the pump. When you turn the key to the “on” position (without starting the engine), you should hear a distinct hum or whir from the frame rail for a few seconds as the pump primes. If it’s weak, intermittent, or absent, the pump is suspect.

- A fuel pressure test will show consistently low pressure at the fuel bowl, even with a fresh filter.

- Check for proper voltage at the fuel pump connector using a multimeter. If the pump isn’t getting adequate power, it won’t operate correctly.

Solution: Replace the fuel pump. This is a more involved job than a filter change, often requiring dropping the fuel tank or at least gaining access to the frame rail where the pump is mounted. Ensure you disconnect the battery and properly relieve any remaining fuel pressure before starting.

Leaking Fuel Lines or O-Rings

Problem: Fuel leaks anywhere in the system can lead to a drop in pressure. Common culprits include cracked or deteriorated fuel lines, loose fittings, or worn O-rings on quick-connect fittings, especially those near the fuel bowl or injectors. Air can also be sucked into the system through leaks, leading to additional problems.

Diagnosis:

- Visual inspection is key. Look for wet spots, fuel stains, or the smell of diesel around the fuel tank, lines, fuel bowl, and injectors.

- Pay close attention to quick-connect fittings and the lines running to and from the fuel bowl.

- For injector O-rings, a contribution test using an OBD-II scanner might indicate specific injector issues, but external leaks are usually visible.

Solution: Identify and repair or replace the leaking component. This might involve replacing a section of fuel line, tightening fittings, or replacing specific O-rings. If injector O-rings are leaking externally, the injectors may need to be pulled and new O-rings installed (a more involved repair). If you smell fuel inside the cabin, inspect the fuel tank sending unit and its seal on top of the tank.

Faulty Fuel Pressure Regulator (FPR)

Problem: The FPR, located in the fuel bowl, is designed to maintain a consistent fuel pressure by diverting excess fuel back to the tank. If the diaphragm or spring inside the FPR fails or gets stuck, it can cause the pressure to be too low (stuck open) or too high (stuck closed, less common for low pressure issues).

Diagnosis:

- A fuel pressure test is crucial here. If the pressure is consistently low, even with a good pump and filter, the FPR is a strong suspect.

- Some technicians will pinch off the return line (briefly!) after the FPR while monitoring the gauge. If the pressure suddenly jumps to high levels, it indicates the FPR was indeed allowing too much fuel to return to the tank. Be extremely careful doing this, as sustained high pressure can damage other components.

- Visual inspection of the FPR for obvious damage or debris is also helpful.

Solution: Replace the 7.3 Powerstroke fuel pressure regulator. This is located within the fuel bowl and is a relatively simple component to swap out. Ensure you have new seals for reinstallation.

Air Intrusion into the Fuel System

Problem: Air in the fuel system is disastrous for a diesel engine. It can cause erratic idle, misfires, and hard starts because the fuel injectors cannot properly atomize a fuel-air mixture. Air can enter through loose fittings, bad O-rings, or even a faulty fuel tank pickup or standpipe.

Diagnosis:

- Symptoms like frequent hard starts, especially after the truck has sat for a while, can point to air intrusion.

- Look for air bubbles in the fuel lines (if clear lines are used, or if you temporarily install a clear section for diagnosis).

- Check all connections for tightness and signs of leaks.

Solution: Systematically check all fuel line connections, the fuel bowl seals, and the fuel tank pickup/sending unit assembly for leaks. Tighten any loose fittings and replace any suspect O-rings or seals. Bleeding the air out of the system might be necessary after repairs; sometimes, simply running the engine will purge the air.

Fuel Tank Issues (Clogged Pickup Screen or Collapsed Tank)

Problem: Less common but still possible. The pickup screen at the bottom of the fuel tank can become clogged with sediment or “algae” from contaminated fuel, restricting flow. In rare cases, a faulty vent system can cause the fuel tank to collapse slightly, also restricting fuel flow.

Diagnosis:

- If all other components check out, and you have consistently low pressure that worsens with a nearly empty tank, suspect tank issues.

- You might hear a whistling or sucking sound from the tank vent if it’s struggling to draw air.

- Inspection usually requires dropping the fuel tank to access the sending unit and pickup tube.

Solution: Clean or replace the fuel tank pickup screen. If the tank is collapsed, it will need to be replaced. Ensure the tank vent system is clear and functioning properly. Using a high-quality fuel and periodic use of a fuel system cleaner can help prevent sediment buildup.

Step-by-Step Troubleshooting: A Diagnostic Flow for 7.3 Powerstroke Fuel Pressure Issues

Here’s a systematic approach to diagnosing low fuel pressure on your 7.3 Powerstroke:

- Gather Your Tools and Ensure Safety: Have your fuel pressure gauge, wrenches, shop rags, and safety gear ready. Disconnect the negative battery terminal if you’re going to be working on electrical components.

- Perform a Thorough Visual Inspection:

- Look for any obvious fuel leaks (wet spots, strong diesel smell) around the fuel tank, lines, fuel pump, and fuel bowl.

- Check the condition of all fuel lines for cracks, kinks, or deterioration.

- Inspect electrical connections to the fuel pump for corrosion or looseness.

- Connect Your Fuel Pressure Gauge:

- Locate the Schrader valve (test port) on the driver’s side of the fuel bowl.

- Carefully remove the dust cap.

- Thread your fuel pressure gauge adapter onto the valve until it’s snug. Do not overtighten.

- Ensure the gauge hose is routed away from hot engine components and belts.

- Perform Key-On Engine-Off (KOEO) Pressure Test:

- Turn the ignition key to the “ON” position (do not start the engine).

- Listen for the fuel pump to prime (humming sound).

- Observe the fuel pressure gauge. It should jump up and hold pressure, typically around 50-70 PSI for a few seconds before the pump shuts off. Note the reading.

- If there’s no pressure or very low pressure, suspect the fuel pump, its relay/wiring, or a major leak.

- Perform Engine Running (Idle) Pressure Test:

- Start the engine and let it warm up slightly.

- Observe the fuel pressure at idle. It should be stable and within the 50-70 PSI range.

- Fluctuating pressure at idle can indicate air intrusion or a failing regulator/pump.

- Perform Under Load/Acceleration Pressure Test:

- While monitoring the gauge, carefully rev the engine to higher RPMs (e.g., 2000-3000 RPM) or drive the truck under light load (if safe to do so with the gauge connected).

- The pressure should remain relatively stable and within the 50-70 PSI range, possibly dropping slightly under heavy acceleration but quickly recovering.

- A significant drop in pressure under load often points to a clogged filter, weak pump, or restricted fuel pickup.

- Interpret Your Readings and Isolate the Problem:

Symptom/Reading Likely Cause(s) Next Step No pressure / Very low KOEO pressure Failed fuel pump, electrical issue (relay/wiring), major leak Check fuel pump operation (sound, voltage), inspect lines for major leaks. Low pressure (e.g., <45 PSI) at idle, worse under load Clogged fuel filter, weak fuel pump, restricted fuel pickup (tank) Replace fuel filter first. If still low, test fuel pump voltage/amps, inspect tank pickup. Low pressure, but normal KOEO static pressure Clogged fuel filter, weak fuel pump, faulty FPR Replace fuel filter. If no change, suspect FPR or fuel pump. Erratic/Fluctuating pressure Air intrusion, weak fuel pump, faulty FPR, restricted fuel flow Inspect for leaks/air bubbles. Check FPR operation. Normal pressure at idle, drops significantly under load Clogged fuel filter, restricted fuel pickup, weak fuel pump Replace fuel filter, check for tank restrictions. - Verify the Fix: After performing any repair, reconnect your fuel pressure gauge and re-test to confirm that the pressure is now within the normal operating range.

Preventative Maintenance for Your 7.3 Powerstroke Fuel System

Proactive maintenance is the best defense against 7.3 Powerstroke fuel pressure issues and ensures the longevity of your engine.

- Regular Fuel Filter Replacement: This cannot be stressed enough. Change your 7.3 Powerstroke fuel filter religiously every 10,000 to 15,000 miles, or more often if you use fuel from questionable sources. This is the single most effective way to prevent many fuel delivery problems.

- Use High-Quality Diesel Fuel: Source your fuel from reputable stations. Cheap or contaminated fuel is a direct pathway to clogged filters and injector problems.

- Keep Your Fuel Tank Full: Especially in colder climates, keeping your fuel tank full reduces condensation buildup, which can lead to water in your fuel and promote microbial growth (algae) that clogs filters.

- Periodically Inspect Fuel Lines and Connections: During oil changes or other routine maintenance, take a few minutes to visually inspect all accessible fuel lines for cracks, chafing, and leaks. Check quick-connect fittings for security.

- Consider Fuel Additives: A quality cetane booster can improve combustion efficiency, and a good lubricity additive can help protect your fuel pump and injectors, especially with modern ultra-low sulfur diesel (ULSD). Some additives also help prevent algae growth and disperse water.

- Address Symptoms Promptly: Don’t ignore early signs of trouble. A hard start today could turn into a breakdown tomorrow. Addressing minor issues before they escalate will save you time and money.

Conclusion

Dealing with 7.3 Powerstroke fuel pressure issues can be frustrating, but with a systematic diagnostic approach and the right tools, you can identify and resolve most problems yourself. The 7.3 Powerstroke is a magnificent engine, and with proper care, it will continue to serve you faithfully for many years to come. By understanding its fuel system, recognizing the symptoms of low pressure, and adhering to a strict maintenance schedule, you can ensure your diesel legend continues to run strong, reliably delivering the power you depend on.

Remember, consistent fuel pressure is the lifeblood of your diesel engine. Don’t neglect it! If you’ve gone through these steps and are still facing challenges, don’t hesitate to consult with a reputable diesel mechanic. Their expertise can be invaluable for more complex or elusive issues, ensuring your truck gets the professional attention it deserves.

🎥 Related Video: 7.3 Powerstroke Low Fuel Pressure Repair

📺 Technician Red

Frequently Asked Questions

What are the common symptoms of low fuel pressure in a 7.3 Powerstroke?

Low fuel pressure can manifest as a lack of power, rough idle, poor acceleration, and difficulty starting, especially when the engine is warm. You might also notice engine stalling under load or a general sluggishness that wasn’t present before.

How do I test the fuel pressure on my 7.3 Powerstroke, and what is the ideal range?

You’ll need a fuel pressure gauge connected to the fuel bowl Schrader valve. The ideal fuel pressure for a healthy 7.3 Powerstroke is typically between 45-65 psi at idle. Pressures below 40 psi are considered low and indicate a problem.

What are the most common causes of low 7.3 Powerstroke fuel pressure?

Several issues can cause low fuel pressure, including a clogged fuel filter, a failing fuel pump (e.g., the lift pump), a faulty fuel pressure regulator (FPR), or a leaky fuel line or injector O-ring. Sometimes, issues with the in-tank fuel pickup or fuel heater can also contribute.

Can a clogged fuel filter cause low fuel pressure on a 7.3 Powerstroke?

Absolutely. A clogged fuel filter is one of the most common and easiest-to-fix culprits for low fuel pressure. It restricts the flow of fuel to the injectors, leading to a significant drop in pressure. Always start your diagnosis by checking or replacing your fuel filter.

How do I know if my 7.3 Powerstroke fuel pump is failing?

A failing fuel pump, also known as the lift pump, often results in consistent low fuel pressure readings, even after replacing the fuel filter. You might also hear unusual noises from the pump area or experience intermittent power loss and hard starting under load.

What role does the Fuel Pressure Regulator (FPR) play in 7.3 Powerstroke fuel pressure issues?

The FPR is crucial for maintaining consistent fuel pressure within the system by returning excess fuel to the tank. If the FPR fails or sticks open, it can cause an uncontrolled drop in fuel pressure, leading to poor engine performance and potential damage to the injectors.