How to Fix 7.3 Powerstroke Air in the Fuel Lines: Common Causes and Fixes

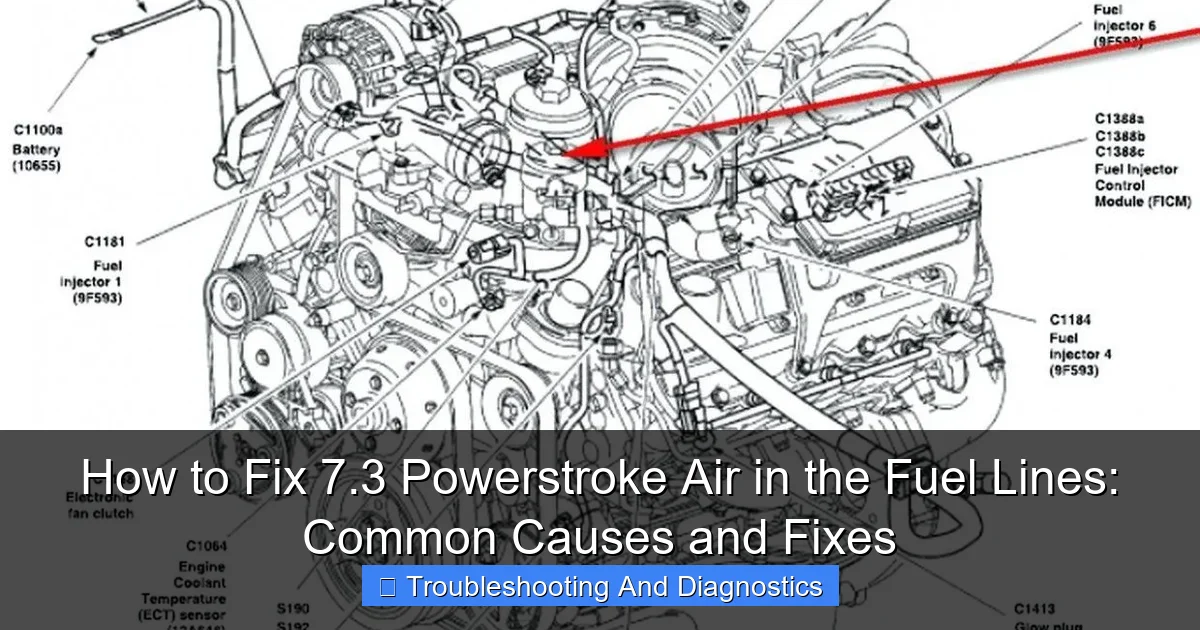

Featured image for this comprehensive guide about How to fix 7.3 Powerstroke air in the fuel lines

Image source: i.pinimg.com

Ah, the legendary 7.3 Powerstroke. A workhorse, a legend, and for many, a way of life. Known for its robust design and incredible longevity, this engine has hauled millions of miles and countless tons of cargo. Yet, even the most legendary engines have their quirks. One of the most common, frustrating, and often misunderstood issues for 7.3 Powerstroke owners is the presence of air in the fuel lines.

If you’re experiencing a rough idle, hard starts (especially after sitting), loss of power, or even stalling, chances are your beloved 7.3 is suffering from a case of fuel system aeration. This isn’t just an annoyance; it can lead to inefficient operation, premature wear on critical components, and leave you stranded. Unlike gasoline engines, diesel engines are highly sensitive to air in the fuel system. Even a tiny air leak can cause significant performance problems because the fuel system relies on precise pressure and an incompressible fluid (fuel) for proper injection.

Don’t despair! While diagnosing and fixing air in the fuel lines on your 7.3 Powerstroke can seem daunting, it’s often a methodical process that many DIY enthusiasts and professional technicians have mastered. This comprehensive guide will walk you through the common causes of air intrusion, provide detailed diagnostic steps to pinpoint the problem, and offer actionable fixes to get your Powerstroke running smoothly again. Get ready to dive deep and banish those pesky air bubbles for good!

Quick Answers to Common Questions

How do I know if I have air in my 7.3 Powerstroke fuel lines?

Your truck might hesitate, have a rough idle, or even stall unexpectedly. You might also notice a loss of power, especially under acceleration, indicating a definite issue with air in your 7.3 Powerstroke fuel lines.

What’s the most common cause of air getting into 7.3 Powerstroke fuel lines?

Often, it’s a cracked fuel bowl housing, a leaky fuel line O-ring, or even a failing fuel filter cap seal. These small issues can easily introduce air into your 7.3 Powerstroke fuel lines, leading to big headaches.

Can I temporarily fix 7.3 Powerstroke air in the fuel lines to get home?

While not a true fix, sometimes cycling the key multiple times to prime the fuel pump can temporarily push some air out of the system. However, you’ll need to address the root cause of the 7.3 Powerstroke air in the fuel lines soon.

What’s the quickest first step to diagnose air in my 7.3 Powerstroke fuel lines?

A great first step is to visually inspect your fuel bowl and all visible fuel lines for any leaks or wet spots. Pay close attention to the fuel filter cap seal and the fuel bowl drain valve, as these are common culprits for 7.3 Powerstroke air in the fuel lines.

Do I need special tools to fix 7.3 Powerstroke air in the fuel lines?

For many common fixes, like replacing O-rings or the fuel filter, basic hand tools are usually sufficient. However, for more advanced diagnostics or repairs, a fuel pressure gauge can be incredibly helpful to truly pinpoint where air is entering your 7.3 Powerstroke fuel lines.

📋 Table of Contents

- Understanding Air in the Fuel Lines: Why It’s a Problem for Your 7.3 Powerstroke

- Common Symptoms of Air in Your 7.3 Powerstroke Fuel System

- Top Causes of Air Intrusion in the 7.3 Powerstroke Fuel System

- Diagnostic Steps: Pinpointing the Source of Air

- Step-by-Step Fixes for Common Air Intrusion Issues

- Preventative Maintenance to Keep Air Out of Your 7.3 Powerstroke

- Common Air Leak Sources, Symptoms, and Fixes Overview

- Conclusion

Understanding Air in the Fuel Lines: Why It’s a Problem for Your 7.3 Powerstroke

To effectively troubleshoot, it’s crucial to understand why air in the fuel system is such a big deal for your 7.3 Powerstroke. Diesel engines, especially the direct-injection type like the 7.3, operate on very precise fuel delivery. Fuel is not only combusted but also acts as a lubricant and coolant for the fuel injectors. When air enters the system, several critical issues arise:

Learn more about How to fix 7.3 Powerstroke air in the fuel lines – How to Fix 7.3 Powerstroke Air in the Fuel Lines: Common Causes and Fixes

Image source: i.ytimg.com

- Loss of Fuel Pressure: Air is compressible, unlike diesel fuel. When the lift pump or injector pump tries to build pressure, the presence of air means a significant portion of that energy is wasted compressing the air instead of pressurizing the fuel. This leads to insufficient fuel delivery to the injectors.

- Poor Atomization: Fuel injectors require high pressure to atomize the fuel into a fine mist for efficient combustion. If pressure is low due to air, the fuel sprays in larger droplets, leading to incomplete combustion, smoke, and reduced power.

- Injector Damage: Fuel also lubricates the precision components within the injectors. If air replaces fuel, these components can run dry, leading to premature wear, sticking, and eventual failure of expensive injectors.

- Hard Starting & Stalling: A common symptom of air in the fuel lines 7.3 Powerstroke is difficulty starting, especially after the truck has sat for a while. This is because air can accumulate in the lines and prevent the fuel system from priming. In severe cases, the engine might start but then quickly stall as it runs out of fuel due to airlock.

- Rough Idle & Misfires: When air intermittently reaches certain injectors, it can cause them to misfire or operate erratically, leading to a rough or surging idle.

The 7.3 Powerstroke fuel system is designed to be a closed loop, maintaining a consistent flow and pressure. Any breach that allows air to enter will disrupt this delicate balance. Identifying the source of air intrusion is paramount to restoring your Powerstroke’s performance and longevity.

| Potential Cause of Air Intrusion | Diagnostic Method | Recommended Fix |

|---|---|---|

| **Fuel Filter Housing (FFH) Leaks:** Worn O-rings, faulty drain valve, cracked housing. | Visually inspect FFH for wet spots or fuel weeping. Perform a “clear hose test” on the fuel return line to observe air bubbles. Check fuel bowl for aeration. | Replace FFH O-ring kit (approx. $20-40). Ensure drain valve is fully closed and not leaking. Consider upgrading to a billet drain valve. |

| **Leaky Fuel Lines/Hoses:** Cracks, chafing, loose fittings, or degraded hose material. | Perform a thorough visual inspection of all fuel lines from the tank to the engine, especially at connections and clamps. Look for damp areas or visible damage. | Replace damaged sections of fuel line or hoses. Tighten all fuel line fittings (e.g., banjo bolts, compression fittings). Upgrade to braided steel lines if chronic. |

| **Fuel Pressure Regulator (FPR) O-rings:** Deteriorated O-rings allowing air past the seal. | Connect a fuel pressure gauge to monitor pressure (should be 55-70 PSI). A rapid drop in pressure after engine shutdown, or inconsistent pressure, indicates FPR issues. | Replace the FPR O-ring kit (inexpensive, ~$10-20). Ensure the regulator is properly seated and torqued. |

| **Loose/Leaky Fuel Heater Element:** Seal around the element in the fuel bowl allows air in. | Inspect the bottom of the fuel filter bowl for any signs of fuel weeping or seepage around the electrical connection for the fuel heater. | Tighten the fuel heater element. If tightening doesn’t stop the leak, replace the element and its sealing washer (approx. $30-60). |

| **Weak/Failing Fuel Pump:** Inability to maintain adequate pressure, causing suction-side air ingress. | Perform a fuel pressure test under various load conditions. Conduct a fuel volume test (should be ~1/3 gallon in 30 seconds). Listen for unusual pump noises. | Replace the electric fuel pump (e.g., OEM equivalent ~$150-300, aftermarket upgrade ~$300-600). Ensure pre-pump filters are clear. |

Common Symptoms of Air in Your 7.3 Powerstroke Fuel System

Recognizing the symptoms early can save you a lot of headache and potential damage. Here’s a list of common indicators that suggest you have air in the fuel lines of your 7.3 Powerstroke:

Learn more about How to fix 7.3 Powerstroke air in the fuel lines – How to Fix 7.3 Powerstroke Air in the Fuel Lines: Common Causes and Fixes

Image source: powerstroke.org

- Hard Starting (Especially After Sitting): This is perhaps the most classic symptom. After the truck sits overnight or for several hours, it cranks for an extended period before firing up. This is because air has seeped into the lines, and the fuel system needs to re-prime itself, pushing the air out.

- Rough Idle: Your engine might feel like it’s “missing” or “surging” at idle. The RPMs might fluctuate, and the engine might vibrate more than usual.

- Loss of Power/Hesitation: Under acceleration, you might notice a significant drop in power, a feeling of hesitation, or a general lack of responsiveness from the engine. This is due to insufficient fuel delivery under load.

- Stalling: In more severe cases, the engine might start and then quickly die, or it could stall randomly while driving. This indicates a significant amount of air interrupting fuel flow.

- Excessive White or Grey Smoke: While various issues can cause smoke, air in the fuel can lead to incomplete combustion, which might manifest as white or light grey smoke from the exhaust, especially during cold starts or under load.

- Decreased Fuel Economy: An engine that isn’t burning fuel efficiently due to air will inevitably consume more fuel to produce the same power, leading to a noticeable drop in MPG.

- Fuel Leaks: Sometimes, the source of air entry is also a source of fuel leakage. Look for visible wet spots or puddles under the truck. Remember, a leak that allows fuel out can also allow air in.

- Fuel Pressure Drop: If you have a fuel pressure gauge installed, you’ll likely observe lower-than-normal pressure, or significant fluctuations in pressure, indicating air affecting the system’s ability to maintain stable pressure.

Pay close attention to when these symptoms occur. Do they happen after refueling? Only when the tank is low? Only after sitting? These details can provide valuable clues for diagnosis.

Top Causes of Air Intrusion in the 7.3 Powerstroke Fuel System

The 7.3 Powerstroke fuel system has several common culprits when it comes to air intrusion. Understanding these will significantly narrow down your diagnostic efforts.

Fuel Filter Housing & O-rings

The fuel filter housing on the 7.3 Powerstroke is a notorious spot for air leaks. The lid, drain valve, and the bowl itself can develop leaks. Over time, the O-rings sealing the lid and the drain valve can harden, crack, or become brittle, allowing air to seep in. A common trick for diagnosing this is to check for dampness around the lid or the drain stem. The drain valve is particularly prone to failure, often leading to a hard start or no start condition.

Fuel Bowl Heater O-ring

Inside the fuel filter housing is a heating element designed to prevent fuel gelling in cold weather. This heater has an O-ring seal that, when it fails, can be a sneaky source of air. While less common than the lid or drain valve, it’s worth checking if other sources are ruled out.

Fuel Pressure Regulator (FPR)

The fuel pressure regulator 7.3 Powerstroke is located on the back of the fuel filter housing. It maintains the correct fuel pressure to the injectors. Inside, it has a spring and diaphragm assembly that can wear out. The O-rings sealing the FPR to the housing can also fail, allowing air to be drawn into the system. A failing FPR can cause low fuel pressure and contribute to aeration.

Fuel Line Leaks & Cracked Hoses

Anywhere fuel flows, there’s a potential for a leak. The rubber fuel lines, especially those exposed to heat and vibration, can crack or develop pinholes. Metal lines can rust or chafe. Pay close attention to connections and crimps. These leaks might not always be visible as dripping fuel, especially if they are on the suction side of the lift pump, where air is drawn in instead of fuel leaking out.

Injector O-rings & Cups

While often associated with internal engine issues, worn or damaged injector O-rings can allow combustion gases into the fuel system (aerating the fuel) or fuel to leak into the oil. Similarly, cracked injector cups (sleeves in the cylinder head) can allow coolant or combustion gases to contaminate the fuel. This is a more complex issue but can certainly lead to severe symptoms of air in the fuel lines.

Lift Pump (Mechanical/Electric)

The 7.3 Powerstroke lift pump, whether it’s the original mechanical pump mounted on the engine block or an aftermarket electric pump, is responsible for drawing fuel from the tank and pushing it to the fuel filter housing. A failing pump can struggle to maintain prime, introduce air into the system through internal leaks, or simply not deliver enough pressure, which can then be exacerbated by air intrusion. Check for leaks around the pump itself, especially if it’s mechanical.

Loose Connections & Fittings

From the fuel tank sending unit to the various lines and sensors, there are numerous connections in the fuel system. A simple loose clamp, a fitting that hasn’t been tightened correctly after a repair, or a damaged flare can create a tiny ingress point for air. Always re-check any areas that have recently been worked on.

Fuel Tank Mod/Pre-Pump Issues

Many 7.3 Powerstroke owners perform the “Hutch” or “Harpoon” tank modifications to address fuel delivery issues. If these mods aren’t done correctly, or if the pickup foot in the tank develops a crack or comes loose, air can be drawn in directly from the tank, especially when the fuel level is low.

Diagnostic Steps: Pinpointing the Source of Air

Diagnosing air in the fuel lines 7.3 Powerstroke requires patience and a systematic approach. Here’s how to go about it:

Visual Inspection

Start with a thorough visual inspection. Look for any signs of fuel leaks – damp spots, drips, or fuel smell – around the fuel filter housing, fuel lines, connections, lift pump, and injector areas. Check for cracked or chafed rubber hoses. Pay attention to the top of the fuel tank area if you’ve recently had work done there or suspect tank issues.

Clear Hose Test

This is one of the most effective ways to confirm the presence of air and often gives a clue as to its location.

- Obtain a section of clear, fuel-resistant hose (e.g., 3/8″ or 1/2″ ID).

- Carefully cut into the fuel line, either before the fuel filter housing (to check the low-pressure suction side) or after the fuel filter housing (to check the high-pressure side feeding the injectors). Many choose to place it just before the fuel filter housing.

- Insert the clear hose with appropriate barb fittings and clamps.

- Start the engine and observe the fuel flowing through the clear hose.

If you see a steady stream of bubbles, especially large ones, you have an air leak. If the bubbles are present before the filter housing but disappear after, the leak is likely on the suction side (tank to lift pump). If they persist or appear after the filter housing, the leak is further downstream.

Fuel Pressure Test

Installing a mechanical fuel pressure gauge (or using a temporary one) is invaluable. The optimal 7.3 Powerstroke fuel pressure should be between 45-70 PSI at idle, with minimal drop under load.

- Connect a fuel pressure gauge to the Schrader valve on top of the fuel filter housing.

- Start the engine and observe the pressure at idle, during acceleration, and under load (if safe to do so).

- A fluctuating or consistently low pressure (below 40 PSI) indicates a problem, potentially related to air or a failing lift pump/FPR.

Record your readings. A significant drop when accelerating points to an inability to maintain fuel supply, often due to air or a weak pump.

Air Leak Detection Methods (Vacuum/Pressure Test)

For persistent or difficult-to-find leaks:

- Vacuum Gauge Test: If you suspect a leak on the suction side (from tank to lift pump), you can connect a vacuum gauge to the line before the lift pump. A high vacuum reading, or one that fluctuates significantly, indicates a restriction or an air leak drawing excessive vacuum.

- Pressurizing the Tank: Some technicians carefully pressurize the fuel tank with a few PSI of air (USE EXTREME CAUTION AND LOW PRESSURE!) and then listen or look for bubbling fuel leaks under the truck. This is a more advanced technique and should only be performed by experienced individuals.

Injector Buzz Test (if applicable for rough idle/misfire)

While not directly for air in fuel lines, if your symptoms include a rough idle or misfire, an injector buzz test (can be done with a diagnostic scanner like FORScan) can help determine if individual injectors are operating correctly. If an injector is receiving aerated fuel, it might fail the test due to insufficient fuel volume or pressure.

Step-by-Step Fixes for Common Air Intrusion Issues

Once you’ve identified the likely culprit, it’s time to get your hands dirty and perform the necessary repairs. Always disconnect the battery and ensure proper safety precautions before working on your fuel system.

Replacing Fuel Filter Housing Components

This is often the first place to start, as it’s a common and relatively easy fix for 7.3 Powerstroke air in the fuel lines.

- Fuel Filter Lid O-rings: Purchase a quality O-ring kit (Motorcraft or equivalent). Remove the fuel filter lid (1-1/8″ wrench or socket), remove the old O-rings, thoroughly clean the grooves, lubricate new O-rings with clean diesel fuel or motor oil, and install. Ensure the filter element is correctly seated.

- Fuel Bowl Drain Valve: If the drain valve is leaking or suspected, it’s best to replace the entire valve assembly. These often come with new O-rings. Follow the same procedure for cleaning and lubricating.

- Fuel Bowl Heater O-ring: If you’re already in the fuel bowl, consider replacing this O-ring. It’s usually a small, often overlooked, potential leak source.

Addressing Fuel Line Leaks

Locate the specific leaking line or connection.

- Rubber Hoses: If a rubber hose is cracked or chafed, replace the entire section. Use high-quality, fuel-rated hose and new hose clamps. Ensure the clamps are tight but don’t overtighten, which can damage the hose.

- Metal Lines: Minor pinholes in metal lines might be temporarily patched with special fuel line repair kits, but full replacement of the section is the most durable solution.

- Loose Connections: Simply tighten any loose fittings or clamps you find during your visual inspection. Be careful not to strip threads or overtighten.

Servicing the Fuel Pressure Regulator (FPR)

A failing FPR or its O-rings can cause significant issues.

- The FPR is on the back of the fuel filter housing. It’s typically held in place by two bolts.

- Remove the bolts and carefully pull the FPR out.

- Inspect the O-rings for wear, cracks, or flatness. Replace them with a quality 7.3 Powerstroke fuel pressure regulator O-ring kit.

- If the internal components of the FPR are suspected (e.g., if pressure is consistently low even after addressing O-rings), it might be best to replace the entire regulator assembly.

Troubleshooting the Lift Pump

The 7.3 Powerstroke lift pump is crucial for maintaining fuel supply.

- Mechanical Pump: If your truck has the original mechanical pump, check for fuel leaks around its mounting point on the engine block. If it’s leaking or consistently fails to maintain pressure (as per your gauge test), it likely needs replacement.

- Electric Pump: If you have an aftermarket electric lift pump, check its electrical connections and listen for it to prime when the key is turned. Check for any leaks in the lines leading to and from the pump. Ensure its pre-filter (if applicable) isn’t clogged.

Many owners upgrade to an electric lift pump even if their mechanical one isn’t failing, as it often provides more consistent pressure and can eliminate some common air intrusion points.

Repairing Injector O-rings and Cups

This is a more involved repair and often requires specialized tools and expertise. If your clear hose test or other diagnostics point to the injectors as the source of air intrusion (e.g., persistent bubbles even after the fuel filter, accompanied by oil in fuel or vice versa, or coolant issues):

- Injector O-rings: Replacing these involves removing the valve covers and then carefully pulling each injector. This is a good opportunity to inspect the injectors and replace all their O-rings.

- Injector Cups: If the cups are cracked, they need to be replaced. This is a very involved process, often requiring special tools to remove and install the cups. It is highly recommended to seek professional help for this specific repair if you’re not experienced.

Checking Fuel Tank Pick-Up and Sender Unit

If all other sources are ruled out and symptoms persist, especially with low fuel levels, investigate the fuel tank.

- Remove the bed or drop the fuel tank to access the sending unit and pick-up assembly.

- Inspect the pick-up foot for cracks or damage.

- Ensure all lines and seals on the sending unit are intact and properly sealed.

- If you have performed the Hutch/Harpoon mod, re-verify all connections and ensure no air can be drawn in.

Preventative Maintenance to Keep Air Out of Your 7.3 Powerstroke

Once you’ve banished the air, you want to keep it out! Regular maintenance is key to preventing future issues with air in the fuel lines 7.3 Powerstroke.

- Regular Fuel Filter Replacement: Change your fuel filter every 10,000-15,000 miles, or annually, using high-quality filters. Always replace the lid O-rings when changing the filter.

- Inspect Fuel Lines: Periodically (e.g., during oil changes), visually inspect all accessible fuel lines and connections for signs of wear, chafing, or leaks.

- Use Quality Fuel: Contaminated or poor-quality fuel can lead to issues that indirectly cause leaks or accelerate wear on components.

- Address Leaks Promptly: Don’t ignore small fuel drips. A small fuel leak can quickly become a significant air intrusion point.

- Consider Upgrades: Many 7.3 owners proactively upgrade to an aftermarket electric fuel pump and a regulated return system. These systems often provide more consistent fuel pressure, better filtration, and can simplify the fuel system, reducing potential leak points.

- Don’t Run on Empty: While not a direct cause of air leaks, consistently running your tank very low increases the chances of drawing in air if there are any marginal seals or pick-up issues in the tank.

Common Air Leak Sources, Symptoms, and Fixes Overview

To help you quickly summarize the information, here’s a data table outlining the key points:

| Air Leak Source | Common Symptoms | Recommended Fix | Complexity / Cost (1-5) |

|---|---|---|---|

| Fuel Filter Housing (Lid/Drain) | Hard starts, rough idle, fuel drips from housing | Replace O-rings, replace drain valve | 1 / Low |

| Fuel Pressure Regulator (FPR) | Hard starts, low fuel pressure, rough idle | Replace O-rings, replace FPR assembly | 2 / Medium |

| Fuel Lines / Hoses | Visible leaks, hard starts, power loss | Replace cracked/worn sections, tighten clamps | 2 / Low-Medium |

| Lift Pump (Mechanical) | Hard starts, low pressure, fuel leak from pump | Replace pump, upgrade to electric | 3 / Medium |

| Injector O-rings | Rough idle, misfires, hard starts, oil in fuel | Replace injector O-rings | 4 / High |

| Injector Cups | Rough idle, coolant loss, persistent air, severe misfires | Replace injector cups | 5 / Very High |

| Fuel Tank Pick-up/Sender | Hard starts, especially on low fuel, power loss on low fuel | Inspect/replace pick-up foot, seal sender unit | 3 / Medium |

Conclusion

Dealing with air in the fuel lines on your 7.3 Powerstroke can be one of the most frustrating aspects of owning this otherwise incredibly reliable diesel engine. However, with a systematic diagnostic approach and a willingness to tackle the common culprits, you can successfully identify and resolve these issues. Remember that patience is key, and starting with the simplest, most common problems will often lead you to the solution.

By understanding how your 7.3 Powerstroke fuel system works, recognizing the tell-tale symptoms of air intrusion, and following our step-by-step guidance for diagnosis and repair, you’ll be well-equipped to restore your truck’s performance and ensure its legendary lifespan continues for many more miles. Don’t let a few air bubbles get the best of your Powerstroke – get out there, diagnose the problem, and enjoy the smooth, powerful ride your 7.3 was built for!

🎥 Related Video: Air Locked 7.3 Powerstroke | How to Fix an Airlocked 7.3 Powerstroke Fast!

📺 Hunter Easterling

In this quick video, we will discuss the process of how to remove the air from your fuel lines in a 7.3 Powerstroke. In the video, we …

Frequently Asked Questions

What are the common symptoms of air in the fuel lines on a 7.3 Powerstroke?

Hard starts, rough idle, loss of power, stumbling under load, or even a no-start condition are classic signs. You might also notice excessive white smoke from the exhaust, especially after cranking.

What are the most common causes of air getting into 7.3 Powerstroke fuel lines?

Leaky fuel line O-rings, a cracked fuel bowl housing, a faulty fuel pressure regulator, or a bad fuel filter cap are frequent culprits. Even a loose fuel filter or a worn-out fuel pump can contribute to air intrusion.

How can I identify the source of air in my 7.3 Powerstroke fuel system?

A common diagnostic method involves inspecting fuel lines for wet spots or using a clear hose section to visually check for bubbles entering the system. Pressurizing the fuel system with a hand pump and listening for hissing can also help pinpoint leaks.

Do I need to bleed the fuel lines after fixing an air leak on my 7.3 Powerstroke?

The 7.3 Powerstroke fuel system is largely self-bleeding. After fixing a leak, cycle the key on and off several times to allow the fuel pump to prime the system, then crank the engine for short bursts until it starts, which may take a few tries.

Can a problem with the fuel bowl cause air in the fuel lines for a 7.3 Powerstroke?

Absolutely, the fuel bowl is a common source of air intrusion. A cracked fuel bowl, a faulty fuel heater O-ring, or a loose fuel filter cap are very common issues that allow air into the 7.3 Powerstroke fuel lines.

What preventative measures can I take to avoid future issues with air in the 7.3 Powerstroke fuel lines?

Regularly replace your fuel filter, ensuring the cap is properly tightened and its O-ring is in good condition. Inspect fuel lines and connections for signs of wear or leaks, especially when performing other engine maintenance.