How to Fix 6.0 Powerstroke High Idle Problems: Troubleshooting Guide

Featured image for this comprehensive guide about How to fix 6.0 Powerstroke high idle problems

Image source: carsrecoverylondon.com

The roar of a diesel engine is music to many ears, but when your 6.0 Powerstroke starts revving higher than it should at idle, that symphony quickly turns into a cacophony of concern. A high idle problem in your Ford Super Duty isn’t just an annoyance; it’s a symptom that something isn’t quite right under the hood, potentially leading to increased fuel consumption, accelerated wear on components, and even safety hazards. For many owners, the 6.0 Powerstroke high idle issue can be particularly frustrating, given the engine’s reputation for complexity.

If you’re experiencing your 6.0 Powerstroke high idle persistently, you’re not alone. This guide is designed to be your comprehensive troubleshooting companion, walking you through the common causes, diagnostic steps, and effective solutions. We’ll dive deep into the intricate systems of your 6.0L engine, from the high-pressure oil system to electrical components, helping you pinpoint the root cause of your elevated RPMs. Our goal is to empower you with the knowledge to either fix the problem yourself or accurately communicate with your mechanic, saving you time, money, and headaches.

Ready to get your F-Series truck purring at its normal, economical idle once again? Let’s equip you with the insights needed to conquer those frustrating 6.0 Powerstroke high idle problems and restore the smooth operation you expect from your powerful diesel workhorse. Let’s get started on this journey to understanding and resolving your Powerstroke high idle fix.

Quick Answers to Common Questions

What are the common culprits for 6.0 Powerstroke high idle problems?

Often, issues like a sticking Idle Air Control (IAC) valve, a faulty accelerator pedal position (APP) sensor, or even a vacuum leak can contribute to your 6.0 Powerstroke’s high idle. Sometimes the FICM (Fuel Injection Control Module) can also be a suspect.

Is a high idle on my 6.0 Powerstroke something I need to worry about immediately?

Yes, it’s definitely worth addressing promptly! A persistent high idle can lead to increased fuel consumption, premature wear on components, and potential safety concerns, so fixing your 6.0 Powerstroke high idle problems is important.

What’s the very first thing I should check when I notice my 6.0 Powerstroke idling high?

Start by checking for any stored diagnostic trouble codes (DTCs) with an OBD-II scanner; these codes can offer immediate clues. Also, visually inspect for obvious vacuum leaks around the intake manifold and hoses, as these are common causes of 6.0 Powerstroke high idle problems.

Can I troubleshoot and potentially fix 6.0 Powerstroke high idle problems myself, or do I need a mechanic?

Many common causes of high idle, like checking sensors, vacuum lines, and cleaning components, are DIY-friendly for those comfortable with basic wrenching. However, for complex electrical issues or if you’re unsure, consulting a professional for your 6.0 Powerstroke high idle problems is always a good idea.

My 6.0 Powerstroke sometimes idles high, but not always. What could cause intermittent high idle problems?

Intermittent 6.0 Powerstroke high idle problems often point to issues like a sensor that’s failing sporadically (e.g., APP or Engine Coolant Temperature sensor), or an electrical connection that’s loose or corroded. Temperature changes can sometimes exacerbate these types of issues.

📋 Table of Contents

- Understanding the 6.0 Powerstroke High Idle Problem

- Initial Diagnostics: What to Check First for High Idle

- Common Culprits: Fuel System and Injection Issues

- Electrical and Sensor-Related Problems

- PCM (Powertrain Control Module) and Software Considerations

- Advanced Troubleshooting and When to Seek Professional Help

- Data Table: Common 6.0 Powerstroke Sensor Operating Ranges (Approximate at Warm Idle)

- Conclusion: Conquering Your 6.0 Powerstroke High Idle

Understanding the 6.0 Powerstroke High Idle Problem

Before we jump into specific fixes, it’s crucial to understand what constitutes a “high idle” for your 6.0 Powerstroke and why it’s a problem. Normally, a healthy 6.0L Powerstroke should idle somewhere in the range of 650-750 RPMs once fully warmed up. If your truck is consistently idling significantly higher than this (e.g., 900-1200 RPMs or more) without manual intervention (like engaging the PTO or using a high idle switch), you have a problem that needs addressing. Often, you might notice your 6.0 Powerstroke RPM surge even when no throttle input is given.

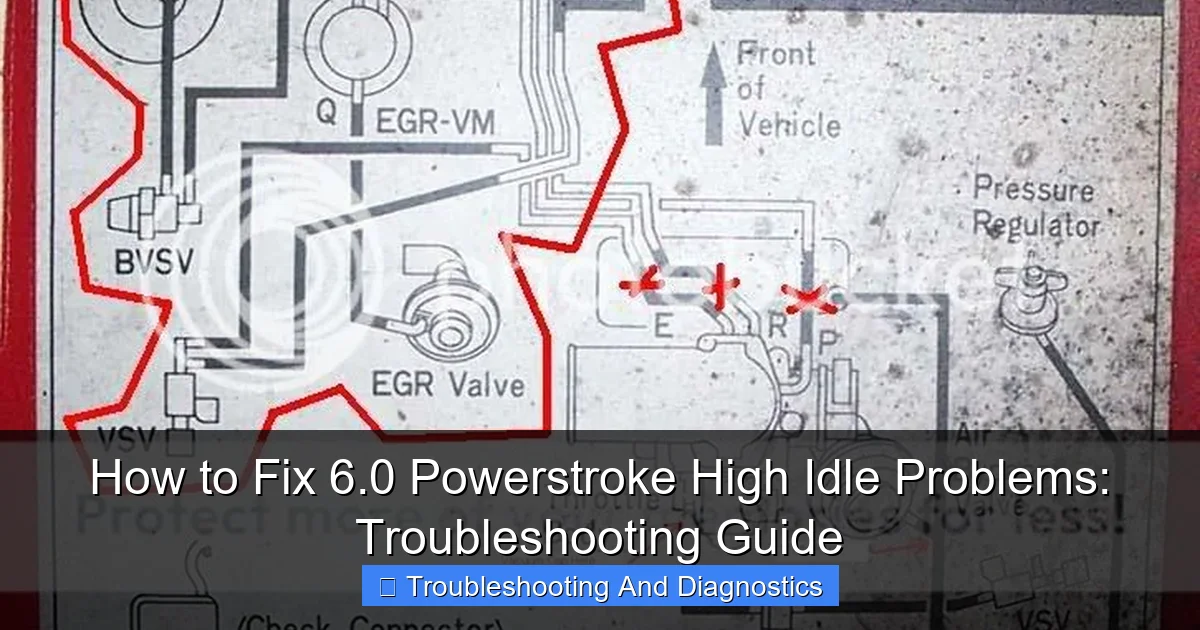

Learn more about How to fix 6.0 Powerstroke high idle problems – How to Fix 6.0 Powerstroke High Idle Problems: Troubleshooting Guide

Image source: img.photobucket.com

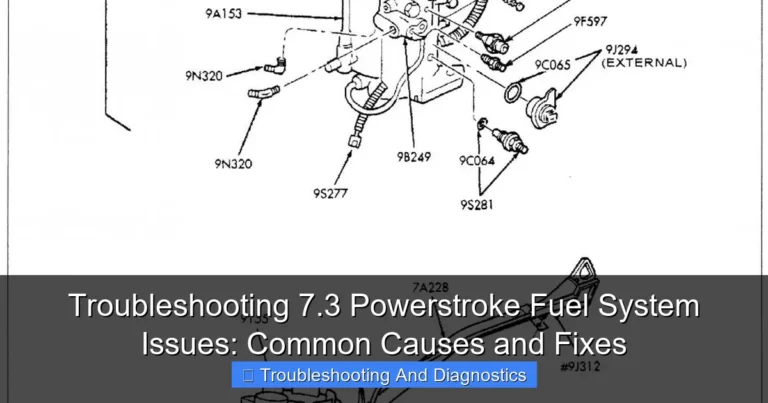

The 6.0L Powerstroke engine is a marvel of diesel engineering, relying on a complex High-Pressure Oil Pump (HPOP) to actuate its fuel injectors (HEUI system). This intricate dance between high-pressure oil, precisely timed fuel delivery, and a sophisticated electronic control unit means that many different components can influence idle speed. A Powerstroke high idle diagnosis isn’t always straightforward because the symptoms can be vague and overlap across multiple potential failures. It’s not just about comfort; a sustained high idle leads to:

| Potential Cause | Diagnostic Clue / Symptom | Key Data to Monitor (Scanner PIDs) | Solution / Repair |

|---|---|---|---|

| Faulty EBP Sensor / Clogged Tube | Fluctuating or inaccurate exhaust back pressure readings. Can cause rough running, black smoke, and erratic or high idle. | EBP sensor voltage (KOEO should be ~0.8-1.0V; engine running EBP should be close to MAP at idle). EBP vs. MAP delta. | Clean or replace EBP sensor and ensure exhaust tube is clear of carbon buildup. |

| FICM Low Voltage (Fuel Injection Control Module) | Hard starting, rough idle, misfires, lack of power. High idle might be the PCM compensating for poor combustion. | FICM_MPWR (Main Power) PID should be 48.0-48.5V consistently during engine operation. Check battery/alternator voltage. | Repair or replace FICM. Address underlying charging system issues (alternator/batteries). |

| ICP Sensor / IPR Valve Issues (High Pressure Oil System) | Long cranks, rough idle, surging, stalling. High idle could be the PCM struggling to maintain correct injection pressure. | ICP_PRESS (Injection Control Pressure) PID (should be 500-750 PSI at warm idle). IPR_DC (IPR Duty Cycle) PID (typically 25-35% at warm idle). | Replace faulty ICP sensor. Diagnose and replace a sticking or failing IPR valve. |

| Accelerator Pedal Position Sensor (APPS) | Engine RPM doesn’t respond correctly to pedal input, can get “stuck” at a higher idle, or erratic RPM. | APP1 and APP2 voltage PIDs (should show smooth, inverse correlation; APP1 typically 0.8V to 4.5V range from idle to WOT). | Replace the Accelerator Pedal Position Sensor assembly. |

| PCM Software Glitch / Corrupted Tune | Unexplained high idle with no other apparent sensor faults or diagnostic trouble codes. May occur after a reflash or battery disconnect. | Scan for “ghost codes.” Review custom tuning details. Monitor all relevant engine PIDs for unexpected values. | Perform a “master reset” (disconnect batteries for 30 minutes). Re-flash the PCM with the latest factory calibration. |

- Increased Fuel Consumption: Burning more diesel than necessary.

- Accelerated Wear: Putting unnecessary stress on the engine and transmission, even at idle.

- Excessive Noise and Emissions: Louder operation and potentially higher emissions.

- Safety Concerns: Reduced control in certain situations, especially during maneuvers.

Pinpointing the exact cause of your 6.0 Powerstroke high idle problems requires a systematic approach, starting with the simplest checks and progressing to more complex diagnostics. Let’s begin our journey to understanding the most frequent offenders.

Initial Diagnostics: What to Check First for High Idle

When faced with a 6.0 Powerstroke high idle, the first step is always to gather as much information as possible. Don’t jump straight to replacing expensive parts. A methodical approach will save you time and money. Here’s where to start your 6.0 high idle diagnosis:

Learn more about How to fix 6.0 Powerstroke high idle problems – How to Fix 6.0 Powerstroke High Idle Problems: Troubleshooting Guide

Image source: i.ytimg.com

1. Check for Diagnostic Trouble Codes (DTCs)

This is your absolute first step. A good quality OBD-II scanner capable of reading enhanced Ford codes is invaluable here. Even if your “Check Engine” light isn’t on, there might be pending or historical codes stored in the Powertrain Control Module (PCM) that can point you directly to the problem area. Look for codes related to:

- Injection Control Pressure (ICP) Sensor

- Injection Pressure Regulator (IPR) Valve

- Throttle/Accelerator Pedal Position (APP) Sensor

- Engine Oil Temperature (EOT) or Engine Coolant Temperature (ECT) Sensors

- Fuel Injection Control Module (FICM)

- Variable Geometry Turbocharger (VGT) control

2. Visual Inspection Under the Hood

A thorough visual inspection can reveal obvious issues. Look for:

- Loose or Damaged Wiring: Pay close attention to connections around sensors, especially the ICP and IPR. Frayed, melted, or corroded wires can cause intermittent or constant issues.

- Vacuum Leaks: While less common for high idle on a 6.0, an unexpected air leak could theoretically contribute.

- Fluid Leaks: Oil leaks, especially around the HPOP cover or turbo, can indicate problems that might indirectly affect the high-pressure oil system.

- Air Filter and Intake: A severely restricted air filter isn’t a common cause of high idle but can affect overall engine performance and confuse the PCM.

3. Verify Fuel Pressure

Adequate fuel pressure is paramount for the 6.0 Powerstroke. Low fuel pressure can starve the injectors, leading to various running issues, including a rough or high idle as the PCM tries to compensate. You’ll need a fuel pressure gauge that can connect to the Schrader valve on the fuel filter housing. The 6.0 Powerstroke fuel pressure should be between 45-70 PSI at idle. Anything below 45 PSI needs immediate attention, likely pointing to a failing fuel pump or clogged fuel filters.

4. Check Engine Oil Level and Condition

Since the 6.0 Powerstroke’s injectors are oil-actuated, the quality and level of your engine oil are critical. Low oil levels or extremely degraded oil can impact the HPOP’s ability to maintain the necessary ICP for proper injection, potentially leading to erratic idle behavior. Ensure your oil is at the proper level and has been changed according to recommended intervals.

Common Culprits: Fuel System and Injection Issues

The intricate HEUI fuel injection system is often at the heart of 6.0 Powerstroke high idle problems. This system relies on high-pressure oil to fire the injectors, making its components prime suspects. Addressing these components is key to a successful 6.0 Powerstroke high idle fix.

1. High-Pressure Oil System (HPOP) Components

The HPOP generates the extreme oil pressure needed for injection. Any issue within this system can manifest as a high or erratic idle.

- ICP Sensor (Injection Control Pressure):

- Function: Measures the oil pressure within the high-pressure oil rail. The PCM uses this reading to command the IPR valve and adjust injection timing.

- Symptoms of Failure: Erratic idle, rough running, stalling, no-start condition, hard starts (hot or cold). A failing 6.0 ICP sensor high idle is a classic symptom.

- Diagnosis: Monitor ICP pressure with a scanner. At idle, expect around 500-700 PSI. If it’s fluctuating wildly, reading unusually high/low, or not building pressure during cranking, it’s suspect. Inspect the wiring harness for oil saturation, a common problem causing shorting.

- Fix: Replace the ICP sensor. For 2003-2004 models, it’s typically in the front of the HPOP cover, under the turbo. Later models moved it to the passenger side valve cover.

- IPR Valve (Injection Pressure Regulator):

- Function: Controls the oil pressure commanded by the PCM by regulating oil flow out of the high-pressure system.

- Symptoms of Failure: Similar to ICP sensor issues – erratic idle, stalling, rough running, no-start. A stuck or failing 6.0 IPR valve high idle can be a direct result of incorrect pressure regulation.

- Diagnosis: Monitor IPR duty cycle with a scanner. At idle, it should be around 14-25%. If it’s much higher or lower, or if ICP pressure won’t build, the IPR could be faulty or there’s an internal oil leak. A “buzz test” may sometimes reveal issues.

- Fix: Replace the IPR valve, located at the back of the HPOP. This often requires removing the turbo.

- Standpipes and Dummy Plugs:

- Function: These components within the high-pressure oil system supply oil to the injectors. They are notorious failure points.

- Symptoms of Failure: Loss of ICP pressure, long crank times, hard starts (especially when hot), rough idle, and potentially a 6.0 high idle problem as the PCM struggles to maintain proper injection.

- Diagnosis: Visual inspection for leaks (though often internal). High IPR duty cycle needed to maintain ICP often points to internal leaks.

- Fix: Replace updated standpipes and dummy plugs. This is a common maintenance item for 6.0 owners.

2. Fuel Injectors

While often associated with misfires or rough running, failing injectors can also contribute to an inconsistent or high idle.

- Stiction (Stuck Injectors):

- Definition: Oil carbonization inside the injector causes the spool valve to stick, leading to delayed or improper injection.

- Symptoms: Rough idle, especially on cold starts, white smoke, engine hesitation. This can sometimes contribute to a perceived 6.0 high idle cold start or general erratic idle.

- Diagnosis: Ford’s “Cylinder Contribution Test” or “Injector Buzz Test” with a capable scanner can help identify sticking injectors. Observing fuel balance rates can also indicate issues.

- Fix: Often, using high-quality oil additives (like Archoil AR9100) specifically designed for stiction can resolve the issue. In severe cases, injector replacement is necessary.

- Worn Injectors: Over time, injectors can wear out, leading to poor spray patterns or fuel leakage, which can disrupt idle quality.

Electrical and Sensor-Related Problems

The 6.0 Powerstroke is heavily reliant on electronic sensors and modules to operate efficiently. Malfunctions in these components can send incorrect signals to the PCM, leading to an unwanted 6.0 Powerstroke high idle.

1. FICM (Fuel Injection Control Module)

- Function: The FICM boosts battery voltage to 48 volts, which is then used to fire the fuel injectors. It’s vital for injector operation.

- Symptoms of Failure: Hard starts, misfires, rough running, stalling, and sometimes a persistent 6.0 FICM high idle or erratic idle as injectors struggle to fire correctly.

- Diagnosis: The most crucial test is to check the FICM’s main power (MPWR) output. With the key on and engine off, and then with the engine running, it should consistently read above 45.0 volts (ideally 48.0V). Lower voltage indicates a failing FICM.

- Fix: If the voltage is low, the FICM needs to be repaired or replaced.

2. Throttle/Accelerator Pedal Position (APP) Sensor

- Function: As the 6.0 is drive-by-wire, the APP sensor (often inaccurately called TPS for diesel) tells the PCM how much the driver is depressing the accelerator pedal.

- Symptoms of Failure: High idle, no throttle response, erratic RPMs, cruise control issues. A faulty 6.0 throttle position sensor high idle signal can essentially tell the PCM to add more fuel/air even when your foot isn’t on the pedal.

- Diagnosis: Monitor APP sensor voltage or percentage with a scanner. At rest (pedal released), it should read around 0-0.5 volts or 0%. As you press the pedal, the voltage/percentage should smoothly increase. Any jumpiness, dead spots, or an elevated base reading suggests a fault.

- Fix: Replace the APP sensor assembly, usually located on the accelerator pedal itself.

3. Other Critical Sensors

- Engine Oil Temperature (EOT) & Engine Coolant Temperature (ECT) Sensors:

- Function: These sensors provide critical temperature data to the PCM. The PCM uses this data for cold start enrichment and to manage glow plug operation and idle speed strategy.

- Symptoms: A faulty sensor reading abnormally cold can cause a persistent 6.0 high idle cold start or even an elevated idle when warm, as the PCM might think the engine is still cold and needs to warm up.

- Diagnosis: Compare EOT and ECT readings with a scanner, especially after the engine has been sitting cold overnight. They should be very close to ambient air temperature. Once warm, they should track together. Significant discrepancies or unrealistic readings indicate a faulty sensor.

- Fix: Replace the faulty EOT or ECT sensor.

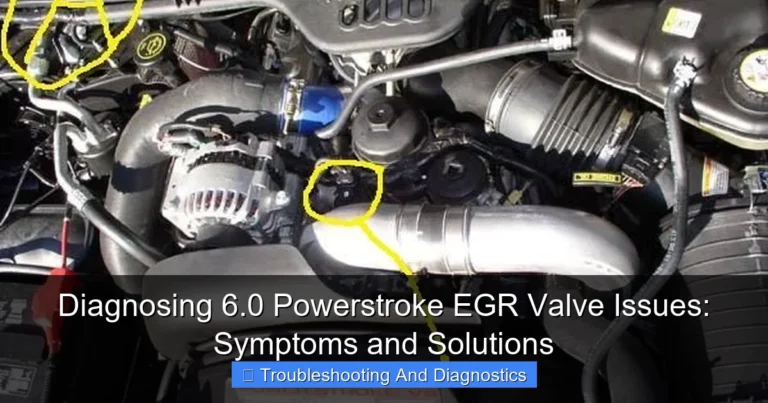

- Variable Geometry Turbocharger (VGT) Solenoid:

- Function: Controls the vanes within the turbo, affecting boost and exhaust backpressure.

- Symptoms: While primarily affecting boost and power, a stuck VGT solenoid could, in some cases, indirectly influence idle by creating excessive exhaust backpressure or altering engine braking characteristics that the PCM might try to compensate for.

- Diagnosis: Monitor VGT duty cycle and exhaust backpressure (EBP) sensor readings with a scanner.

- Fix: Clean or replace the VGT solenoid, or address issues with the turbo vanes themselves.

PCM (Powertrain Control Module) and Software Considerations

Sometimes, the hardware is fine, but the brain of the operation – the Powertrain Control Module (PCM) – or its programming is the source of your 6.0 Powerstroke high idle problems. The PCM is responsible for interpreting all sensor inputs and commanding various engine functions, including idle speed.

1. PCM Reflash and Updates

- Outdated Software: Ford frequently released software updates for the 6.0 Powerstroke to address known issues, improve drivability, and optimize performance. If your truck’s PCM has never been updated, it might be running on old software that has bugs or less refined idle strategies.

- Diagnosis: A Ford dealership or a reputable shop with access to Ford’s IDS (Integrated Diagnostic System) can check your PCM’s current calibration and see if any newer versions are available.

- Fix: A PCM reflash to the latest factory calibration can resolve numerous issues, including erratic or high idle, especially if no hardware faults are found.

2. Aftermarket Tunes and Programmers

- If your 6.0 Powerstroke has an aftermarket tuner or custom programming, this could be the direct cause of your high idle problem. Some tunes might intentionally raise idle speed, or a poorly written tune could cause unintended consequences.

- Diagnosis: Return the PCM to its factory calibration (unmarry the tuner). If the high idle resolves, the tune was the culprit.

- Fix: Remove the aftermarket tune or work with the tuner provider to get a revised calibration.

3. Wiring Harness Issues

- Beyond individual sensor wires, the main engine wiring harness can suffer from chafing, corrosion, or internal breaks. These issues can lead to intermittent or incorrect signals being sent to the PCM, confusing it.

- Diagnosis: A thorough visual inspection of the entire engine harness, especially where it passes near hot components or sharp edges. Wiggle tests while monitoring live data can sometimes reveal intermittent connections.

- Fix: Repair or replace damaged sections of the wiring harness. This can be tedious but essential.

4. PCM Failure

- While less common, a faulty PCM itself can cause a myriad of symptoms, including uncommanded high idle. This is typically a last resort diagnosis after ruling out all other possibilities.

- Diagnosis: This usually requires specialized diagnostic tools or swapping with a known good PCM (if possible, though this often requires reprogramming).

- Fix: Replace and program a new or remanufactured PCM.

Advanced Troubleshooting and When to Seek Professional Help

While many 6.0 Powerstroke high idle problems can be diagnosed and fixed by a skilled DIYer, there are times when specialized tools, experience, or deeper diagnostic capabilities are required. Don’t be afraid to recognize when it’s time to call in the professionals.

1. When DIY Isn’t Enough

- Intermittent Issues: Problems that only occur under specific conditions (e.g., only when hot, only after a long drive) can be notoriously difficult to pinpoint.

- No Codes, Persistent Problem: If your scanner shows no active or pending DTCs, but the high idle persists, the issue might be mechanical or a subtle electronic fault that doesn’t trigger a code.

- Lack of Specialized Tools: Some diagnostics, like comprehensive injector balance tests, advanced HPOP system pressure tests, or precise fuel pressure monitoring under load, require specialized equipment beyond a basic OBD-II scanner.

- Complexity of the Repair: Jobs like removing the turbo to access the IPR valve or HPOP can be challenging and require specific tools and knowledge to avoid further damage.

2. The Value of Professional Diagnostics

A reputable diesel mechanic or Ford dealership will have access to:

- Ford IDS Software: This factory-level diagnostic tool offers the most comprehensive testing and live data monitoring for the 6.0 Powerstroke. It can perform tests like the FICM “MPower” test, “Cylinder Contribution Test,” and monitor all critical parameters with pinpoint accuracy.

- Specialized Pressure Testers: For accurately testing high-pressure oil systems and fuel systems.

- Experience: Diesel mechanics who regularly work on 6.0 Powerstrokes have seen these issues before and often know the common failure points and diagnostic pathways.

3. Preventative Maintenance is Key

Many 6.0 Powerstroke high idle problems can be prevented or mitigated by adhering to a strict maintenance schedule:

- Frequent Oil Changes: Use high-quality 5W-40 or 15W-40 oil (depending on climate) and change it every 5,000 miles or sooner. Clean oil is vital for the HEUI system.

- Fuel Filter Changes: Replace both upper and lower fuel filters every 10,000-15,000 miles to ensure clean fuel delivery and protect your fuel pump and injectors.

- Coolant System Maintenance: Flush and refill your coolant system with proper Ford-spec ELC (Extended Life Coolant) every 100,000 miles. A healthy cooling system ensures proper temperature regulation, which impacts sensor readings.

- FICM Voltage Monitoring: Periodically check your FICM voltage to catch a failing module before it causes bigger problems.

By staying proactive with maintenance and knowing when to seek expert help, you can significantly reduce the likelihood of encountering frustrating issues like a 6.0 Powerstroke high idle.

Data Table: Common 6.0 Powerstroke Sensor Operating Ranges (Approximate at Warm Idle)

Having a reference for normal operating parameters can be immensely helpful when diagnosing your 6.0 Powerstroke high idle problems. Use a diagnostic scanner to monitor these values at warm idle. Significant deviations can point to a faulty sensor or an underlying issue in the system it monitors. Please note that these are approximate values and can vary slightly based on specific truck configuration, ambient temperature, and engine load.

| Parameter | Acronym | Normal Range (Warm Idle) | Potential Issue if Out of Range |

|---|---|---|---|

| Injection Control Pressure | ICP | 500-750 PSI | Low: HPOP, IPR, standpipes, dummy plugs, injector leaks; High: Stuck IPR, wiring |

| Injection Pressure Regulator Duty Cycle | IPR DC | 14-25% | High: Internal oil leak, HPOP failure; Low: Stuck IPR, wiring |

| FICM Main Power | FICM MPWR | 46.0-48.5 Volts (Key On/Engine Off & Running) | Low: Failing FICM, wiring, battery/alternator issue |

| Fuel Pressure (Post-Filter) | FP | 45-70 PSI | Low: Fuel pump, filters, clogged pickup screen |

| Engine Oil Temperature | EOT | 185-220°F (Warmed Up) | Incorrect readings: Faulty EOT sensor, thermostat, oil cooler |

| Engine Coolant Temperature | ECT | 185-220°F (Warmed Up) | Incorrect readings: Faulty ECT sensor, thermostat |

| Accelerator Pedal Position | APP % | 0% (Pedal Released) | >0% at rest: Faulty APP sensor |

| Exhaust Back Pressure | EBP | 0-1.5 PSI above BARO (Key On/Engine Off) | High: Clogged EBP tube, faulty sensor, VGT issue |

By comparing your live data readings to this table, you can quickly narrow down the list of potential culprits for your 6.0 Powerstroke high idle. Remember, these are general guidelines, and a Ford-specific diagnostic tool will provide the most accurate and detailed information.

Conclusion: Conquering Your 6.0 Powerstroke High Idle

Dealing with 6.0 Powerstroke high idle problems can be a significant headache, transforming the normally reassuring rumble of your diesel into an irritating surge. However, by understanding the complex interplay of the high-pressure oil, fuel, and electrical systems, you’re now equipped with a comprehensive strategy to diagnose and address these issues. From initial diagnostic scans and visual inspections to deep dives into the ICP, IPR, FICM, and other critical sensors, we’ve covered the most common culprits and their solutions.

Remember, a systematic approach is your best friend. Start with the easy checks, leverage your diagnostic scanner for crucial data, and work your way through the more complex systems. Don’t underestimate the importance of regular maintenance – clean oil, fresh fuel filters, and a healthy cooling system are your first lines of defense against many 6.0 Powerstroke high idle issues. While the 6.0L Powerstroke has a reputation for being finicky, with the right knowledge and a bit of patience, most of its challenges, including an unwanted high idle, can be successfully overcome.

Whether you’re tackling the fix yourself or seeking professional help, this guide provides the foundation for an accurate 6.0 Powerstroke high idle diagnosis and a lasting Powerstroke high idle fix. Get your truck back to its smooth, efficient idle, and enjoy the power and reliability you expect from your Ford Super Duty. Drive safe and keep those RPMs where they belong!

🎥 Related Video: Hidden Feature (High Idle) – How to Enable it on Your Ford 6.0 Powerstroke Diesel

📺 ProjectTimeGarage

This video will show you how to access a hidden feature of your 6.0 Ford Powerstroke Diesel – High Idle. This feature is built into …

Frequently Asked Questions

What are the common causes of a 6.0 Powerstroke high idle?

A high idle on your 6.0 Powerstroke can stem from several issues, including a faulty Injection Control Pressure (ICP) sensor, a sticking or malfunctioning Injection Pressure Regulator (IPR) valve, or even a failing FICM (Fuel Injection Control Module). Vacuum leaks in the intake system or problems with the throttle position sensor can also contribute to this problem.

How can I diagnose a high idle problem on my 6.0 Powerstroke?

Begin by using an OBD-II scanner to check for any diagnostic trouble codes (DTCs), as these can point you towards the problematic component. Additionally, monitor live data such as ICP and IPR duty cycle readings to see if they are out of the expected range. A visual inspection for obvious vacuum leaks or loose electrical connections is also a good starting point.

My 6.0 Powerstroke idles high intermittently. What could be causing this?

Intermittent high idle on a 6.0 Powerstroke often suggests an electrical issue, a sensor that is failing under specific conditions, or a marginal component. Check for loose or corroded connectors, especially on the ICP and IPR, and consider testing the FICM’s voltage output under various operating temperatures, as it can be prone to intermittent failures.

Can a faulty ICP (Injection Control Pressure) sensor cause a 6.0 Powerstroke high idle?

Yes, a faulty ICP sensor is a very common cause of a 6.0 Powerstroke high idle. If the ICP sensor sends incorrect pressure readings to the PCM, the engine’s computer may overcompensate by increasing fuel pressure, which can result in a sustained high idle. Replacing a failing ICP sensor often resolves this issue.

What is the recommended first step if my 6.0 Powerstroke develops a high idle?

The very first step should be to connect an OBD-II scanner to read any present diagnostic trouble codes. These codes provide valuable clues that can significantly narrow down your troubleshooting efforts. Following that, a quick visual inspection of the engine bay for any obvious disconnected hoses or electrical connectors is advisable.

Is it safe to drive my 6.0 Powerstroke with a high idle problem?

It is generally not recommended to drive your 6.0 Powerstroke for extended periods with a high idle. A sustained high idle can lead to increased fuel consumption, accelerated wear on engine components, and may indicate a more serious underlying issue that could worsen over time. It’s best to diagnose and repair the problem promptly to prevent further damage.