How to Diagnose 7.3 Powerstroke Turbocharger Failure: Fixing Turbo Problems

Featured image for this comprehensive guide about How to diagnose 7.3 Powerstroke turbocharger failure

Image source: cdn.shopifycdn.net

How to Diagnose 7.3 Powerstroke Turbocharger Failure: Fixing Turbo Problems

Category: Troubleshooting and Diagnostics

The legendary 7.3 Powerstroke diesel engine is renowned for its durability, reliability, and impressive pulling power. For over a decade, from 1994.5 to 2003, this engine powered millions of Ford F-Series trucks and E-Series vans, earning a loyal following that continues to this day. A significant part of the 7.3’s brute strength comes from its turbocharger, a precision-engineered component that forces more air into the engine, dramatically boosting horsepower and torque. When your 7.3 Powerstroke turbocharger failure strikes, it’s not just an inconvenience; it can significantly diminish your truck’s performance, fuel economy, and overall driving experience.

Understanding how to identify the early warning signs and systematically diagnose 7.3 Powerstroke turbo issues is crucial for any owner. Ignoring these symptoms can lead to more severe damage, potentially extending beyond the turbocharger itself to the engine. Whether you’re a seasoned mechanic or a DIY enthusiast who loves working on your truck, this comprehensive guide will walk you through the tell-tale signs, diagnostic procedures, and common culprits behind 7.3 Powerstroke turbo problems, empowering you to effectively troubleshoot and get your mighty diesel roaring back to life.

Don’t let a failing turbo leave you stranded or frustrated. By the end of this post, you’ll have the knowledge and actionable steps needed for a precise 7.3 Powerstroke turbo diagnosis, ensuring you can confidently address the issue and keep your beloved 7.3 Powerstroke performing at its peak. Let’s dive into the world of turbo troubleshooting!

Quick Answers to Common Questions

What are the first signs of 7.3 Powerstroke turbocharger failure I should look out for?

You’ll often notice a significant loss of power, excessive black or blue smoke from the exhaust, and decreased fuel economy. These are strong indicators that your turbo isn’t happy.

What kind of sounds indicate a 7.3 Powerstroke turbocharger failure?

Listen for a distinct high-pitched whine, a scraping noise, or even a siren-like sound coming from the turbo area. These unusual noises suggest internal component damage.

How will 7.3 Powerstroke turbocharger failure impact my truck’s performance?

Your truck will feel sluggish, struggling to accelerate and produce power, especially under load. It’s essentially running like a naturally aspirated engine without the crucial boost.

Is there a quick visual check I can do to help diagnose 7.3 Powerstroke turbocharger failure?

Absolutely! Disconnect the intake boot and check for excessive oil inside the compressor housing or if the compressor wheel has noticeable play or damage. These are strong indicators.

Can excessive smoke or oil leaks confirm a 7.3 Powerstroke turbocharger failure?

Yes, excessive blue smoke often points to oil leaking past the turbo seals, while black smoke can indicate a lack of boost due to compressor issues. Both are big red flags that demand attention!

📋 Table of Contents

- Understanding the 7.3 Powerstroke Turbocharger System

- Common Symptoms of 7.3 Powerstroke Turbocharger Failure

- Preliminary Visual and Auditory Inspections

- Advanced Diagnostic Steps: Boost Testing & Sensor Checks

- Common Causes of 7.3 Powerstroke Turbo Problems

- What to Do After Diagnosing 7.3 Powerstroke Turbocharger Failure

- Conclusion: Empowering Your 7.3 Powerstroke’s Lifespan

Understanding the 7.3 Powerstroke Turbocharger System

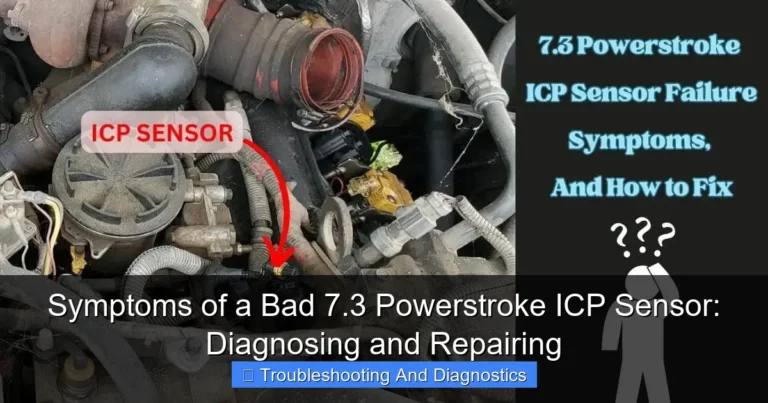

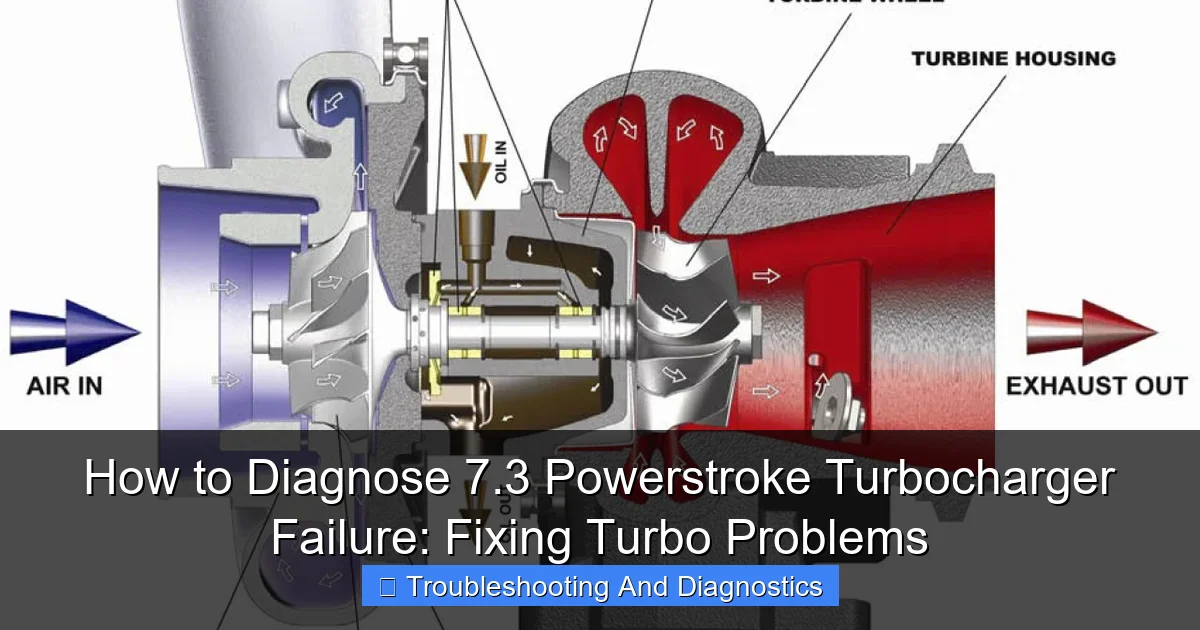

Before we delve into diagnosing problems, it’s helpful to briefly understand how your 7.3 Powerstroke’s turbocharger operates. The 7.3L Powerstroke utilizes a fixed geometry turbocharger (Garrett TP38 in early models, followed by the Garrett GTP38/GTP38R for later models). This system works by harnessing the exhaust gases leaving the engine.

Learn more about How to diagnose 7.3 Powerstroke turbocharger failure – How to Diagnose 7.3 Powerstroke Turbocharger Failure: Fixing Turbo Problems

Image source: seideldieselgroup.com

- Turbine: Hot exhaust gases spin a turbine wheel.

- Shaft: This turbine is connected by a shaft to a compressor wheel.

- Compressor: As the turbine spins, it drives the compressor wheel, which draws in ambient air and compresses it.

- Intercooler: The compressed, heated air is then sent through an intercooler (charge air cooler) to cool it down, making it denser.

- Engine Intake: Finally, this dense, cool, pressurized air is fed into the engine’s intake manifold, allowing for more oxygen to be mixed with fuel, resulting in a more powerful combustion cycle.

The 7.3 Powerstroke also features an Exhaust Back Pressure Valve (EBPV), which can sometimes be mistaken for a turbo issue. The EBPV is designed to help the engine warm up faster in cold weather by restricting exhaust flow. A faulty EBPV can mimic some 7.3 Powerstroke turbo problems, such as a lack of power or unusual noises. Keeping this in mind will be crucial during your 7.3 Powerstroke turbo diagnosis.

| Symptom / Observation | Diagnostic Action | Typical Reading / Inspection (Healthy vs. Failing) | Potential Turbo Issue |

|---|---|---|---|

| **Lack of Power / Delayed Boost** Engine feels sluggish, slow acceleration, especially under load. |

Monitor boost pressure via gauge or scan tool (e.g., Forscan). | **Healthy:** 18-25+ PSI under heavy acceleration. **Failing:** Consistently < 10 PSI, 0 PSI, or very slow to build boost. |

Boost leak (CAC pipes), seized turbo shaft, wastegate malfunction, severely damaged compressor. |

| **Excessive Exhaust Smoke** Heavy blue, black, or white smoke from tailpipe. |

Visually inspect turbocharger (compressor/turbine side) for oil. Check turbo shaft for excessive play. | **Healthy:** Minimal to no oil sheen; minimal shaft play. **Failing:** Excessive blue smoke (oil burning), significant oil in exhaust/intake. Shaft play is excessive radially/axially. |

Worn turbo oil seals, damaged bearings, cracked turbine housing. |

| **Unusual Whining/Grinding Noises** High-pitched “siren” or grinding sound from the engine bay, especially under boost. |

Remove intake hose, manually check compressor wheel for contact with housing and shaft play. | **Healthy:** Smooth rotation, no blade contact, minimal shaft play. **Failing:** Blades scraping housing, excessive radial/axial shaft play (e.g., > 0.003″ axial, > 0.020″ radial). |

Worn thrust bearings, damaged compressor/turbine blades, foreign object damage (FOD). |

| **Oil in Charge Air Cooler (CAC) Pipes** Significant oil accumulation in intercooler boots and pipes. |

Disconnect CAC pipes, inspect for oil puddles. Check turbo shaft for play. | **Healthy:** Minimal to no oil sheen; no puddles. **Failing:** Puddles of oil present, oil visibly dripping. |

Worn compressor-side oil seal, excessive crankcase pressure, faulty pedestal O-rings. |

| **Damaged Compressor/Turbine Blades** Visible chips, bends, or missing pieces on the turbo wheels. |

Remove air intake/downpipe for visual inspection of both turbo wheels. | **Healthy:** Blades intact, smooth, no visible damage. **Failing:** Bent, chipped, or missing blades; signs of foreign object impact. |

Foreign object damage (FOD), manufacturing defect, extreme bearing wear causing contact. |

Common Symptoms of 7.3 Powerstroke Turbocharger Failure

Identifying the symptoms is the first and often most critical step in addressing any mechanical issue. A failing turbocharger will often provide several clear indicators that something is amiss. Pay close attention to these common turbo symptoms 7.3 Powerstroke owners often report:

Learn more about How to diagnose 7.3 Powerstroke turbocharger failure – How to Diagnose 7.3 Powerstroke Turbocharger Failure: Fixing Turbo Problems

Image source: i2.wp.com

1. Loss of Power and Sluggish Acceleration

This is arguably the most common and noticeable symptom of a failing turbo. If your truck feels significantly less powerful, struggles to accelerate, or has a noticeable “lag” when you press the accelerator, insufficient boost pressure is the likely culprit. The turbo isn’t delivering the compressed air needed for optimal combustion. This can often manifest as 7.3 Powerstroke lack of power, making simple tasks like merging onto a highway feel like a chore. You might also notice that the engine struggles to maintain speed on inclines or under heavy load.

2. Excessive Exhaust Smoke

The color of your exhaust smoke can provide valuable clues about the nature of the turbo problem:

- Black Smoke: Often indicates too much fuel for the available air, a common sign of low boost. The engine is trying to inject enough fuel for a full power stroke but isn’t getting the necessary air from a failing turbo. This is a classic symptom of excessive smoke 7.3 issues.

- Blue Smoke: Points to oil being burned in the combustion chamber. If your turbo’s oil seals are failing, oil can leak into the exhaust or intake side of the turbo and be consumed by the engine, producing blue smoke.

- White Smoke: While often associated with coolant leaks, a very thick, acrid white smoke can sometimes indicate severe oil burning or injector issues that may be exacerbated by poor turbo performance.

3. Unusual Noises from the Engine Bay

A healthy turbo operates relatively quietly, primarily producing a subtle whistle. A failing turbo, however, can generate a range of alarming sounds:

- Whining or Siren Sound: A high-pitched, increasingly loud whine that resembles a police siren is a classic sign of worn turbo bearings or contact between the compressor/turbine wheels and the housing. This is often referred to as a turbo whine 7.3.

- Screeching or Grinding: These sounds indicate severe wear or physical damage, such as a blade making contact with the housing. This suggests immediate attention is needed to prevent catastrophic failure.

- Surging or Fluttering: A “whooshing” or “fluttering” sound, especially during acceleration or deceleration, can indicate compressor surge, often caused by boost leaks or improper wastegate (or EBPV) operation.

4. Increased Oil Consumption

As mentioned with blue smoke, damaged oil seals within the turbocharger allow engine oil to leak into either the exhaust system (where it burns) or the intake system (where it’s also burned in the engine). If you find yourself consistently needing to top off your oil between changes, and there are no visible external leaks, your turbo seals might be failing.

5. Poor Fuel Economy

When the turbo isn’t efficiently delivering boost, the engine has to work harder to produce the same amount of power. This increased effort often translates directly into a noticeable drop in fuel efficiency. While many factors can affect MPG, a sudden and significant decrease alongside other turbo symptoms points strongly to a turbo issue.

6. Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs)

Modern vehicles are equipped with sophisticated sensor systems. A failing turbocharger can trigger various Diagnostic Trouble Codes (DTCs) related to boost pressure, exhaust back pressure, or air/fuel mixture. While the 7.3 Powerstroke is older, it still has diagnostic capabilities. A P0236 (Turbocharger/Supercharger Boost Sensor “A” Circuit Range/Performance) or codes related to the EBP sensor (P0470-P0478) are common indicators of 7.3 Powerstroke turbocharger failure or related issues. Always scan for codes first if your CEL illuminates.

Preliminary Visual and Auditory Inspections

Before diving into advanced diagnostics, a thorough visual and auditory inspection can often reveal obvious issues or narrow down the possibilities for your 7.3 Powerstroke turbo diagnosis.

1. Under-the-Hood Visual Inspection

Start by opening the hood and carefully examining the turbocharger and its surrounding components. Look for:

- Oil Leaks: Check around the turbocharger housing, oil feed lines, and drain lines for any signs of oil seepage. Leaks indicate failed seals or loose connections.

- Boost Leaks: Inspect all boost tubes, intercooler pipes, and clamps for cracks, loose connections, or punctures. Even small leaks can significantly reduce boost pressure, leading to 7.3 Powerstroke lack of power. Pay close attention to the connections to the intercooler and intake manifold.

- Damaged Fins: Remove the intake boot from the compressor side of the turbo and carefully inspect the compressor wheel (the “cold” side). Look for bent, chipped, or missing fins. This is often caused by foreign object ingestion. Do NOT attempt to spin the wheel with your fingers in an operational engine.

- Shaft Play: Gently try to move the compressor wheel side-to-side and in-and-out. A slight amount of side-to-side play is normal (up to around 0.003-0.005 inches), but any significant in-and-out (axial) play is a strong indicator of worn thrust bearings and severe 7.3 Powerstroke turbo problems.

- EBPV Actuator and Rod: The Exhaust Back Pressure Valve (EBPV) is located in the exhaust housing of the turbo. Check the actuator and rod that control it. Ensure it moves freely and isn’t stuck open or closed. A stuck EBPV can cause reduced boost or excessive back pressure.

2. Air Intake and Exhaust System Check

A restricted air intake or exhaust system can severely impact turbo performance, mimicking a 7.3 Powerstroke turbocharger failure:

- Air Filter: A heavily clogged air filter will starve the turbo of air, leading to reduced boost and power. Replace it if it looks dirty.

- Intake Manifold: Check for any obstructions or debris in the intake path.

- Exhaust Restriction: A collapsed muffler, clogged catalytic converter (if equipped), or restricted exhaust pipe can increase exhaust back pressure, hindering the turbo’s ability to spin freely and efficiently. This can contribute to turbo lag 7.3 and overall poor performance.

3. Listen for Clues

With the engine running, listen carefully to the turbocharger area. Have a helper briefly rev the engine while you listen. A pronounced whistle, grinding, or rubbing noise during acceleration confirms internal turbo issues. Listen for hissing sounds that would indicate a boost leak.

Advanced Diagnostic Steps: Boost Testing & Sensor Checks

If preliminary checks don’t pinpoint the problem, it’s time to get a bit more technical. These steps are crucial for a precise diagnose 7.3 Powerstroke turbo problem.

1. Monitoring Boost Pressure

This is arguably the most definitive test for turbo performance. You’ll need either a mechanical boost gauge or a diagnostic scan tool capable of reading live data (like Forscan or AE). Connect the gauge/scan tool and observe boost pressure during a wide-open throttle (WOT) acceleration run.

- Healthy 7.3 Powerstroke Turbo: Should generate between 18-22 PSI (pounds per square inch) of boost under full load. Some modified engines may see higher.

- Low Boost: If you’re consistently seeing significantly lower numbers (e.g., 5-10 PSI), it confirms a severe boost leak or an internal turbo issue. This is a clear sign of boost issues 7.3.

- No Boost: A complete lack of boost indicates a major failure, such as a completely seized turbo, a massive boost leak, or a critically failed sensor.

2. Checking the EBP (Exhaust Back Pressure) Sensor

The EBP sensor is vital for the 7.3 Powerstroke’s engine management. It measures exhaust back pressure and tells the PCM (Powertrain Control Module) whether to activate the EBPV or detect issues. A faulty EBP sensor can send incorrect readings to the PCM, leading to:

- Reduced Power: The PCM might incorrectly activate the EBPV, restricting exhaust flow and reducing boost.

- Turbo Lag: Delayed response from the turbo.

- Check Engine Light: Often with codes P0470-P0478.

To check: Disconnect the sensor and inspect the tube leading to it for carbon buildup or blockages. Use a scan tool to monitor EBP readings at idle (should be close to atmospheric pressure, around 14.7 PSI at sea level) and compare them to MAP (Manifold Absolute Pressure) readings under load. A significant discrepancy could indicate a faulty sensor or a clogged EBP tube.

3. MAP (Manifold Absolute Pressure) Sensor Check

The MAP sensor measures the pressure in the intake manifold (which includes boost pressure). If the MAP sensor is dirty or faulty, it can send inaccurate boost readings to the PCM, leading to performance issues even if the turbo itself is fine. Clean or replace if suspected. Compare MAP readings to a known good mechanical boost gauge if possible.

4. Intercooler and Piping Integrity Test (Smoke Test)

For persistent boost leaks that are hard to find visually, a smoke test is highly effective. A specialized smoke machine injects harmless smoke into the intake system. Any leaks will reveal themselves by emitting wisps of smoke. This is invaluable for locating elusive cracks in intercooler hoses, clamps, or even the intercooler itself, which often lead to 7.3 Powerstroke lack of power.

Common Causes of 7.3 Powerstroke Turbo Problems

Understanding the root causes of 7.3 Powerstroke turbocharger failure can help prevent future issues and ensure you address the problem comprehensively during repair.

1. Lack of Oil Lubrication / Dirty Oil

This is the most common killer of turbochargers. The turbo’s bearings spin at incredibly high RPMs (up to 200,000 RPM) and are lubricated and cooled by engine oil. Insufficient oil pressure, a clogged oil feed line, or simply dirty, degraded oil can lead to premature bearing wear and catastrophic failure. Always use high-quality diesel-specific oil and adhere to regular oil change intervals.

2. Foreign Object Damage

Even a tiny foreign object ingested into the compressor or turbine side can cause significant damage to the delicate fins. This could be anything from a loose screw, a piece of a disintegrating air filter, or even a carbon fragment from the exhaust manifold. Inspecting the compressor and turbine wheels for bent or chipped blades is crucial for your 7.3 Powerstroke turbo diagnosis.

3. Worn Bearings and Seals

Over time, the high heat and immense rotational speeds will naturally wear down the turbo’s internal bearings (journal and thrust bearings) and seals. Excessive shaft play is a direct result of worn bearings, leading to oil leaks, contact between the wheels and housing, and eventually complete turbo failure.

4. Exhaust Back Pressure Valve (EBPV) Issues

As mentioned, a stuck or malfunctioning EBPV can severely impact turbo performance. If it’s stuck closed, it creates excessive back pressure, hindering the turbo’s ability to spin. If stuck open, it can reduce the efficiency of warm-up and potentially contribute to turbo lag. Inspect the EBPV actuator for proper movement.

5. Boost Leaks

As detailed above, leaks in the intercooler, boost tubes, or connections can dramatically reduce the amount of pressurized air reaching the engine. This results in 7.3 Powerstroke lack of power and often triggers P0236 codes or similar “boost deviation” errors.

6. Sensor Malfunctions

While not a direct turbo failure, a faulty EBP sensor or MAP sensor can trick the PCM into mismanaging the engine’s air and fuel, leading to symptoms identical to 7.3 Powerstroke turbo problems. Always verify sensor readings with a scan tool or manual tests.

What to Do After Diagnosing 7.3 Powerstroke Turbocharger Failure

Once you’ve confirmed that your 7.3 Powerstroke turbocharger failure is indeed the issue, you have several paths forward.

Repair vs. Replace

The decision to repair or replace depends on the extent of the damage and your budget. If the damage is minor (e.g., a simple boost leak, a clogged EBP tube), repair is usually straightforward. However, if there’s significant shaft play, damaged compressor/turbine wheels, or severe oil leaks, replacement is generally the most reliable and cost-effective long-term solution. Turbo rebuild kits are available, but rebuilding a turbo requires specialized tools and expertise to ensure proper balancing and longevity.

Choosing a Replacement Turbo

When replacing, you typically have a few options:

- OEM (Original Equipment Manufacturer): Guarantees fitment and performance equivalent to factory specifications. Often the most expensive but offers peace of mind.

- Aftermarket: Many reputable aftermarket manufacturers offer turbos that meet or exceed OEM specifications. These can be a good balance of performance and cost. Be wary of extremely cheap options, as quality can vary wildly.

- Remanufactured: A cost-effective option where a used turbo core is completely disassembled, inspected, worn parts replaced, and then reassembled to factory tolerances. Ensure you purchase from a reputable rebuilder with a good warranty.

- Upgraded Turbos: Many 7.3 owners choose to upgrade their turbos (e.g., to a Garrett GTP38R ball-bearing turbo or other larger units) for increased performance. This is an excellent option if you’re already going through the trouble of replacement and desire more power, but ensure your engine is capable of handling the extra boost and consider necessary supporting modifications.

Addressing Root Causes

Crucially, don’t just replace the turbo without addressing the underlying cause of its failure. If it failed due to oil starvation, figure out why (clogged line, faulty oil pump, neglected oil changes). If foreign object damage occurred, find the source and prevent it. Ignoring the root cause means you’ll likely face another 7.3 Powerstroke turbocharger failure down the road.

Professional Help

If you’re uncomfortable with any of the diagnostic steps or the replacement process, don’t hesitate to seek professional help. A qualified diesel mechanic with experience in 7.3 Powerstrokes can quickly and accurately pinpoint the issue and perform the necessary repairs, ensuring your truck is fixed correctly and safely. Investing in professional diagnosis and repair can save you time, money, and frustration in the long run when dealing with complex issues like 7.3 Powerstroke turbo problems.

Here’s a quick summary table of common symptoms and their potential causes:

| Symptom | Primary Suspects | Diagnostic Action |

|---|---|---|

| Loss of Power / Sluggish Acceleration | Boost leak, clogged air filter, worn turbo bearings, faulty EBPV, clogged EBP tube | Check boost pressure with a gauge/scan tool, inspect intake/intercooler for leaks, check EBPV function, inspect EBP sensor/tube |

| Excessive Black Smoke | Insufficient boost (turbo issue), severe boost leak, dirty air filter, fueling issues | Verify boost pressure, inspect air filter, perform smoke test for leaks |

| Excessive Blue/White Smoke | Turbo oil seal failure, worn valve guides/piston rings, injector issues | Inspect turbo for oil leaks, check shaft play, monitor oil consumption |

| Whining/Screeching/Grinding Noise | Worn turbo bearings, excessive shaft play, compressor/turbine wheel contact with housing, foreign object damage | Inspect turbo wheels for damage, check shaft play |

| Increased Oil Consumption | Turbo oil seal failure, internal engine issues | Inspect turbo for external oil leaks, check for blue smoke, check shaft play |

| Check Engine Light (CEL) | Faulty EBP sensor, MAP sensor, boost deviation, IPR/ICP sensor issues | Scan for DTCs (e.g., P0236, P0470-P0478), test related sensors |

| Turbo Lag (Delayed Response) | Boost leak, EBPV stuck, worn turbo, exhaust restriction | Check boost, verify EBPV operation, inspect exhaust system |

Conclusion: Empowering Your 7.3 Powerstroke’s Lifespan

Your 7.3 Powerstroke turbocharger failure doesn’t have to spell the end for your trusty truck. With the comprehensive information and actionable steps outlined in this guide, you’re now equipped to effectively diagnose 7.3 Powerstroke turbo problems, understand their root causes, and plan for their resolution. From recognizing subtle symptoms like turbo whine 7.3 and excessive smoke 7.3 to performing detailed boost tests and sensor checks, you have the tools to troubleshoot confidently.

Remember, early detection and addressing the underlying issues, not just the symptoms, are key to preventing further damage and ensuring the longevity of your engine. Whether you undertake the repair yourself or enlist the help of a professional, accurate diagnosis is the first and most critical step towards fixing 7.3 turbo issues and restoring your Powerstroke to its legendary power and reliability. Drive confidently, knowing you have the knowledge to keep your 7.3 roaring for years to come!

🎥 Related Video: Symptoms of a Failing Turbo: 9 Bad Turbocharger Signs

📺 Honest Mechanic Colorado

Today I want to talk about some common signs that your turbocharger may be failing and symptoms of a bad turbo to look out for.

Frequently Asked Questions

What are the common symptoms of a failing 7.3 Powerstroke turbocharger?

Common signs of a failing 7.3 Powerstroke turbocharger include a significant loss of engine power, excessive black or blue smoke from the exhaust, and unusual noises like a high-pitched whine or screeching sound. You might also notice decreased fuel economy and a slower throttle response.

How can I confirm my 7.3 Powerstroke turbocharger is the source of my engine problems?

To confirm, you should first check for boost pressure using a gauge; low or no boost is a strong indicator. Visually inspect the turbocharger’s compressor wheel for damage and check the turbo shaft for excessive play by attempting to wiggle it side to side or in and out.

What typically causes a 7.3 Powerstroke turbocharger to fail?

Common causes for a 7.3 Powerstroke turbocharger failure include lack of proper lubrication due to infrequent oil changes or low oil levels, which leads to premature bearing wear. Foreign object ingestion into the compressor or turbine housing, as well as excessive heat from other engine issues, can also lead to failure.

Could my 7.3 Powerstroke’s symptoms be caused by something other than the turbocharger?

Yes, many symptoms can overlap with other issues. For instance, exhaust leaks, a faulty Exhaust Back Pressure Valve (EBPV), clogged air filters, or even injector problems can mimic a failing turbocharger on a 7.3 Powerstroke. A thorough diagnosis is crucial to pinpoint the exact cause.

Is it safe to drive my 7.3 Powerstroke if I suspect a turbocharger failure?

It is generally not recommended to drive your 7.3 Powerstroke if you suspect a turbocharger failure. Continuing to drive could lead to more severe engine damage, such as metal fragments entering the intake or exhaust system, or increased strain on other engine components.

What initial inspections can I perform to diagnose a 7.3 Powerstroke turbocharger problem?

Begin by checking all charge air cooler (CAC) boots and hoses for leaks or cracks, as these can cause a loss of boost pressure. Next, remove the air intake boot to inspect the compressor wheel for any bent or missing fins and check for excessive shaft play by gently moving the shaft with your fingers.