Detecting High-Pressure Oil Pump Problems in 6.0 Powerstroke (Full Guide)

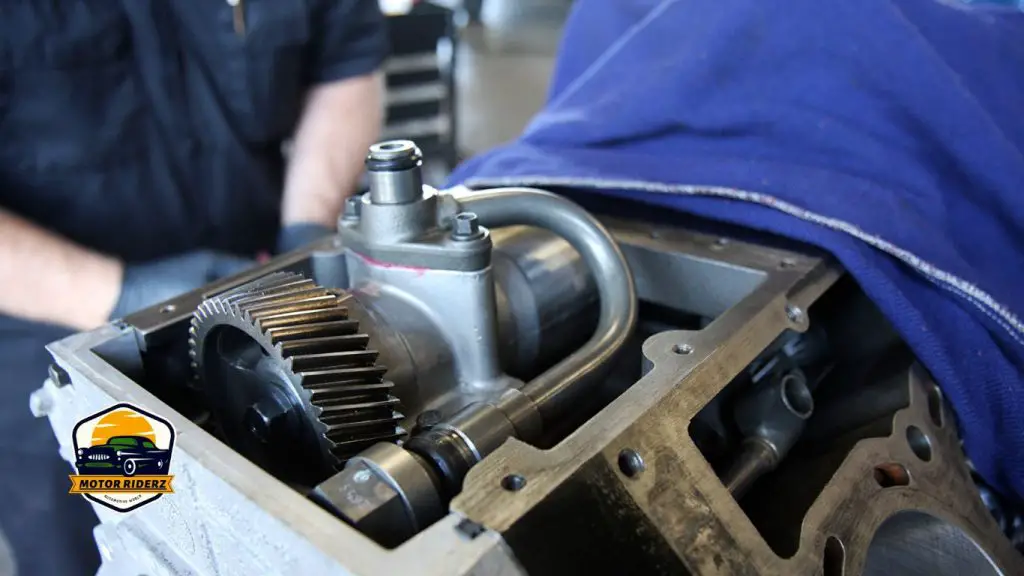

The 6.0 Powerstroke engine, commonly found in Ford Super Duty trucks, utilizes a high-pressure oil pump to supply oil to the fuel injectors. The high-pressure oil pump plays a crucial role in the engine’s performance by providing the necessary pressure to atomize fuel and ensure proper combustion. However, like any mechanical component, the high-pressure oil pump can develop issues over time.

Detecting problems with the high-pressure oil pump is essential for maintaining the engine’s efficiency and preventing potential damage. Fortunately, there are several signs and symptoms that can help you identify a malfunctioning high-pressure oil pump in a 6.0 Powerstroke.

One of the most common indicators of a high-pressure oil pump problem is a loss of power or performance. If you notice a decrease in acceleration, sluggishness, or reduced towing capacity, it could be a result of insufficient oil pressure reaching the fuel injectors. Additionally, you might experience rough idling, stalling, or misfiring, which can be attributed to an inadequate fuel supply.

In this guide, we will explore the key steps to detect a high-pressure oil pump issue in a 6.0 Powerstroke. By recognizing the signs and symptoms early on, you can address the problem promptly and prevent further engine damage.

An OBD-II scanner allows you to connect to the vehicle’s onboard diagnostic system and retrieve valuable information about various engine parameters, including oil pressure.

What steps can be taken to test the High Pressure Oil Pump and other related engine components for issues?

To test the High Pressure Oil Pump and other related engine components for issues, you should first identify any potential problems by observing symptoms such as misfiring during engine start or a decrease in fuel efficiency. Upon noting these signs, it is crucial to perform a comprehensive test on the high pressure oil pump. Additionally, testing other critical components like the injection pressure regulator valve can provide valuable insights into the overall health of the engine system. When testing the injection pressure regulator valve, ensure that it is effectively maintaining fuel pressure within the fuel injection system. A malfunctioning valve can lead to various issues, including misfiring upon engine start or reduced fuel efficiency. If the test reveals a faulty valve, consider procuring a replacement IPR valve to address the issue promptly. Another essential component to test is the EGR cooler. This device plays a key role in reducing NOx emissions by lowering the temperature of exhaust gases. Signs of a failing EGR cooler may include the presence of white smoke from the tailpipe or coolant leakage from the exhaust system. If these symptoms are observed, it is recommended to seek out suitable replacement EGR coolers tailored to the specific make and model of the vehicle. By following these testing procedures and keeping a close eye on the high pressure oil pump, injection pressure regulator valve, and EGR cooler, you can effectively diagnose and address any issues within the engine system.

How do long cranking times relate to the functioning of the High Pressure Oil Pump?

Long cranking times in a diesel engine can often be linked to issues with the High Pressure Oil Pump (HPOP). The HPOP plays a crucial role in providing the necessary pressure for fuel injection and engine start-up. When a diesel engine takes longer than usual to start after extended cranking periods, this delay could indicate a problem with the HPOP. In colder weather conditions, the functioning of the HPOP can be further impacted. Low temperatures below 32 degrees Fahrenheit may result in air getting trapped inside the pump, causing the engine to require additional time to start – typically around 2.5 seconds. However, if the prolonged cranking times persist in warmer or moderate temperatures, it suggests that the HPOP itself may be at fault. This could indicate issues such as decreased pressure output, leaks, or other malfunctions within the pump that require attention and potential repair.

How does the High Pressure Oil Pump work in a diesel engine?

The High Pressure Oil Pump in a diesel engine functions by pressurizing oil at a high level, typically around 3,000 PSI. This pressurized oil is crucial for ensuring the proper functioning of the injectors by compressing fuel effectively. Along with this primary role, the pump also distributes oil to various engine components like rotating bearings, sliding pistons, and the camshaft for lubrication. Furthermore, it is responsible for aiding in the operation of small actuators and can even be utilized as a tensioner for systems like timing belts in specific diesel engine models.

Powerstroke High-Pressure Oil Pump Symptoms

1. Oil Leak

Symptoms of a faulty high-pressure oil pump in a Powerstroke engine can manifest in various ways. One common indication of an issue is an oil leak. If you notice oil pooling or dripping underneath the engine, particularly near the front or bottom of the motor, it could be a sign of a high-pressure oil pump leak.

The high-pressure oil pump operates under extreme pressure, and over time, seals and gaskets can deteriorate, leading to leaks. Oil leaks from the high-pressure oil pump can result in a loss of oil pressure, which can impact the overall performance and reliability of the engine.

To confirm if the oil leak is related to the high-pressure oil pump, it is important to inspect the pump itself and its surrounding components. Look for signs of oil residue or wetness on the pump housing, fittings, and connections. Additionally, check the high-pressure oil lines and connectors for any signs of leakage.

If you suspect an oil leak from the high-pressure oil pump, it is crucial to address the issue promptly. Continuing to operate the engine with a leaking pump can lead to oil starvation and severe engine damage. Seeking professional assistance or consulting a knowledgeable mechanic is recommended to diagnose and resolve the problem effectively.

2. Engine Weakness

Another common symptom of a faulty high-pressure oil pump in a Powerstroke engine is engine weakness or a noticeable loss of power. The high-pressure oil pump is responsible for delivering pressurized oil to the fuel injectors, which aids in the atomization and combustion of fuel. If the pump is not functioning correctly, it can result in insufficient oil pressure reaching the injectors, leading to a decrease in engine performance.

You may experience a lack of power during acceleration, especially when towing or carrying heavy loads. The engine might feel sluggish or struggle to reach higher speeds. Additionally, you may notice a decrease in overall engine responsiveness and a delay in throttle response.

Engine weakness can also manifest as rough idling, stalling, or misfiring. Inadequate fuel supply caused by a malfunctioning high-pressure oil pump can disrupt the combustion process, leading to an irregular idle or engine misfires.

If you observe these symptoms, it is advisable to have the high-pressure oil pump inspected and tested. A professional mechanic with experience in Powerstroke engines will be able to diagnose the issue accurately and recommend the necessary repairs or replacements. Ignoring engine weakness caused by a faulty high-pressure oil pump can potentially lead to further engine damage and decreased overall performance.

3. High Exhaust Gas Temperature Level

“In what ways can Extreme Exhaust Gas Temperatures signal a problem with the High-Pressure Oil Pump? A third symptom that can indicate a problem with the high-pressure oil pump in a Powerstroke engine is a high exhaust gas temperature (EGT) level. The high-pressure oil pump plays a crucial role in delivering the required oil pressure to the fuel injectors for proper combustion. When the pump malfunctions, it can lead to inadequate fuel atomization and incomplete combustion, resulting in higher EGT levels.

Elevated EGT levels can be identified through various means, such as a warning light on the instrument panel or a dedicated EGT gauge. If you notice that the EGT reading is consistently higher than normal during regular driving conditions, it could be a sign of a malfunctioning high-pressure oil pump. High EGT levels indicate that the engine is not efficiently burning fuel, leading to increased heat production. Prolonged exposure to high EGT levels can cause damage to engine components, including valves, pistons, and turbochargers.

It is crucial to address this symptom promptly to prevent further engine damage and maintain optimal engine performance. To further investigate the issue, consider using an EGT sensor to accurately measure the temperature of the exhaust before drawing conclusions. Additionally, if you suspect a problem with the high-pressure oil pump, try reducing the amount of fuel going into the engine by taking your foot off the accelerator. These steps may help diagnose the potential pump malfunction and prevent any lasting damage to your vehicle.”<

4. Long Cranking

In addition to the previously mentioned symptoms, another potential indication of a problem with the high-pressure oil pump in a PowerStroke engine is experiencing long cranking times. When you attempt to start the engine, it may take longer than usual for it to fire up.

The high-pressure oil pump plays a vital role in building the necessary oil pressure to activate the fuel injectors and initiate the combustion process. If the pump is not functioning properly, it may struggle to generate sufficient pressure quickly, resulting in extended cranking times before the engine starts.

You may notice that the engine takes several seconds of continuous cranking or multiple attempts before it finally starts running. This can be especially noticeable when the engine is cold or has been sitting for a while.

Long cranking times can be frustrating and inconvenient, and they can also put additional strain on the starter motor and other components involved in the starting process.

5. Oil Pressure Warning Light

One more symptom that can indicate a potential problem with the high-pressure oil pump in a Powerstroke engine is the illumination of the oil pressure warning light. The oil pressure warning light is designed to alert you when the engine’s oil pressure drops below the recommended level.

If the high-pressure oil pump is not functioning correctly or if there is a loss of oil pressure in the system, the oil pressure warning light may come on. This serves as an important signal that the engine may not be receiving sufficient lubrication, which can lead to severe damage if left unaddressed.

It is crucial not to ignore the oil pressure warning light, as low oil pressure can result in engine wear, increased friction, and potential engine failure. If you notice the oil pressure warning light illuminated on your dashboard, it is recommended to immediately stop the vehicle in a safe location and check the oil level. If the oil level is adequate, it is likely that the issue lies with the high-pressure oil pump or related components.

6. Noise From Valve Train

One crucial sign that may hint at a looming issue with the high-pressure oil pump in a PowerStroke engine is the presence of abnormal noise emanating from the valve train. The valve train, comprising vital components like valves, lifters, pushrods, and camshafts, relies on optimal oil pressure for smooth operation.

Should the high-pressure oil pump falter or experience diminished performance, it might result in inadequate oil reaching the valve train components. This insufficiency in lubrication can trigger escalated friction, metal-on-metal contact, and ensuing noise generation. Drivers might detect peculiar tapping, ticking, or clattering sounds originating from the engine’s valve train zone. These noises could be particularly conspicuous during engine startup, idle periods, or while under load. It is imperative to differentiate these sounds from other customary engine noises, such as those stemming from fuel injectors or typical valve train function.

7. Noisy Oil Pump

Another telltale sign that could indicate a potential issue with the high-pressure oil pump in a Powerstroke engine is a noisy oil pump. Ordinarily, the oil pump operates quietly, ensuring the requisite oil pressure for proper engine functionality. However, if the high-pressure oil pump is defective or encountering complications, it may emit abnormal sounds. A noisy oil pump can manifest in various forms, including whining, grinding, or rattling noises.

These sounds might become more pronounced when the engine is in operation, particularly during acceleration phases or at elevated RPM levels. It is vital to discern these noises from other standard engine sounds, such as those linked to belt operations or pulley vibrations. A malfunctioning high-pressure oil pump may be grappling to generate the necessary oil pressure, resulting in excessive strain on the pump’s internal components. This heightened strain can lead to mechanical wear, misalignments, or damaged bearings, culminating in the production of atypical noises.

Can You Fix A High-Pressure Oil Pump On 6.0 Power Stroke?

Yes, a high-pressure oil pump on a 6.0 Power Stroke can be repaired or replaced if it is experiencing issues. The specific approach to fixing the high-pressure oil pump will depend on the nature and severity of the problem.

In some cases, if the issue is relatively minor, it may be possible to repair the existing pump. This could involve replacing worn-out seals, gaskets, or other components within the pump to restore its functionality. Repairing the pump can be a cost-effective solution if the damage is localized and the pump’s overall condition is still good.

However, in instances where the high-pressure oil pump is severely damaged or beyond repair, replacement is often the recommended course of action. Replacing the pump with a new or remanufactured unit ensures reliable performance and peace of mind. It is essential to use a high-quality replacement pump that meets the manufacturer’s specifications to ensure proper function and compatibility.

What tools, parts, and torque specifications are needed for repairing a 7.3 HPOP leak?

To repair a 7.3 HPOP (High Pressure Oil Pump) leak, you will need the following tools, parts, and torque specifications:

- Tools:

- A 3/16″ Allen wrench to remove the plug.

- Parts:

- If you are removing or replacing the HPOP Reservoir oil, it is recommended to use a hand-held fluid transfer pump. You can find one on Amazon.

- To replace the inspection port plug, you will need the part number GZ-13-007. You can find this part on RIFFRAFF DIESEL’s website. Additionally, this plug can also be used for pressure port fittings on the rear of the 99-03 Ford 7.3 Powerstroke fuel bowls.

- Torque Specifications:

- Ensure that you follow the recommended torque specifications for the specific components you are working on. These specifications can vary depending on the specific part or plug being installed or removed.

What are the causes and consequences of a leak in the oil line fittings?

A potential cause of a leak in the oil line fittings of a 7.3 Powerstroke HPOP (High Pressure Oil Pump) is the failure of one or both of the o-rings on the fittings. These o-rings are prone to deteriorate over time, resulting in oil leaks. This can lead to lower oil pressure within the engine.

When there is a leak in the oil line fittings, the decreased oil pressure can cause difficulties for the injectors in delivering the necessary amount of fuel to the engine. The injectors may struggle to function properly, resulting in an inadequate fuel supply and potentially affecting the overall performance of the vehicle.

One of the immediate consequences of a 7.3 HPOP leak is the engine experiencing chugging, missing, or running in a rough manner. These symptoms can be attributed to the injectors being deprived of sufficient fuel due to the decreased oil pressure caused by the leak. The engine may no longer operate smoothly or efficiently.

In summary, a leak in the oil line fittings of a 7.3 Powerstroke HPOP can be primarily caused by the failure of the o-rings on the fittings. This can result in lower oil pressure, leading to issues such as inadequate fuel delivery by the injectors and subsequent engine performance problems like chugging, missing, or rough running.

How does a leaking HPOP affect fuel delivery and engine performance?

A leaking HPOP (High Pressure Oil Pump) can significantly impact both fuel delivery and engine performance in a 7.3 Powerstroke. When there is a sudden drop in MPG or noticeable issues with idling and acceleration, it may be indicative of an HPOP leak. This leak causes a decrease in oil pressure, which directly affects the 7.3’s injectors’ ability to deliver an adequate amount of fuel.

As the injectors become starved for fuel due to the low oil pressure caused by the HPOP leak, several problems may arise. First, the engine may exhibit chugging or missing, causing it to run unevenly and roughly. This uneven combustion results in reduced power and overall poor engine performance.

Furthermore, the excess fuel not properly delivered by the injectors due to the inefficient operation caused by the HPOP leak is ultimately released through the exhaust system. This release of unburned fuel can appear as black or white smoke emitting from the exhaust pipe. Not only does this indicate that fuel is not being properly burned in the combustion chamber, but it also represents a waste of fuel resources.

In summary, a leaking HPOP affects fuel delivery and engine performance in multiple ways. The decrease in oil pressure hampers the injectors’ ability to deliver fuel efficiently, leading to issues such as rough running and reduced power. Additionally, the presence of smoke in the exhaust is a clear indication of fuel not being burned effectively and is a consequence of the excess fuel escaping through the tailpipe.

Frequently Asked Questions

Q: What are some common high-pressure oil pump problems in a 6.0 Powerstroke?

A: The 6.0 Powerstroke diesel engine is known for its high-pressure oil system issues. Some common problems associated with the high-pressure oil pump (HPOP) include leaks, failure of internal components, low pressure, or erratic pressure.

Q: Can I repair a faulty high-pressure oil pump in a 6.0 Powerstroke, or does it need replacement?

A: In most cases, a faulty high-pressure oil pump in a 6.0 Powerstroke will require replacement rather than repair. The internal components of the pump, such as the gears or pistons, can wear out or fail over time. It’s recommended to replace the pump with a new or remanufactured unit to ensure proper functionality and reliability.

Q: Should I attempt to diagnose and repair high-pressure oil pump problems myself, or seek professional help?

A: Diagnosing and repairing high-pressure oil pump problems in a 6.0 Powerstroke can be challenging, especially for those without experience working on diesel engines. It involves complex components and requires specialized tools and knowledge. Unless you have the necessary expertise, it’s generally advisable to seek professional help from a qualified mechanic or diesel technician who has experience with the 6.0 Powerstroke engine. They will have the skills and equipment needed to diagnose the issue accurately and perform the appropriate repairs.