Expert Guide: Master the Art of Checking Timing on 5.4 3V Like a Pro!

If you’re experiencing performance issues with your Ford 4 3V engine, it may be time to check the timing. The timing is crucial to the engine’s overall performance, and if it’s not set correctly, you’ll notice a drop in power and efficiency.

But how do you check the timing on a 4 3V engine? Don’t worry, we’ve got you covered. In this article, we’ll walk you through the steps to check the timing and get your engine running smoothly.

From setting top dead center to using a timing light, we’ll cover everything you need to know to get the job done right. So, let’s dive into the world of engine timing and get your Ford running like a dream.

Gather Necessary Tools

“How to check timing on a 4 3v engine” Before starting the process of checking the timing on your 4 3v engine, you will need to gather the necessary tools.

The most important tool you will need is a timing light. A timing light allows you to accurately measure the timing of your engine by illuminating timing marks on the crankshaft and camshaft. You will also need a ratchet and socket set to remove the timing cover, a torque wrench to tighten the bolts when reassembling the cover, and a set of pliers to remove and replace the distributor cap.

Additionally, you may need an assistant to help you turn the engine over and watch the timing mark while you adjust the timing on the distributor. Once you have all of these tools, you will be ready to move on to the next step of checking the timing on your 4 3v engine.

Timing Light, Socket Set, Wrench, Safety Glasses

When it comes to working on your car, having the right tools is essential. If you’re planning on performing some maintenance on your car’s ignition system, you’ll need a timing light, socket set, wrench, and safety glasses. These tools will allow you to adjust the timing of your engine, which can help to improve its performance and gas mileage.

The timing light is used to ensure that the ignition timing is set correctly, while the socket set and wrench are necessary for removing and installing spark plugs and other ignition components. Safety glasses are also a must-have, as they will protect your eyes from any flying debris or sparks that may come loose during the repair process. By gathering these necessary tools beforehand, you can save yourself time and frustration down the road, making the repair process smoother and more efficient.

So, be sure to have all of these tools on hand before diving into your next car repair project!

Locate Timing Marks

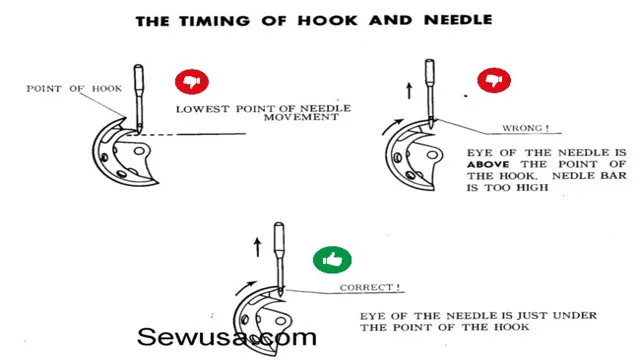

If you want to know how to check timing on 4 3v, the first step is to locate the timing marks. These marks are typically found on the crankshaft, camshaft, and timing chain.

The easiest way to locate them is to consult the owner’s manual or a reliable online resource. Once you’ve found them, you’ll want to make sure they are lined up properly. This will ensure that the engine is firing at the correct time and will help prevent damage.

It is important to note that checking timing requires some technical skill and equipment, so if you’re unsure about the process it’s best to seek professional help. However, if you’re experienced with engines and have the right tools, checking the timing on your 4 3v engine is a relatively straightforward process.

Crankshaft and Camshaft Timing Marks

If you’re working on your engine and need to adjust the timing, you’ll need to locate the timing marks on your crankshaft and camshaft. Timing marks are small indicators on these components that allow you to properly align them with each other. To find the timing marks, you’ll need to consult your engine’s manual as the placement of these marks can vary from engine to engine.

Once you’ve located the timing marks, you’ll need to use them to make sure that your engine is firing at the correct time. This can be a finicky process, so it’s important to be patient and take your time. With the right tools and some careful measurement, however, you should be able to get your engine running smoothly in no time.

Set Engine to Top Dead Center (TDC)

If you’re checking the timing on a 4 3v engine, the first step is to set the engine to top dead center (TDC). This means that the piston in the number one cylinder is at the very top of its stroke and both valves are closed.

So, how do you do it? First, remove the valve cover on the driver’s side of the engine. Then, remove the spark plug from the number one cylinder and insert a long, thin screwdriver into the spark plug hole. Slowly turn the crankshaft until the screwdriver reaches its highest point.

You can use a degree wheel to make sure you’re at exactly 0 degrees TDC if you want to be really precise. Next, you’ll need to check the alignment of the timing marks on the camshaft and crankshaft. These marks should be aligned at TDC.

You can use a timing chain wedge tool to hold the timing chain in place while you check the alignment. If the marks aren’t lined up, you’ll need to adjust the timing using the camshaft phaser or distributor (depending on your engine). Checking the timing on a

4 3v engine can be a bit tricky, but taking the time to do it properly can prevent a lot of problems down the road. Don’t rush it and be sure to double-check your work before moving on to the next step.

Align TDC Mark on Crankshaft with Timing Pointer

Setting the engine to Top Dead Center (TDC) is a crucial step in ensuring your engine runs smoothly and efficiently. One of the key components of setting the engine to TDC is aligning the TDC mark on the crankshaft with the timing pointer. This ensures that the engine’s pistons are at the highest point in the cylinder, and that the valves are closed.

To do this, you’ll first need to locate the timing pointer on your engine. Once you’ve located it, you can use a timing light to adjust the ignition timing until the TDC mark on the crankshaft lines up with the timing pointer. It’s important to note that if the timing is off, it can cause a slew of problems, from decreased engine performance to increased fuel consumption.

So, taking the time to set your engine to TDC is well worth it in the long run. Remember to always consult your vehicle’s owner manual for specific instructions on how to set your engine to TDC.

Check Camshaft Timing

If you own a 4 3v engine, it’s important to know how to check the camshaft timing to ensure it’s running at optimal performance. The process involves removing the valve covers, then the timing cover to access the timing mark.

Use a timing light and line up the timing mark on the crankshaft bolt and the mark on the timing cover for the top dead center. Then, confirm that the marks on the camshaft are in alignment with the marks on the timing cover. If they’re not, you’ll need to make adjustments until they do.

Remember, accurate timing ensures your engine is running at its best, so it’s worth taking the time to check and adjust if needed.

Align Camshaft Timing Marks with Cylinder Head

When it comes to engine maintenance, checking the camshaft timing is a crucial step that shouldn’t be overlooked. One way to ensure that your camshaft timing is correct is to align the camshaft timing marks with the cylinder head. This may sound intimidating, but it’s actually a simple process that can save you from potential engine damage down the road.

First, locate the camshaft timing marks on your engine. Next, rotate the engine until the camshaft timing marks are in the correct position. This will ensure that the camshaft is properly timed with the cylinder head.

It’s important to use caution when rotating the engine, as you don’t want to damage any components. Additionally, double-check your work by verifying that the timing marks are still aligned after they have been set. This way, you can have peace of mind that your engine will perform at its best.

So, don’t overlook camshaft timing – it’s an important part of maintaining a healthy engine.

Check Ignition Timing

If you own a vehicle with a 4 3v engine, it’s essential to know how to check the ignition timing. Timing is crucial for the engine to run correctly and efficiently.

To begin, you’ll need a timing light and a wrench. The first step is to locate the timing marks on the crankshaft and the timing cover. Connect the timing light to the battery and spark plug wire on the number one cylinder.

Start the engine and aim the timing light at the timing mark. The timing mark should line up with the desired degree of advance listed in the vehicle manual. If the timing is off, use the wrench to adjust the distributor until the timing is set correctly.

Checking the timing regularly can improve performance, fuel efficiency, and prolong engine longevity. Just remember to always refer to your vehicle owner’s manual for specific instructions and recommended timing settings.

Connect Timing Light to Battery and #1 Cylinder

Ignition Timing When it comes to checking ignition timing, the first step is to connect your timing light to the battery and the #1 cylinder. This is an essential step before you can proceed with adjusting your timing. To do this, you will need to locate the battery and connect the positive clip of your timing light to the positive terminal.

Then, you can connect the negative clip of your timing light to the spark plug wire of your #1 cylinder. Once you have connected the timing light, start your engine and allow it to idle. The timing light will flash each time the spark plug fires, allowing you to see exactly where your timing is set.

This will help you to adjust your timing if necessary, ensuring that your engine is running at its optimal performance level. So, if you want to ensure your engine is running smoothly, make sure to check your ignition timing regularly!

Check Timing by Adjusting Distributor or PCM if necessary

One crucial aspect of maintaining proper engine performance is checking the ignition timing regularly. This involves adjusting the distributor timing or programming the PCM (powertrain control module) to ensure that the spark plug fires at the correct moment. Failure to do so can result in poor fuel efficiency, reduced power, and even engine damage.

To check the timing, use a timing light and follow the manufacturer’s instructions for your specific vehicle. If the timing is off, adjust the distributor or PCM as necessary. Think of it like hitting a baseball – if you swing too early or too late, you won’t make good contact.

Similarly, if the spark plug fires too early or too late, your engine won’t perform optimally. So take the time to check and adjust your ignition timing on a regular basis. It’ll keep your engine running more smoothly, giving you better performance and fuel economy.

Wrap-Up and Tips

If you own a Ford truck or SUV with a 4-liter 3-valve engine, checking the timing is a crucial part of routine maintenance. The timing system ensures that the engine’s cylinders fire at precisely the right moment, maximizing performance and fuel efficiency.

The good news is that checking the timing on a 4 3v engine is relatively easy, and you don’t need any special tools. First, locate the timing marks on the crankshaft and camshaft sprockets.

Then, use a timing light to make sure that the timing marks line up correctly. If they don’t, you’ll need to adjust the position of the camshaft using the timing chain tensioners. It’s always best to refer to your vehicle’s owner’s manual for specific instructions and to follow safety protocols when performing any maintenance on your vehicle.

By keeping up with the timing system, you can help ensure that your 4 3v engine runs smoothly for many miles to come.

Reinstall Timing Cover and Double Check Timing Marks

As we wrap up this project of reinstalling the timing cover and double-checking the timing marks, there are a few tips to keep in mind. First and foremost, take your time and be patient. Rushing through this process could result in mistakes that could be costly down the road.

When reinstalling the timing cover, make sure to use the appropriate sealant and torque the bolts to the recommended specifications. Before starting the engine back up, it’s essential to double-check the timing marks. The timing of the engine is critical to its performance, and if the marks are even slightly off, it could result in engine damage, or worse, complete engine failure.

Use a timing light to confirm that the timing marks line up correctly. Another tip is to keep the workspace clean and organized. This will make the process easier and more efficient.

It’s also essential to have the right tools on hand. Using tools that are damaged or the wrong size can result in damage to the engine or components. In summary, reinstalling the timing cover and double-checking the timing marks is a crucial step in the engine assembly process.

Take your time, be patient, and follow the recommended torque specifications and sealant use. Double-check the timing marks before starting the engine back up, and keep a clean and organized workspace to make the process easier. By following these tips, you can ensure a successful engine rebuild and reliable performance on the road.

Conclusion

In conclusion, checking the timing on a 4 3v engine may seem like a daunting task, but with a little bit of patience and the right tools, it can be a breeze. Just remember to line up your timing marks, turn the crankshaft to the desired position, and verify that everything lines up correctly.

And if all else fails, just give your engine a wink and a smile – sometimes a little bit of charm is all it takes to get things running smoothly.”

FAQs

What is the importance of checking the timing on a 5.4 3v engine?

Checking the timing on the 5.4 3v engine is important to ensure that the ignition system is functioning properly and to improve the overall performance of the engine.

How do I know if my 5.4 3v timing is off?

Signs of an off-timing on a 5.4 3v engine include poor engine performance, decrease in fuel efficiency, and engine misfire.

Can I check the timing on my 5.4 3v engine myself?

Yes, you can check the timing on your 5.4 3v engine yourself with the help of a timing light and some basic instructions.

What is the procedure for checking the timing on a 5.4 3v engine?

The procedure for checking the timing on a 5.4 3v engine involves connecting a timing light to the spark plug wire of the engine, starting the engine, and adjusting the distributor until the timing mark aligns with the desired timing setting.