Fuel up Your Knowledge: A Comprehensive Guide on How to Bench Test a Fuel Pump

If you’re experiencing engine trouble, you may be wondering if it’s your fuel pump at fault. A fuel pump plays a critical role in your vehicle’s performance, ensuring that fuel is delivered from the tank to the engine. However, diagnosing a faulty fuel pump can be complicated since there are different ways to determine if it is the issue or not.

Bench testing a fuel pump is one of the most reliable methods for diagnosing its health. Think of it as taking your vehicle’s fuel pump to the doctor for an examination. In this blog, we’ll dive into what bench testing involves and why it’s essential to ensure the smooth operation of your vehicle.

Gather Necessary Tools

To conduct a successful fuel pump bench test, you’ll need certain tools to ensure accurate testing. The primary tool you’ll need is a fuel pressure gauge, which will help you verify that the fuel pump is providing the correct fuel pressure. A multimeter is also essential as it will help you measure the fuel pump’s electrical output.

Furthermore, you’ll need a fuel line disconnect tool to separate the fuel line from the fuel pump. Finally, you may need a wrench to remove the fuel pump from the engine compartment for bench testing. Suffice it to say, having these tools handy will ensure that your fuel pump test runs smoothly and accurately so that you can determine whether or not the fuel pump needs to be replaced.

Multimeter, Fuel Pressure Gauge

If you’re planning to test your vehicle’s fuel pressure, you’ll need to gather a few tools first. Two of the most important tools for fuel pressure testing are a multimeter and a fuel pressure gauge. A multimeter is a versatile device that can measure various electrical characteristics, including voltage, resistance, and continuity.

It can help you test the voltage at the fuel pump to determine if it’s receiving power. A fuel pressure gauge, on the other hand, is used to measure the pressure of the fuel in the system. With this tool, you can check if the pressure level meets the manufacturer’s specifications.

Additionally, you may also require a specialty wrench or socket to remove the fuel line and a catch can to collect fuel during the test. Be sure to follow the manufacturer’s recommendations and safety guidelines when using these tools to avoid any mishaps. With the right tools in hand, you can troubleshoot your fuel system and ensure your vehicle is performing optimally.

Disconnect Electrical Connections

If you’re wondering how to bench test a fuel pump, the process can seem intimidating at first. However, with the right steps, it can be quite simple. The first step is to disconnect all of the electrical connections to the fuel pump.

This includes the electrical connectors, the fuel gauge sending unit, and any other connections. This will ensure that there is no power going to the fuel pump during the testing process, which is essential for safety reasons. Once all of the electrical connections are disconnected, you can move on to the next step in the testing process.

Remember to always exercise caution when working with fuel and electricity, and follow all safety procedures to avoid accidents.

Battery, Fuel Pump, Fuel Pressure Regulator

When it comes to disconnecting electrical connections for your car’s battery, fuel pump, and fuel pressure regulator, safety should be your top priority. Before starting the process, make sure you’re wearing protective gloves and glasses to avoid any injuries. First, you need to disconnect the negative terminal of your car’s battery to prevent any electrical shocks.

Then, locate the fuel pump and fuel pressure regulator, which are usually located near the fuel tank. Use a wrench to loosen the connection and gently pull it out to disconnect it. Take extra care not to damage the clips or pins.

Once you’ve disconnected the connections, use electrical tape to cover any exposed wires to prevent any accidents. Remember to follow the manufacturer’s instructions and refer to your car manual to make sure you’re doing everything correctly. By following these steps, you’ll be able to safely disconnect the electrical connections of your car’s battery, fuel pump, and fuel pressure regulator.

Check Pump’s Voltage

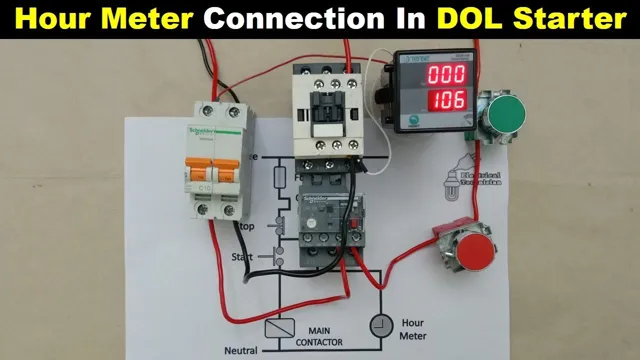

If you’re wondering how to bench test a fuel pump, one of the first things you should check is the pump’s voltage. This is important because if the voltage is too low, the pump won’t be able to function properly, and if it’s too high, it could burn out the motor. To check the voltage, you’ll need to use a multimeter and attach the positive lead to the positive terminal on the pump and the negative lead to the negative terminal.

Then, turn on the pump and check the voltage reading. The pump’s specifications should indicate the proper range, which is typically between 12 and 14 volts for most electric fuel pumps. If the voltage is outside of the proper range, you may need to troubleshoot other components of the fuel system before proceeding with further testing.

Connect Multimeter, Turn on Ignition Key

To check the voltage of your fuel pump, you’ll need to connect a multimeter and turn on the ignition key. This will allow you to see how much power is being sent to the pump, which can help you diagnose any issues that may be affecting its performance. Once the multimeter is properly connected, you should be able to see the voltage reading on its display.

Ideally, you’ll want to see a reading of around 12 volts, as this indicates that the pump is receiving the power it needs to function properly. Keep in mind that a low voltage reading could be a sign of a bad relay or wiring issue, while a high voltage reading may suggest that the pump is drawing too much power and overloading the circuit. So, be sure to take note of the reading and use it to troubleshoot any issues you may encounter with your fuel pump.

Check Fuel Pressure

If you suspect that your fuel pump is not working correctly, one of the first things you should do is to check the fuel pressure. A fuel pressure gauge can help you determine if the fuel pump is delivering fuel at the correct pressure levels. To bench test a fuel pump, you will need to remove it from the vehicle and connect it to a power source.

Then you can use the fuel pressure gauge to check the fuel pressure. The fuel pump should be able to deliver fuel at the correct pressure range specified by the manufacturer. If the pressure reading is too low, it could indicate a clogged fuel filter or a weak fuel pump.

If the pressure reading is too high, it could mean that the fuel pressure regulator is faulty. Remember to follow safety precautions when working with fuel and electrical components and always refer to the manufacturer’s instructions before conducting any tests.

Connect Fuel Pressure Gauge, Turn on Ignition Key

When it comes to checking the fuel pressure on your vehicle, one of the essential steps is connecting the fuel pressure gauge and turning on the ignition key. This step is critical because it allows you to determine whether your vehicle is getting enough fuel to start and run smoothly. It’s important to note that you may need to consult your vehicle’s manual to locate the fuel pressure gauge connection point and understand the recommended fuel pressure level for your particular vehicle.

Once you have connected the gauge, turn on the ignition key and observe the gauge’s readings. If the fuel pressure reading falls within the manufacturer’s recommended range, your vehicle’s fuel pressure is most likely sufficient. On the other hand, if the fuel pressure is too low, you may need to check for a fuel pump malfunction, clogged fuel filter, or a faulty fuel pressure regulator.

By checking your fuel pressure regularly, you can prevent potential fuel-related problems and keep your vehicle running smoothly.

Confirm Fuel Flow

If you want to bench test a fuel pump, it’s essential to confirm fuel flow. To do this, you’ll need to connect the fuel pump to a power source and turn it on. Once activated, you can quickly check to see if fuel is being delivered through the pump.

You can use a pressure gauge to measure the amount of fuel being pumped, or you can observe the flow visually. It’s crucial to make sure you’ve properly connected the pump to the power source before conducting the test, so you don’t damage the fuel pump. Once you’ve confirmed fuel flow, you’ll know if the fuel pump is operating correctly and can move on to testing other components.

By following these steps and properly testing your fuel pump, you can ensure your vehicle is running smoothly and efficiently.

Disconnect Fuel Return Line, Turn on Ignition Key

Disconnecting the fuel return line and turning on the ignition key is an essential step in confirming fuel flow. This process ensures that the fuel pump is operating correctly and able to supply enough fuel to the engine. The fuel return line serves as a feedback mechanism, allowing the fuel system to regulate the pressure and flow of fuel to the engine.

Once the fuel return line is disconnected, turn on the ignition key and wait for a few seconds. You should hear the fuel pump run and see fuel flowing out of the disconnected line. This confirms that the fuel pump is working correctly and supplying enough fuel.

If there is no fuel flow, it could indicate a clogged fuel filter, faulty fuel pump, or other issues that require further diagnosis. However, if the fuel is flowing correctly, you can reconnect the fuel return line and continue with your engine maintenance or repairs. Remember that engine care and routine maintenance are crucial to keep your vehicle running smoothly, efficiently, and safely.

Conclusion and Final Thoughts

In summary, bench testing a fuel pump is a crucial step in ensuring its proper functionality. Not only does it allow you to diagnose issues before installation, but it also saves you time and money by preventing failed installations. So, don’t skip this step and remember to treat your fuel pump like a bench-warming athlete, always preparing it for the big game!”

FAQs

What equipment is required to bench test a fuel pump?

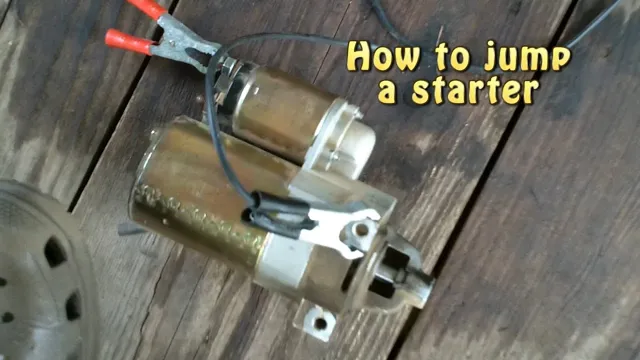

To bench test a fuel pump, you will need a fuel pressure gauge, jumper wires, and a power source such as a battery.

How do you connect the fuel pump to the power source for bench testing?

You can use jumper wires to connect the fuel pump to a 12-volt power source, such as a car battery, to test if the fuel pump is functioning properly.

Can you bench test a fuel pump without a fuel pressure gauge?

While a fuel pressure gauge is recommended, you can still test the fuel pump using a power source and listening for the fuel pump to make noise indicating that it is running.

How can you tell if a fuel pump is faulty during bench testing?

If the fuel pump does not produce the recommended pressure level, or if it does not run at all, it may be faulty and in need of replacement.