Mastering the Art of Semi Truck Clutch Adjustment: A Comprehensive Guide

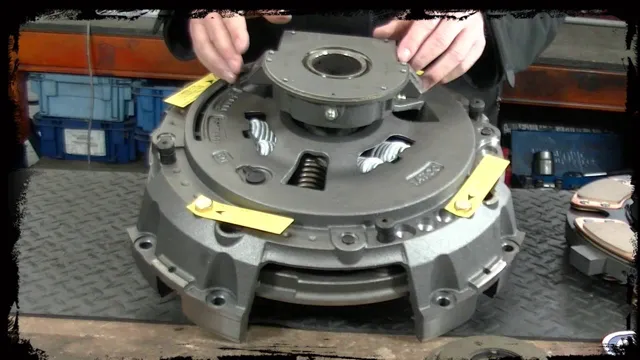

Whether you’re a rookie trucker or a seasoned veteran, adjusting semi-truck clutch can sometimes be tricky. The clutch is one of the most essential components of a semi-truck’s transmission system. Without it, the wheels and gears would never get a chance to turn.

The clutch is responsible for engaging the engine to the transmission, allowing the vehicle to move forward or backward. Learning how to properly adjust the semi-truck clutch can save you from costly repairs and downtime, not to mention the frustration and stress that comes along with it. So, buckle up and prepare to learn everything you need to know about adjusting the semi-truck clutch!

Preparation

Adjusting the semi truck clutch can be a daunting task, but with proper preparation and technique, it can be done with ease. Before getting started, ensure the truck is in a safe and level area. This will make it easier to work on as well as limit the chances of accidents.

Next, gather the necessary tools and equipment. This usually includes a torque wrench, socket set, and a clutch brake adjustment tool. It’s important to have the right tools to avoid damage to the clutch system.

Lastly, consult the manufacturer’s manual for instructions, torque specifications, and safety precautions. With these preparations in place, you’ll be ready to tackle the task of adjusting the semi truck clutch and keep your vehicle running smoothly.

Gather Tools and Materials

When starting a new project, it’s crucial to gather all the necessary tools and materials beforehand. Preparation is key to ensuring a smooth and successful project. Begin by deciding which tools you’ll need for the job, such as hammers, saws, drills, or screwdrivers.

Make a list and check your toolbox to see what you already have and what you need to purchase or borrow. Don’t forget about safety equipment, such as gloves, goggles, and masks. Once you have a list of the necessary tools, consider the materials you’ll need to acquire.

This can include lumber, pipes, concrete, or wiring. Knowing what you’ll need ahead of time will save you from making multiple trips to the store and potentially delaying your progress. Plus, it’ll save you from frustration and stress when you start your project.

By preparing in advance, you’ll be able to focus on the task at hand and feel confident in your abilities to complete it successfully.

Park the Truck on a Level Surface

To properly park your truck, the first step is to find a level surface. This will ensure that your truck remains balanced and secure while parked. Parking on an inclined surface can put pressure on your tires and cause damage to your vehicle’s suspension system.

Additionally, parking on a level surface can make it easier to exit and enter your truck since it will remain stationary. Before parking, it’s important to make sure that any loose items in the bed of your truck are secured and that your truck is in park. By starting with a level surface, you can set yourself up for a successful and safe parking experience.

So, take the time to find a flat spot before you park your truck.

Adjusting the Clutch

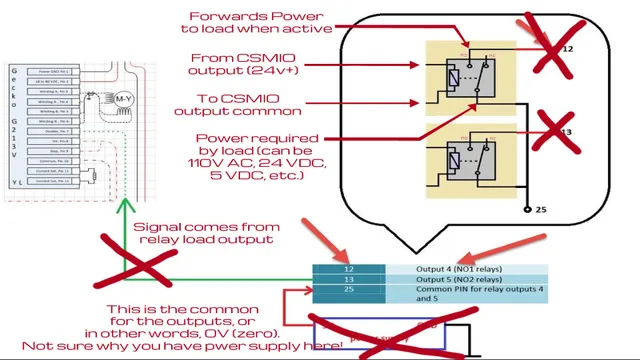

Learning how to adjust a semi truck clutch is an important skill for any truck driver. When the clutch is not properly adjusted, it can cause problems with shifting gears and even damage the transmission. The first step is to locate the clutch adjustment mechanism, which is typically found near the clutch pedal.

Next, you’ll need to loosen the lock nut and turn the adjustment screw until there is slight resistance felt when pressing down on the clutch pedal. From there, you can fine-tune the adjustment to ensure smooth shifting and optimal performance. It’s important to note that over-adjusting the clutch can cause it to slip, so be sure to double-check your work and test it out before hitting the road.

With some practice, adjusting the clutch will become second nature.

Locate the Clutch Brake

Have you been experiencing difficulty with shifting gears in your vehicle? One possible culprit could be a misadjusted clutch. To adjust the clutch, the first step is to locate the clutch brake. This is typically located near the clutch pedal and looks similar to a brake pad.

The clutch brake is used to stop the rotation of the clutch when changing gears, ensuring a smoother shift. To adjust the clutch, you will need to adjust the clutch pedal height and travel. This can typically be done through an adjustment screw or nut located near the clutch pedal.

Making these adjustments will ensure that the clutch engages and disengages properly, allowing for smoother gear changes in your vehicle. So if you’re having trouble with your clutch, don’t panic! Just locate the clutch brake and make the necessary adjustments for an easier, more efficient driving experience.

Measure the Clutch Brake Free Play

Adjusting the clutch in a vehicle is important for smooth shifting and overall performance. One aspect of this process is measuring the clutch brake free play. This refers to the distance the clutch pedal has to travel before engaging the clutch itself.

To measure this, first locate the clutch brake on the clutch pedal assembly, typically found near the top of the pedal. Next, push on the clutch pedal and measure the distance between the clutch brake and the switch contacts. This distance should be between 0.

08-0.12 inches for most vehicles. If the measurement is outside of this range, adjustments may need to be made to the clutch linkage or clutch pedal assembly.

It’s important to have the correct clutch brake free play to prevent unnecessary wear and tear on the clutch components. Overall, measuring and adjusting the clutch brake free play is a crucial step in maintaining the health of your vehicle’s clutch system.

Adjust the Clutch Brake

Adjusting the clutch brake is an important maintenance task, especially if you notice that your clutch is not working as smoothly as it once did. The clutch brake is responsible for stopping the clutch from spinning, allowing you to change gears without grinding them. To adjust the clutch brake, start by locating the adjusting screw on the clutch pedal.

Turn the screw in the direction indicated in your vehicle manual, usually clockwise, until you can feel tension on the clutch pedal. Once you’ve adjusted the screw, test your clutch to ensure it’s working smoothly. If you’re still experiencing problems after adjusting the clutch, it’s best to take your vehicle to a mechanic for further inspection.

Remember, a well-maintained clutch is essential for the smooth operation of your vehicle, so don’t neglect this important task.

Test the Clutch

If you’re experiencing difficulties with your semi-truck’s clutch system, you may want to consider adjusting it. Adjusting the clutch can help to improve your truck’s performance and prevent damage to the transmission. To start, you should test the clutch by driving the truck and shifting gears.

If you find that the clutch is slipping or it’s difficult to shift gears, you may need to adjust it. Adjusting the clutch involves adjusting the clutch pedal, the clutch fork, and the clutch cable. First, you’ll need to locate the clutch pedal and adjust it to a comfortable position that allows for smooth operation.

Then, adjust the clutch fork and clutch cable to ensure the proper amount of tension between the clutch disc and the pressure plate. It’s important to note that adjusting a semi-truck clutch can be a challenging task and it’s recommended to seek the assistance of a professional mechanic to avoid costly mistakes.

Start the Truck

When it comes to starting a truck, one of the first things you need to check is the clutch. Testing the clutch will help you determine if it’s functioning properly before you take off for your journey. To test the clutch, you need to start the engine and press down on the clutch pedal.

If it feels spongy or loose when you press it, this may indicate a problem with the clutch. You should also pay attention to any strange noises or vibrations when you press down on the pedal. If you notice any of these issues, you may need to have your clutch replaced.

On the other hand, if the pedal feels firm and the engine sounds smooth, you’re good to go. Testing the clutch is an important step in ensuring that your truck is functioning safely and efficiently on the road. By taking the time to check the clutch before you drive, you can save yourself from potentially costly repairs down the line.

So why risk it? Give your clutch a test before you start that engine!

Put the Truck in Gear

Testing the clutch before you put the truck in gear is an essential step for any driver. The clutch is the mechanism that connects the engine to the transmission and allows you to shift gears smoothly. To test the clutch, start by pressing the clutch pedal all the way down and shifting the transmission into neutral.

While the clutch is depressed, start the engine and listen for any unusual sounds or vibrations. Next, gradually release the clutch pedal while in neutral and feel for any resistance or slipping. You can also lightly touch the accelerator pedal to ensure the engine revs smoothly.

If everything feels normal, you’re ready to shift into first gear and continue driving. However, if the clutch pedal feels spongy or doesn’t engage properly, it may need to be adjusted or repaired by a professional mechanic. Remember, a well-functioning clutch is important for safe and efficient driving.

Ensure Smooth Shifting

Ensuring smooth shifting is an essential factor for a comfortable and safe driving experience. When it comes to manual transmissions, the clutch is the most critical component to test to ensure your car will shift smoothly. The clutch is responsible for disengaging the engine from the drivetrain, which allows the driver to change gears.

To test the clutch, start by finding a flat surface and put your car in neutral. Then, press the clutch pedal to the floor and start the engine. Release the parking brake and slowly release the clutch pedal.

If the engine stalls, the clutch is engaging correctly. If the clutch fails to engage, the clutch could be worn and might need to be replaced. A successful clutch test determines if it is functioning correctly, which will lead to smooth gear changes, reducing wear and tear on transmission components.

Remember, replacing the clutch on a manual transmission is a major and costly repair that can be avoided with these simple tests. Test your clutch regularly, and keep those shifting problems at bay!

Conclusion

Adjusting a semi truck clutch may seem like a daunting task, but with the right tools and knowledge, it can be as smooth as the ride from a well-adjusted clutch. Just remember to be patient, take your time, and don’t be afraid to ask for help if needed. After all, a good clutch adjustment is crucial for the success of the trip, just like a clever conclusion is for any piece of writing.

“

FAQs

What are the symptoms of a failing semi truck clutch?

Some symptoms of a failing semi truck clutch include difficulty shifting gears, slipping during acceleration, strange noises, and a burning smell.

How do you adjust the clutch on a semi truck?

To adjust the clutch on a semi truck, locate the adjustment screw on the clutch pedal linkage and turn it until the pedal play is within manufacturer specifications.

How often should you adjust the clutch on a semi truck?

It is recommended to adjust the clutch on a semi truck every 100,000-150,000 miles or as needed if performance issues arise.

Can a driver adjust their own semi truck clutch?

While some drivers may have experience with clutch adjustments, it is recommended to seek the assistance of a certified mechanic to avoid risking damage to the clutch or other parts of the vehicle.