Homemade Freeze Plug Tool : DIY Solution for Easy Repair

Freeze plugs, also known as expansion plugs or frost plugs, are crucial components in an engine block. They seal the holes left during the casting process and help prevent coolant leaks. Over time, freeze plugs can deteriorate and require replacement. While there are commercial freeze plug installation tools available, you can also make a homemade freeze plug tool with a few simple materials.

If you’re a DIY mechanic or simply someone who enjoys working on cars, you may have come across the need to install or remove freeze plugs (also known as core plugs) in an engine. These small plugs help to prevent coolant leaks and protect the engine block from damage. While specialized tools for this task are available commercially, they can be quite expensive. Fortunately, making a homemade freeze plug tool is an easy and cost-effective solution. In this article, we’ll guide you through the steps to create your own tool for installing freeze plugs.

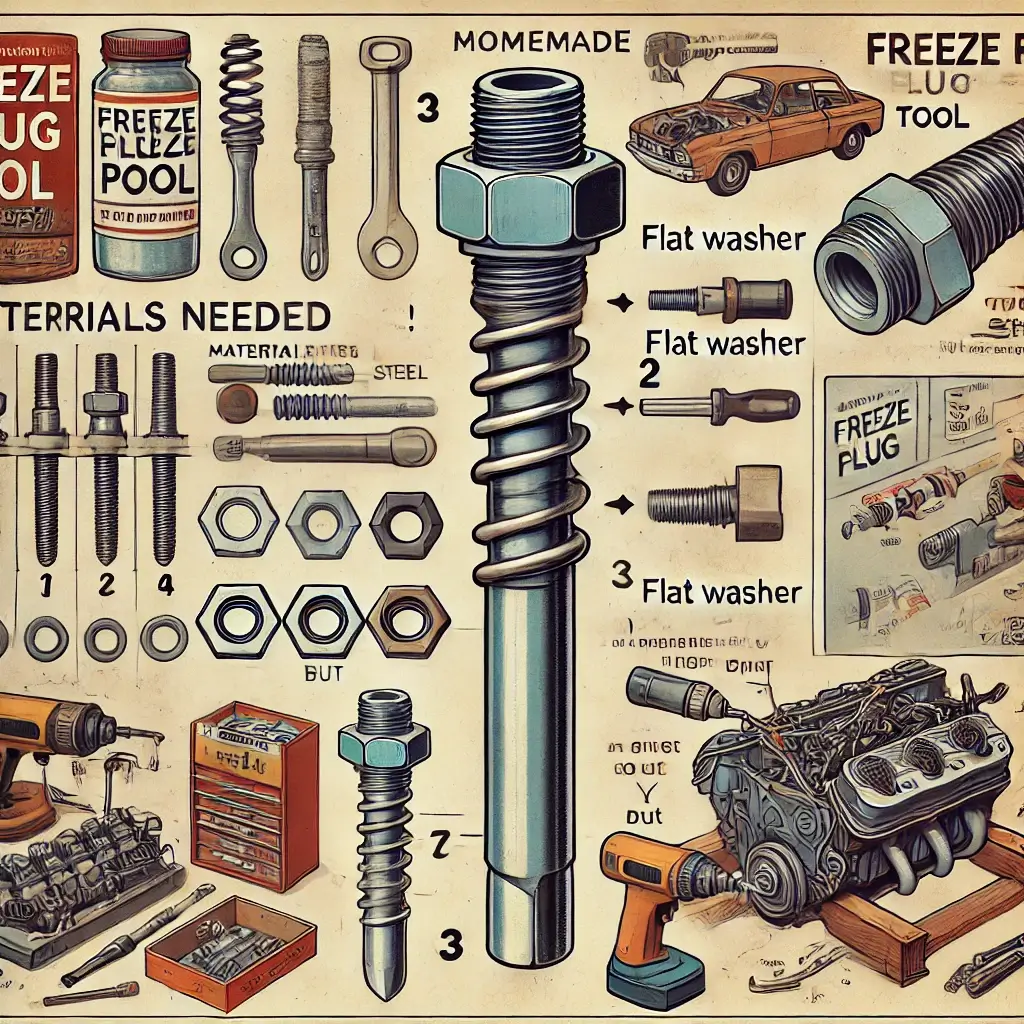

Materials Needed

Before you start making your homemade freeze plug tool, gather the necessary materials:

- Steel rod

- Flat steel piece

- Welder

- Grinder

- Hammer

- Drill and drill bits

- Protective gloves and goggles

Steps to Make the Homemade Freeze Plug Tool

Follow these steps to create your homemade freeze plug tool:

Step 1: Cut The Steel Rod

Using a saw or cutting tool, cut the steel rod to the desired length. The length will depend on the size of the freeze plug and the clearance within the engine bay.

Step 2: Shape The Flat Steel Piece

Take the flat steel piece and shape it into a disc. This disc will be used to evenly distribute the force when installing the freeze plug.

Step 3: Weld The Steel Rod And Disc Together

Secure the steel rod and the disc together using a welder. Make sure the connection is strong and will be able to withstand the force required to install the freeze plug.

Step 4: Grind The Edges

Use a grinder to smooth out any rough edges and ensure that the tool is safe to handle. This step is crucial to prevent any injuries during the installation process.

Step 5: Drill A Hole

Drill a small hole at the end of the steel rod. This hole will allow you to insert a tool or handle to provide leverage when installing the freeze plug.

Tips for Success

- Use Lubrication: Applying a thin layer of grease to the freeze plug can make installation easier.

- Work Carefully: Ensure that all components are aligned correctly to avoid damaging the engine block or the freeze plug.

- Test Fit: Before fully tightening, make sure the freeze plug is seated properly to prevent any leaks after installation.

Using the Homemade Freeze Plug Tool

Once you have made your homemade freeze plug tool, it’s essential to know how to use it correctly.

- Position the freeze plug in the engine block hole.

- Place the homemade freeze plug tool over the freeze plug.

- Use a hammer to gently tap the tool and press the freeze plug into place.

- Continue tapping the tool until the freeze plug is flush with the engine block.

It’s important to apply even pressure to avoid damaging the freeze plug or the engine block.

Frequently Asked Questions For Homemade Freeze Plug Tool : Diy Solution For Easy Repair

What Materials Do I Need For A Homemade Freeze Plug Tool?

You will need a steel rod, large washers, nuts, and a socket for a homemade freeze plug tool.

How Do I Create A Homemade Freeze Plug Tool?

Cut the steel rod to the desired length, drill holes for the bolts, and assemble with washers and nuts.

What Are The Benefits Of Using A Homemade Freeze Plug Tool?

A homemade freeze plug tool can save time and money compared to purchasing one from a store.

Can I Use A Homemade Freeze Plug Tool On Any Vehicle?

Yes, a homemade freeze plug tool can be used on most vehicles, but it’s always best to check for compatibility.

Conclusion

Making a homemade freeze plug tool is a practical solution for DIY enthusiasts and those who want to save on commercial tools. With the right materials and a bit of effort, you can create a reliable tool that will help you install freeze plugs with ease. Remember to prioritize safety when working with tools and equipment, and always wear protective gear when handling metalworking processes.