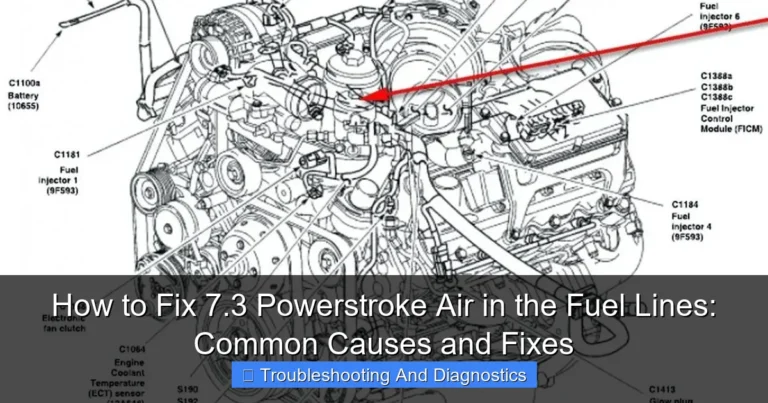

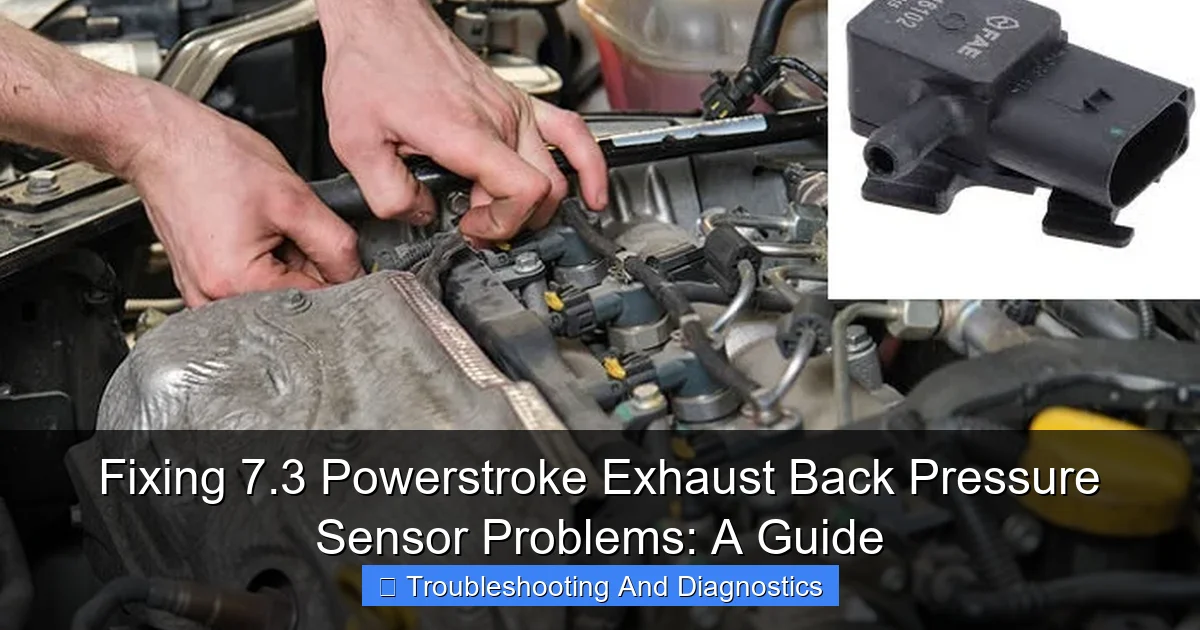

Fixing 7.3 Powerstroke Exhaust Back Pressure Sensor Problems: A Guide

Featured image for this comprehensive guide about Fixing 7.3 Powerstroke exhaust back pressure sensor problems

Image source: cararac.com

The 7.3 Powerstroke engine is a legend in the diesel world, renowned for its rugged durability and impressive power. For many, it’s not just an engine; it’s a way of life, powering countless trucks through grueling work and adventurous journeys. However, even legends have their quirks, and one common issue that can plague this otherwise bulletproof engine relates to its exhaust system: specifically, problems with the Exhaust Back Pressure (EBP) sensor.

If your beloved 7.3 Powerstroke is experiencing a mysterious loss of power, poor fuel economy, or unexplained turbo lag, the EBP sensor might be the silent culprit. This often-overlooked component plays a crucial role in your engine’s performance, emissions, and overall health. When it malfunctions, it can lead to a cascade of issues that make your truck feel sluggish and unreliable. But don’t fret! Many 7.3 Powerstroke EBP sensor problems are entirely fixable with a bit of knowledge and the right approach.

This comprehensive guide is your ultimate resource for fixing 7.3 Powerstroke exhaust back pressure sensor problems. We’ll dive deep into understanding what the EBP sensor does, how to identify its failure, step-by-step diagnostic procedures, common causes of malfunction, and, most importantly, actionable solutions to get your 7.3 Powerstroke roaring back to life. Get ready to troubleshoot, diagnose, and restore your engine’s optimal performance!

Quick Answers to Common Questions

What are the signs my 7.3 Powerstroke exhaust back pressure sensor is failing?

You might notice poor fuel economy, a lack of power, rough idle, or even excessive smoke from your exhaust. Often, your Check Engine Light will come on with codes like P0470 or P0476, pointing directly to a problem with your 7.3 Powerstroke exhaust back pressure sensor.

Is cleaning the 7.3 Powerstroke exhaust back pressure sensor an option, or do I always need to replace it?

Sometimes, the problem isn’t the sensor itself but a clogged tube leading to it, which can be cleaned. However, if the 7.3 Powerstroke exhaust back pressure sensor is internally faulty or damaged, replacement is the only reliable long-term fix.

How difficult is it to replace the 7.3 Powerstroke exhaust back pressure sensor myself?

Replacing the 7.3 Powerstroke exhaust back pressure sensor is a fairly common DIY job that typically requires basic hand tools. The most challenging part can sometimes be accessing it due to tight spaces or dealing with old, seized bolts on the exhaust tube.

What happens if I ignore a bad 7.3 Powerstroke exhaust back pressure sensor?

Ignoring a faulty 7.3 Powerstroke exhaust back pressure sensor can lead to significant engine performance issues, including reduced power, decreased fuel efficiency, and even potential damage to other emission components over time. It’s crucial for your truck’s overall health to fix it promptly.

What’s the most common cause of a 7.3 Powerstroke exhaust back pressure sensor problem?

The most frequent culprit is a clogged exhaust tube leading to the 7.3 Powerstroke exhaust back pressure sensor, which often gets packed with carbon soot. This blockage prevents the sensor from accurately reading exhaust pressure, causing a cascade of performance issues.

📋 Table of Contents

- Understanding the 7.3 Powerstroke EBP Sensor and Its Role

- Common Symptoms of a Failing 7.3 Powerstroke EBP Sensor

- Diagnosing 7.3 Powerstroke EBP Sensor Problems: Step-by-Step

- Common Causes of 7.3 Powerstroke EBP Sensor Failure

- Fixing 7.3 Powerstroke Exhaust Back Pressure Sensor Problems

- Preventing Future EBP Sensor Issues

- Conclusion

Understanding the 7.3 Powerstroke EBP Sensor and Its Role

Before we can fix a problem, we need to understand the component causing it. The Exhaust Back Pressure (EBP) sensor is a vital part of your 7.3 Powerstroke‘s engine management system. But what exactly does it do, and why is it so important?

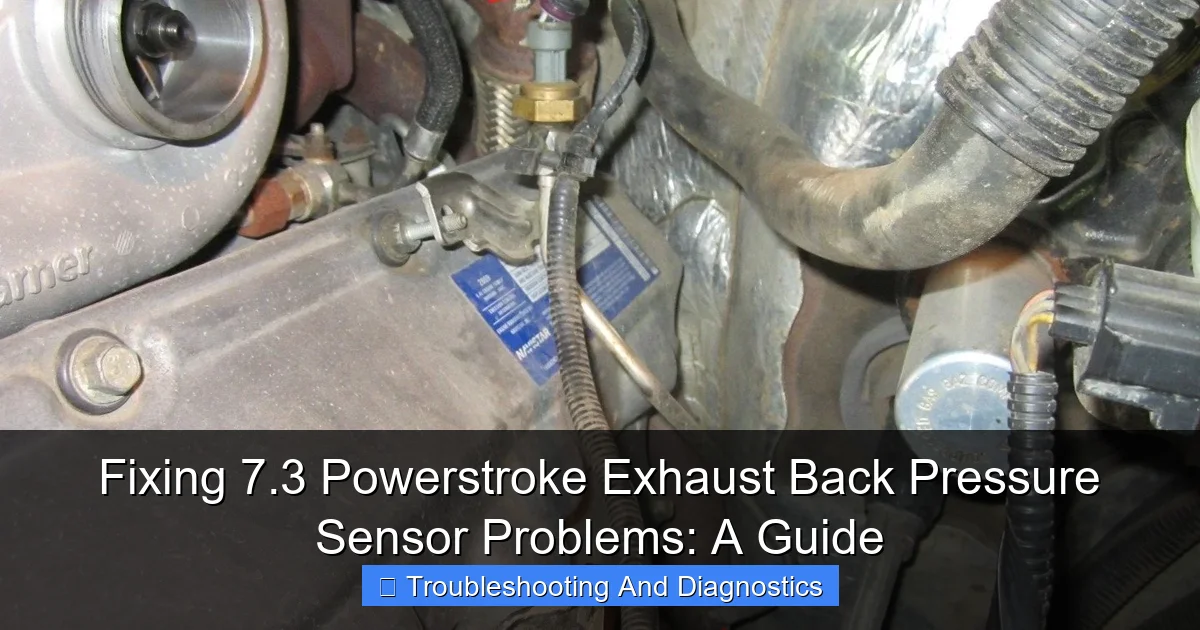

Learn more about Fixing 7.3 Powerstroke exhaust back pressure sensor problems – Fixing 7.3 Powerstroke Exhaust Back Pressure Sensor Problems: A Guide

Image source: i.ytimg.com

What is the EBP Sensor?

The EBP sensor is typically located on the passenger side of the engine, mounted to the exhaust manifold or an exhaust tube that taps into the manifold. It’s connected to the exhaust stream via a small steel tube, often referred to as the EBP tube or exhaust sensor tube. Its primary function is to measure the pressure of the exhaust gases exiting the engine. This pressure reading is then sent as an electrical signal to the Powertrain Control Module (PCM).

| Symptom / DTC | Diagnostic Steps | Common Solution(s) |

|---|---|---|

| Check Engine Light (CEL) with DTCs P0470, P0472, P0473 | Scan for specific EBP sensor codes. Inspect wiring harness for damage/corrosion. Monitor EBP sensor voltage (Key On Engine Off – KOEO should be ~0.8-1.0V). Visually inspect EBP tube for clogs or damage. | Clean or replace the EBP sensor tube. Repair/replace damaged wiring. Replace the EBP sensor itself. |

| No DTCs, but poor cold starts, excessive smoke (especially cold), turbo lag, poor fuel economy, rough idle | Monitor EBP and MAP sensor PIDs with a scanner. At KOEO, EBP and MAP readings should be within 0.5 PSI of each other (ambient pressure). At idle, EBP should rise slowly. Check for inconsistent or erratic EBP readings under various load conditions. | Remove and thoroughly clean the EBP sensor tube and sensor port. Replace the EBP sensor if its readings are still inconsistent or deviate significantly from MAP at KOEO. |

| Consistently high EBP readings (e.g., >1 PSI at KOEO) or EBP reads significantly higher than MAP | Disconnect the EBP tube from the sensor and try to blow air through it – it should be clear. Visually inspect the tube for heavy carbon buildup or internal obstructions. Re-check EBP vs. MAP at KOEO after disconnecting the tube from the sensor. | The EBP sensor tube is likely clogged. Remove and clean the tube using a wire, drill bit, or carb cleaner. Ensure both ends are clear before reinstalling. |

| Visible soot, oil, or exhaust residue around the EBP sensor or tube connections | Perform a detailed visual inspection of the EBP sensor’s threads, the tube’s connections to the manifold and sensor, and the tube itself for cracks or leaks. Listen for exhaust leaks. | Tighten connections. Replace any damaged or cracked EBP tubes. Clean and re-seal threaded connections (e.g., with high-temp thread sealant). Replace the EBP sensor if its housing is cracked or leaking. |

Why is Exhaust Back Pressure Important?

Exhaust back pressure isn’t just a byproduct of the combustion process; it’s a critical factor in how your 7.3 Powerstroke operates. The PCM uses the EBP sensor data for several key functions:

- Turbocharger Control: The EBP sensor provides crucial information for controlling the turbocharger’s wastegate (though the 7.3 Powerstroke uses an exhaust back pressure valve for warm-up and engine braking, it still relies on EBP data). Proper back pressure ensures the turbo spools efficiently, delivering boost when needed and preventing over-boosting.

- Exhaust Back Pressure Valve (EBPV) Operation: On the 7.3 Powerstroke, the EBPV (a butterfly valve in the exhaust) closes to increase exhaust back pressure during cold starts to help the engine warm up faster, reducing white smoke and improving driveability. It also acts as an exhaust brake in some applications. The EBP sensor’s readings tell the PCM when and how much to close this valve.

- Fuel Efficiency and Emissions: By optimizing turbocharger and EBPV operation, the PCM can ensure more efficient combustion, leading to better fuel economy and reduced harmful emissions.

- Engine Performance: Incorrect EBP readings can lead to inaccurate fuel delivery, timing issues, and turbocharger mismanagement, resulting in a noticeable drop in engine performance.

How the EBP Sensor Works with the PCM

The 7.3 Powerstroke EBP sensor is a variable resistor sensor. As exhaust pressure changes, its internal resistance changes, altering the voltage signal sent to the PCM. The PCM interprets this voltage as a specific pressure value. For example, at idle, a healthy EBP sensor might read around 14.7 PSI (atmospheric pressure), while under heavy acceleration, it could climb significantly. The PCM then uses this information, alongside data from other sensors like the MAP (Manifold Absolute Pressure) sensor, to make crucial adjustments to fuel delivery, injection timing, and exhaust management.

Common Symptoms of a Failing 7.3 Powerstroke EBP Sensor

Recognizing the symptoms of a failing EBP sensor is the first step toward fixing 7.3 Powerstroke exhaust back pressure sensor problems. A faulty sensor can manifest in various ways, often mimicking other engine issues. Knowing what to look for can save you time and money on misdiagnosis.

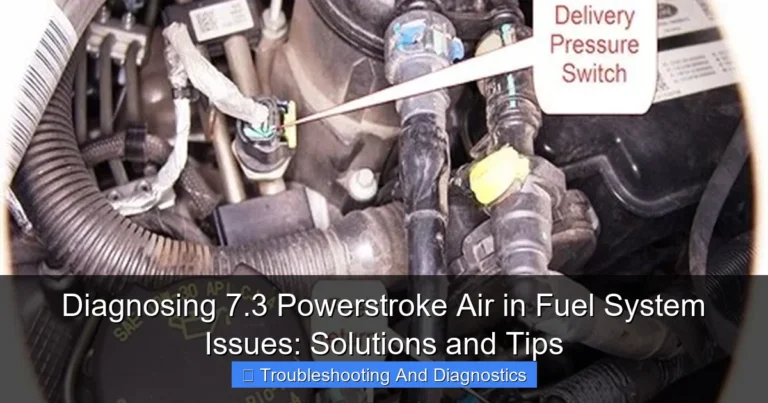

Learn more about Fixing 7.3 Powerstroke exhaust back pressure sensor problems – Fixing 7.3 Powerstroke Exhaust Back Pressure Sensor Problems: A Guide

Image source: powerstroke.org

Performance-Related Symptoms

- Loss of Power and Poor Acceleration: This is one of the most common complaints. If the EBP sensor reports incorrect pressure, the PCM might limit fuel or boost, causing the engine to feel sluggish and unresponsive.

- Reduced Turbocharger Performance / Turbo Lag: An inaccurate EBP signal can prevent the turbo from spooling up correctly or cause the EBPV to operate improperly, leading to noticeable delays in power delivery. Your truck might feel like it’s struggling to get going.

- Rough Idle: While not always directly linked, a faulty EBP sensor can sometimes contribute to an unstable or rough idle, especially during cold starts if the EBPV isn’t working as intended.

- Hesitation or Stumbling: Under certain loads or RPMs, the engine might hesitate or stumble as the PCM struggles to compensate for bad EBP data.

Fuel Economy and Emissions Issues

- Decreased Fuel Economy (MPG): When the engine isn’t running optimally due to incorrect EBP data, it often burns more fuel to achieve the desired power, leading to a noticeable drop in miles per gallon. Many owners report a significant dip, sometimes as much as 1-3 MPG.

- Excessive Black or White Smoke:

- Black Smoke: Often indicates incomplete combustion due to rich fuel conditions or insufficient air, which can be triggered by incorrect EBP readings messing with fuel trim.

- White Smoke: Especially on cold starts, excessive white smoke can point to the EBPV not closing properly, preventing the engine from warming up efficiently.

Diagnostic Trouble Codes (DTCs)

One of the most definitive signs of a 7.3 Powerstroke EBP sensor problem is the illumination of your Check Engine Light (CEL) and the storage of specific Diagnostic Trouble Codes (DTCs). Using an OBD-II scanner is crucial here. Common EBP-related codes include:

- P0470: Exhaust Pressure Sensor A Circuit Malfunction

- P0471: Exhaust Pressure Sensor A Range/Performance Problem

- P0472: Exhaust Pressure Sensor A Low Input

- P0473: Exhaust Pressure Sensor A High Input

- P0476: Exhaust Pressure Control Valve Range/Performance

- P0478: Exhaust Pressure Control Valve High

Note that while P0476 and P0478 specifically mention the control valve, the EBP sensor’s readings are fundamental to the valve’s operation, so these codes can also point to a sensor issue.

Other Indirect Indicators

- Hard Starts (especially cold): If the EBPV isn’t functioning due to a faulty sensor, your 7.3 Powerstroke may take longer to start and run rough until it warms up.

- Unusual Engine Noises: In some cases, a malfunctioning EBPV (which relies on EBP data) could lead to strange noises from the exhaust system or turbocharger area.

Diagnosing 7.3 Powerstroke EBP Sensor Problems: Step-by-Step

Accurate diagnosis is key to fixing 7.3 Powerstroke exhaust back pressure sensor problems without unnecessary part replacement. This section will guide you through a systematic approach to pinpoint the exact issue.

Visual Inspection

Start with the simplest steps first. A thorough visual inspection can reveal obvious problems.

- Locate the Sensor and Tube: Identify the EBP sensor (usually on the passenger side exhaust manifold) and the steel tube running from it to the manifold.

- Check Wiring and Connector: Look for any frayed, cut, or damaged wires leading to the EBP sensor connector. Ensure the connector is firmly seated and free from corrosion. A common issue is oil saturation of the connector due to leaks elsewhere.

- Inspect the EBP Tube: This is a critical step. The steel tube is prone to clogging with carbon and soot buildup. Look for any visible kinks, cracks, or signs of severe corrosion. Many problems stem from a blocked tube, not a faulty sensor.

- Examine the Sensor Itself: While less common for the sensor body to be visibly damaged, check for any physical damage or excessive oil/soot buildup on the sensor housing.

Using an OBD-II Scanner for Live Data

A good OBD-II scanner capable of displaying live data is your best friend when diagnosing EBP sensor problems. This allows you to see what the PCM “sees.”

- Monitor EBP Readings at Key On Engine Off (KOEO): With the key on but the engine off, the EBP sensor should read approximately atmospheric pressure (around 14.7 PSI or 101 kPa at sea level). Significant deviation (e.g., 0 PSI or 50 PSI) indicates a faulty sensor or an open/short circuit.

- Monitor EBP Readings at Idle: Start the engine and let it idle. A healthy EBP sensor should read close to atmospheric pressure at idle, perhaps slightly above (e.g., 15-18 PSI). If it reads very high or very low, it’s a red flag.

- Monitor EBP Readings Under Load (Driving): Safely drive the truck and observe EBP readings under various loads and RPMs. The pressure should increase significantly with acceleration and boost. Compare EBP readings with MAP (Manifold Absolute Pressure) readings; they should track together, with EBP typically being higher than MAP under load. If EBP readings are stuck, erratic, or don’t correlate with engine load, it indicates an issue.

- Check EBPV Operation: If your scanner allows, command the EBPV to open and close. Observe the EBP readings. When closed, pressure should increase notably, especially during cold starts.

Pro Tip: Many faulty 7.3 Powerstroke EBP sensors will read very high (e.g., 40+ PSI) even at KOEO or idle, fooling the PCM into thinking there’s excessive back pressure, which then limits performance.

Multimeter Testing (for electrical checks)

If live data is erratic or missing, you might need to test the sensor’s electrical circuit. You’ll typically find three wires: a 5-volt reference, a signal return (ground), and the sensor signal wire.

- Verify 5-Volt Reference: With the key on, disconnect the EBP sensor connector. Use a multimeter to check for 5 volts at the reference wire pin.

- Verify Ground: Check for continuity or near-zero resistance between the ground pin and chassis ground.

- Test Sensor Resistance (if applicable): Some sensors can be tested for resistance, but measuring voltage output is usually more practical. With the sensor connected and the engine running, backprobe the signal wire and observe the voltage. It should typically be around 0.5V at KOEO/idle and increase with engine speed/load (up to around 4.5V).

Physical Testing: The EBP Tube

A clogged EBP tube is arguably the most frequent cause of 7.3 Powerstroke EBP sensor problems. The sensor itself might be perfectly fine, but it’s receiving false readings because the tube is blocked.

- Remove the Sensor: Unscrew the EBP sensor from its mounting bracket and disconnect it from the EBP tube.

- Inspect and Clear the Tube: Look into the tube. It’s often completely caked with carbon. You can use a wire brush (like a gun cleaning brush), a drill bit (smaller than the tube diameter), or compressed air to clear it out. Be careful not to force debris into the exhaust manifold.

- Confirm Clearance: Ensure you can see daylight through the entire length of the tube once cleaned. This is crucial.

The “Cold Start” Test

For trucks with an operational EBPV, observe its behavior on a cold start (below 40°F/5°C). The EBPV should close, increasing exhaust back pressure to help warm the engine. If it doesn’t close, or opens too quickly, and the EBP sensor readings don’t reflect an increase in pressure, it points to either a faulty sensor, a clogged tube, or a malfunctioning EBPV solenoid/actuator (which is still influenced by EBP data).

Common Causes of 7.3 Powerstroke EBP Sensor Failure

Understanding why EBP sensor problems occur can help in both diagnosis and prevention. While the sensor itself can fail, it’s often external factors that lead to its demise or incorrect readings.

Soot and Carbon Buildup: The Primary Culprit

This is by far the most common reason for 7.3 Powerstroke EBP sensor problems. The exhaust gases contain soot, especially in diesel engines. Over time, this soot, combined with condensation and oil vapors, accumulates and hardens, not just on the sensor’s tip but, more critically, inside the EBP tube. A completely blocked tube will cause the sensor to read atmospheric pressure (if the blockage is near the manifold) or an artificially high/low pressure, leading the PCM to make incorrect decisions.

Electrical Issues

- Corrosion: The EBP sensor is exposed to the elements and engine heat. The electrical connector pins can corrode over time, leading to poor signal transmission or an open circuit.

- Frayed or Damaged Wires: Vibration, heat, and rubbing against other components can cause the wiring harness leading to the sensor to fray, short circuit, or break.

- Faulty Connector: The plastic connector itself can become brittle, crack, or have internal pin damage, preventing a secure connection.

Sensor Malfunction

While often a secondary cause, the sensor itself can simply fail internally due to age, extreme heat cycling, or manufacturing defects. The internal electronics or diaphragm can degrade, leading to inaccurate readings or a complete lack of signal. This is less common than a clogged tube but certainly happens.

Damaged EBP Tube

Beyond clogging, the steel EBP tube can suffer physical damage. Kinks, dents, or cracks can disrupt the pressure reading, or a complete break can vent exhaust gases before they reach the sensor, causing it to read atmospheric pressure when it shouldn’t. Exhaust heat can also lead to fatigue and cracking over time.

Fixing 7.3 Powerstroke Exhaust Back Pressure Sensor Problems

Now that you’ve diagnosed the issue, it’s time to get your hands dirty and start fixing 7.3 Powerstroke exhaust back pressure sensor problems. Depending on your diagnosis, the fix might be simple cleaning or a full replacement.

Cleaning the EBP Sensor and Tube

This is the most common and often successful fix, especially if the sensor itself isn’t completely dead.

- Remove the Sensor: Disconnect the electrical connector and carefully unscrew the EBP sensor from its mounting bracket. Be gentle, as old sensors can be brittle.

- Remove the EBP Tube: Disconnect the EBP tube from both the sensor and the exhaust manifold. This usually involves a few bolts or a flare nut fitting.

- Clean the Tube:

- Use a stiff wire brush (like a gun cleaning brush for 9mm or .45 cal) or a drill bit slightly smaller than the tube’s internal diameter to scrape out carbon buildup.

- Blast compressed air through the tube from both ends to dislodge stubborn deposits.

- You can also soak the tube in carburetor cleaner, brake cleaner, or diesel fuel overnight to help soften carbon, then scrub and air blast.

- Crucially, ensure you can see clear daylight through the entire length of the tube when finished.

- Clean the Sensor Tip: Gently clean the tip of the EBP sensor with carburetor cleaner or a soft brush. Avoid using anything abrasive that could damage the sensor diaphragm.

- Reassemble: Reinstall the cleaned tube, ensuring a tight seal, and then screw the sensor back in. Reconnect the electrical connector.

Replacing the EBP Sensor

If cleaning doesn’t resolve the issue, or if multimeter/live data tests clearly indicate a faulty sensor, replacement is the next step.

- Purchase a New Sensor: It’s highly recommended to use an OEM (Original Equipment Manufacturer) Ford sensor or a high-quality aftermarket equivalent from a reputable brand. Cheaper sensors often fail quickly or provide inaccurate readings.

- Remove the Old Sensor: Disconnect the electrical connector and unscrew the old sensor.

- Clean the EBP Tube (Again!): Even if you’re replacing the sensor, it’s vital to ensure the EBP tube is perfectly clean. A new sensor will quickly become clogged if the tube is blocked.

- Install the New Sensor: Screw the new sensor into place, reconnect the electrical connector. Some new sensors may come with anti-seize applied; if not, a small amount on the threads can help for future removal.

- Clear Codes: Use your OBD-II scanner to clear any stored DTCs.

Addressing Wiring and Connector Issues

If your diagnosis pointed to electrical problems, you’ll need to repair or replace the wiring/connector.

- Repair Frayed Wires: Use solder and heat shrink tubing for a durable repair. Avoid simple crimp connectors in engine bay environments.

- Replace Damaged Connectors: If the connector is cracked, brittle, or has corroded pins, purchase a replacement pigtail harness and splice it in. Again, solder and heat shrink are recommended.

- Dielectric Grease: After ensuring good connections, apply dielectric grease to the pins of the connector before reassembly. This helps prevent future corrosion.

Replacing the EBP Tube

If the EBP tube is severely kinked, cracked, or rusted beyond repair/cleaning, it must be replaced. New tubes are readily available from Ford or aftermarket suppliers. Ensure you get the correct length and bend for your specific year 7.3 Powerstroke.

Post-Repair Testing and Verification

After any repair, it’s crucial to verify that the fix was successful.

- Clear DTCs: Use your scanner to clear all stored codes.

- Test Drive: Take your truck for a drive, including varying speeds and loads. Observe for changes in performance, turbo lag, and any lingering symptoms.

- Monitor Live Data: Re-check EBP sensor live data with your OBD-II scanner. Ensure readings are consistent with atmospheric pressure at KOEO, slightly above at idle, and increase appropriately under load.

- Cold Start Check: If applicable, perform a cold start to ensure the EBPV operates correctly and helps with engine warm-up.

Typical 7.3 Powerstroke EBP Sensor Readings

Understanding what “normal” looks like is crucial for diagnosis. Here’s a general guide:

| Condition | Expected EBP Reading (PSI at Sea Level) | Expected EBP Reading (kPa at Sea Level) | Diagnostic Implication if Deviated |

|---|---|---|---|

| Key On Engine Off (KOEO) | ~14.7 PSI | ~101 kPa |

Significantly Low: Open circuit, faulty sensor (reading 0 PSI). |

| Engine Idling (Warm) | 15-18 PSI | 103-124 kPa |

Low: Leaking exhaust, faulty sensor, clogged tube (near manifold). |

| Heavy Acceleration (WOT) | 25-50+ PSI | 172-345+ kPa |

Low: Exhaust leak, turbo issues, faulty sensor, clogged tube (unable to read high pressure). |

| EBPV Closed (Cold Start) | 25-40+ PSI | 172-276+ kPa |

Low: EBPV not closing, exhaust leak, faulty sensor, clogged tube. |

Preventing Future EBP Sensor Issues

Once you’ve successfully addressed your 7.3 Powerstroke EBP sensor problems, proactive measures can help prevent a recurrence and keep your legendary engine running strong for years to come.

Regular Maintenance is Key

- Engine Oil Changes: Ensure you use the correct oil (e.g., CI-4 rated oil for older diesels) and change it at recommended intervals. Clean oil reduces soot formation and keeps exhaust gas recirculation (EGR, though minimal on early 7.3s, still affects exhaust) cleaner.

- Fuel Filters: Replace fuel filters regularly. Clean fuel ensures efficient combustion, which minimizes soot output.

- Air Filter: A clean air filter ensures the engine gets enough clean air for complete combustion, again reducing soot.

Periodic Inspection and Cleaning

Consider making the EBP sensor and tube a regular part of your maintenance routine. Many experienced 7.3 Powerstroke owners recommend removing and cleaning the EBP tube every 50,000 to 100,000 miles, or even sooner if you experience performance issues or drive in conditions that promote carbon buildup (e.g., lots of idling, short trips).

- Schedule Checks: Incorporate EBP sensor and tube inspection into your annual service or major maintenance intervals.

- Visual Scan: Quick visual checks of the sensor, wiring, and tube for damage or obvious leaks can catch problems early.

Driving Habits

How you drive your 7.3 Powerstroke can also impact EBP sensor longevity.

- Avoid Excessive Idling: Prolonged idling in diesel engines can lead to increased soot production and lower exhaust gas temperatures, making carbon buildup more likely.

- Proper Warm-Up and Cool-Down: Allow your engine to reach operating temperature before putting it under heavy load. Similarly, let the turbo cool down after heavy use before shutting off the engine.

- “Italian Tune-Up”: Occasionally, driving your truck under load at highway speeds can help burn off some carbon deposits in the exhaust system.

Quality Parts for Replacements

When it comes time to replace the EBP sensor or other related components, invest in quality parts. As mentioned earlier, OEM Ford sensors or reputable aftermarket brands are generally worth the extra cost. They are designed to withstand the harsh environment of the engine bay and provide accurate, reliable readings for longer.

Conclusion

The 7.3 Powerstroke exhaust back pressure sensor might be a small component, but its impact on your engine’s performance, fuel economy, and overall health is undeniable. From frustrating turbo lag and reduced power to mysterious check engine lights, a malfunctioning EBP sensor can significantly detract from the legendary reliability of your 7.3 Powerstroke.

By understanding its function, recognizing the common symptoms, and following our comprehensive diagnostic and repair steps, you’re now well-equipped to tackle any 7.3 Powerstroke EBP sensor problems that come your way. Remember, many issues can be resolved with a thorough cleaning of the EBP tube, a simple and cost-effective solution. If replacement is needed, opting for quality parts and proper installation will ensure long-lasting performance.

Don’t let a small sensor steal your 7.3 Powerstroke‘s thunder. With this guide, you have the knowledge to diagnose, fix, and prevent future issues, keeping your beloved diesel roaring down the road with the power and efficiency it was designed for. Happy wrenching!

🎥 Related Video: 7.3L Powerstroke Exhaust Back Pressure Valve Repair

📺 CNC Fabrication

This is a DIY explanation on how to remove the butterfly valve inside the turbo outlet flange to turn it into a high flow outlet for your …

Frequently Asked Questions

What are the common symptoms of a failing 7.3 Powerstroke exhaust back pressure sensor?

A failing EBP sensor can cause a range of issues including poor fuel economy, reduced power, rough idle, and excessive black smoke. You might also notice the “Check Engine” light illuminated on your dashboard, often accompanied by specific diagnostic trouble codes related to the sensor.

Where is the 7.3 Powerstroke exhaust back pressure sensor located on the engine?

The EBP sensor is typically found at the front of the 7.3 Powerstroke engine, usually on the passenger side, mounted into the exhaust manifold or a short steel tube leading from it. It’s identifiable by an electrical connector and the steel tube that routes exhaust pressure to the sensor.

How can I test my 7.3 Powerstroke EBP sensor to confirm it’s faulty?

You can test the sensor by monitoring its live voltage output with a multimeter or a diagnostic scan tool. Look for erratic readings or a reading that doesn’t change appropriately with engine RPM, or compare its voltage to a known good sensor’s readings under similar conditions.

Can a clogged EBP tube cause problems that mimic a bad 7.3 Powerstroke exhaust back pressure sensor?

Yes, absolutely. A clogged EBP tube is a very common issue and prevents the sensor from accurately reading exhaust back pressure, leading to symptoms identical to a faulty sensor. Always check and clean the EBP tube when diagnosing back pressure sensor problems.

Is replacing the 7.3 Powerstroke exhaust back pressure sensor a difficult DIY job?

For most DIY enthusiasts, replacing the 7.3 Powerstroke EBP sensor is a relatively straightforward task. It typically involves removing one or two bolts, disconnecting an electrical connector, and detaching the pressure tube. However, seized bolts or a stubborn tube can sometimes make the process more challenging.

What is the best method for cleaning a clogged 7.3 Powerstroke EBP tube?

The most effective method involves removing the EBP tube from the engine and using a small wire brush, pipe cleaner, or compressed air to clear carbon buildup. Soaking the tube in a carbon-dissolving cleaner or penetrating oil can also help loosen stubborn deposits before mechanical cleaning.