Essential Tools for 7.3 Powerstroke Engine Repair: Must-Have Gear

Featured image for this comprehensive guide about Essential tools for 7.3 Powerstroke engine repair

Image source: i.pinimg.com

The Ford 7.3 Powerstroke diesel engine isn’t just an engine; it’s a legend. Revered for its robust design, incredible durability, and legendary longevity, this powerhouse has earned a special place in the hearts of truck enthusiasts and heavy-duty workers alike. From its production years between 1994 and 2003, it powered countless F-Series trucks and E-Series vans, becoming a benchmark for reliability in the diesel world. Many of these beasts are still on the road today, racking up hundreds of thousands of miles, a testament to their engineering.

However, even legends need maintenance and occasional repair. Whether you’re a seasoned diesel mechanic or a passionate DIYer looking to keep your beloved 7.3 Powerstroke running strong, having the right set of tools is not just helpful—it’s absolutely essential. Attempting complex repairs without the proper gear can lead to frustration, damage, and ultimately, more costly fixes. This comprehensive guide will walk you through the essential tools for 7.3 Powerstroke engine repair, ensuring you’re well-equipped for any challenge that comes your way.

We’ll cover everything from fundamental diagnostic equipment to highly specialized tools designed specifically for the 7.3 Powerstroke‘s unique components. Our goal is to provide you with actionable insights, professional tips, and a clear understanding of what you need to tackle common and complex repairs confidently. Get ready to equip your garage with the must-have gear that will make working on your 7.3 Powerstroke a more efficient, effective, and ultimately rewarding experience.

Quick Answers to Common Questions

What’s the very first thing I should grab for my 7.3 Powerstroke toolkit?

Start with a good quality socket and wrench set (both metric and SAE) and a trusty torque wrench. These are truly **essential tools for 7.3 Powerstroke engine repair** to handle most common tasks with precision.

Are there any specific Ford or diesel tools I absolutely must have for my 7.3 Powerstroke?

Absolutely! A fuel line disconnect tool is a lifesaver for tackling common fuel leaks. Also, a reliable diagnostic scanner that can read Powerstroke-specific codes is an **essential tool for 7.3 Powerstroke engine repair** to pinpoint problems quickly.

Do I really need a specialized tool for injectors, or can I get by without it?

While some basic maintenance can be done without it, if you plan on replacing injectors, a specialized injector removal and installation tool becomes an **essential tool for 7.3 Powerstroke engine repair**. It prevents damage and makes the job much smoother.

What about simple fluid changes – what essential tools will I need for those on my 7.3 Powerstroke?

For routine fluid changes, you’ll definitely want a sturdy oil filter wrench, a drain pan, and a funnel. These basic but **essential tools for 7.3 Powerstroke engine repair** make servicing your truck clean and straightforward.

What’s one often overlooked but essential tool for 7.3 Powerstroke engine repair that I might not think of?

A good quality test light or multimeter is often overlooked but invaluable for troubleshooting electrical issues. Don’t underestimate its importance among the **essential tools for 7.3 Powerstroke engine repair** when diagnosing sensor failures or wiring problems.

📋 Table of Contents

- Diagnostic and General Hand Tools: The Foundation of Any Repair

- Specialized Fuel and Oil System Tools: The Heart of the Powerstroke

- Engine Component and Turbocharger Tools: Power and Airflow

- Electrical and Sensor Tools: Navigating the Wiring Maze

- Fluid Management and Sealing Tools: Preventing Leaks and Ensuring Longevity

- Heavy-Duty and Specialized Lifting Equipment: The Big Jobs

- Key Tool Checklist and Common Repair Match-up

- Conclusion: Empowering Your 7.3 Powerstroke Journey

Diagnostic and General Hand Tools: The Foundation of Any Repair

Before you even think about turning a wrench, understanding what’s going on with your 7.3 Powerstroke is paramount. Diagnostic tools are your eyes and ears into the engine’s complex systems. Coupled with a solid set of general hand tools, these form the bedrock of any successful repair operation. Skipping proper diagnostics often leads to guesswork, wasted time, and unnecessary parts replacement. Remember, the 7.3 Powerstroke, while analog in many ways compared to modern diesels, still relies on a sophisticated electronic control system (PCM) that communicates with various sensors.

Learn more about Essential tools for 7.3 Powerstroke engine repair – Essential Tools for 7.3 Powerstroke Engine Repair: Must-Have Gear

Image source: storage.monocil.jp

Essential Diagnostic Equipment

- OBD-II Scanner with Enhanced Ford Diesel Capabilities: A generic OBD-II scanner can read basic trouble codes, but to truly diagnose a 7.3 Powerstroke, you need a scanner that can access proprietary Ford data streams. Look for tools like AutoEnginuity (with the Ford bundle), Forscan (with an ELM327 adapter), or dedicated diesel scan tools. These allow you to monitor critical parameters like Injector Pressure Regulator (IPR) duty cycle, Injector Control Pressure (ICP), Exhaust Back Pressure (EBP), and more, providing invaluable insights into engine performance and potential faults.

- Digital Multimeter (DMM): An indispensable tool for electrical diagnostics. You’ll use it to check voltages, continuity, resistance, and amperage. Issues like bad sensors, faulty wiring, or problematic relays are common on any older vehicle, and a good DMM is crucial for pinpointing them. For example, testing glow plug resistance or voltage at the Injector Driver Module (IDM) relies heavily on a reliable multimeter.

- Fuel Pressure Gauge Kit: The 7.3 Powerstroke relies on specific fuel pressure to operate correctly. Insufficient fuel pressure can lead to injector issues, hard starts, and a loss of power. A gauge allows you to monitor the fuel pressure directly at the filter housing, helping diagnose common problems like a failing fuel pump or clogged fuel filter. Maintaining optimal fuel pressure (typically 45-70 PSI) is vital for injector longevity.

- Oil Pressure Gauge: While you have a dash gauge, a separate mechanical or digital oil pressure gauge provides a more accurate reading. This is crucial for diagnosing High-Pressure Oil Pump (HPOP) issues or other lubrication system concerns.

- Compression Tester Kit (Diesel Specific): For more serious engine performance issues, a compression test can reveal problems with piston rings, valves, or head gaskets. Diesel compression testers are designed for the much higher compression ratios of diesel engines.

Fundamental General Hand Tools

You’ll need a comprehensive set of standard tools, built to handle the heavy-duty nature of a diesel engine.

| Tool Name | Primary Use for 7.3L Powerstroke | Estimated Cost Range (USD) | Why It’s Essential |

|---|---|---|---|

| Injector Sleeve/Cup Tool Kit | Replacing injector O-rings and copper washers to prevent fuel/coolant leaks. | $150 – $400 | Specialized tool crucial for common 7.3L leaks, ensures proper sealing. |

| High-Pressure Oil Pump (HPOP) Cover Socket | Removing and installing the HPOP reservoir cover for maintenance or replacement. | $30 – $80 | Simplifies access to HPOP, preventing damage from improper tools. |

| Diesel Fuel Pressure Gauge Kit | Diagnosing fuel delivery issues, hard starts, and low power conditions. | $50 – $150 | Critical for troubleshooting fuel system problems; prevents misdiagnosis. |

| Ford-Specific OBD-II Scan Tool (Enhanced Data) | Reading specific Ford codes, live data (ICP, IPR, EBP), and injector buzz test. | $150 – $500+ | Unlocks crucial diagnostic information unique to the 7.3L for accurate troubleshooting. |

| Heavy-Duty Diesel Compression Tester | Identifying cylinder issues, worn rings, or valve problems, crucial for engine health. | $100 – $300 | Essential for diagnosing internal engine wear; helps avoid costly repairs if caught early. |

- Wrench and Socket Sets (Metric & SAE): Both metric and SAE sizes are present on the 7.3 Powerstroke. Ensure you have deep and shallow sockets, extensions, and universal joints. Impact-rated sockets are highly recommended for stubborn bolts.

- Torque Wrenches (1/2″ and 3/8″ Drive): Proper torque is critical for virtually every component on a 7.3 Powerstroke engine, from valve covers to cylinder head bolts. Having at least a 1/2″ drive (for higher torque specs) and a 3/8″ drive (for smaller fasteners) is non-negotiable for preventing leaks and component failure.

- Screwdriver Sets: Phillips, flathead, and Torx bits will be frequently used for various fastenings and cover removals.

- Pliers and Cutters: Various types, including needle-nose, locking, and wire cutters, are essential for working with lines, hoses, and electrical components.

- Pry Bars and Picks: Useful for separating components, removing O-rings, and general leverage.

- Rubber Mallet and Hammer: For gentle persuasion or more forceful removal when necessary.

- Shop Rags and Parts Cleaner: Keeping your workspace and components clean is crucial for preventing contamination and ensuring proper reassembly.

Specialized Fuel and Oil System Tools: The Heart of the Powerstroke

The 7.3 Powerstroke utilizes a unique HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) fuel system, meaning engine oil is used at high pressure to actuate the fuel injectors. This design requires specific tools for proper diagnosis and repair of its intricate components, from the High-Pressure Oil Pump (HPOP) to the injectors themselves. These are the tools that truly differentiate a general mechanic from a Powerstroke specialist.

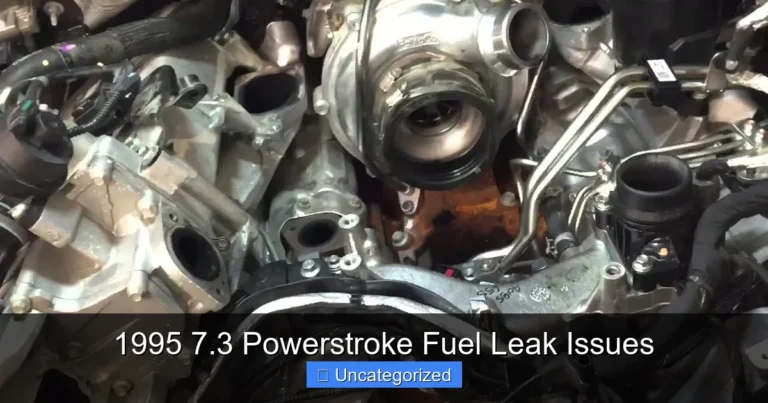

Learn more about Essential tools for 7.3 Powerstroke engine repair – Essential Tools for 7.3 Powerstroke Engine Repair: Must-Have Gear

Image source: i.ytimg.com

High-Pressure Oil System Tools

The HPOP is critical for injector operation. Issues with it or its related components are common and require precise tools.

- HPOP Reseal Kit Tool: If your HPOP is leaking, a reseal kit is often the solution. This tool helps safely remove and reinstall the reservoir and gear.

- HPOP Disassembly/Assembly Tool (if rebuilding): For those tackling a full HPOP rebuild, specialized jigs and presses might be needed to handle the internal components.

- IPR (Injector Pressure Regulator) Socket: The IPR valve is a common failure point, regulating the oil pressure sent to the injectors. This specialized socket is deep and often has a unique design to access the valve located deep within the engine valley.

- ICP (Injector Control Pressure) Sensor Wrench: Similar to the IPR, the ICP sensor monitors oil pressure and is critical for engine operation. A specific offset wrench or socket may be needed for removal and installation due to its location.

- High-Pressure Oil Line Disconnect Tool: These lines connect the HPOP to the cylinder heads. They are under immense pressure and require a specific tool for safe disconnection without damaging the fittings.

Fuel Injector and Glow Plug Tools

Injectors and glow plugs are central to the 7.3 Powerstroke‘s performance. When they act up, you’ll need specialized tools.

- 7.3 Powerstroke Injector Removal Tool: Injectors can be stubborn and difficult to remove. This slide hammer-style tool attaches to the injector and provides the leverage needed to pull it out without damaging the cylinder head. Trying to pry them out with screwdrivers is a recipe for disaster.

- Injector O-Ring Kit and Installation Tool: When replacing or resealing injectors, new O-rings are essential for preventing oil and fuel leaks. Some kits come with specialized tools to help slide the new O-rings onto the injector body without tearing them.

- Valve Cover Gasket with Integral Harness Tool: The 7.3 Powerstroke‘s valve cover gaskets contain the wiring harnesses for the injectors and glow plugs. When replacing these, you’ll need to carefully disconnect and reconnect them. A specific set of picks or small, angled wrenches can help maneuver the internal harness clips.

- Glow Plug Wrench/Socket: Glow plugs are recessed into the cylinder heads and can be fragile. A specific thin-wall, deep socket (often 10mm or 12mm depending on the year) is needed to avoid stripping or breaking them. Anti-seize compound is your friend during reinstallation.

- Glow Plug Removal Tool (if seized): If a glow plug is seized or broken, a specialized extraction kit may be required to remove the remaining portion without damaging the cylinder head threads. This can save you from a costly head removal.

Engine Component and Turbocharger Tools: Power and Airflow

The 7.3 Powerstroke is renowned for its straightforward design, but specific components like the turbocharger, exhaust manifolds, and various sensors still require specialized attention. From ensuring proper airflow to maintaining exhaust integrity, these tools are crucial for keeping your diesel performing optimally, whether it’s for towing heavy loads or simply daily driving. The turbocharger, in particular, is a source of immense power and requires careful handling.

Turbocharger System Tools

- Turbocharger Mounting Gasket Kit: When removing and reinstalling the turbo, having a new gasket kit (including pedestal O-rings, up-pipe gaskets, and downpipe gasket) is critical for preventing boost leaks and exhaust leaks.

- Specialized EBPV (Exhaust Back Pressure Valve) Disassembly Tool: The EBPV, located within the turbo housing, can become clogged or fail. While many opt for removal, if you plan to service it, specific wrenches or removal tools might be needed.

- Large Breaker Bars and Extensions: Turbo mounting bolts and exhaust manifold bolts can be incredibly stubborn, especially after years of heat cycling. A long breaker bar provides the leverage needed to loosen them safely.

- Oxygen Sensor/EGT Sensor Socket: While the 7.3 Powerstroke doesn’t have an oxygen sensor in the traditional sense, Exhaust Gas Temperature (EGT) sensors are common aftermarket additions. A specialized sensor socket prevents damage to the sensor or wiring during removal/installation.

General Engine Component Tools

- Valve Cover Bolt Sockets: These can be tricky due to the integrated wiring harness. A swivel socket or specific deep, thin-walled socket can make access easier.

- Serpentine Belt Tensioner Tool: Changing the serpentine belt is a routine maintenance item. A specialized tool or a long wrench designed for the tensioner allows for safe and easy belt removal and installation.

- Fan Clutch Wrench Set: The fan clutch can be a beast to remove. A specific set of large, thin wrenches (often 36mm or 47mm depending on the year) along with a holding tool for the water pump pulley makes this job manageable.

- Oil Cooler Removal/Installation Kit: The 7.3 Powerstroke oil cooler is prone to leaks. Specialized seals and a specific tool for removal and installation are necessary to prevent damage and ensure a leak-free seal.

- Harmonic Balancer Puller: If you ever need to access the front cover or timing components, removing the harmonic balancer is necessary. A robust puller designed for heavy-duty applications is essential.

Electrical and Sensor Tools: Navigating the Wiring Maze

Despite its older design, the 7.3 Powerstroke relies on a sophisticated network of sensors and electrical connections to run efficiently. From diagnosing rough idle to pinpointing starting issues, having the right electrical tools is crucial. These tools go beyond a simple multimeter, allowing you to trace circuits, test components, and ensure robust connections.

Advanced Electrical Testing Tools

- Test Light/Power Probe: A simple test light can quickly verify if a circuit has power or ground. A Power Probe takes this a step further, allowing you to supply fused power or ground to components for testing. This is invaluable for troubleshooting relays, injectors, or glow plug circuits.

- Wiring Diagram Manual: An absolute must-have. While not a physical tool, a detailed wiring diagram (often found in service manuals or online databases) is your map to the 7.3 Powerstroke‘s electrical system. It helps you understand circuit paths, component locations, and pinouts, drastically reducing diagnostic time.

- Terminal Release Tools: When working with electrical connectors, simply pulling on the wires can damage them. Terminal release tools allow you to safely remove individual pins from connectors, useful for repairing damaged wires or adding new circuits.

- Crimping Tools and Connectors: For repairing or modifying wiring harnesses, a quality crimping tool (for insulated and non-insulated terminals) and a supply of appropriate heat-shrink connectors are essential for creating durable, weather-resistant repairs.

- Heat Gun: For use with heat-shrink tubing and connectors, ensuring a watertight and secure electrical connection.

Sensor-Specific Tools and Considerations

- Specialized Sensor Sockets: Beyond the ICP/IPR sensors, various other sensors (like the Exhaust Back Pressure (EBP) sensor, Mass Air Flow (MAF) sensor, or Intake Air Temperature (IAT) sensor) may require specific sockets or wrenches for removal and installation without damage.

- Dielectric Grease: While not a tool, applying dielectric grease to electrical connectors (especially those exposed to the elements or high heat) helps prevent corrosion and ensures good contact. This is particularly important for the notorious 7.3 Powerstroke under-valve-cover harnesses.

Fluid Management and Sealing Tools: Preventing Leaks and Ensuring Longevity

The 7.3 Powerstroke, like any engine, relies on various fluids—engine oil, coolant, transmission fluid, and fuel—to operate correctly. Maintaining these fluids and preventing leaks is paramount for the engine’s long-term health. This section focuses on the tools that help you manage these fluids, replace seals, and ensure your Powerstroke remains leak-free, a common concern for older diesel engines. Proper sealing prevents oil consumption, coolant loss, and fuel contamination, all of which can severely impact performance and lifespan.

Fluid Service Tools

- Fluid Drain Pans: Large capacity drain pans are essential for catching significant volumes of oil, coolant, and fuel during service. The 7.3 Powerstroke holds a substantial amount of oil (around 15 quarts), so plan accordingly.

- Fluid Transfer Pumps/Syphons: For adding fluids in hard-to-reach places (like transmission fluid or gear oil) or for evacuating fluids, a manual or electric fluid transfer pump is invaluable.

- Funnel Set: A variety of funnels, especially those with filters, helps prevent spills and contamination when refilling fluids.

- Oil Filter Wrench (Cap Style): The 7.3 Powerstroke oil filter is a cartridge style. A specific cap-style wrench that fits over the filter housing is necessary for easy removal and installation without damage.

- Coolant System Pressure Tester: This tool allows you to pressurize the cooling system to check for leaks in hoses, radiators, or the degas bottle, identifying common coolant loss issues.

Sealing and Gasket Tools

- Gasket Scrapers (Plastic and Metal): Thoroughly cleaning old gasket material from mating surfaces is critical for a leak-free seal. Plastic scrapers prevent damage to aluminum surfaces, while metal scrapers are useful for more stubborn residues on cast iron.

- Seal Pullers and Drivers: For replacing crankshaft seals, camshaft seals, or wheel seals, specialized pullers and drivers (or appropriate-sized sockets) ensure the new seal is installed squarely and without damage.

- RTV Silicone Sealant and Gasket Maker: High-quality, oil-resistant RTV (Room Temperature Vulcanizing) silicone or specific gasket maker (e.g., Ultra Black, The Right Stuff) is frequently used on the 7.3 Powerstroke, particularly for the oil pan, front cover, and valve covers.

- Thread Sealant and Anti-Seize Compound: Thread sealant (e.g., Loctite 545) is crucial for tapered pipe threads to prevent fluid leaks. Anti-seize compound prevents fasteners from seizing due to corrosion or heat, especially on exhaust components or glow plugs.

Heavy-Duty and Specialized Lifting Equipment: The Big Jobs

Some 7.3 Powerstroke engine repair tasks go beyond simple component replacement and delve into major overhaul territory. When you’re dealing with the sheer weight and size of a diesel engine and its associated heavy-duty components, specialized lifting and support equipment becomes absolutely non-negotiable for safety and efficiency. These are the tools that enable you to tackle engine-out rebuilds, transmission replacements, or even just heavy component removal with confidence.

Lifting and Support Tools

- Engine Hoist (Engine Crane): If you ever plan on pulling the 7.3 Powerstroke engine out of the truck (a common scenario for comprehensive rebuilds or transmission work), a robust engine hoist with at least a 2-ton capacity is essential. Diesel engines are incredibly heavy.

- Engine Stand: Once the engine is out, an engine stand allows you to safely mount and rotate the engine for easy access to all sides during a rebuild. Ensure it’s rated for the substantial weight of a 7.3 Powerstroke (a minimum of 1,500 lbs, preferably 2,000 lbs capacity).

- Transmission Jack: If you’re dropping the transmission for service or replacement, a dedicated transmission jack provides the necessary stability and maneuverability to safely lower and raise the heavy unit.

- Heavy-Duty Floor Jack and Jack Stands: For lifting the truck safely. Due to the weight of the F-Series trucks, you’ll need a jack with significant lifting capacity (3-ton minimum, 6-ton preferred) and sturdy jack stands. Never work under a vehicle supported only by a jack.

- Wheel Chocks: An often-overlooked safety item. Always chock the wheels when the vehicle is lifted or on an incline.

Large and Impact Tools

- Air Compressor and Impact Wrenches (1/2″ and 3/4″ Drive): Many fasteners on a 7.3 Powerstroke, especially chassis and drivetrain components, are extremely tight. A powerful air compressor (at least 20-30 gallon tank, 5 CFM @ 90 PSI minimum) paired with 1/2″ and even 3/4″ drive impact wrenches will save you immense time and effort. This is one of the most impactful investments for heavy-duty work.

- Large Sockets (Impact Rated): For wheel nuts, axle nuts, and other large fasteners, a set of impact-rated sockets in both metric and SAE (up to 1 1/2″ or 36mm and larger) is necessary.

- Pneumatic Die Grinder/Cut-off Tool: Useful for removing seized bolts, cutting exhaust components, or cleaning rust. Always use appropriate PPE (Personal Protective Equipment) with these tools.

Key Tool Checklist and Common Repair Match-up

To help you prioritize your tool acquisition and understand their application, here’s a quick reference table matching common 7.3 Powerstroke repair tasks with the specific essential tools you’ll need.

| Common 7.3 Powerstroke Repair Task | Essential Tools Required | Pro-Tip |

|---|---|---|

| Injector Replacement | Injector removal tool, O-ring kit & installation tool, Torque wrench, Valve cover gasket (with harness), Socket set | Clean injector cups thoroughly; ensure O-rings are lubricated with clean oil before installation. |

| HPOP/IPR/ICP Service | IPR socket, ICP sensor wrench, HPOP line disconnect tool, Torque wrench, Diagnostic scanner | Monitor ICP and IPR duty cycle with a scanner for proper diagnosis before disassembly. |

| Glow Plug Replacement | Glow plug socket (thin-wall), Torque wrench, Dielectric grease, Anti-seize compound | Apply anti-seize to new glow plug threads; avoid overtightening to prevent breakage. |

| Turbocharger R&R (Removal & Reinstallation) | Breaker bars, Large socket set, Torque wrench, Turbo gasket kit, Impact wrench | Inspect up-pipes for leaks and condition of the EBPV; ensure all surfaces are clean for new gaskets. |

| Oil Cooler Reseal | Oil cooler removal/installation tool, Gasket scraper, Torque wrench, Sealant/RTV | Thoroughly clean all mating surfaces; use a quality oil cooler kit with new O-rings. |

| Fuel Filter Change / Fuel Pressure Check | Fuel pressure gauge kit, Socket set, Drain pan, Funnel | Check fuel pressure before and after filter change to diagnose potential issues. |

| Electrical Diagnostic (e.g., No Start) | OBD-II scanner (Ford enhanced), Digital Multimeter, Test light/Power Probe, Wiring diagrams | Always start with scanner codes, then systematically test circuits and components using a DMM. |

| Engine Removal/Overhaul | Engine hoist, Engine stand, Transmission jack, Heavy-duty jack & stands, Large socket/wrench sets, Torque wrenches, Impact wrenches | Label everything! Take photos during disassembly. Invest in a good service manual. |

Conclusion: Empowering Your 7.3 Powerstroke Journey

The 7.3 Powerstroke diesel engine is an engineering marvel, a testament to Ford’s commitment to durability and performance. Keeping these legendary engines on the road for hundreds of thousands of miles requires dedication, knowledge, and, most importantly, the right tools. Investing in the essential tools for 7.3 Powerstroke engine repair isn’t just about fixing what’s broken; it’s about empowering yourself to understand, maintain, and extend the life of your prized diesel truck.

From the foundational diagnostic equipment that helps you pinpoint elusive issues to the specialized wrenches and pullers designed for the 7.3 Powerstroke‘s unique components, each tool plays a critical role. Remember, attempting repairs with inadequate tools often leads to stripped bolts, damaged parts, and increased frustration. By equipping your garage with the gear discussed in this comprehensive guide, you’re not just buying tools; you’re investing in efficiency, safety, and the long-term health of your Powerstroke.

Whether you’re tackling a glow plug replacement, an injector swap, or a full engine overhaul, having these must-have tools at your disposal will transform your repair experience. So, roll up your sleeves, gather your gear, and continue to enjoy the unparalleled power and reliability that only a well-maintained 7.3 Powerstroke can offer. Happy wrenching!

🎥 Related Video: Does your 7.3 powerstroke have forged rods?

📺 Shadetree7.3

Frequently Asked Questions

What are the absolute essential hand tools needed for basic 7.3 Powerstroke engine maintenance and repair?

For fundamental tasks on your 7.3 Powerstroke, a robust set of metric and standard wrenches and sockets, including deep-well options, is crucial. You’ll also need screwdrivers (Phillips and flathead), pliers, a hammer, and a torque wrench for accurate tightening of components.

Are there any specialized tools that are indispensable for working on the 7.3 Powerstroke specifically?

Yes, several specialized tools significantly ease common 7.3 Powerstroke repairs. An injector removal tool, oil rail plugs for air tests, and a high-pressure oil pump (HPOP) socket or removal tool are highly recommended. These can save significant time and prevent damage compared to improvised methods.

What diagnostic tools should a 7.3 Powerstroke owner consider for troubleshooting engine problems?

A reliable OBD-II scan tool capable of reading Ford-specific codes and live data is paramount for diagnosing your 7.3 Powerstroke. Additionally, a quality multimeter for electrical testing and a fuel pressure gauge for checking the fuel delivery system are invaluable for pinpointing issues.

Can a DIY enthusiast perform significant 7.3 Powerstroke engine repairs without a professional-grade shop setup?

Absolutely, many significant 7.3 Powerstroke repairs are achievable for a DIY enthusiast with proper tools and patience. While a lift is convenient, robust jack stands and a good floor jack suffice for most under-vehicle work, making major repairs possible in a home garage.

What safety equipment is non-negotiable when undertaking any repair on a 7.3 Powerstroke engine?

Safety should always be your top priority when working on your 7.3 Powerstroke engine. Essential safety gear includes impact-resistant safety glasses, sturdy work gloves, and appropriate hearing protection. Always use robust jack stands when lifting the vehicle and have a fire extinguisher nearby for emergencies.

Beyond basic hand tools, what power tools or larger equipment are beneficial for a 7.3 Powerstroke owner?

While not always essential for every task, certain power tools can greatly assist with 7.3 Powerstroke repairs. An impact wrench (air or electric) significantly speeds up stubborn fastener removal, and a sturdy engine hoist or cherry picker becomes indispensable for major engine component removal or installation.