Diagnosing Ford 6.0 Powerstroke Crankshaft Position Sensor Problems

Featured image for this comprehensive guide about Diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems

Image source: autokitslab.com

The Ford 6.0 Powerstroke engine is a legend among diesel enthusiasts and heavy-duty truck owners. Known for its robust capabilities, it’s also notorious for a few common quirks that can leave even seasoned mechanics scratching their heads. One such issue, often a culprit behind perplexing performance problems, is a malfunctioning crankshaft position sensor (CPS). This tiny, yet vital, component plays an enormous role in your engine’s operation, and when it falters, your mighty Powerstroke can quickly become a frustrating paperweight.

Imagine cruising down the highway, your 6.0 purring along, when suddenly, the engine sputters, stalls, or refuses to start altogether. Or perhaps you’re experiencing intermittent power loss, rough idling, or a mysterious check engine light. These are all tell-tale signs that your Ford 6.0 Powerstroke crankshaft position sensor might be on its way out, or has already failed. But how do you pinpoint this specific issue amidst the complex symphony of your diesel engine? This comprehensive guide will equip you with the knowledge, tools, and step-by-step diagnostic procedures to confidently identify and address 6.0 Powerstroke CPS problems, getting your truck back on the road with minimal fuss.

Understanding the intricacies of your engine’s sensors is key to effective troubleshooting. The crankshaft position sensor is not just another part; it’s the conductor of your engine’s timing, dictating when fuel is injected and spark plugs (if it were a gas engine) fire. A precise signal from this sensor is critical for your engine’s control unit (PCM) to synchronize everything. So, let’s dive deep into the world of diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems and empower you to become your own diesel detective.

Quick Answers to Common Questions

What are the tell-tale signs of a failing Ford 6.0 Powerstroke crankshaft position sensor?

You might experience a no-start condition, extended crank times, or sudden engine stalling while driving. The engine could also run rough or misfire if the sensor is sending intermittent signals, all pointing to potential Ford 6.0 Powerstroke crankshaft position sensor problems.

Will a bad Ford 6.0 Powerstroke crankshaft position sensor prevent my truck from starting?

Absolutely, a faulty crankshaft position sensor can prevent your engine from starting entirely because the PCM won’t receive the crucial timing information needed to fire the injectors and ignite the fuel. It’s a very common cause of a no-start condition when diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems.

Can I diagnose Ford 6.0 Powerstroke crankshaft position sensor problems without fancy tools?

While a scan tool to check for diagnostic trouble codes is highly recommended, you can sometimes identify symptoms like long crank times or stalling. For a definitive diagnosis, however, reading codes and monitoring sensor data is best to confirm a Ford 6.0 Powerstroke crankshaft position sensor issue.

What diagnostic trouble codes (DTCs) are typically associated with a bad Ford 6.0 Powerstroke crankshaft position sensor?

The most common code you’ll see is P0335, which indicates a problem with the crankshaft position sensor “A” circuit. You might also encounter related codes, but P0335 is your primary clue when diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems.

Is replacing the Ford 6.0 Powerstroke crankshaft position sensor a difficult DIY job?

It’s generally considered a moderately easy DIY task, as the sensor is located on the passenger side of the engine block, above the starter. You’ll need basic hand tools, but access can be a bit tight, making it slightly challenging for some when replacing the Ford 6.0 Powerstroke crankshaft position sensor.

📋 Table of Contents

- Understanding the Heartbeat: What the 6.0 Powerstroke Crankshaft Position Sensor Does

- Warning Signs: Common Symptoms of a Failing 6.0 Powerstroke CPS

- Gearing Up: Essential Tools for Diagnosing Your 6.0 Powerstroke CPS

- The Diagnostic Deep Dive: Step-by-Step Troubleshooting for Crank Sensor Issues

- Beyond the Diagnosis: What to Do After Identifying a Faulty 6.0 Powerstroke Crankshaft Position Sensor

- Keeping Your 6.0 Powerstroke Running Strong: Prevention and Final Thoughts

Understanding the Heartbeat: What the 6.0 Powerstroke Crankshaft Position Sensor Does

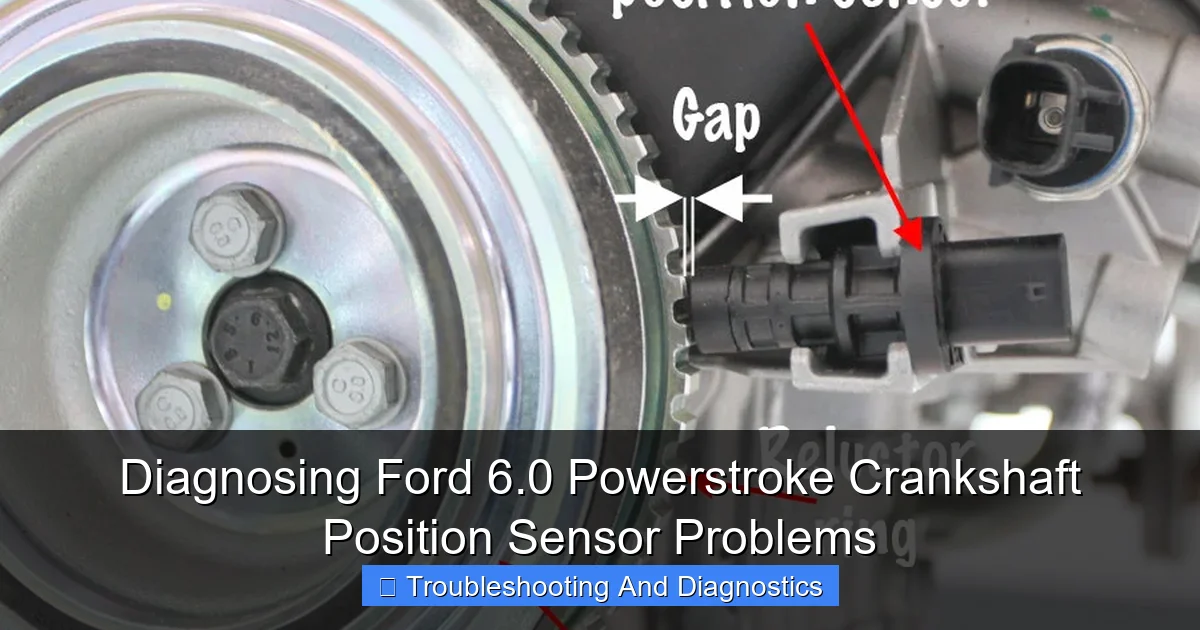

Before we can effectively diagnose a problem, it’s crucial to understand the component’s function. The crankshaft position sensor on your Ford 6.0 Powerstroke is an inductive sensor that monitors the rotational speed and position of the crankshaft. It reads a reluctor wheel (or tone ring) located on the crankshaft. As the crankshaft spins, teeth on this wheel pass by the sensor, generating a pulsed signal. This signal is then sent to the Powertrain Control Module (PCM).

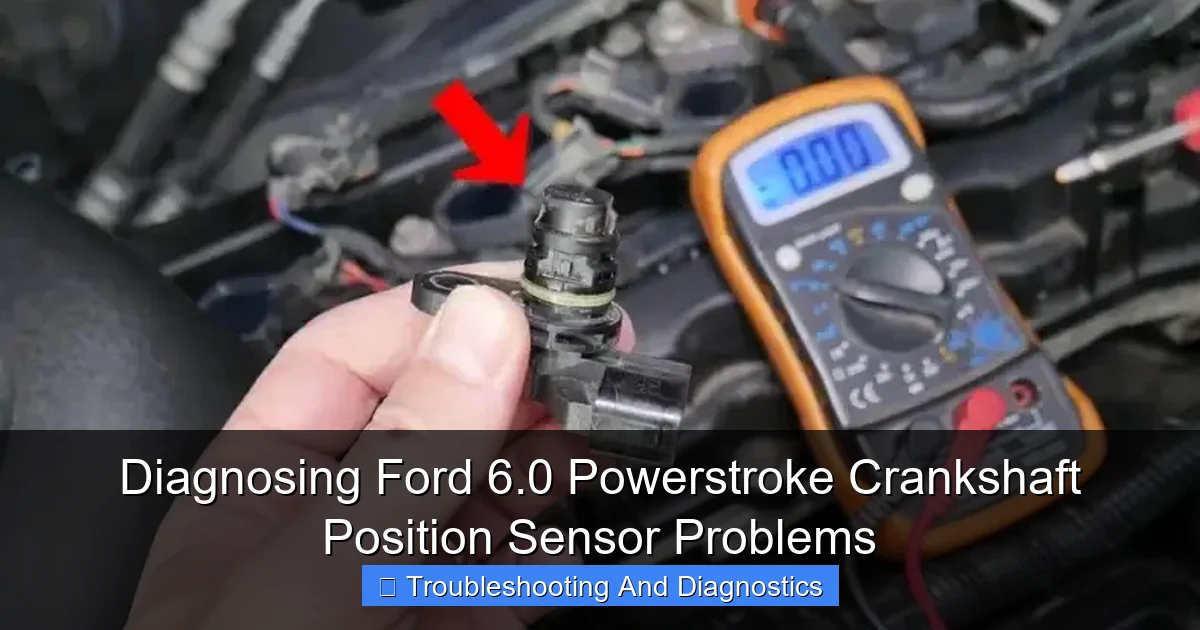

Learn more about Diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems – Diagnosing Ford 6.0 Powerstroke Crankshaft Position Sensor Problems

Image source: samarins.com

Why is this signal so important? The PCM uses the crankshaft position sensor’s input for several critical functions:

| Symptom / Diagnostic Trouble Code (DTC) | Likely CPS Condition / Cause | Key Diagnostic Action | Expected Reading / Indication of Fault |

|---|---|---|---|

| Cranks, No Start (P0335, P0336) | Complete signal loss due to sensor failure or wiring issue. | Monitor Engine RPM (PID) via scan tool during cranking. Check CPS wiring connector. | Scanner shows 0 RPM or erratic RPM (e.g., 50-70 RPM) while cranking. |

| Intermittent Stalling / Dying While Driving | Sensor signal loss due to heat, vibration, or internal short. | Monitor live RPM data. Perform a “wiggle test” on CPS connector/wiring while engine is running. | RPM drops abruptly to 0 before/during stall. Wiggling wires triggers stall or DTC. |

| Extended Crank Time (especially when warm) | Degraded signal quality or weak sensor output, causing delayed RPM signal. | Compare initial RPM build-up time during cranking to a known good 6.0L (target 150 RPM). | Takes 3+ seconds to reach required ~150 RPM for start (healthy is ~1-2s). |

| Rough Idle / Erratic Engine Behavior | Inconsistent or noisy signal affecting fuel injection timing. | Monitor RPM stability (PID) and Injection Control Pressure (ICP) during idle and light load. | RPM PID shows constant, unnatural fluctuations (+/- 50 RPM at idle). |

- Fuel Injection Timing: It tells the PCM precisely when to activate the injectors for optimal combustion.

- Engine Speed (RPM) Calculation: The PCM calculates engine RPM based on the frequency of the CPS signal.

- Synchronization with Camshaft Position Sensor: The CPS works in tandem with the camshaft position sensor (CMP) to ensure proper engine timing. The PCM uses both signals to determine piston position relative to valve events.

- Ignition Timing (Indirectly): While a diesel engine doesn’t have spark plugs in the traditional sense, the CPS signal is fundamental for timing the fuel injection event, which is analogous to ignition timing in a gasoline engine.

Essentially, the 6.0 Powerstroke CPS is the primary input the PCM uses to know if the engine is rotating and at what speed. Without an accurate signal, the PCM cannot properly control fuel delivery, leading to a wide range of performance issues, from a simple misfire to a complete no-start condition. Early 6.0 Powerstrokes (2003-2004) often utilized a Hall effect style sensor, while later models (2005-2007) typically employed an inductive type. While their internal workings differ slightly, their purpose remains the same: provide precise crankshaft position data to the PCM.

Warning Signs: Common Symptoms of a Failing 6.0 Powerstroke CPS

When your Ford 6.0 Powerstroke crankshaft position sensor starts to fail, it rarely does so without putting up a fight. The symptoms can range from subtle annoyances to debilitating malfunctions. Recognizing these signs early can save you a lot of headache and potential damage. Here are the most common indicators that your 6.0 Powerstroke CPS might be acting up:

Learn more about Diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems – Diagnosing Ford 6.0 Powerstroke Crankshaft Position Sensor Problems

Image source: i.ytimg.com

Intermittent Stalling or Rough Idling

One of the most frustrating and common symptoms is intermittent stalling, especially after the engine warms up, or during acceleration. Your engine might run fine for a while, then suddenly die, or struggle to maintain a consistent idle, feeling rough and uneven. This is often due to the sensor intermittently losing its signal, confusing the PCM.

No-Start Condition or Extended Cranking

This is perhaps the most definitive symptom. If your 6.0 Powerstroke cranks but won’t start, or takes an unusually long time to fire up, a failing crankshaft position sensor is a prime suspect. Without a consistent signal, the PCM doesn’t know when to inject fuel, resulting in a lack of combustion. You might notice the tachometer not registering any RPMs during cranking, even if the engine is turning over.

Reduced Engine Performance or Loss of Power

A faulty CPS can cause the PCM to make incorrect fueling decisions, leading to a noticeable drop in power, poor acceleration, or a general feeling of sluggishness. The engine might enter a “limp mode” to protect itself, further restricting performance.

Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs)

Of course, the dreaded Check Engine Light is a common companion to many engine problems. For 6.0 Powerstroke CPS issues, you’ll typically see specific diagnostic trouble codes (DTCs). These codes are your first line of attack in troubleshooting:

- P0335: Crankshaft Position Sensor ‘A’ Circuit Malfunction – This is the most common code, indicating a general fault in the sensor circuit.

- P0336: Crankshaft Position Sensor ‘A’ Circuit Range/Performance – Suggests the sensor signal is present but inconsistent or out of expected range.

- Other related codes might appear, but P0335 and P0336 are primary indicators.

Erratic Tachometer Readings

Because the PCM calculates RPM based on the CPS signal, a failing sensor can send inaccurate data, causing your tachometer to jump erratically, read zero during cranking, or provide inconsistent readings while driving.

Increased Fuel Consumption

When the engine’s timing and fueling are out of sync due to a bad CPS, efficiency suffers. The PCM might over-fuel or under-fuel, leading to noticeable decrease in fuel economy.

Gearing Up: Essential Tools for Diagnosing Your 6.0 Powerstroke CPS

Successful diagnosis requires the right tools. While some basic symptoms can be observed visually or audibly, truly pinpointing a crankshaft position sensor problem on your 6.0 Powerstroke necessitates a few key pieces of equipment. Don’t worry, most of these are readily available and valuable additions to any DIY mechanic’s toolbox.

- OBD-II Scanner/Diagnostic Tool: An absolute must-have. This will allow you to read and clear DTCs (like P0335 or P0336) and, more importantly, monitor live data. Look for one that can display engine RPM during cranking, fuel pressure, and other critical parameters. A professional-grade scanner will offer even more in-depth data.

- Digital Multimeter (DMM): Essential for checking voltage, resistance, and continuity in electrical circuits. You’ll use this to test the sensor itself and its wiring harness.

- Wiring Diagram for Ford 6.0 Powerstroke: Knowing which wires go where on the CPS connector and what their expected voltages should be is invaluable. Many online resources and service manuals provide these.

- Test Light (Optional but Recommended): Useful for quickly checking for power or ground at specific points in a circuit.

- Basic Hand Tools: Sockets, wrenches, screwdrivers – whatever you need to access the sensor (which is typically on the passenger side, near the starter) and potentially remove components for better access.

- Safety Glasses and Gloves: Always prioritize safety when working on your vehicle.

Having these tools at your disposal will not only help you diagnose a faulty 6.0 Powerstroke crankshaft position sensor but also assist in troubleshooting many other potential issues that may arise with your truck.

The Diagnostic Deep Dive: Step-by-Step Troubleshooting for Crank Sensor Issues

Now that you understand the symptoms and have your tools ready, let’s get down to the nitty-gritty of diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems. Follow these steps systematically to avoid misdiagnosis and save time.

Step 1: Check for Diagnostic Trouble Codes (DTCs)

Connect your OBD-II scanner and read any stored DTCs. As mentioned, P0335 and P0336 are strong indicators of a crank sensor issue. Even if no CPS-specific codes are present, other related codes might point you in the right direction. Make note of all codes before clearing them.

Step 2: Monitor Live Data During Cranking (No-Start Condition)

This is a critical step for a no-start condition. With your scanner connected, crank the engine while observing the live data stream. Specifically, look at the “Engine RPM” reading. If the 6.0 Powerstroke CPS is working correctly, you should see an RPM reading (typically 100-200 RPM) while cranking. If the RPM gauge remains at zero or shows erratic readings, this is a very strong indication that the crankshaft position sensor is either faulty or not receiving power/ground.

Also, check the following during cranking:

- ICP (Injection Control Pressure) and IPR (Injection Pressure Regulator) Duty Cycle: Ensure you’re building sufficient oil pressure for the injectors to fire (typically above 500 PSI ICP). While not directly a CPS issue, a no-start can be compounded by low ICP.

- FICM (Fuel Injection Control Module) Voltage: Ensure FICM voltage is healthy (typically 48V).

Step 3: Visual Inspection of the Sensor and Wiring

Locate the crankshaft position sensor. On the 6.0 Powerstroke, it’s typically located on the passenger side of the engine block, near the back, often above the starter. It can be a bit challenging to access. Once located:

- Check the Electrical Connector: Ensure it’s securely plugged in, free from corrosion, dirt, or damage. Unplug and re-plug it a few times to ensure good contact.

- Inspect Wiring: Look for any signs of frayed wires, exposed insulation, pinches, or cuts along the sensor harness, especially where it might rub against engine components.

- Examine the Sensor Itself: While you can’t see the internal components, check for any physical damage to the sensor housing.

Step 4: Electrical Tests at the Sensor Connector (Key On, Engine Off – KOEO)

This requires your multimeter and a wiring diagram. Disconnect the CPS connector. Using your DMM, perform the following tests:

- Power Supply Check: Identify the power wire (usually 5V or 12V reference, consult your diagram) and ground wire. With the key in the “ON” position (KOEO), check for the correct voltage at the power wire relative to a good ground. Also, check for continuity to ground on the ground wire. If you’re missing power or ground, the issue is in the wiring harness or the PCM, not the sensor itself.

- Signal Wire Check: The third wire is typically the signal return. You can check for any residual voltage, but the main test for the signal will come when the engine is cranking.

Note: If your sensor is an inductive type, it generates its own AC voltage signal when the engine cranks, so a 5V reference might not be present on all pins when simply testing with KOEO. Always refer to your specific year’s wiring diagram for accurate pin-out and voltage specifications.

Step 5: Testing the Sensor’s Output Signal (Engine Cranking)

This is where an oscilloscope shines, but a DMM set to AC voltage can give you an indication. With the sensor connected and the engine cranking:

- AC Voltage Output: If you have an inductive sensor, set your DMM to AC voltage and back-probe the signal wire while the engine is cranking. You should see a fluctuating AC voltage, typically between 0.5V and 2.0V or more, indicating the sensor is generating a signal. No AC voltage suggests a dead sensor.

- RPM with Scan Tool: Re-emphasizing this, if your scan tool shows no RPM during cranking, despite a healthy FICM and ICP, it’s a very strong indicator the CPS is not sending a signal.

Step 6: Testing Sensor Resistance (Ohm Test – Inductive Sensors)

For inductive-style sensors, you can often test their internal resistance. Disconnect the sensor and set your DMM to the Ohms (Ω) setting. Measure the resistance across the two signal pins (or as specified by your wiring diagram). A typical healthy resistance for an inductive CPS is usually within a specific range, often around 800-1200 ohms. A reading of infinity (open circuit) or zero (short circuit) indicates a faulty sensor. Again, consult your specific model’s service manual for the exact resistance specifications.

Step 7: The Last Resort – Swapping the Sensor

If all tests point to a faulty sensor, or if you’re unable to get definitive readings but all other systems (fuel pressure, battery voltage, FICM, ICP) check out, replacing the crankshaft position sensor is the next logical step. Given its relatively low cost compared to other components, and the difficulty in definitively testing every nuance of its signal without an oscilloscope, many mechanics will proceed with replacement if symptoms are strong and DTCs are present.

Remember, always use an OEM (Original Equipment Manufacturer) or a reputable aftermarket sensor. Cheap, no-name sensors are a common cause of recurring problems and can lead to frustration down the line. A Bosch sensor is often a reliable choice for the 6.0 Powerstroke.

Beyond the Diagnosis: What to Do After Identifying a Faulty 6.0 Powerstroke Crankshaft Position Sensor

Once you’ve confidently diagnosed a failing crankshaft position sensor on your 6.0 Powerstroke, the next step is replacement. While this guide focuses on diagnosis, a brief overview of what comes next is important.

Replacing the CPS

The 6.0 Powerstroke CPS is located on the passenger side of the engine block, often requiring removal of the starter for better access on many models. This can be a bit labor-intensive due to its location. Here’s a general outline:

- Disconnect Batteries: Always disconnect both negative battery terminals for safety.

- Gain Access: Depending on your specific truck year and configuration, you might need to remove the starter, which involves disconnecting its wiring and unbolting it. This provides the best access to the CPS.

- Remove Old Sensor: The sensor is typically held in place by a single bolt. Remove the bolt and carefully pull the sensor out. Be prepared for a small amount of oil to leak out.

- Install New Sensor: Ensure the O-ring on the new sensor is properly seated and lubricated with a little clean engine oil. Insert the new sensor, making sure it seats fully, then re-install and tighten the retaining bolt to the manufacturer’s specified torque.

- Reconnect Wiring and Components: Reconnect the electrical connector to the new CPS. Reinstall the starter (if removed) and reconnect its wiring.

- Reconnect Batteries and Test: Reconnect the battery terminals. Start the engine and check for proper operation. Clear any stored DTCs with your scanner.

Remember, torque specifications are important for the CPS bolt to ensure proper sealing and retention without damaging the sensor or block.

Clearing Codes and Test Driving

After replacement, use your OBD-II scanner to clear any stored diagnostic trouble codes. Then, take your truck for a thorough test drive. Pay attention to how the engine idles, accelerates, and if any of the previous symptoms (stalling, power loss) reappear. A successful repair should result in smooth engine operation and no illuminated check engine light.

Keeping Your 6.0 Powerstroke Running Strong: Prevention and Final Thoughts

While component failure is sometimes unavoidable, a proactive approach can help minimize the chances of a premature Ford 6.0 Powerstroke crankshaft position sensor problem. Here are some preventative tips and final thoughts to keep your diesel running reliably:

- Use Quality Parts: When it’s time for replacement, always opt for OEM or high-quality aftermarket sensors. Cheap, generic sensors are a false economy and often lead to recurring problems. Bosch is a widely trusted brand for the 6.0 Powerstroke’s sensors.

- Maintain Wiring Integrity: Periodically inspect engine wiring harnesses for signs of wear, chafing, or corrosion, especially around critical sensors. Secure loose wires to prevent them from rubbing against moving or hot components.

- Proper Maintenance: Keep up with your regular engine maintenance schedule. While not directly related to the CPS, a well-maintained engine is less likely to experience secondary failures that could stress other components.

- Address Codes Promptly: Don’t ignore a “Check Engine” light. Even if your truck seems to be running fine, a stored DTC can be an early warning sign of a developing problem. Addressing issues early can prevent more significant failures down the road.

- Stay Informed: The 6.0 Powerstroke has a wealth of information available online. Engage with online forums and communities dedicated to these engines. Learning from others’ experiences can be invaluable in troubleshooting.

Diagnosing Ford 6.0 Powerstroke crankshaft position sensor problems can seem daunting at first, but with a methodical approach, the right tools, and an understanding of how the sensor functions, you can confidently identify and resolve these issues. Remember, patience and attention to detail are your best allies in diesel diagnostics. By understanding the common symptoms, leveraging diagnostic tools, and following a logical troubleshooting path, you can ensure your powerful 6.0 Powerstroke remains a reliable workhorse for years to come.

Don’t let a tiny sensor bring your mighty truck to a halt. Empower yourself with knowledge, and you’ll be able to keep your Ford 6.0 Powerstroke thriving on the road.

🎥 Related Video: 6.0 Powerstroke Crank Sensor Replacement made simple!

📺 Dominion Overland

This is the easy way to change a Crank Sensor in a Ford Excursion 6.0 powerstroke.

Frequently Asked Questions

What are the common symptoms of a failing Ford 6.0 Powerstroke crankshaft position sensor?

Common symptoms include extended cranking before starting, intermittent stalling while driving, or a complete no-start condition. You might also notice rough idling, misfires, or a sudden loss of power, as the engine’s computer struggles to get accurate timing information.

How can I tell if my starting or running issues are specifically due to the crankshaft position sensor and not another problem?

While symptoms can overlap with other issues, a diagnostic scan tool revealing codes related to the crankshaft position sensor (e.g., P0335) is a strong indicator. Observing erratic RPM readings on the tachometer during cranking without actual engine rotation can also point to this sensor.

Where is the crankshaft position sensor located on a Ford 6.0 Powerstroke, and how difficult is it to access?

The crankshaft position sensor on a 6.0 Powerstroke is typically located on the passenger side of the engine block, near the back, above the starter. Access can be somewhat challenging due to its position, often requiring removal of the starter for better reach.

What are the steps to test a Ford 6.0 Powerstroke crankshaft position sensor to confirm it’s faulty?

You can test the crankshaft position sensor by checking its resistance with a multimeter, although this isn’t always conclusive. A more reliable method involves monitoring its signal output using an oscilloscope while cranking the engine, looking for a clear, consistent waveform.

What diagnostic trouble codes (DTCs) might indicate a problem with the Ford 6.0 Powerstroke crankshaft position sensor?

The most common diagnostic trouble code associated with a faulty crankshaft position sensor is P0335, indicating a “Crankshaft Position Sensor ‘A’ Circuit Malfunction.” Other related codes, such as P0336, P0337, P0338, or P0339, may also appear depending on the specific fault.

Can a faulty Ford 6.0 Powerstroke crankshaft position sensor cause a no-start condition or intermittent stalling?

Yes, absolutely. If the crankshaft position sensor provides an incorrect or no signal, the engine’s computer cannot accurately determine engine speed and piston position, preventing proper fuel injection and ignition timing, which leads to a no-start or stalling.