Diagnosing 7.3 Powerstroke Air in Fuel System Issues: Solutions and Tips

Featured image for this comprehensive guide about Diagnosing 7.3 Powerstroke air in fuel system issues

Image source: trade.mechanic.com.au

The iconic 7.3 Powerstroke diesel engine has earned its legendary status through unparalleled reliability, brute force, and a mechanical simplicity that endeared it to truck owners for decades. Thousands of these powerhouses are still on the road today, faithfully hauling, towing, and tackling tough jobs. However, even the most robust engines have their Achilles’ heel, and for the 7.3L, one of the most frustrating and common culprits behind performance woes is the insidious problem of air in the fuel system.

Imagine your trusty F-Series or Excursion suddenly acting up: a rough idle that makes your coffee slosh, a hesitant acceleration when you need power most, or an extended crank that leaves you wondering if it will ever fire up. These are often tell-tale signs that your engine isn’t getting the pure, air-free diesel fuel it desperately needs. When air infiltrates the fuel lines, it disrupts the precise timing and pressure required for optimal combustion, leading to a cascade of performance issues. Diagnosing these problems can feel like chasing ghosts, but with the right knowledge and a systematic approach, you can pinpoint and fix these pesky air leaks.

This comprehensive guide is designed to empower every 7.3 Powerstroke owner, from the seasoned wrench-turner to the curious DIYer, with the ultimate resource for diagnosing 7.3 Powerstroke air in fuel system issues. We’ll delve into the symptoms, explore diagnostic techniques, uncover common sources of air intrusion, and provide actionable solutions and preventative maintenance tips. Get ready to reclaim your 7.3’s legendary performance and keep it roaring for many more miles to come.

Quick Answers to Common Questions

What are the tell-tale signs of air in my 7.3 Powerstroke fuel system?

You’ll often notice a rough idle, extended cranking times, a loss of power, or even the engine dying unexpectedly, especially under load. These symptoms are classic indicators of air in the fuel system.

Why is air in the fuel system such a problem for my 7.3 Powerstroke?

The 7.3L diesel engine relies on a bubble-free fuel supply for its injectors to operate correctly. Air causes cavitation, hinders proper fuel pressure, and leads to misfires or a complete lack of combustion.

Where does air most commonly enter the 7.3 Powerstroke fuel system?

Common culprits for air in the fuel system include cracked fuel lines, a failing fuel filter housing O-ring or lid, or issues with the fuel tank pickup (often called the “hutch” mod area).

How can I quickly check if I have air in my 7.3 Powerstroke fuel system without special tools?

A simple visual check involves observing the fuel flow through the clear line on top of the fuel filter housing; you’ll easily spot bubbles if air is present. You can also listen for a “gurgling” sound near the fuel tank or filter.

Is it safe to drive my 7.3 Powerstroke if I suspect air in the fuel system?

While you might manage a short trip, it’s not recommended as it can lead to poor performance, potential injector damage over time, and leave you stranded. It’s best to address air in the fuel system promptly.

📋 Table of Contents

- Understanding the 7.3 Powerstroke Fuel System Basics

- Common Symptoms of Air in the 7.3 Powerstroke Fuel System

- Pinpointing the Culprit: Diagnostic Procedures for Air in Fuel

- Common Sources of Air Intrusion in the 7.3 Powerstroke Fuel System

- Solutions and Preventative Maintenance for an Air-Free 7.3 Fuel System

- Comparative Overview: 7.3 Powerstroke Fuel System Issues & Solutions

- Conclusion: Keep Your 7.3 Powerstroke Roaring Strong

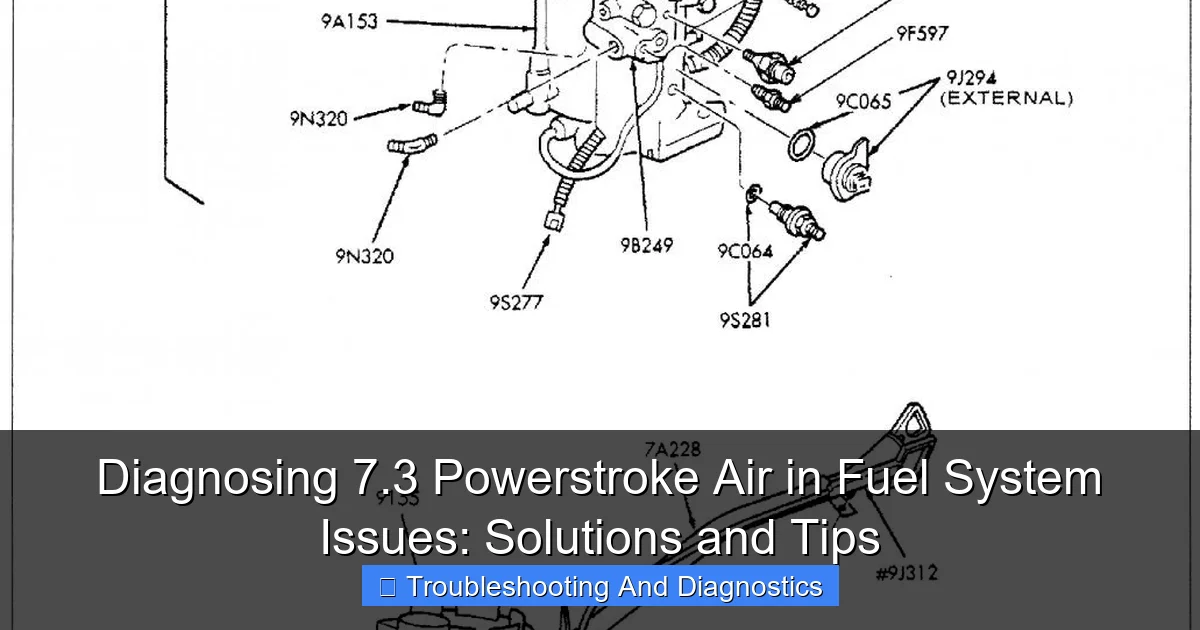

Understanding the 7.3 Powerstroke Fuel System Basics

Before you can effectively tackle air in the fuel system, it’s crucial to understand how the 7.3 Powerstroke fuel system operates. Unlike modern common rail diesels, the 7.3 uses a unique Hydraulic Electronic Unit Injection (HEUI) system, which relies heavily on an air-free, consistent fuel supply.

Learn more about Diagnosing 7.3 Powerstroke air in fuel system issues – Diagnosing 7.3 Powerstroke Air in Fuel System Issues: Solutions and Tips

Image source: dieselbombers.com

How the 7.3 Fuel System Works

The journey of diesel fuel in your 7.3 Powerstroke begins in the fuel tank and ends in the combustion chamber, a meticulously orchestrated process:

| Symptom | Common Air-in-Fuel Cause | Diagnostic Procedure | Expected Finding / Repair Focus |

|---|---|---|---|

| Hard Start / Extended Crank (cold or hot) | Leaking fuel bowl O-rings, loose fuel line connections, faulty check valve (FPR or fuel pump), cracked fuel pickup tube. | Clear fuel bowl cap (engine running, if possible) and check for excessive bubbles/foam. Perform a fuel pressure test (0-60 PSI gauge) on the filter housing. | Visible bubbles in fuel bowl/return line, low/erratic fuel pressure (<40 PSI), pressure bleed-off when engine off. Focus on fuel bowl, lines, tank module. |

| Rough Idle / Stalling (especially after sitting) | Minor air leak in suction side, leaking fuel filter housing/cap, restricted fuel filter causing cavitation. | Visual inspection of all fuel lines, filter housing, and fuel bowl for wet spots or loose fittings. Listen for unusual fuel pump noise. | Visible fuel leaks, bubbling around filter housing, abnormal fuel pump whine (starving for fuel). Replace seals, tighten fittings, change filter. |

| Loss of Power / Misfire under Load | Significant air intrusion, collapsing fuel lines, failing in-tank fuel pump, restricted tank vent. | Perform a road test with fuel pressure gauge connected (monitor under heavy load). Observe fuel return line at tank for continuous air bubbles. | Significant drop in fuel pressure under acceleration (>10 PSI), constant stream of small bubbles in return line. Inspect tank sender unit, main fuel lines. |

| Excessive White Smoke (especially on cold start) | Air in fuel leads to incomplete combustion due to insufficient fuel for proper ignition (often combined with weak glow plugs or injector issues). | Rule out glow plug system and injector issues first. Then, confirm fuel system is air-free using methods above. | Smoke persists after glow plug/injector check, but resolves or lessens after air in fuel is fixed. Focus on ensuring fuel delivery is pure liquid. |

| External Fuel Leak / Strong Fuel Smell | While a leak *out* isn’t always air *in*, it’s a primary entry point for air on the suction side (e.g., fuel bowl drain, filter housing, cracked lines). | Thorough visual inspection with a flashlight around fuel components. Use a clean rag to wipe suspected areas and check for fresh fuel residue. | Visible fuel drips/wetness. Replace leaking component (O-rings, lines, drain valve). Addressing the leak *out* prevents air *in*. |

- Fuel Tank: Holds the diesel fuel. Inside, a pickup assembly draws fuel.

- Lift Pump (Fuel Pump): Typically frame-mounted or in-tank, this pump draws fuel from the tank and pushes it forward to the engine bay.

- Fuel Filter Housing: A critical component that houses the fuel filter, removing contaminants before the fuel reaches the injectors. It also often includes a fuel heater and a water separator.

- Fuel Lines: A network of lines (supply and return) transports fuel throughout the system.

- Fuel Pressure Regulator (FPR): Located on the fuel filter housing, it maintains the correct fuel pressure to the cylinder heads (approximately 45-80 PSI).

- Cylinder Head Fuel Galleries: The fuel is delivered into passages within the cylinder heads, supplying the injectors.

- Injectors: These are the heart of the HEUI system. They use high-pressure engine oil (supplied by the High-Pressure Oil Pump – HPOP) to atomize and inject fuel into the cylinders. The oil pressure acts as a hydraulic intensifier, creating extremely high fuel pressure at the injector nozzle.

- Return Lines: Excess fuel and oil are returned to their respective tanks.

For the HEUI system to function correctly, the fuel supplied to the injectors must be completely free of air bubbles. Any air introduced into this high-pressure, precisely timed system can have significant consequences.

Why Air is the Enemy

Diesel fuel, like any liquid, is largely incompressible. This property is vital for the precise hydraulic action of the injectors and the consistent timing of fuel delivery. Air, however, is highly compressible. When air bubbles enter the fuel system:

- Disrupted Injection Timing: The compressible air bubbles can cause delays or inconsistencies in the hydraulic response within the injectors, leading to erratic fuel injection.

- Reduced Fuel Delivery: Air takes up space where fuel should be, effectively reducing the actual volume of fuel delivered to the combustion chamber.

- Cavitation: High-speed movement of fuel around air bubbles can lead to cavitation, which can damage fuel system components over time.

- Inconsistent Pressure: The presence of air makes it difficult for the fuel pump and regulator to maintain stable fuel pressure, which is crucial for the injectors.

Ultimately, air in the fuel system directly translates to poor combustion, reduced engine performance, and potential long-term damage if left unaddressed. Understanding these fundamentals is your first step in successfully diagnosing 7.3 Powerstroke air in fuel system issues.

Common Symptoms of Air in the 7.3 Powerstroke Fuel System

Your 7.3 Powerstroke isn’t shy about telling you something’s wrong. When air has infiltrated the 7.3 Powerstroke fuel system, it manifests through a variety of recognizable symptoms. Being able to identify these signs is key to effectively diagnosing 7.3 Powerstroke air in fuel system issues.

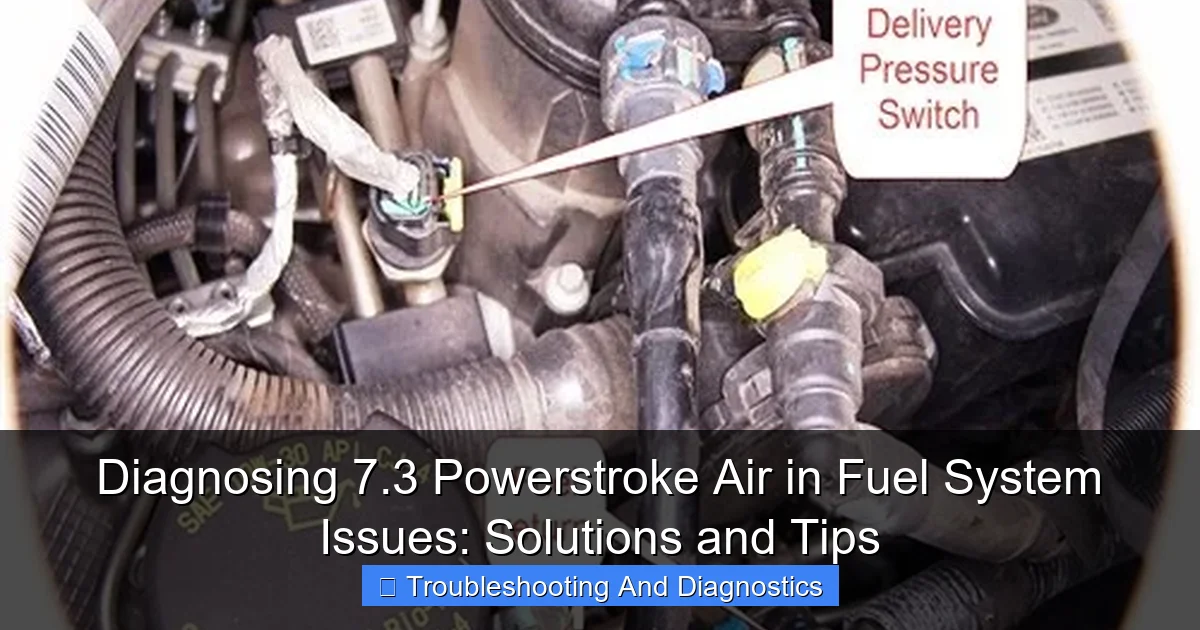

Learn more about Diagnosing 7.3 Powerstroke air in fuel system issues – Diagnosing 7.3 Powerstroke Air in Fuel System Issues: Solutions and Tips

Image source: i.ytimg.com

Performance-Related Symptoms

These symptoms directly impact how your truck drives and responds:

- Rough Idle: This is one of the most common and frustrating symptoms. The engine idles unevenly, often shaking, missing, or sounding like it’s “loping.” This occurs because injectors aren’t firing consistently due to air pockets.

- Misfires or Hesitation: Under acceleration, you might feel a distinct hesitation or a “miss” as the engine struggles to deliver consistent power. This is especially noticeable when trying to pass or accelerate quickly.

- Loss of Power: A general feeling of reduced power, the engine might feel sluggish, and your truck struggles to maintain speed on inclines or with a load.

- Stalling: In severe cases, particularly under load or after extended idling, the engine might simply cut out due to insufficient fuel supply caused by significant air intrusion.

- Poor Fuel Economy: While not always a primary indicator, struggling combustion and inconsistent fueling can lead to a noticeable drop in your miles per gallon (MPG).

Starting and Operational Symptoms

These signs often appear during startup or affect the general operation of the engine:

- Hard Start or Extended Crank Times: The engine takes much longer than usual to fire up, often requiring multiple cranking attempts. This happens because the fuel system needs to “bleed” the air out before consistent fuel pressure can be built.

- White or Excessive Smoke from Exhaust: Unburnt fuel, a direct consequence of inconsistent injection and poor combustion, often appears as white or light gray smoke, especially during startup or under load. It might also have a distinct raw diesel smell.

- Gurgling Noises from the Fuel System: If you listen carefully around the fuel tank, frame rail, or fuel filter housing, you might hear distinct gurgling or bubbling noises, indicating air moving through the fuel lines.

- Pulsating Fuel Pressure: While requiring a fuel pressure gauge to confirm, erratic fluctuations in fuel pressure can be a strong indicator of air in the system.

If you’re experiencing one or more of these symptoms, it’s highly probable that you’re dealing with air in the fuel system. The next step is to systematically diagnose the exact source.

Pinpointing the Culprit: Diagnostic Procedures for Air in Fuel

When faced with the tell-tale signs of air in the fuel system, a methodical approach to diagnosis is crucial. Rushing to replace parts without proper testing can be costly and frustrating. Here’s how to effectively start diagnosing 7.3 Powerstroke air in fuel system issues.

Visual Inspection – The First Line of Defense

Many air leaks are visible. Start with a thorough visual check of your entire 7.3 Powerstroke fuel system:

- Fuel Filter Housing: This is a notoriously common culprit. Look for any wetness or diesel smell around the lid, the drain valve, and the lines entering/exiting the housing. Check the O-rings on the lid and the drain valve for signs of cracking or wear.

- Fuel Lines and Connections: Trace all fuel lines from the tank to the engine. Look for chafed lines, cracks, wet spots, or loose connections. Pay close attention to quick-disconnect fittings, especially near the frame rail and at the fuel filter housing. These fittings often have internal O-rings that can dry out and leak air.

- Lift Pump: Inspect the mechanical or electric lift pump (depending on your year/setup) for leaks around its seals or fittings.

- Fuel Tank Sending Unit/Pickup: While harder to see without dropping the tank, look for any signs of external damage to the tank itself that could indicate an issue with the pickup module.

- Injector O-rings (Less Common for External Air): While rare for external air to get in here, degraded injector O-rings can cause fuel dilution of oil or misfires. Typically, this is not the primary source of air intrusion into the fuel system itself, but rather an internal issue.

The Clear Hose Test (Crucial DIY Diagnostic)

This is arguably the most effective and easiest DIY method for diagnosing 7.3 Powerstroke air in fuel system issues. It provides direct visual evidence of air bubbles.

- Preparation: Acquire about 1-2 feet of clear vinyl hose (3/8″ or 1/2″ ID, depending on your line size) and two hose clamps.

- Installation: Locate the fuel return line that runs from the engine back to the tank. This is usually a smaller line (often 3/8″) coming off the fuel filter housing or cylinder heads. Carefully cut a section of this return line and insert the clear vinyl hose, securing both ends with hose clamps. Ensure a tight seal.

- Observation: Start the engine. Watch the clear hose immediately.

- Interpretation:

- No Bubbles: Excellent! Your problem likely isn’t air in the fuel system, or the leak is very small/intermittent.

- Small, Occasional Bubbles: Could be normal aeration from fuel returning, or a very minor, intermittent leak. Monitor closely.

- Consistent Stream of Small Bubbles: Indicates a definite air leak somewhere in the fuel supply system.

- Large, Intermittent Bubbles or Gushes of Air: A significant air leak. This will cause noticeable performance problems.

- Troubleshooting with the Test: To narrow down the source, you can try isolating sections. For example, clamp off the return line before the clear hose (temporarily and carefully) to see if bubbles persist. You can also move the clear hose to different points in the system, but the return line is usually the easiest and most effective starting point.

Fuel Pressure Testing

Monitoring fuel pressure is another critical step. The 7.3 Powerstroke requires a steady fuel pressure of 45-80 PSI (some recommend keeping it above 60 PSI) at the fuel filter housing. A fluctuating or consistently low fuel pressure can indicate a weak lift pump, a clogged filter, or an air leak.

- Tools: You’ll need a mechanical fuel pressure gauge with a suitable adapter (often a 1/8″ NPT port on the fuel filter housing, or an adapter for the Schrader valve on some later models).

- Procedure: Connect the gauge, start the engine, and observe the pressure at idle, during acceleration, and under load (if safe to do so).

- What to Look For:

- Low Pressure (<45 PSI): Could be a weak lift pump, clogged fuel filter, or a significant air leak.

- Fluctuating Pressure: A clear sign of a problem, often associated with air in the system or a dying lift pump.

- Pressure Drop During Acceleration: Indicates the pump can’t keep up with demand, possibly due to cavitation from air, a weak pump, or restriction.

Injector Buzz Test and Contribution Test (Brief Mention)

While primarily for diagnosing injector electrical or mechanical failures, an injector buzz test (using an OBD-II scanner capable of running Powerstroke-specific tests) can help confirm if a specific cylinder is misfiring. If misfires are present but the buzz test is good, and you have confirmed air in the fuel, then the air is likely causing the misfire. A contribution test, also done with a capable scanner, measures each cylinder’s power output and can pinpoint a weak cylinder.

By combining visual inspection with the clear hose test and fuel pressure measurements, you’ll be well on your way to effectively diagnosing 7.3 Powerstroke air in fuel system issues.

Common Sources of Air Intrusion in the 7.3 Powerstroke Fuel System

With diagnostics underway, it’s time to zero in on the usual suspects. Knowing the most common failure points for air in the fuel system in a 7.3 Powerstroke fuel system will guide your repair efforts and help in efficiently diagnosing 7.3 Powerstroke air in fuel system issues.

Fuel Filter Housing Leaks

This is arguably the #1 offender. The fuel filter housing on the 7.3 Powerstroke is a complex unit with multiple potential leak points:

- Fuel Filter Housing O-rings (Lid and Drain Valve): The rubber O-rings sealing the fuel filter lid and the drain valve become brittle, crack, or flatten over time and with exposure to diesel fuel. These are extremely common sources of air intrusion, especially the drain valve O-rings, which can allow air to be drawn in, particularly when the fuel level is low.

- Cracked Housing: Less common, but the plastic or metal housing itself can crack, often due to overtightening or age.

- Fuel Heater Element O-ring: If equipped, the O-ring for the fuel heater element can also degrade.

Solution: Often, a simple and inexpensive fuel filter housing rebuild kit (including new O-rings for the lid, drain valve, and heater element) will resolve the issue. Always use quality OEM or reputable aftermarket O-rings.

Damaged Fuel Lines and Connectors

The network of fuel lines and their connections can degrade over the years:

- Chafed or Cracked Rubber Lines: Vibration and age can cause the rubber sections of the fuel lines to rub against chassis components or simply crack, creating small pinholes for air.

- Quick-Disconnect Fittings: These spring-loaded fittings, commonly found on the fuel lines at the frame rail, near the tank, and at the fuel filter housing, contain internal O-rings that can harden, crack, or wear out. They are notorious for allowing air to be drawn in, especially on the suction side of the system.

- Loose Hose Clamps: Old or improperly tightened hose clamps on rubber lines can allow air entry.

Solution: Visually inspect all lines. Replace any cracked or chafed sections. If quick-disconnects are leaking, try replacing their internal O-rings, or for a more permanent fix, many owners opt to convert to AN fittings or use high-quality fuel injection hose and clamps.

Fuel Tank Pickup/Module Issues

Problems within the fuel tank itself are a significant source of air in the fuel system, particularly for older trucks:

- Cracked Fuel Pickup Foot: Inside the tank, the plastic fuel pickup foot can crack due to age or stress, allowing air to be drawn in, especially when the tank is less than 1/4 full.

- Degraded O-rings on Tank Sending Unit: The O-rings sealing the fuel sending unit (which houses the pickup) to the tank can fail.

- “Hutch Mod” and “Harpoon Mod”: These popular aftermarket modifications directly address known issues with the factory 7.3 Powerstroke fuel pickup system. The “Hutch Mod” replaces the restrictive in-tank pickup and lines with larger, less restrictive components, often eliminating quick-disconnect fittings and using a pre-pump filter. The “Harpoon Mod” involves cutting off the vent tube extensions inside the tank, preventing the fuel pump from running dry at low fuel levels.

Solution: Dropping the fuel tank is often required for these repairs. Consider performing the “Hutch Mod” and “Harpoon Mod” simultaneously to permanently address in-tank air intrusion and improve fuel flow.

Lift Pump (Fuel Pump) Problems

The lift pump, whether mechanical or electric, is vital for pushing fuel to the engine. A failing pump can contribute to air problems:

- Weak Pump: An aging or failing lift pump might not generate enough pressure to overcome minor restrictions, leading to cavitation and air bubbles forming due to insufficient suction.

- Internal Leaks/Worn Seals: Less common, but internal seals within the pump itself can fail, allowing air to be drawn in.

Solution: Test fuel pressure. If low and other air sources are ruled out, consider replacing the lift pump. Many owners upgrade to higher-quality aftermarket electric fuel pumps for better performance and reliability.

Aftermarket Fuel System Components

While aftermarket upgrades can improve performance, poorly chosen or improperly installed components can also be sources of leaks:

- Substandard Fittings: Cheap or incorrect fittings can fail to create a proper seal.

- Improperly Installed Lines: Kinked lines, overtightened clamps, or cross-threaded fittings.

Solution: Always use quality components from reputable brands. Ensure all fittings are properly tightened, and lines are routed correctly without kinks or chafing.

By systematically checking these common points, you’ll significantly increase your chances of successfully diagnosing 7.3 Powerstroke air in fuel system issues and getting your truck running strong again.

Solutions and Preventative Maintenance for an Air-Free 7.3 Fuel System

Once you’ve identified the source of air in the fuel system, the good news is that most 7.3 Powerstroke fuel system air leaks are fixable with some patience and the right tools. Beyond immediate repairs, adopting a proactive maintenance approach can prevent future occurrences.

DIY Repair Tips

Many common air intrusion issues can be tackled in your driveway:

- Replacing Fuel Filter Housing O-rings: This is a straightforward task. Purchase a quality rebuild kit. Lubricate new O-rings with clean diesel fuel or assembly lube before installation to prevent pinching. Ensure the lid is tightened evenly, but do not overtighten the drain valve.

- Swapping Damaged Fuel Lines: For rubber hose sections, use fuel-rated hose (SAE J30R9 or better) and high-quality worm-drive clamps or fuel injection clamps. When replacing quick-disconnect fittings, consider using repair kits for the internal O-rings, or as mentioned, upgrading to AN fittings for a more robust, leak-free connection.

- Addressing Tank Issues (Hutch/Harpoon Mod): While dropping the fuel tank is a bigger job, the “Hutch Mod” and “Harpoon Mod” are widely documented DIY projects. They involve replacing the in-tank fuel pickup with a less restrictive, air-tight setup and modifying the vent lines. This not only eliminates common air leak points but also improves fuel flow, potentially boosting performance. Make sure your tank is near empty, disconnect the battery, and take all necessary safety precautions when working with fuel.

- Fuel Bleeding: After any fuel system repair, you’ll need to bleed the air out. Cycle the key to the “run” position (don’t start) several times, allowing the lift pump to run for about 30 seconds each time. This primes the system. Then, try to start the engine. It may crank longer than usual and run rough initially as the remaining air purges itself. Drive the truck gently for a few miles to ensure all air is out.

When to Call a Professional

While many repairs are DIY-friendly, some situations warrant professional help:

- Lack of Proper Tools or Experience: If you don’t have the necessary tools (e.g., fuel pressure gauge, specialized wrenches) or are uncomfortable working with diesel fuel systems.

- Persistent Issues: If you’ve tried common fixes and are still experiencing air in the fuel system symptoms, a professional diesel mechanic has advanced diagnostic equipment and experience to trace more elusive leaks.

- Complex Component Failure: Issues with injectors, the HPOP, or major electrical faults may mimic fuel system problems but require specialized expertise.

- Safety Concerns: If you’re unsure about safety procedures (e.g., working under a heavy vehicle, handling fuel), it’s always best to consult an expert.

Preventative Maintenance

An ounce of prevention is worth a pound of cure. Implement these practices to keep your 7.3 Powerstroke fuel system air-free:

- Regular Fuel Filter Replacement: Follow Ford’s recommended intervals (typically 15,000-30,000 miles, or more frequently if using lower quality fuel). Always use high-quality, reputable brand fuel filters. Each filter change is an opportunity to inspect the housing O-rings.

- Inspect Fuel Lines Periodically: During oil changes or other maintenance, take a few minutes to visually inspect your fuel lines for any signs of wear, chafing, or leaks.

- Use Quality Diesel Fuel and Additives: Poor quality fuel can lead to contamination and accelerate wear on components. Using a good quality diesel fuel additive (cetane booster for better combustion, lubricity improver for pump/injector life, and anti-gelling agents in cold weather) can help maintain system health.

- Avoid Running the Tank Critically Low: While the “Harpoon Mod” helps, consistently running your fuel tank below 1/4 full can increase the chances of the fuel pump drawing in air, especially on inclines or during hard acceleration.

By staying vigilant with maintenance and knowing how to effectively tackle issues, you can minimize the chances of diagnosing 7.3 Powerstroke air in fuel system issues in the future, ensuring your legendary diesel remains a reliable workhorse.

Comparative Overview: 7.3 Powerstroke Fuel System Issues & Solutions

To help visualize the connection between common symptoms, their air-related causes, and the steps to take, here’s a quick reference table:

| Symptom | Probable Cause (Air-Related) | Primary Diagnostic Step | Potential Solution |

|---|---|---|---|

| Hard Start / Extended Crank | Fuel filter housing O-rings, fuel line leaks, tank pickup issue | Clear hose test, visual inspection, fuel pressure test | Replace O-rings, replace lines/fittings, Hutch/Harpoon mod |

| Rough Idle / Misfire | Leaky fuel lines, fuel filter housing O-rings, weak lift pump cavitating | Clear hose test, fuel pressure test, visual inspection | Replace lines/fittings, replace O-rings, replace lift pump |

| Loss of Power / Hesitation | Significant air leak in fuel lines, tank pickup issue, weak lift pump | Fuel pressure test, clear hose test | Repair air leaks, Hutch/Harpoon mod, replace lift pump |

| Excessive White Smoke (Cold Start) | Air in fuel causing poor atomization/unburnt fuel | Clear hose test, visual inspection | Repair air leaks, ensure proper fuel pressure |

| Gurgling Noises (Fuel System) | Air being drawn into fuel lines, often at tank or quick-disconnects | Listen carefully, clear hose test | Inspect/repair fuel lines, fittings, tank module |

| Stalling (Under Load/Long Idle) | Severe air intrusion, inability to maintain fuel supply | Clear hose test, fuel pressure test | Thoroughly repair all air leaks, ensure strong lift pump |

This table serves as a quick reference, but remember that thorough diagnostics, as described in this guide, are always the best approach for accurately diagnosing 7.3 Powerstroke air in fuel system issues.

Conclusion: Keep Your 7.3 Powerstroke Roaring Strong

The 7.3 Powerstroke diesel engine is a testament to Ford’s engineering prowess, a true workhorse that continues to serve its owners faithfully. However, even legends require proper care and attention. Air in the fuel system is a surprisingly common, yet often misunderstood, issue that can significantly degrade your truck’s performance and reliability. From frustrating hard starts to concerning power loss, the symptoms are clear calls for action.

By understanding the fundamentals of your 7.3 Powerstroke fuel system, recognizing the diverse array of symptoms, and diligently following the diagnostic procedures outlined in this guide – particularly the indispensable clear hose test – you are now equipped to confidently approach diagnosing 7.3 Powerstroke air in fuel system issues. Whether it’s replacing a simple O-ring on the fuel filter housing, upgrading leaky quick-disconnects, or tackling a comprehensive “Hutch Mod,” the solutions are often within reach for the average DIY enthusiast.

Remember, preventative maintenance is your best defense. Regular fuel filter changes, periodic inspections of your fuel lines, and using quality fuel will go a long way in ensuring your 7.3 Powerstroke remains an air-free, peak-performing machine. Don’t let a few bubbles spoil the legacy of your powerful diesel. Take the steps to diagnose, repair, and maintain, and your 7.3 Powerstroke will reward you with many more years of its legendary reliability and performance. Happy wrenching!

🎥 Related Video: How To Diagnose Air in The Fuel System of a 7.3

📺 Adam’s Welding

How To Diagnose Air in The Fuel System of a 7.3 In this video I show a method to diagnose a fuel system on a older 7.3 motor.

Frequently Asked Questions

What are the common symptoms of air in the 7.3 Powerstroke fuel system?

Typical signs include a hard start, especially after sitting, rough idle, loss of power under acceleration, and excessive white smoke from the exhaust. You might also notice frequent surging or sputtering as the engine struggles to maintain consistent fuel pressure.

What are the most common causes of air entering the 7.3 Powerstroke fuel system?

Air leaks often originate from deteriorated O-rings in the fuel filter housing (fuel bowl), loose fuel line connections, or a failing fuel pump. Cracked fuel lines or a faulty fuel pressure regulator can also allow air to be drawn into the system.

How can I diagnose if there’s air in my 7.3 Powerstroke’s fuel system?

A common diagnostic method involves installing a section of clear hose on the fuel supply line leading to the fuel filter housing. Observe the fuel flowing through the clear line; persistent bubbles or foam indicate air in the system. You can also listen for a gurgling sound in the fuel tank or lines.

Is it safe to drive my 7.3 Powerstroke with air in the fuel system?

Driving with significant air in the fuel system is not recommended for extended periods. It can lead to unreliable engine operation, potential damage to the fuel injectors due to lack of lubrication, and increased wear on the fuel pump. Address the issue promptly to prevent further complications.

Where are the most frequent leak points for a 7.3 Powerstroke air in fuel system issue?

The most common culprits for air intrusion are the O-rings and seals within the fuel filter housing, particularly the lid O-ring and the drain valve O-ring. Other frequent leak points include the quick-disconnect fittings on the fuel lines, the fuel pump itself, and any cracked or porous fuel lines.

What tools and parts will I need to fix air in my 7.3 Powerstroke’s fuel system?

You’ll typically need basic hand tools, a set of O-rings for the fuel filter housing, and potentially new fuel line quick-disconnects or replacement fuel lines. A clear hose for diagnosis, a fuel pressure gauge, and a new fuel filter are also highly recommended to pinpoint and resolve the problem effectively.